Novel immobilized 8-hydroxyquinoline type chelate adsorption material and preparation method thereof

A hydroxyquinoline-type, chelating adsorption technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of small adsorption capacity and low bonding amount of 8-hydroxyquinoline, and achieve a simple and high-quality preparation process. Coordination and complexation ability, the effect of easy preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Example 1: In a four-necked flask, add 1.0 g of amino-containing silane coupling agent-modified silica gel particles, 5 mL of hydroxyethyl methacrylate and 100 mL of DMF and H 2 Mixed solvent of O (V:V=1:1), blow nitrogen for 30min, heat up to 30°C, add 0.0537g of ammonium persulfate aqueous solution to the reaction system, react at constant temperature for 12h, filter with suction, and extract the filter cake with methanol Dry at 70°C for 24 hours to obtain silica gel particles PHEMA / SiO grafted with polyhydroxyethyl methacrylate 2 . The graft rate of poly(hydroxyethyl methacrylate) is 41.3%.

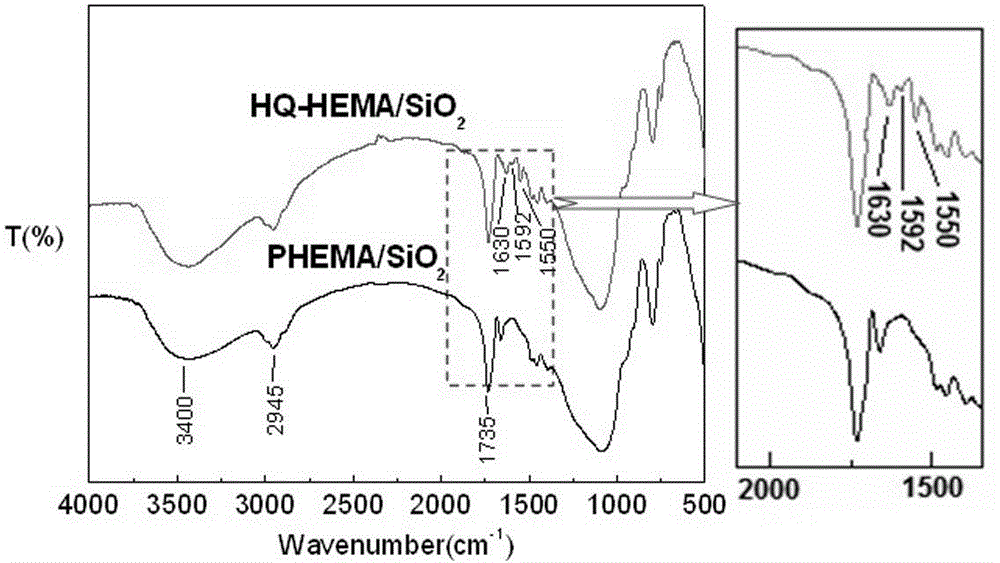

[0020] In the four-neck flask, add 0.5g grafted particle PHEMA / SiO 2 , 1.82g 5-chloromethyl-8-hydroxyquinoline CHQ and 20mL dimethyl sulfoxide, heated to 90°C, and added 1.5gNa 2 CO 3 , N 2 Under the atmosphere, react at constant temperature for 6 hours, filter, wash with water, wash with absolute ethanol, and dry to obtain the functional composite particle HQ-PHEMA / SiO wit...

Embodiment 2

[0021] Example 2: In a four-necked flask, add 1.0 g of amino-containing silane coupling agent-modified silica gel particles, 4.5 mL of hydroxyethyl methacrylate and 100 mL of DMF and H 2 Mixed solvent of O (V:V=1:1), blow nitrogen for 30min, heat up to 25°C, add 0.0483g of ammonium persulfate aqueous solution to the reaction system, react at constant temperature for 14h, filter with suction, and extract the filter cake with methanol Dry at 70°C for 24 hours to obtain silica gel particles PHEMA / SiO grafted with polyhydroxyethyl methacrylate 2 . The graft rate of poly(hydroxyethyl methacrylate) is 35.6%.

[0022] In the four-neck flask, add 0.5g grafted particle PHEMA / SiO 2 , 1.82g 5-chloromethyl-8-hydroxyquinoline CHQ and 20mL nitrobenzene, heated to 80°C, and added 1.4g NaHCO 3 , N 2 Under the atmosphere, react at constant temperature for 7 hours, filter, wash with water, wash with absolute ethanol, and dry to obtain the functional composite particle HQ-PHEMA / SiO with 8-hy...

Embodiment 3

[0023] Example 3: In a four-necked flask, add 1.0 g of amino-containing silane coupling agent-modified silica gel particles, 5.5 mL of hydroxyethyl methacrylate and 90 mL of DMF and H 2Mixed solvent of O (V:V=1:1), blow nitrogen for 30min, heat up to 35°C, add 0.0591g of ammonium persulfate aqueous solution to the reaction system, react at constant temperature for 12h, filter with suction, and extract the filter cake with methanol Dry at 70°C for 24 hours to obtain silica gel particles PHEMA / SiO grafted with polyhydroxyethyl methacrylate 2 . The graft rate of poly(hydroxyethyl methacrylate) is 39.8%.

[0024] In the four-neck flask, add 0.5g grafted particle PHEMA / SiO 2 , 1.82g 5-chloromethyl-8-hydroxyquinoline CHQ and 20mL N,N-dimethylformamide, heated to 100°C, and added 1.5g NaHCO 3 , N 2 Under the atmosphere, react at constant temperature for 5 hours, filter, wash with water, wash with absolute ethanol, and dry to obtain the functional composite particle HQ-PHEMA / SiO w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com