Method for enriching and recovering thallium from lead smelting system

A lead smelting and enrichment technology, applied in the direction of improving process efficiency, etc., to achieve the effects of reducing production costs, low toxicity, and ensuring product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

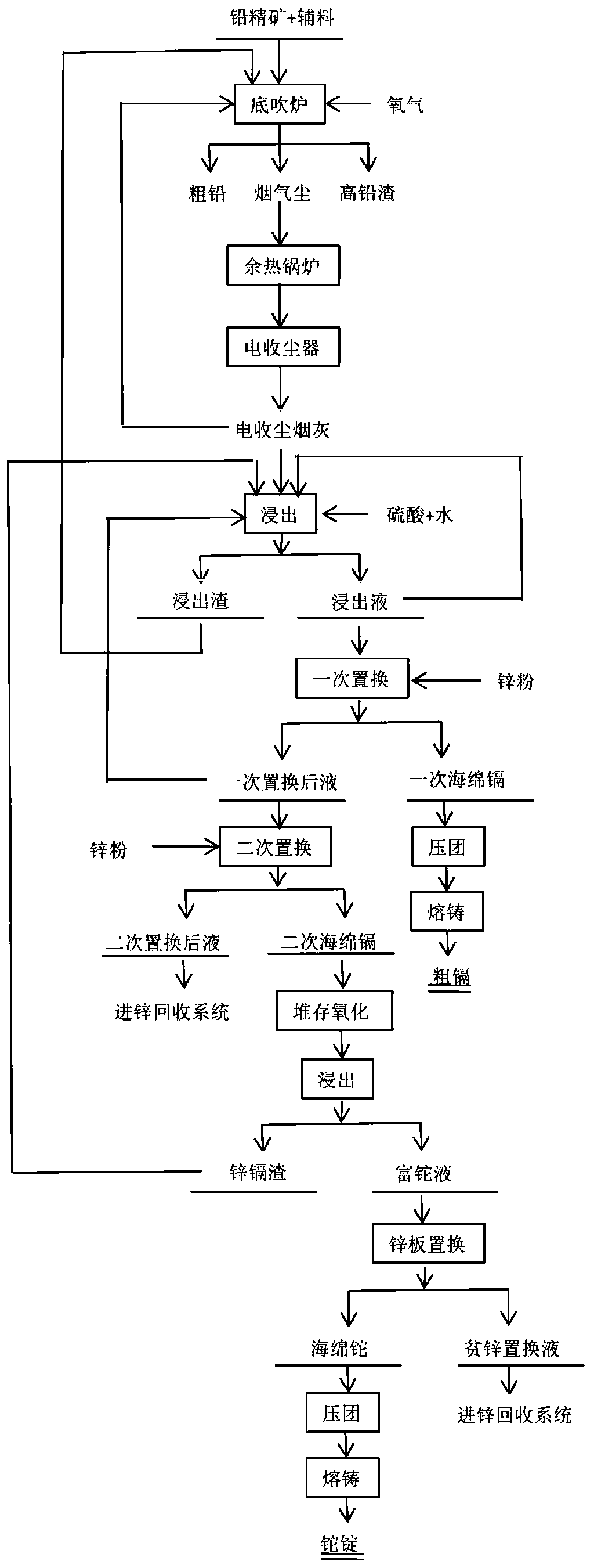

Image

Examples

Embodiment 1

[0045] A method for enriching and recovering thallium from a lead smelting system, the method comprising the following steps:

[0046] (1) Thallium and cadmium soot is collected from the lead concentrate smelting system; the specific process is as follows:

[0047] A: Put lead concentrate and auxiliary materials (stone, limestone, crushed coal, coke, about 10% of the total amount of auxiliary materials) into the oxygen-enriched bottom-blown furnace, and then use an oxygen lance to blow in oxygen (oxygen pressure is 0.5-1.2MPa, oxygen The blowing volume is 90-130m per ton of the mixture of lead concentrate and auxiliary materials. 3 oxygen. ), heating and smelting, oxidation smelting and desulfurization at 950-1300°C to produce high-lead slag, crude lead and high-temperature SO 2 Flue gas dust, high temperature SO 2 After the flue gas and dust are discharged, they are cooled by the waste heat boiler (to 270-370°C) and then subjected to electric dust collection (both cooling ...

Embodiment 2

[0061] A method for enriching and recovering thallium from a lead smelting system, the method comprising the following steps:

[0062] (1) Thallium and cadmium soot is collected from the lead concentrate smelting system; the specific process is as follows:

[0063] A: Put lead concentrate and auxiliary materials (stone, limestone, crushed coal, coke, about 10% of the total amount of auxiliary materials) into the oxygen-enriched bottom-blown furnace, and then use an oxygen lance to blow in oxygen (oxygen pressure is 0.5-1.2MPa, oxygen The blowing volume is 90-130m per ton of the mixture of lead concentrate and auxiliary materials. 3 oxygen. ), heating and smelting, oxidation smelting and desulfurization at 950-1300°C to produce high-lead slag, crude lead and high-temperature SO 2 Flue gas dust, high temperature SO 2 After the flue gas and dust are discharged, they are cooled by the waste heat boiler (to 270-370°C) and then subjected to electric dust collection (both cooling ...

Embodiment 3

[0077] A method for enriching and recovering thallium from a lead smelting system, the method comprising the following steps:

[0078] (1) Thallium and cadmium soot is collected from the lead concentrate smelting system; the specific process is as follows:

[0079] A: Put lead concentrate and auxiliary materials (stone, limestone, crushed coal, coke, about 10% of the total amount of auxiliary materials) into the oxygen-enriched bottom-blown furnace, and then use an oxygen lance to blow in oxygen (oxygen pressure is 0.5-1.2MPa, oxygen The blowing volume is 90-130m per ton of the mixture of lead concentrate and auxiliary materials. 3 oxygen. ), heating and smelting, oxidation smelting and desulfurization at 950-1300°C to produce high-lead slag, crude lead and high-temperature SO 2 Flue gas dust, high temperature SO 2 After the flue gas and dust are discharged, they are cooled by the waste heat boiler (to 270-370°C) and then subjected to electric dust collection (both cooling ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com