Jewelry Item Having Reduced Weight and Enhanced Strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

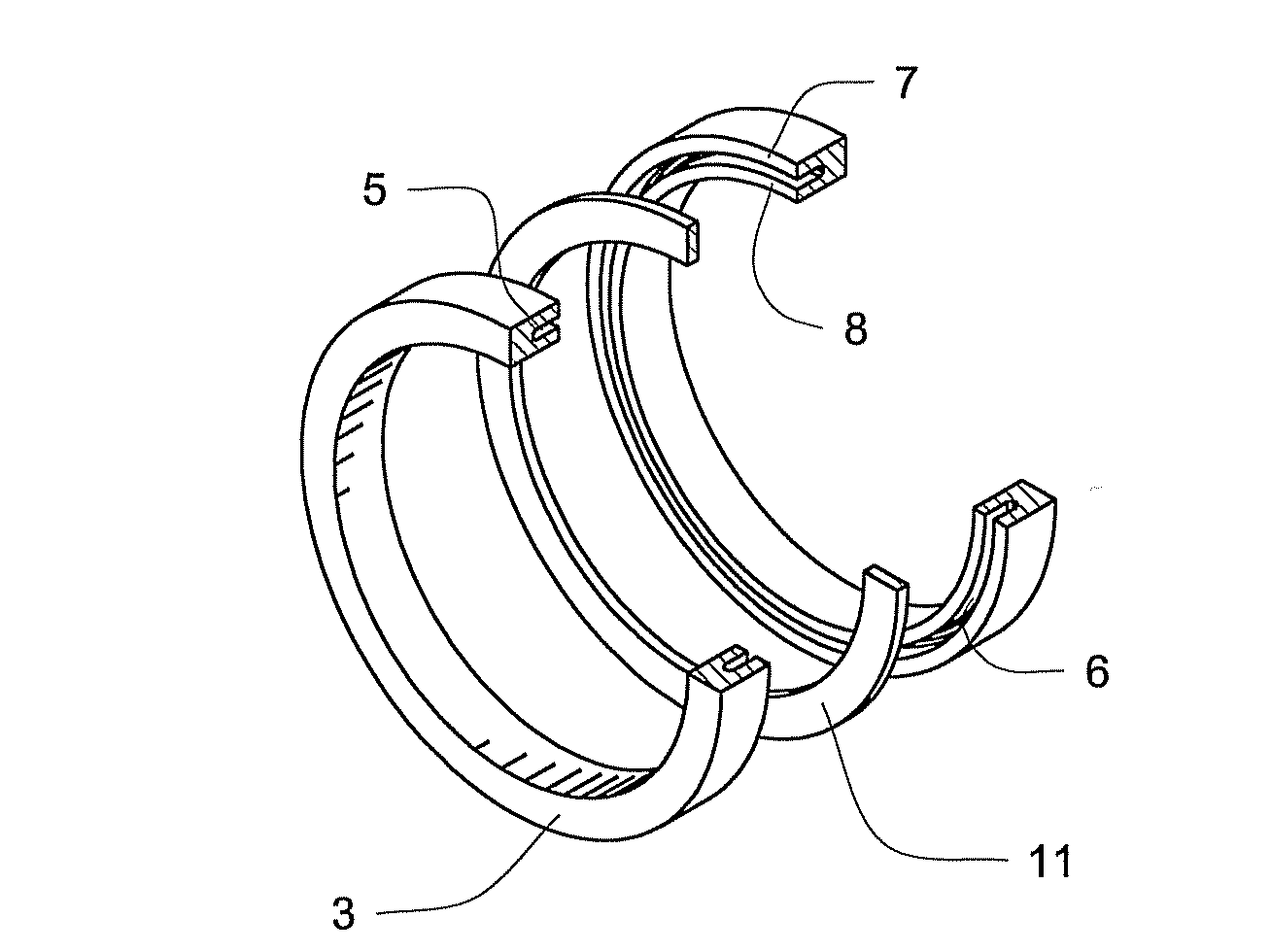

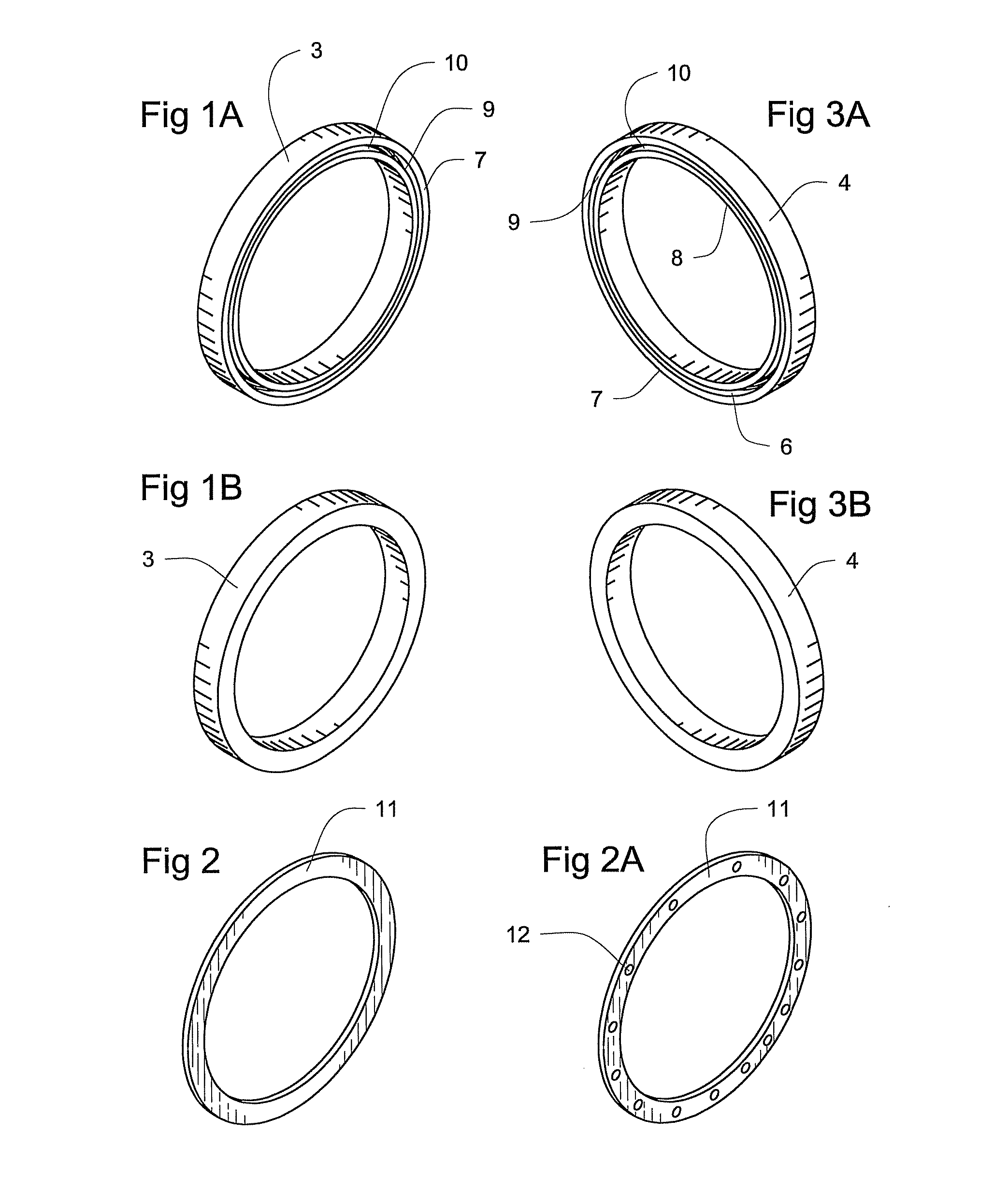

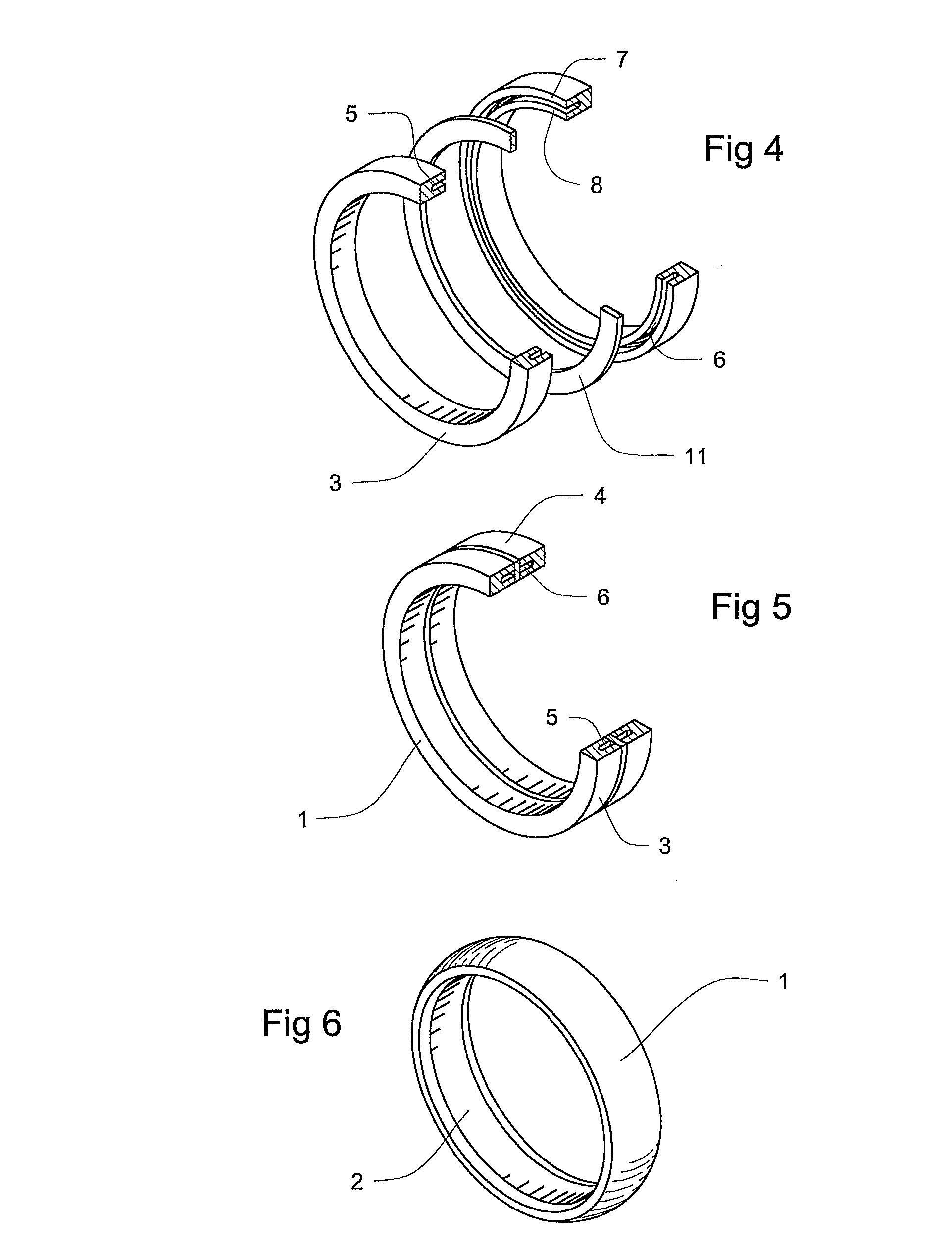

[0023]A reduced weight jewelry piece 1 is disclosed. It will be appreciated that jewelry piece 1 may be any conventional jewelry item, such as brooches, pendants, earrings, chain links, and so forth. However, in the most preferred embodiment, jewelry piece 1 is a ring 2.

[0024]In the preferred embodiment, jewelry piece 1 is comprised of a left section 3 and a right section 4. Left section 3 and right section 4 are preferably mirror images of each other. Each section 3, 4 is preferably provided with a hollow channel 5, 6. Channels 5, 6 will preferably run the length or circumference of each section 3, 4. Each channel 5, 6 has an exterior wall 7 and an interior wall 8. Exterior wall 7 will face the surface of jewelry piece 1 and interior wall 8 will face the side of jewelry piece 1 adjacent the wearer. However, it will be appreciated that for some jewelry pieces, such as hoop earrings or chain links, there will be no distinction between the surfaces of the jewelry piece and thus, no di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com