Patents

Literature

39results about How to "Achieving Scale Utilization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

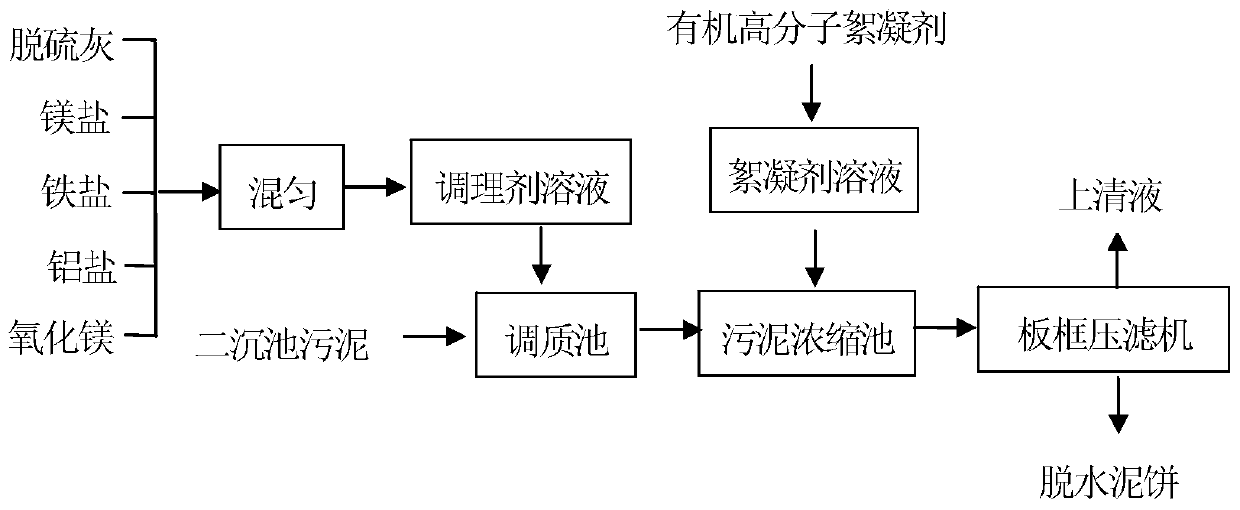

Sludge dewatering conditioning agent and dewatering method thereof

ActiveCN105314815AThe conditioning process is simpleReduce dosageSludge treatment by de-watering/drying/thickeningChemistryIron salts

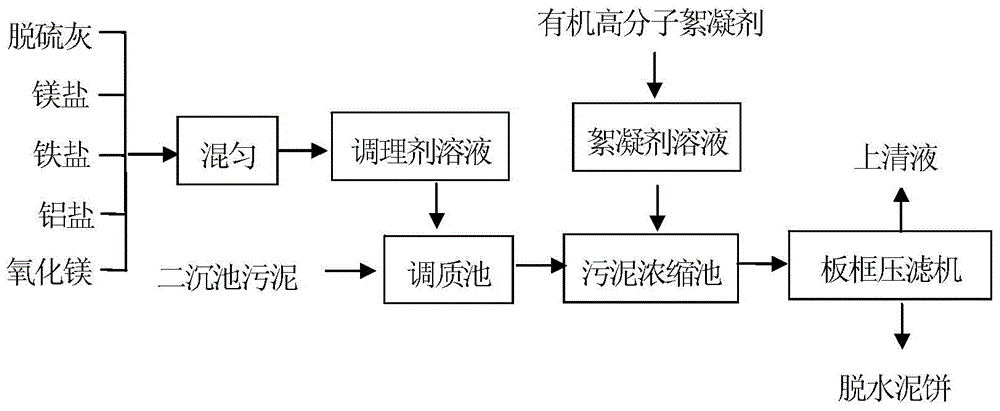

The present invention discloses a sludge dewatering conditioning agent, which comprises, by weight, 30-70% of desulfurization ash, 5-15% of a magnesium salt, 5-30% of an iron salt, 2-20% of an aluminum salt, and 0.1-15% of magnesium oxide. The invention further provides a dewatering method of the conditioning agent, wherein the dewatering method comprises conditioning agent solution preparing, sludge conditioning, flocculant solution preparing, sludge dewatering and other steps. According to the present invention, the characteristics of wide used raw material source, and low raw material price, low preparation cost and good dewatering effect are provided, the method can be performed through the existing sludge dewatering facility, the implementation process is simple, the stability and the reliability of the sludge dewatering process can be effectively improved, and the sludge dewatering conditioning agent and the dewatering method can be widely used for treatments of various wastewater, sewage and sludge.

Owner:BAOSHAN IRON & STEEL CO LTD +1

Method and device for producing firedamp

InactiveCN101165010AIncrease temperatureSolve temperature problemsBio-organic fraction processingWaste based fuelOrganic manureBiogas production

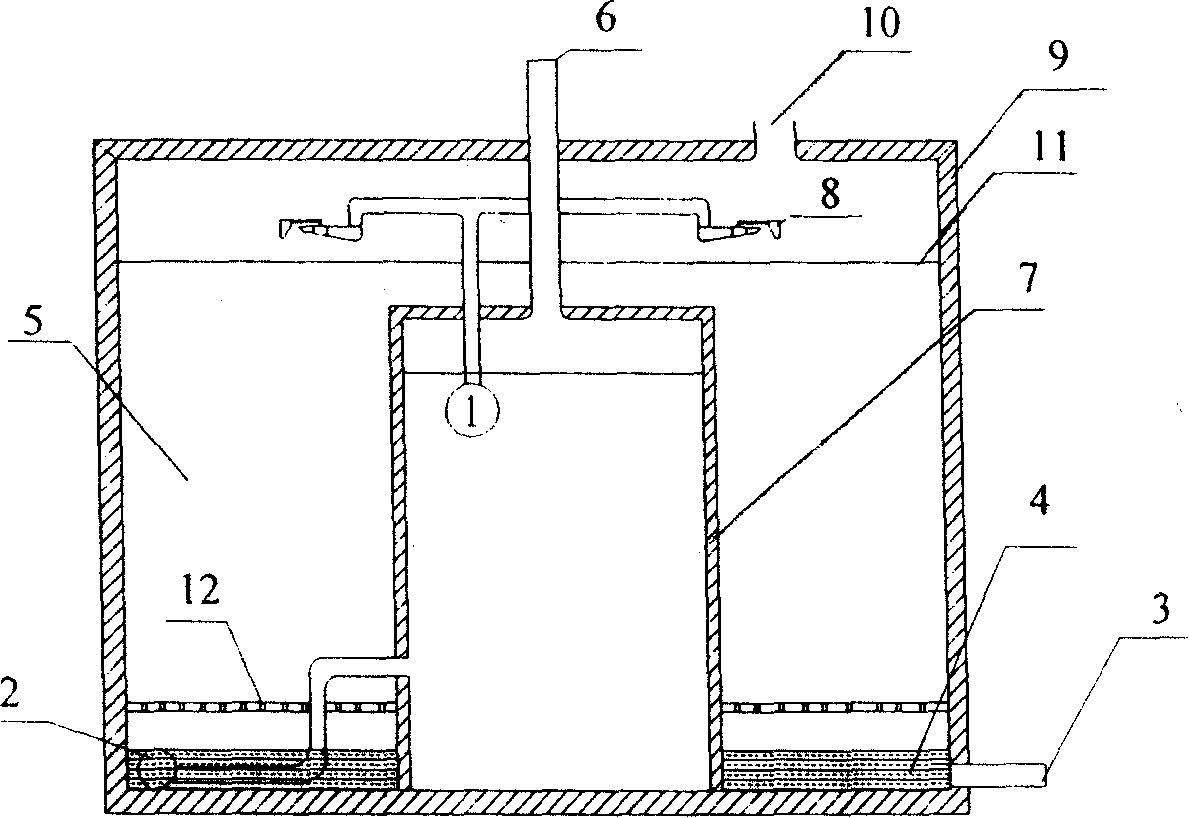

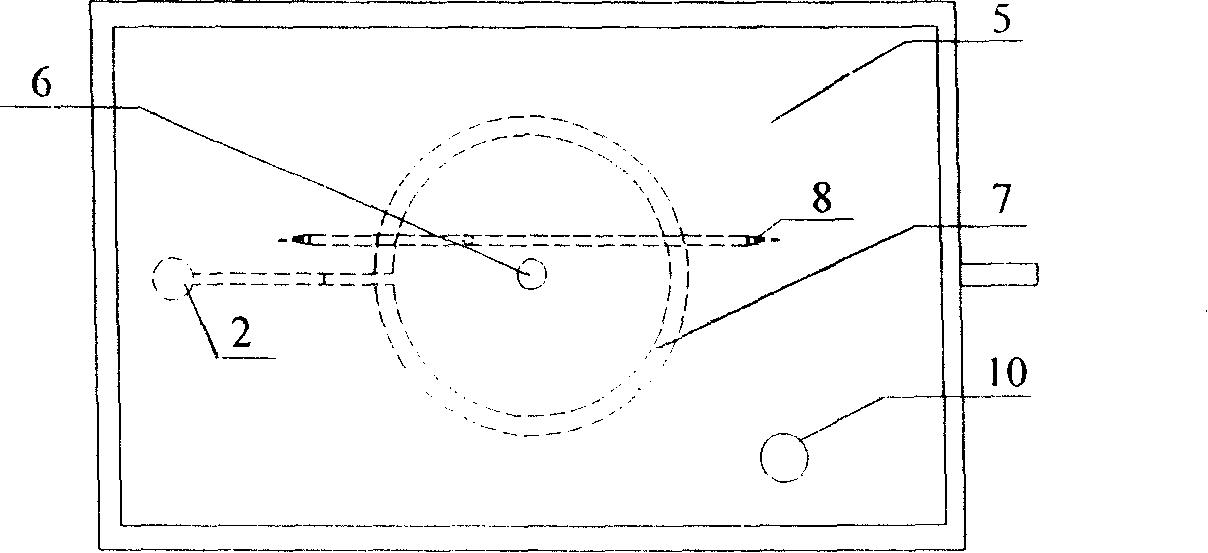

The present invention discloses marsh gas producing process and apparatus, and belongs to the field of environment engineering and energy source technology. The technological scheme includes setting aerobically fermented compost around the anaerobic fermenter. The marsh gas producing apparatus includes one marsh gas tank, one outer cover with space for holding the aerobically fermented compost between the outer wall of the marsh gas tank and the outer cover, one first submersible pump with one jet in the upper part inside the marsh gas tank, one compost filter below the compost, and one second submersible pump with outlet inside the marsh gas tank below the compost filter. The present invention can ensure the temperature for anaerobic fermentation in winter and the organic material supply, so as to produce marsh gas and fertilizer in high yield and protect environment.

Owner:CHINA AGRI UNIV

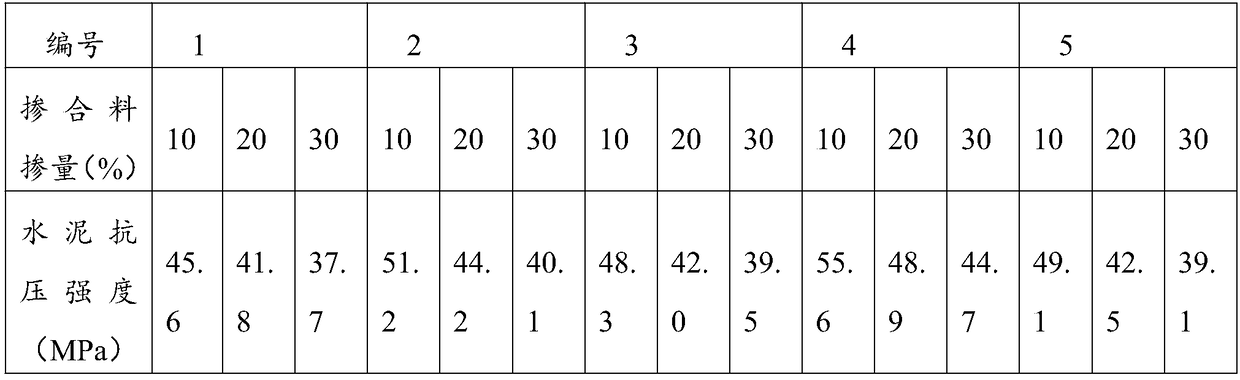

Cement admixture prepared from tungsten tailings and application of cement admixture

InactiveCN103979808AAchieving Scale UtilizationIncrease added valueCement productionMetallurgySilicate Cement

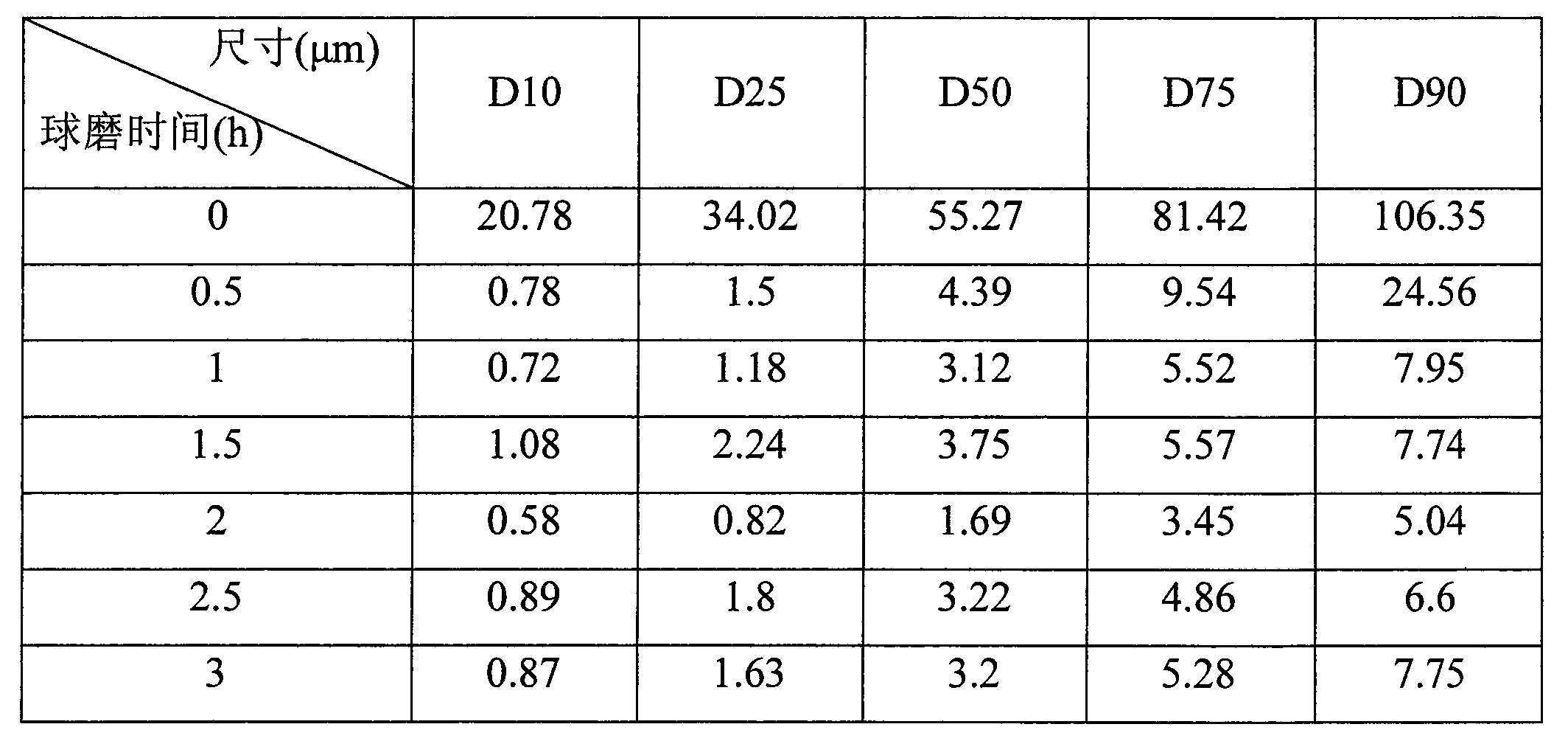

The invention provides a cement admixture prepared from tungsten tailings and an application of the cement admixture, and belongs to the field of comprehensive utilization of solid wastes. The cement admixture comprises the tungsten tailings and quicklime, wherein the adding amount of the quicklime accounts for 0% to 15% by the mass of the tungsten tailings; the content of garnet in the tungsten tailings is higher than 70%; the tungsten tailings are mechanically and chemically activated so as to prepare the cement admixture. A mechanical activation method comprises the following step: preparing fine powder of the tungsten tailings via a classification method in a superfine processing manner, wherein the superfine processing comprises ball milling, airflow milling or vibration milling; the classification comprises screening and air classification. A chemical activation method comprises the following step: adding a chemical excitation agent, wherein the quicklime is taken as the chemical excitation agent. The prepared cement admixture can be used for preparing different grades of silicate cement meeting the requirement of national standard. The preparation method is simple and easy to implement; the cement admixture is produced by utilizing the tungsten tailings, so that the large-scale utilization of the tungsten tailings is realized. Thus, the additional value of the tungsten tailings is greatly increased; the cement production cost is lowered. Thus, the preparation method provided by the invention has good economic and social effects.

Owner:CENT SOUTH UNIV +1

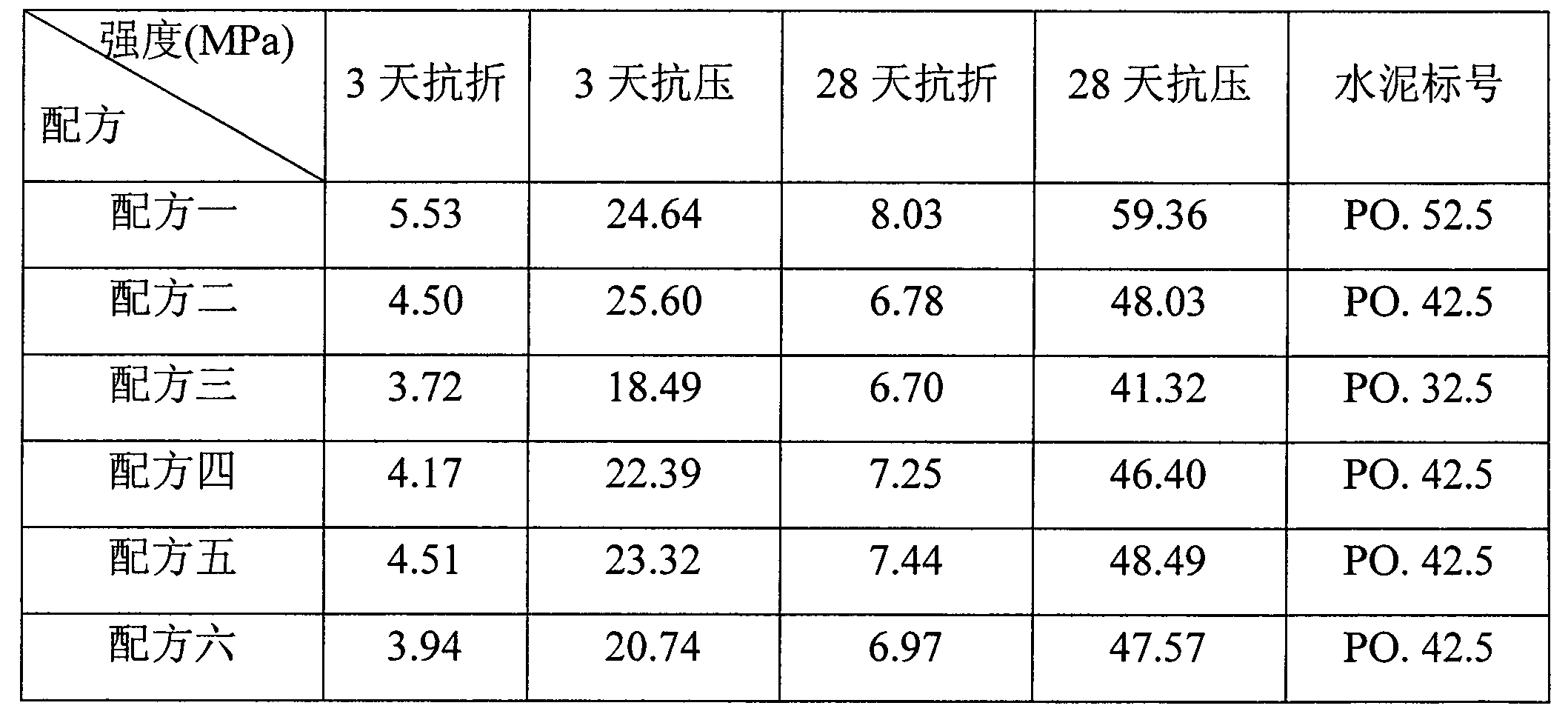

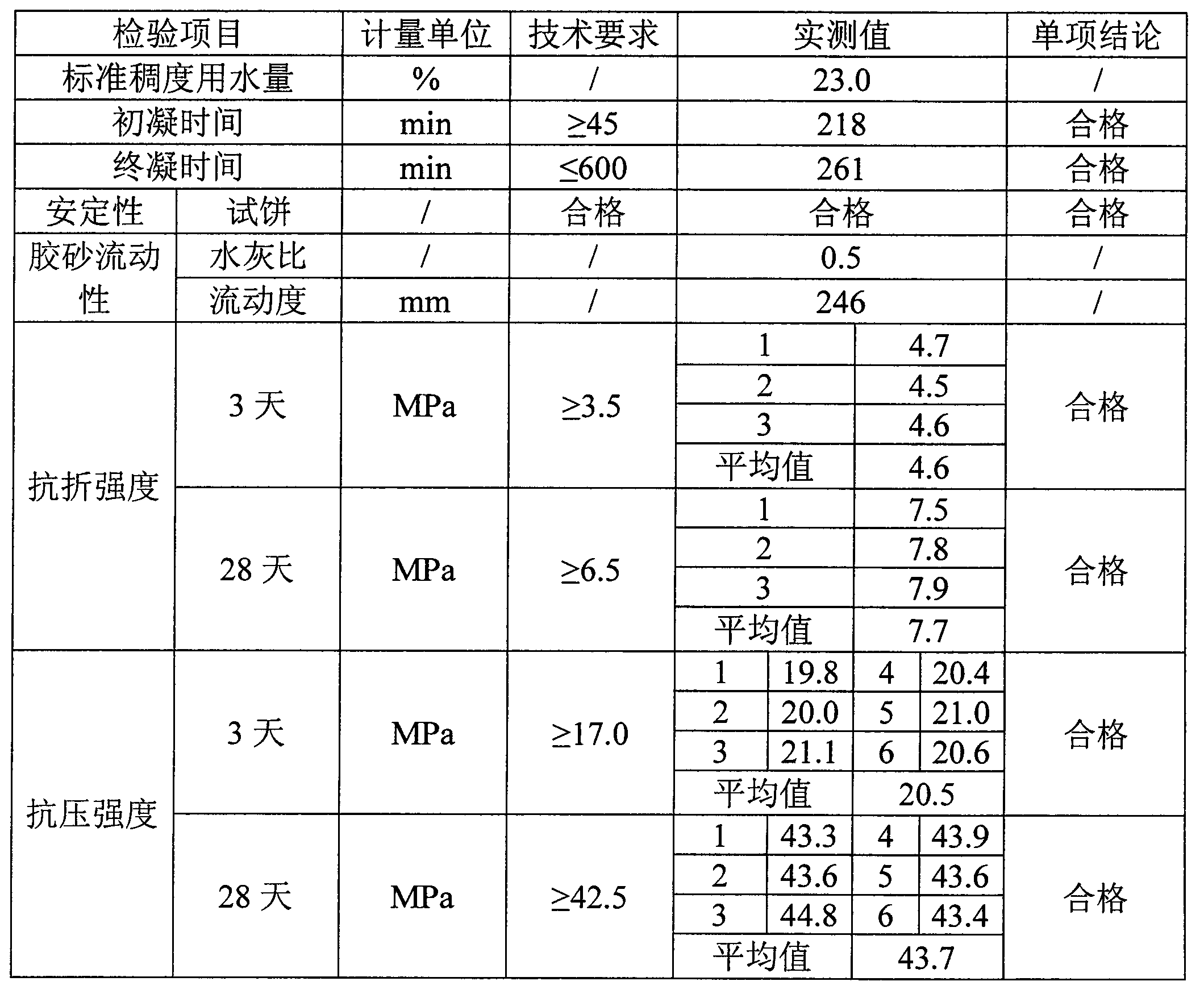

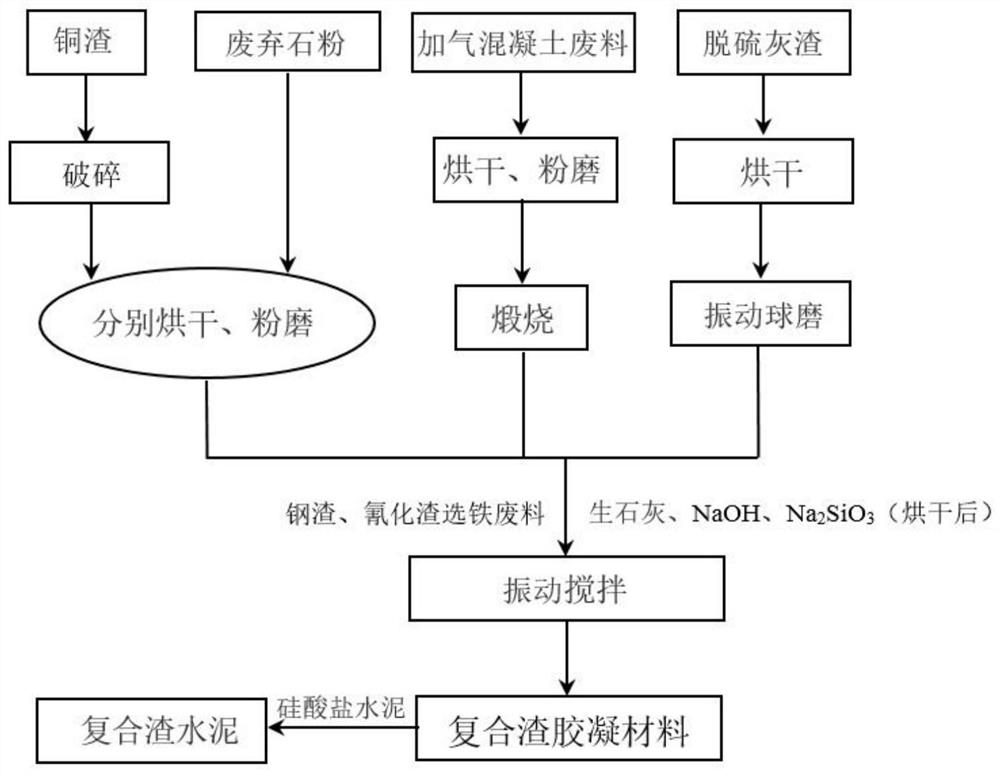

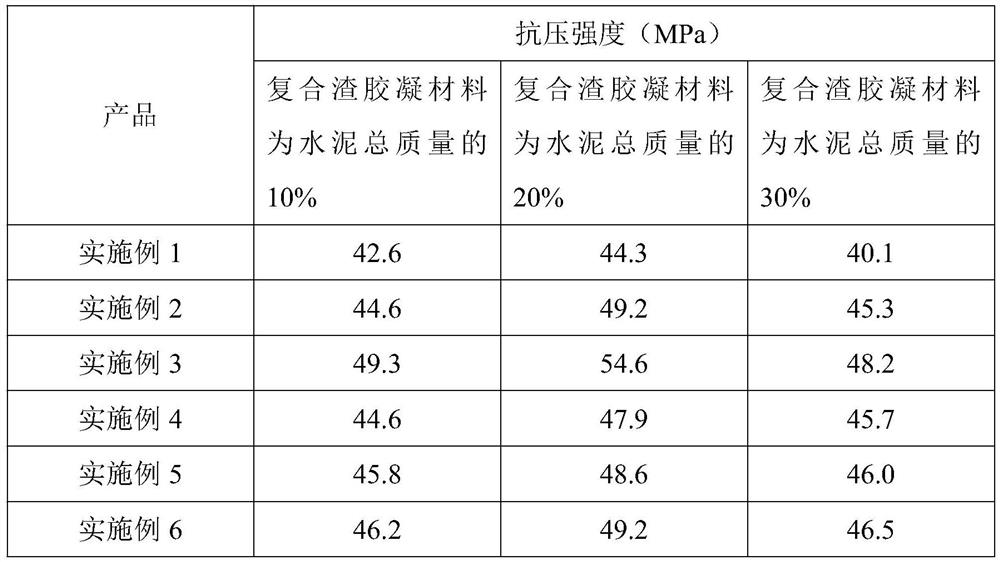

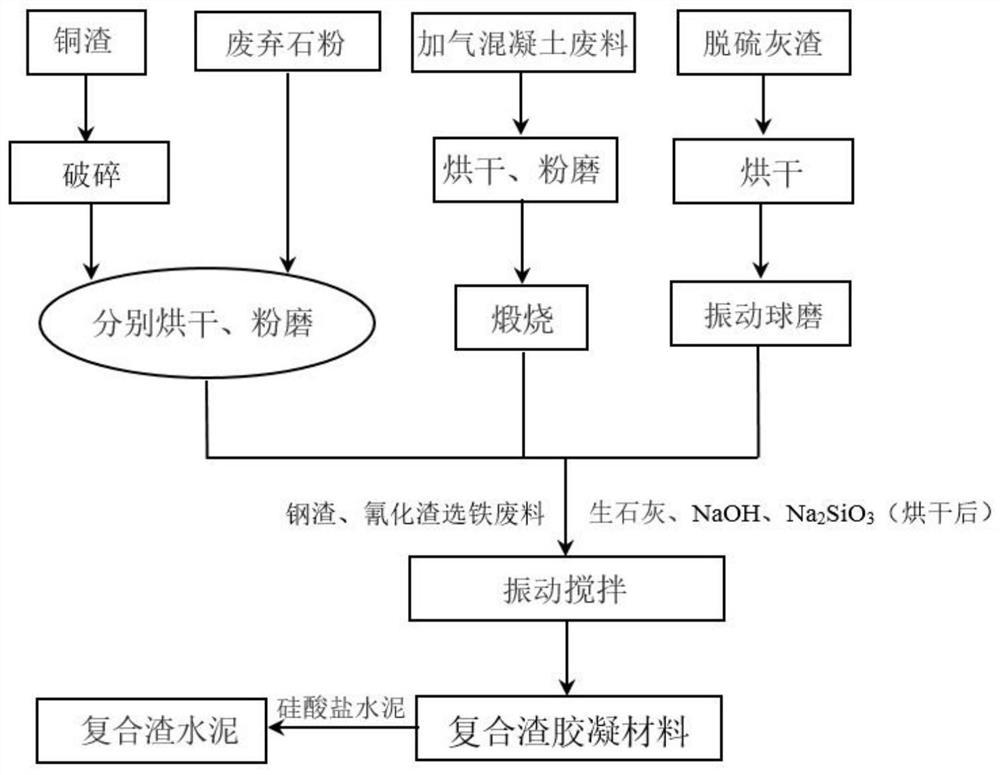

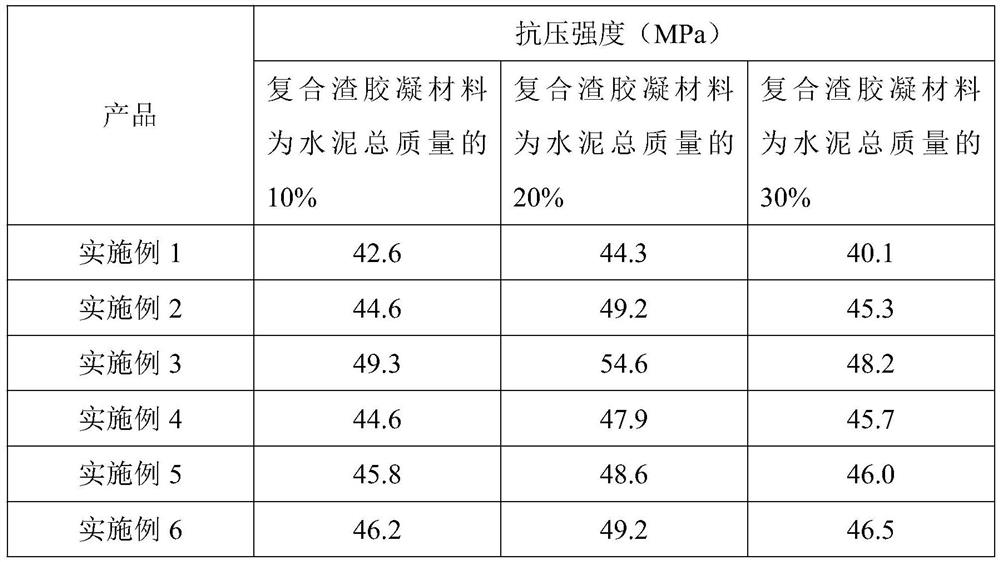

Composite tailing cementing material as well as preparation method and application thereof

ActiveCN111704374AAchieving Scale UtilizationIncrease added valueCement productionSocial benefitsStone dust

The invention provides a composite tailing cementing material as well as a preparation method and application thereof. The composite tailing cementing material is prepared from steel slag and cyaniding slag iron separation waste, copper slag, aerated concrete waste, quick lime, desulfurized ash, NaOH, Na2SiO3 and waste stone powder. The preparation method comprises the following steps: crushing, drying and grinding the copper slag; drying and grinding the aerated concrete waste, calcining the waste at high temperature, and cooling the calcined product; drying and grinding the desulfurized ash,drying and grinding the waste stone powder, mixing the materials with steel slag, cyaniding slag iron separation waste, quick lime, NaOH and Na2SiO3 in proportion, and then uniformly stirring the mixture in a vibration stirrer, thereby finally producing the composite tailing cementing material. According to the method, the steel slag and cyaniding slag iron separation waste, the aerated concretewaste and the copper slag can be effectively utilized, waste is turned into wealth, environmental pollution is greatly reduced, and meanwhile great economic benefits and social benefits can be achieved.

Owner:HEBEI UNIV OF ENG +1

High-fiber and low-sugar potato nutritional compound powder and preparation method thereof

PendingCN107212329AReduce moisture contentReduced activityDough treatmentYeast food ingredientsFiberPotato starch

The present invention provides high-fiber and low-sugar potato nutritional compound powder and a preparation method thereof. A potato starch by-product of potato residues is subjected to a wet method superfine crushing treatment and a preliminary dehydration, starch, proteins, and at least one of any of dry ingredients of polyphenols, food gums, food grade mineral salts, food grade vitamins, etc., are added into the wet materials, the mixture is subjected to a preliminary "backfilling and moisture absorbing", then a drying is conducted to remove water content in the mixed materials, and the high-fiber and low-sugar potato nutritional compound powder is obtained. The backfilling and moisture absorbing can reduce drying energy consumption. Besides, main nutrient contents can be adjusted according to requirements of products and customers at will, the finally adjusted product has nutrient contents comparative to or even more than that of commercially available potato full powder. A processing performance of the potato nutritional compound powder is better than that of the commercially available potato full powder due to the fact that starch at relatively low temperature is almost never gelatinized in a production process. The potato nutritional compound powder can be used for processing of potato staple food and snack food, and can play effects of lowering blood lipids and blood sugar in a long-term consumption.

Owner:INST OF AGRO FOOD SCI & TECH CHINESE ACADEMY OF AGRI SCI +1

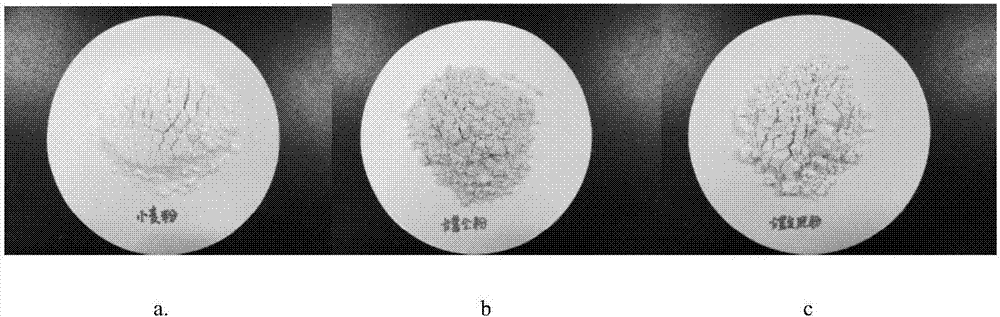

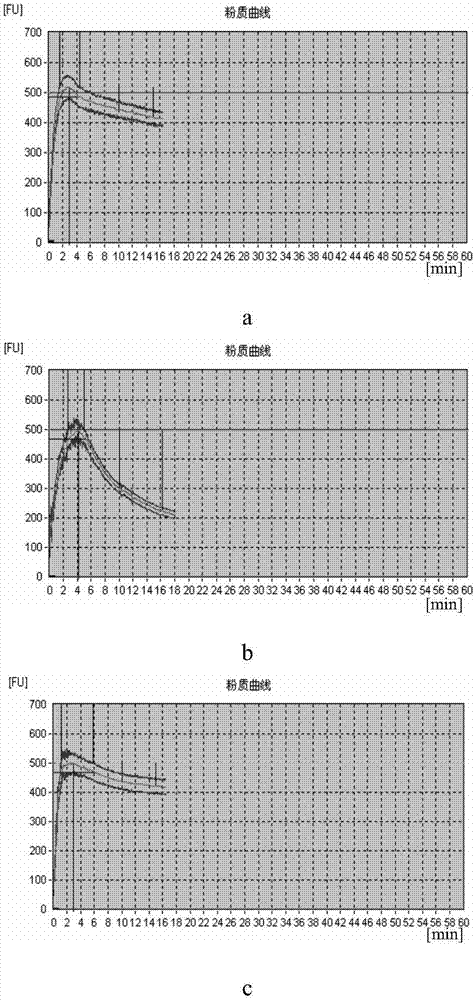

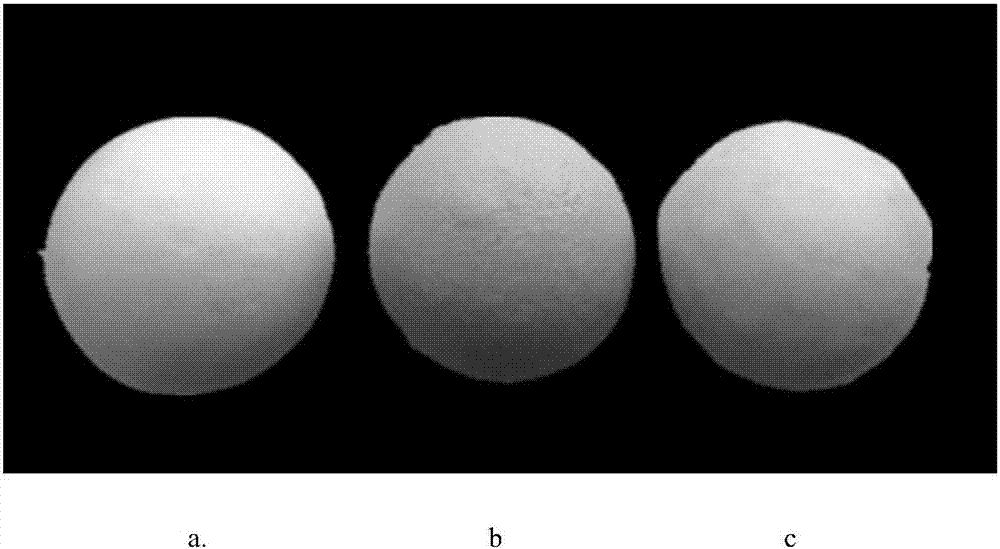

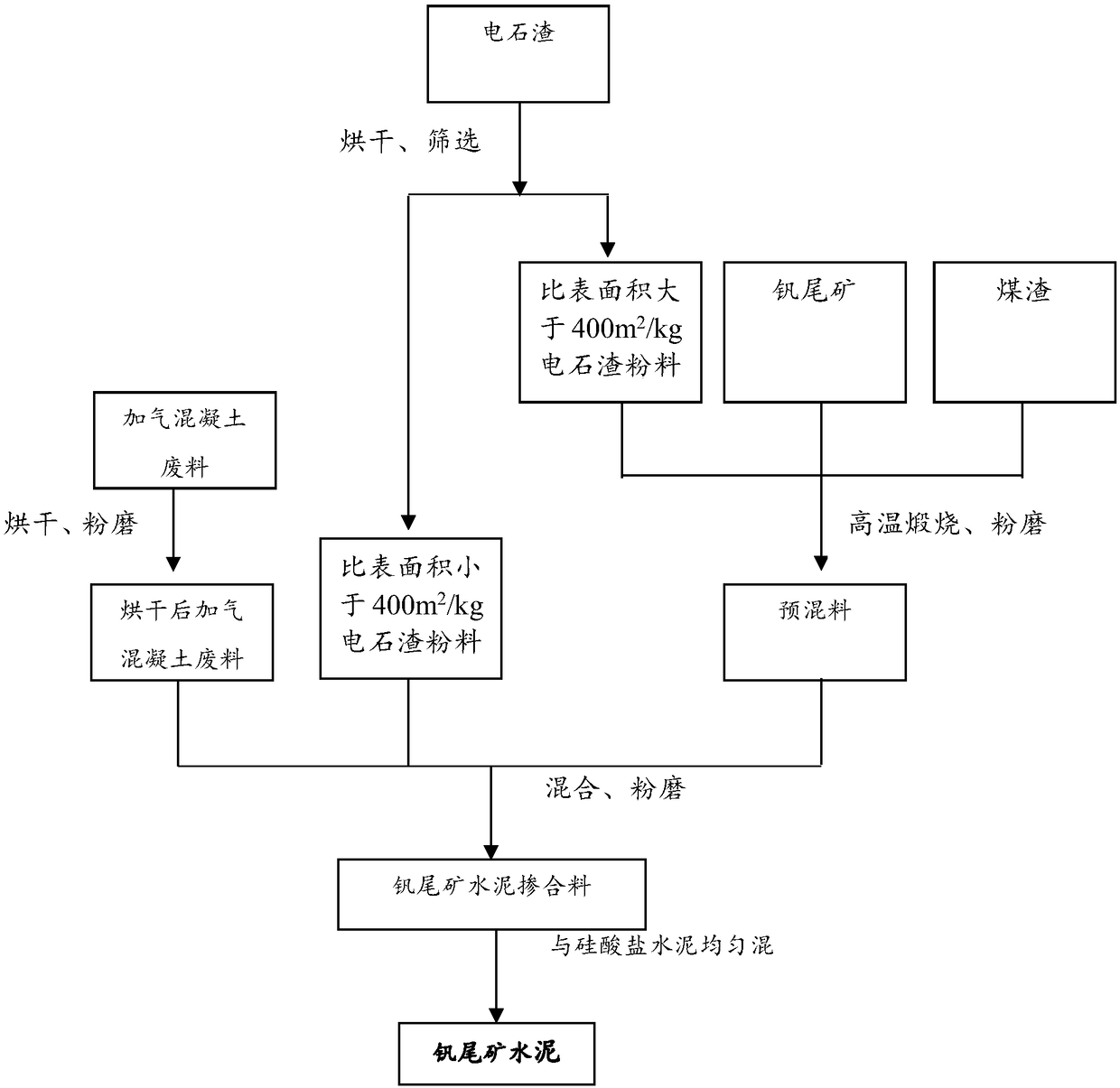

Vanadium tailings and cement blended material and preparation method and application thereof

The invention discloses a vanadium tailings and cement blended material and a preparation method and application thereof. The preparation method comprises the following steps: drying carbide slag, andsorting out carbide slag powder of which the specific surface area is greater than 400 m<2> / kg and carbide slag powder of which the specific surface area is smaller than 400 m<2> / kg by using a powdersorting machine; mixing the carbide slag powder of which the specific surface area is greater than 400 m<2> / kg with vanadium tailings and coal slag, and carrying out high-temperature calcination; grinding the calcined powder to obtain ground premix; breaking aerated concrete wastes into materials of which the granularity is smaller than 10 mm, then drying until the water is smaller than 1%, and then grinding the materials; adding the carbide slag powder of which the specific surface area is smaller than 400 m<2> / kg and the dried aerated concrete wastes in the premix and grinding the mixture to obtain the vanadium tailings and cement blended material. The prepared mineral blended material can be used in industrial production of cement. The preparation method is simple and feasible, large-scale utilization of the vanadium tailings can be realized, the additional value of the vanadium tailings is increased, the production cost for the cement is reduced, and the economic effect and the social effect are good.

Owner:中煤地质集团有限公司北京生态环境分公司 +2

Polycarboxylic acid water reducing agent preparation method, and retarder and preparation method thereof

The present invention discloses a polycarboxylic acid water reducing agent preparation method, and a retarder compounded with the prepared polycarboxylic acid water reducing agent. According to the method, a water phase free radical copolymerization reaction is performed in water by using acrylic acid and other unsaturated acids as a small monomer, using isobutylene alcohol polyoxyethylene ether as a large monomer, using persulfate as an initiator, and using thioglycolic acid and / or mercaptopropionic acid as a chain transfer agent. According to the present invention, the retarder comprises, byweight, 75-90 parts of the polycarboxylic acid water reducing agent (calculated as the weight of the effective component), 1-10 parts of sodium tripolyphosphate, 10-25 parts of citric acid, and 1-10parts of a calcium increasing agent, has good retarding effect, and can significantly prolong the retarding time of desulfurized building gypsum, such that the desulfurized gypsum can overcome the drawbacks that the construction requirement cannot be met due to the rapid solidification, and the strength loss of the desulfurized gypsum after solidification is low.

Owner:BEIJING NEW BUILDING MATERIALS PLC

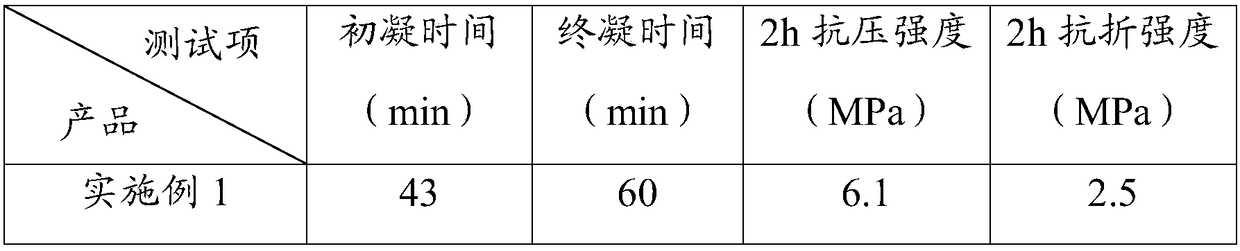

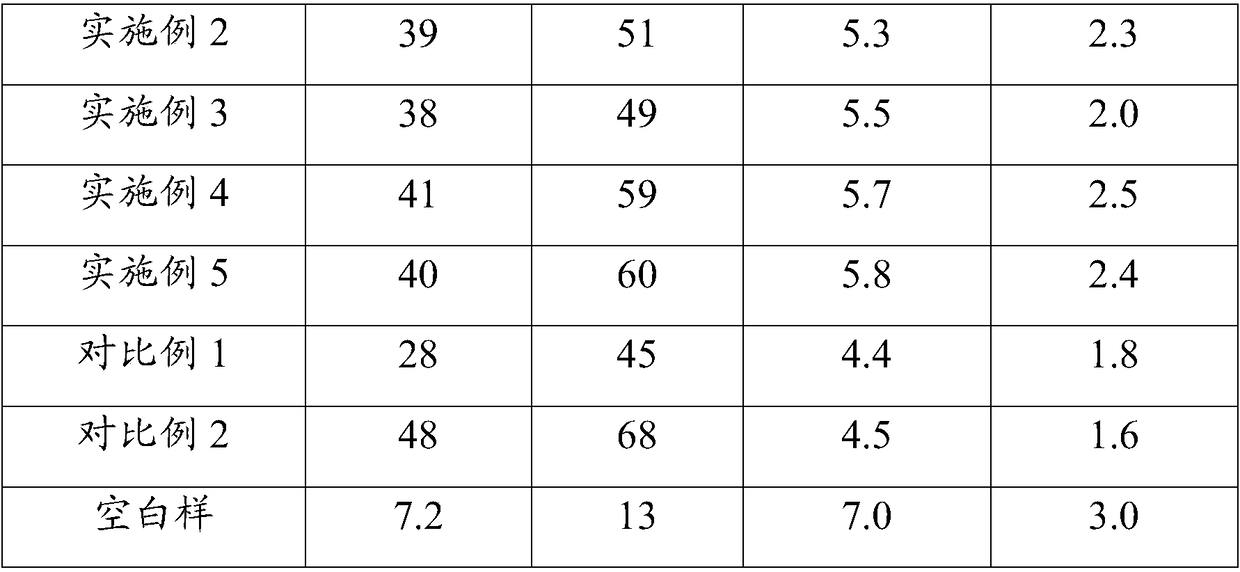

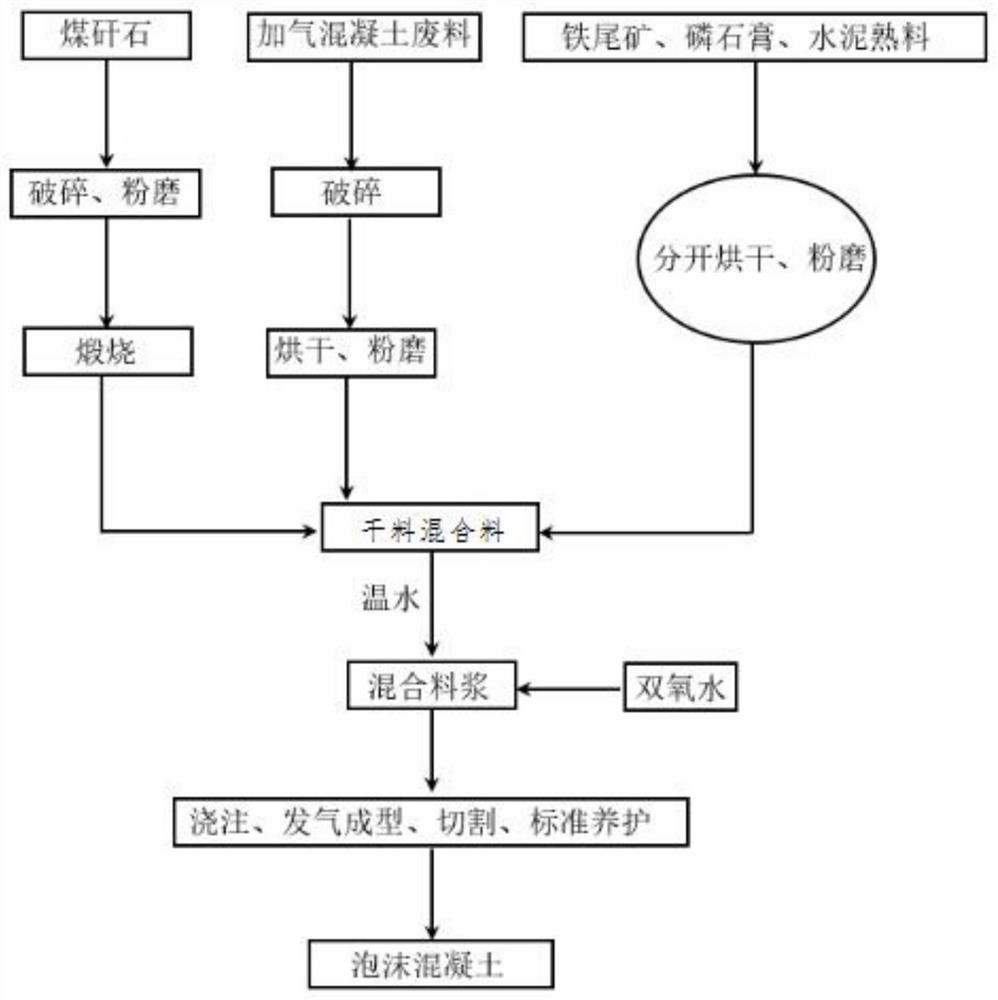

Method for preparing foam concrete from iron tailings and aerated concrete wastes

ActiveCN111039610ARealize comprehensive utilizationEfficient use ofCeramicwareFoam concreteWarm water

The invention belongs to the technical field of building materials, and relates to a method for preparing foam concrete from iron tailings and aerated concrete waste. The method comprises the following steps: 1, crushing and grinding coal gangue, and calcining the ground material to obtain a coal gangue base material; 2, crushing aerated concrete wastes to be smaller than 2 mm, and drying and grinding into fine materials to obtain an aerated concrete waste base material; 3, pretreating the iron tailings, phosphogypsum and cement clinker, and mixing the pretreated material with the coal ganguebase material and the aerated concrete waste base material to obtain a dry material mixture; 4, adding warm water into the dry material mixture, uniformly stirring, then adding hydrogen peroxide, anduniformly stirring to obtain a mixed slurry; and 5, pouring the mixed slurry, carrying out gas generation forming, then taking out and cutting a blank obtained after gas generation forming, and then performing standard maintenance to obtain the foam concrete.

Owner:HEBEI UNIV OF ENG +1

Method for filling urban road roadbed with slag

InactiveCN107938452AAchieving Scale UtilizationSolve the problem of filler shortageRoadwaysUrban main roadSlag

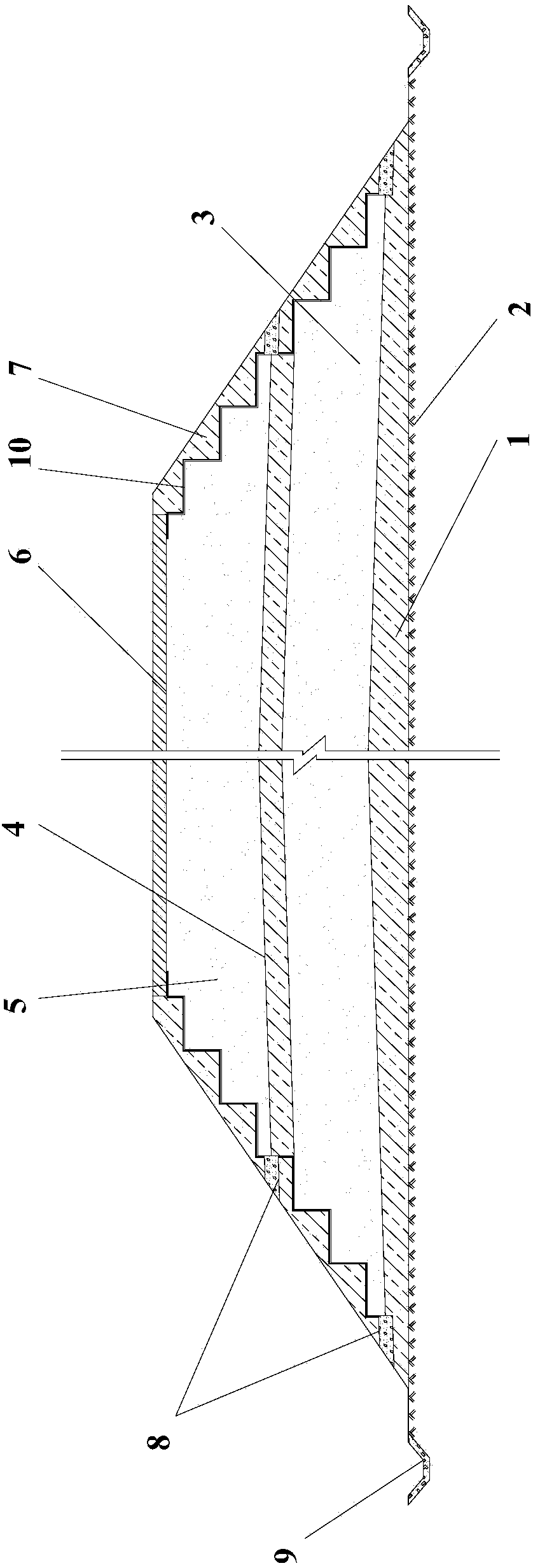

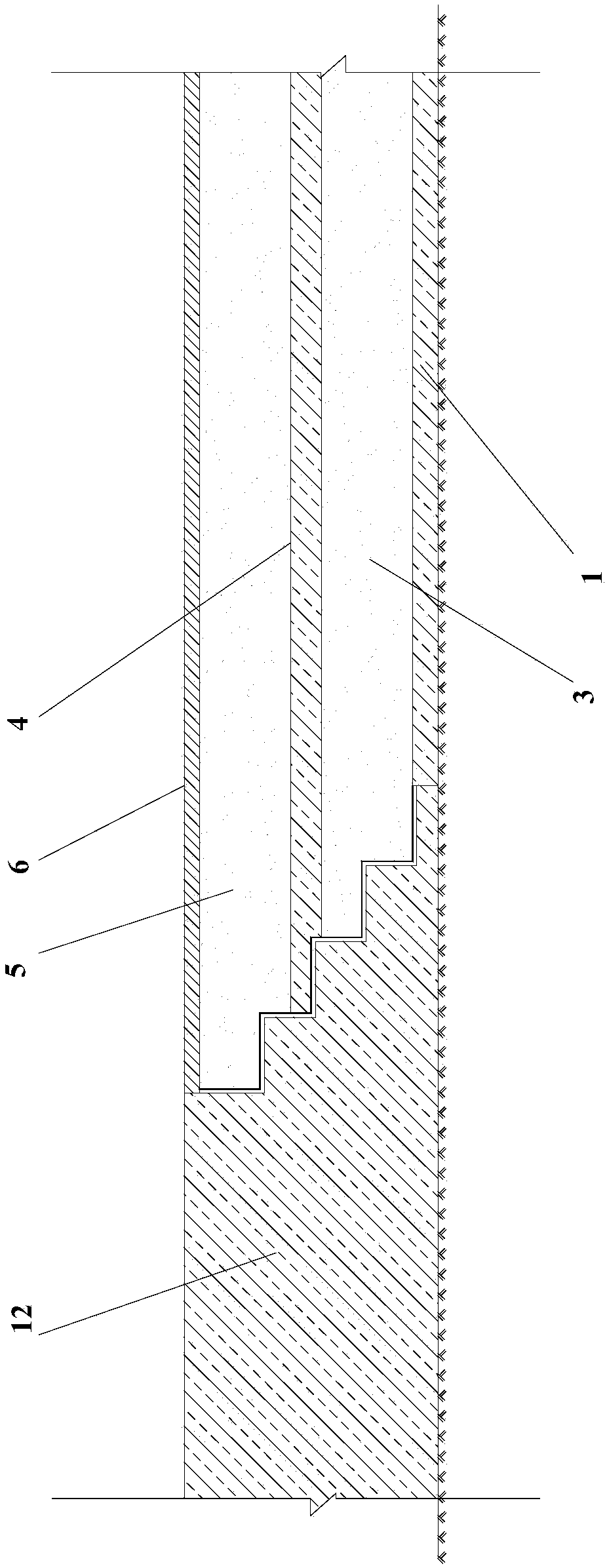

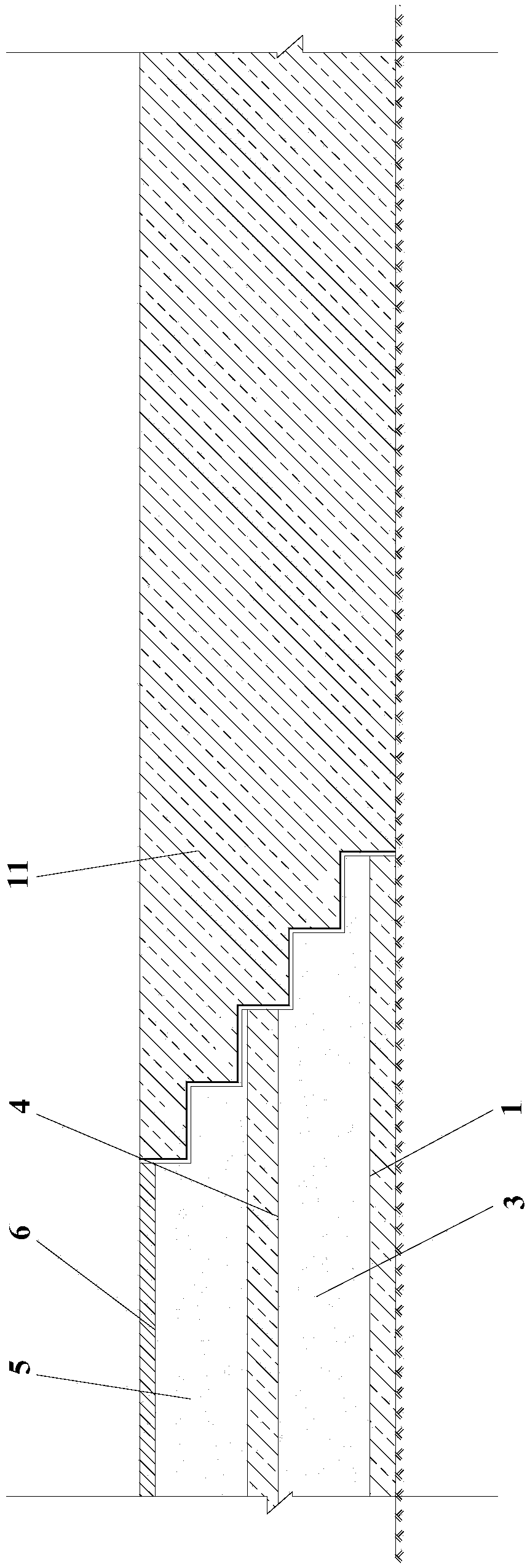

The invention provides a method for filling an urban road roadbed with slag. The method comprises the following steps: step 10: paving the clay with plasticity index greater than or equal to 6 at theroadbed bottom and forming a bottom sealing layer;step 20: paving the slag, with stable performance after the treatment of hot splashing, water quenching, hot sealing or aging, on the bottom sealing layer and forming a lower-layer embankment; step 30: paving the clay with plasticity index greater than or equal to 6 at the top of the lower-layer embankment, and forming an interlayer; step 40: paving the slag, with stable performance after the treatment of hot splashing, water quenching, hot sealing or aging, on the interlayer and forming an upper-layer embankment; step 50: paving lime-ash soil,37 lime earth or cement stabilized soil at the top of the upper-layer embankment and forming a top sealing layer; step 60: paving the clay with plasticity index greater than or equal to 6 at the periphery of the lower-layer embankment, the periphery of the interlayer and the periphery of the upper-layer embankment, and forming a revetment. The method provided by the invention can realize large-scale utilization of the slag.

Owner:MCC CAPITAL ENGINEERING & RESEARCH

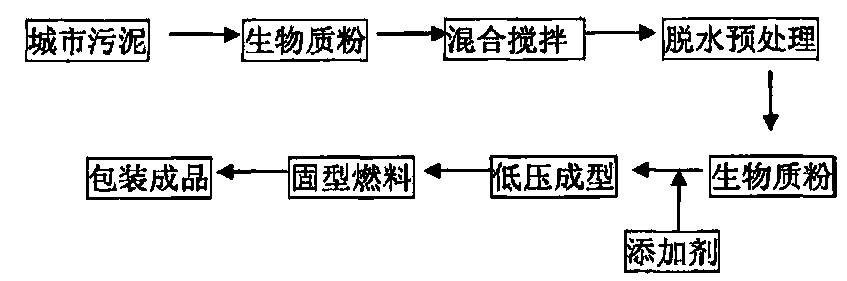

Method for preparing high calorific value fuel from municipal sludge and biomass synergistically

InactiveCN108753403APerishableSmall particlesSludge treatment by de-watering/drying/thickeningHeat recovery systemsSludgePolyacrylamide

The invention discloses a method for preparing high calorific value fuel from municipal sludge and biomass synergistically. The method comprises the following steps: pumping municipal biochemical sludge into a conditioning tank, adding gardening wastes and cationic PAM (polyacrylamide) for conditioning, carrying out mechanical dewatering till a water content of 60%, further deeply drying the sludge by a multi-stage heat recycling air source heat pump till a water content of 15%, and putting additives into the sludge, pelletizing, thereby obtaining the high calorific value biomass fuel. Compared with the prior art, the method has the advantages that gardening greening crushed twigs and macromolecule environmentally-friendly type materials are adopted as swelling agents and conditioning agents, the cost of common chemical conditioning is reduced, secondary pollution is reduced, novel ways are provided for gardening wastes, sludge is deeply dried at a low temperature by the multi-stage heat recycling air source heat pump, the targets of energy recycling and 'treating waste with waste' are achieved, the energy is saved, the efficiency is improved, the sludge treatment cost is reduced,secondary pollution is reduced, and waste recycling and combination of social, economic and environment benefits in an environment treatment process are achieved.

Owner:南京师范大学镇江创新发展研究院

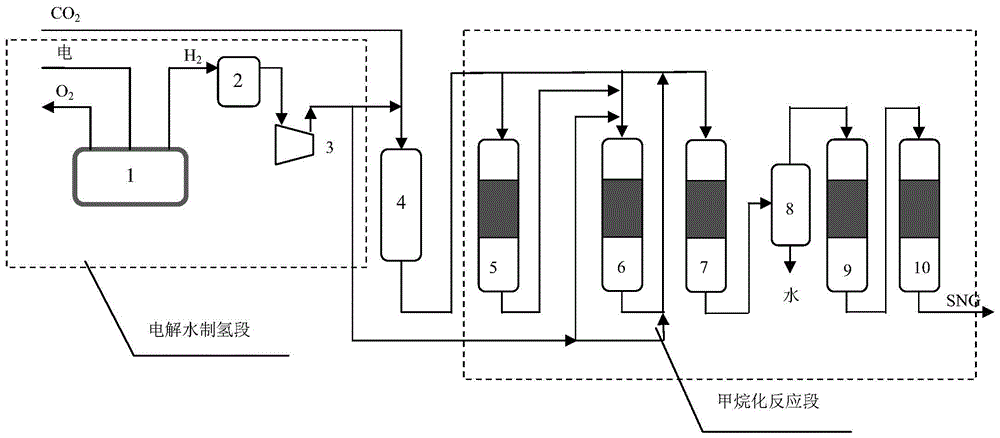

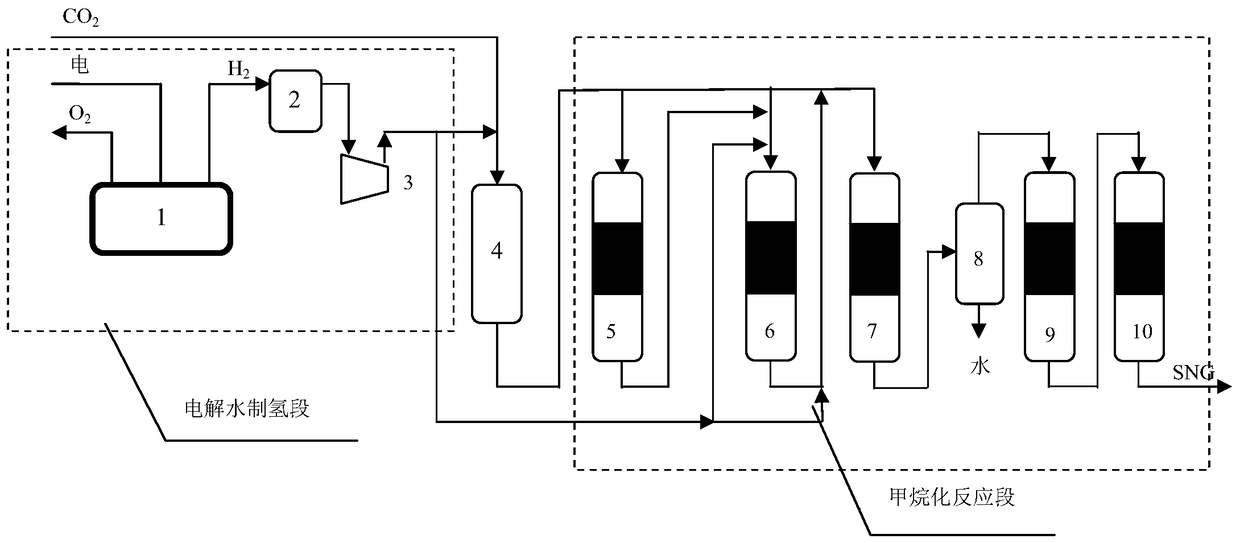

Method for utilizing electricity to gas (ETG)

ActiveCN105695013AEmission reductionReduce pressure on environmental protectionGaseous fuelsMethanationNuclear power

The invention discloses a method for utilizing electricity to gas (ETG). The method comprises the following steps: (1) preparing hydrogen by using water electrolyzed by surplus electricity, and collecting the produced oxygen as a by-product; (2) increasing the pressure of the hydrogen to 0.5-5MPa, and then heating up to 220-350 DEG C; (3) enabling the heated hydrogen to be divided into two parts, inputting one part of hydrogen into a gas mixer, and inputting the other part of hydrogen into a methanation reaction zone; (4) inputting carbon dioxide into the gas mixer to enabled the carbon dioxide to be mixed with the hydrogen; (5) arranging at least four methanation reactors which are connected in series and / or in parallel in the methanation reaction zone, and collecting natural gas at an outlet of the last methanation reactor, wherein the surplus electricity comes from the abandoned light, wind, water and / or nuclear power. According to the method, the reactant is taken as a diluent of the raw material gas, so that the situation that the product gas is needed to be introduced into the raw material gas for diluting the reactant concentration by a recycle compressor in the traditional methanation technology can be avoided; therefore, the compressor is omitted, and the power consumption of mechanical equipment is reduced.

Owner:CHINA NAT OFFSHORE OIL CORP +1

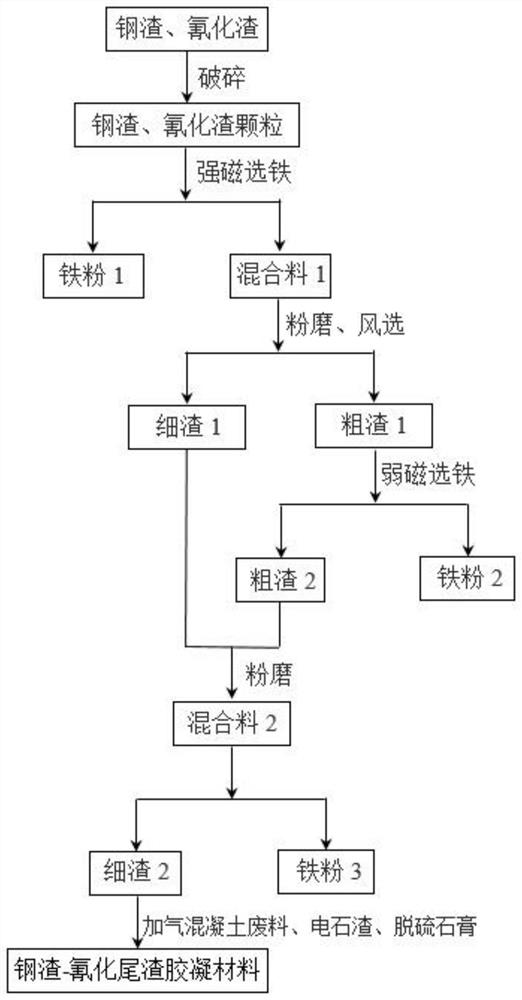

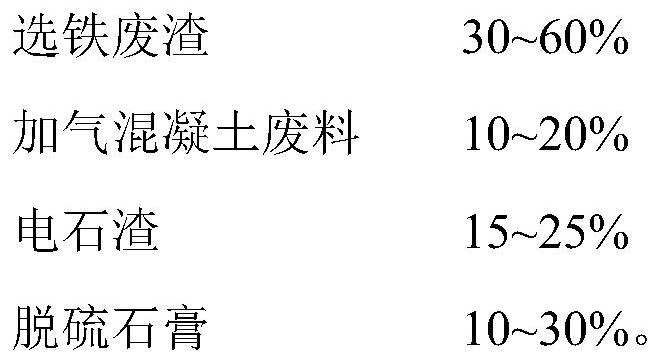

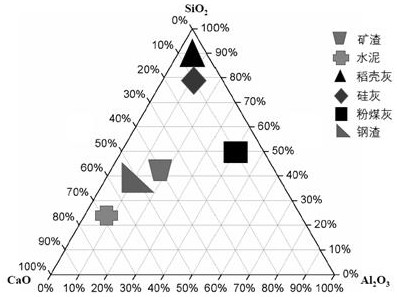

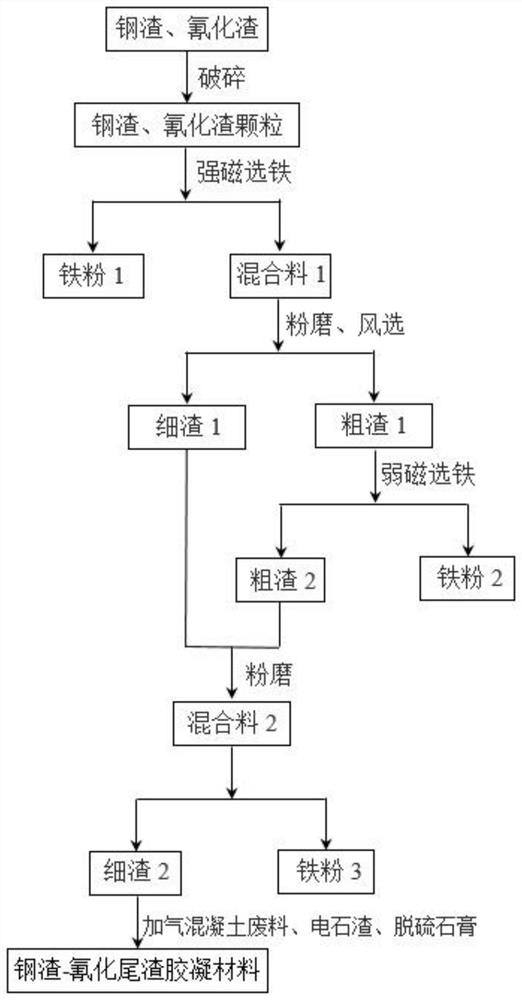

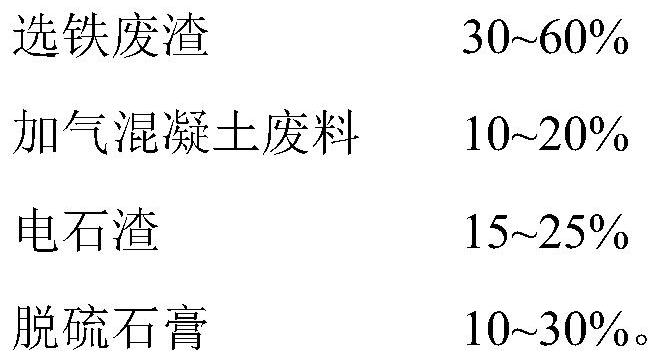

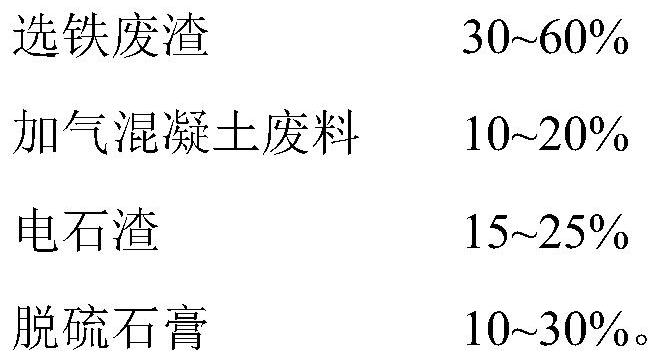

Steel slag-cyaniding tailing cementing material as well as preparation method and application thereof

ActiveCN112408831AEasy to prepareIncrease added valueSolid waste managementMagnetic separationSlagSilicate Cement

The invention provides a steel slag cyaniding tailing cementing material as well as a preparation method and an application thereof. The steel slag cyaniding tailing cementing material is prepared from the following substances in percentage by mass: 30 to 60 percent of iron-selecting waste slag, 10 to 20 percent of aerated concrete waste, 15 to 25 percent of carbide slag and 10 to 30 percent of desulfurized gypsum. The method comprises the following steps: calcining the carbide slag, naturally cooling, and grinding; crushing, drying and grinding the aerated concrete waste; and grinding the desulfurized gypsum, and mixing the ground desulfurized gypsum with the iron separation waste residues of the steel slag cyaniding tailings in proportion to prepare the steel slag cyaniding tailing cementing material; and mixing the cementing material with Portland cement to prepare the steel slag cyaniding tailing cement. The preparation method disclosed by the invention is simple and easy to implement, can realize the synergistic utilization of various wastes, improves the additional value of the wastes, reduces the production cost of the cement, and has good social and economic effects.

Owner:HEBEI UNIV OF ENG +1

Straw modified composite material

InactiveCN106313769AAchieving Scale UtilizationReduce pollutionLayered productsCoatingsFiberCoupling

The invention discloses a straw modified composite material. The straw modified composite material is a multilayer composite structure, and comprises a wear layer, a color film layer, a substrate and a base material from top to bottom; the wear layer is a transparent film with the external surface containing an UV coating; straw fibers are added to the base material; the base material is a straw wood plastic wood plastic polyvinyl chloride and chlorinated polyvinyl chloride crusted and foamed plate; straw fibers are produced from crop straws through a steam blasting technology; the straw fibers are preprocessed through a surface composite treatment technology (ethylene glycol / coupling); and inorganic nanoparticles and SiC nanopowder are added to the base material. The straw modified composite material has the advantages of overcoming of defects of the straw fibers, realization of large-scale utilization of the straws, high strength, good toughness and good wear resistance.

Owner:TAIZHOU HUALI PLASTIC

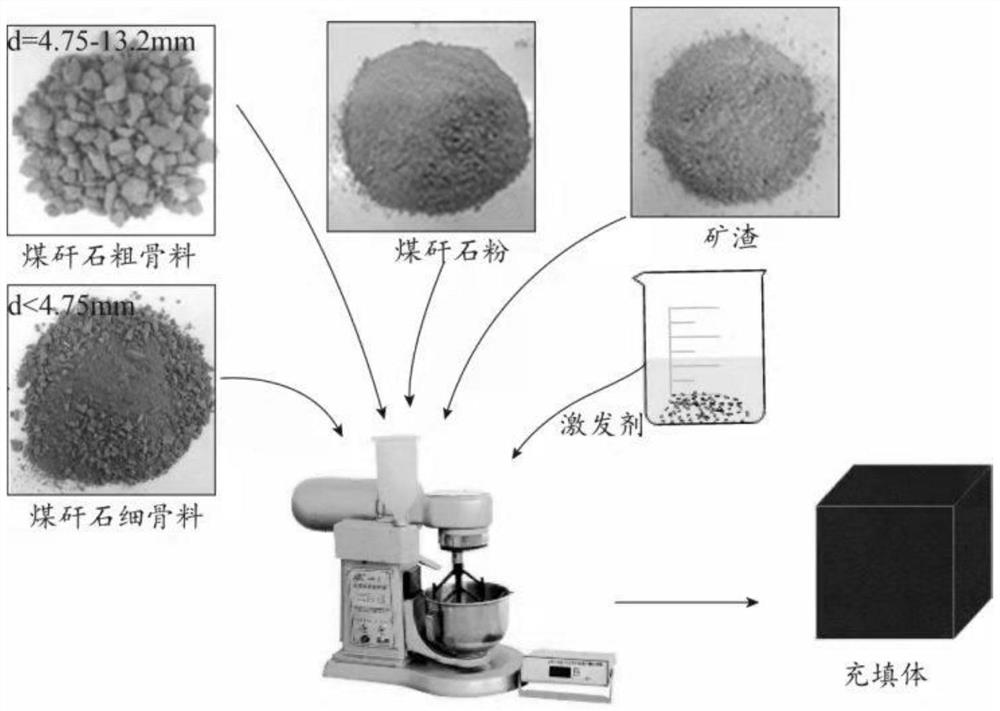

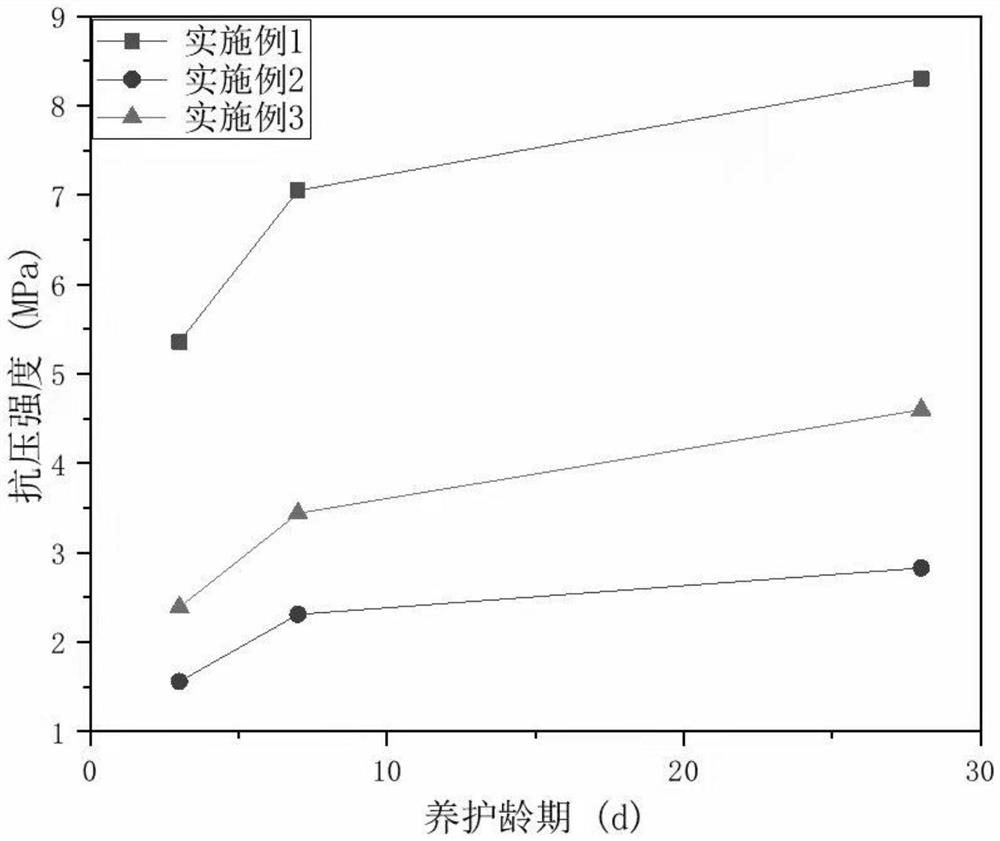

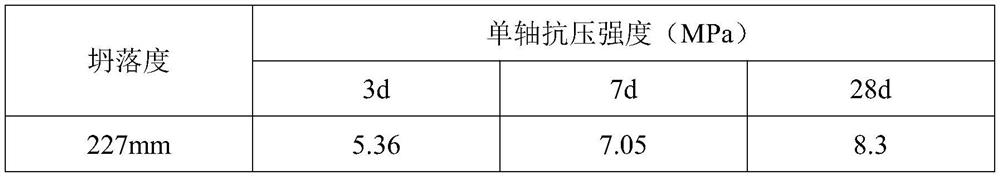

Coal gangue-based mine filling material and preparation method thereof

The invention discloses a filling body doped with coal gangue and slag. The filling body is prepared from 70%-100% of coal gangue powder and 0-30% of slag, the mass ratio of fine-particle-size gangue to coarse-particle-size gangue is (1-2.3): 1, the bone-glue ratio is 3-5, the mass concentration is 81%-83%, and the mass ratio of an alkali activator NaOH to a cementing material is (2-6): 100. And pouring the excitation solution into the material to obtain the filling slurry. The coal gangue powder and the slag are used for preparing the cementing material, the coal gangue is added for preparing the filling body, the strength and fluidity requirements of the filling body are met, the production cost is reduced, and the environmental problem caused by mining is solved. The slurry is applied to mine filling and has certain practical significance.

Owner:LIAONING TECHNICAL UNIVERSITY

A kind of sludge dehydration conditioner and dehydration method thereof

ActiveCN105314815BSolve the use problemSolve the slow expansion defectSludge treatment by de-watering/drying/thickeningIron saltsMagnesium salt

The invention discloses a sludge dehydration conditioner, which comprises the following components in weight percentage: 30-70% desulfurization ash, 5-15% magnesium salt, 5-30% iron salt, 2-20% aluminum salt, 0.1 ~15% Magnesium Oxide. At the same time, it also provides a dehydration method of the conditioner, including the steps of preparation of conditioner solution, conditioning of sludge, preparation of flocculant solution, sludge dehydration and the like. The raw materials used in the present invention have wide sources, low price, low preparation cost, convenient use, good dehydration effect, can rely on existing sludge dewatering facilities, simple implementation process, and can effectively improve the stability and reliability of the sludge dewatering process It can be widely used in the treatment of various waste water, sewage and sludge.

Owner:BAOSHAN IRON & STEEL CO LTD +1

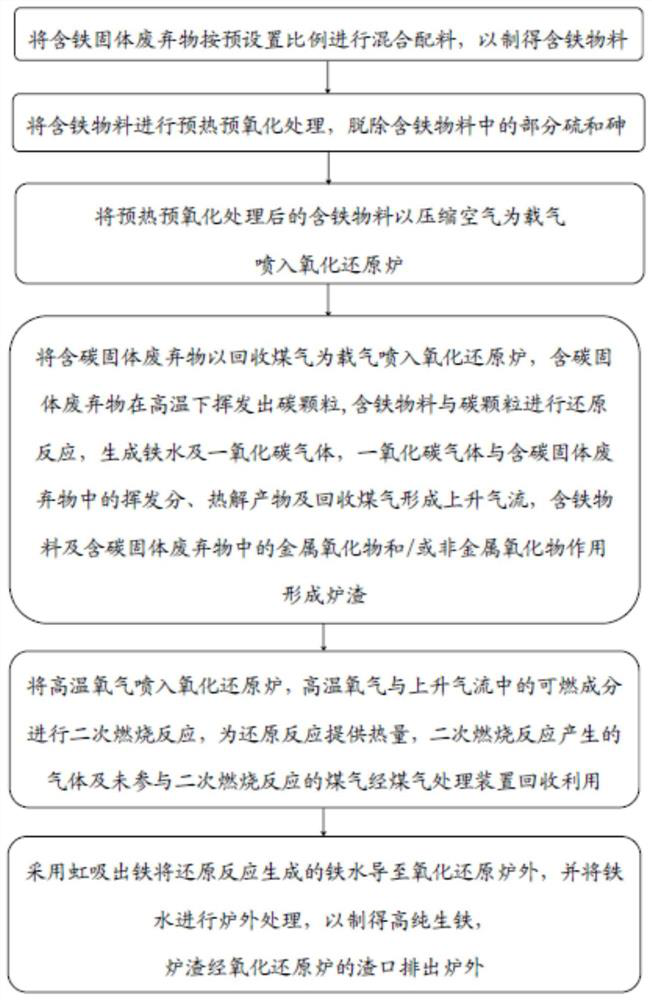

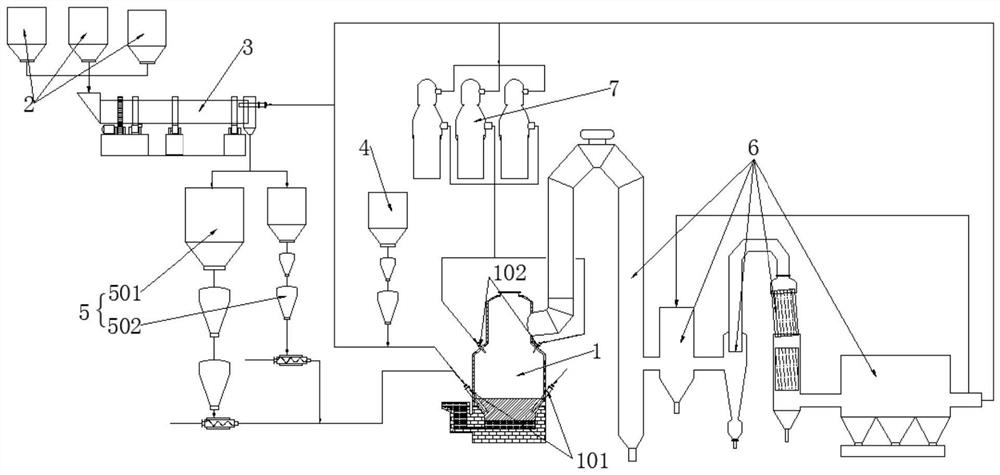

Method and system for treating solid waste through smelting reduction process

InactiveCN112708713ARealize resourcesAchieving Scale UtilizationProcess efficiency improvementCombustionSlag

The invention provides a method and system for treating solid waste through a smelting reduction process. The method comprises the following steps of mixing and batching iron-containing solid waste to prepare an iron-containing material; preheating and pre-oxidizing the iron-containing material; spraying the preheated and pre-oxidized iron-containing material into an oxidation-reduction furnace by taking compressed air as carrier gas; spraying carbon-containing solid waste into the oxidation-reduction furnace by taking recycled coal gas as carrier gas, and reacting the carbon-containing solid waste with the iron-containing material to generate molten iron, carbon monoxide and furnace slag; and spraying high-temperature oxygen into the oxidation-reduction furnace, carrying out a secondary combustion reaction on the high-temperature oxygen and combustible components in ascending gas flow, and recycling coal gas generated by the secondary combustion reaction and coal gas which does not participate in the secondary combustion reaction. According to the method, traditional fuel, lime, dolomite and other fluxing agents do not need to be added, compressed air and recycled coal gas are adopted as carrier gas to convey materials, high-temperature oxygen is adopted as a combustion improver, and solid waste recycling and large-scale comprehensive utilization are achieved.

Owner:SHANDONG MOLONG PETROLEUM MACHINERY

A method for preparing foam concrete from iron tailings and aerated concrete waste

ActiveCN111039610BRealize comprehensive utilizationEfficient use ofCeramicwareFoam concreteWarm water

The invention belongs to the technical field of building materials, and relates to a method for preparing foamed concrete from iron tailings and aerated concrete waste, including: step 1, crushing and grinding coal gangue, and then calcining the ground material to obtain Coal gangue base material; step 2, crush the aerated concrete waste to <2mm, then dry and grind it into fine material to obtain the aerated concrete waste base material; step 3, mix iron tailings, phosphogypsum and cement clinker Carrying out pretreatment, mixing the pretreated material with coal gangue base material and aerated concrete waste base material to obtain a dry material mixture; step 4, adding warm water to the dry material mixture, stirring evenly, and then adding hydrogen peroxide , stirring evenly to obtain a mixed slurry; Step 5, pouring the mixed slurry, gas forming, and then taking out the gas-molded green body for cutting, and then performing standard maintenance to obtain foam concrete.

Owner:HEBEI UNIV OF ENG +1

Preparation technology of wood-plastic composite material

The invention discloses a preparation technology of a wood-plastic composite material. The preparation technology comprises the following steps: 1), mixing mulberry branch fiber with recycled plasticparticles and an auxiliary agent at high speed / low speed, and then adding into a double-stage (double-screw / single-screw) mixing unit for performing extrusion granulation to obtain wood-plastic composite material masterbatch; 2), adding the wood-plastic composite material masterbatch into an extrusion moulding machine for extruding a wood-plastic composite plate material. By the preparation technology, large-scale utilization of mulberry branches can be achieved.

Owner:王秋林

Low-emission and low-smoke density natural fiber modified PVC green facing composite material

InactiveCN106313814AReduce pollutionAchieving Scale UtilizationSynthetic resin layered productsLaminationMolten stateEpoxy

The invention discloses a low-emission and low-smoke density natural fiber modified PVC green facing composite material. The composite material comprises a wearing layer, a color film layer, a base material and a substrate from top to bottom; the base material and the substrate are hot-pressed; the wearing layer is a transparent film with the external surface containing a UV coating; wood powder, straws and other natural fibers are added to the base material; the wood powder, straws and other natural fibers are treated through a surface composite treatment technology; the wear layer is a transparent film, and the external surface of the transparent film contains carbon nanotubes with the surface grafted with methyl methacrylate and a nano-TiO2 modified epoxy acrylic resin coating with the surface being hydrophobically modified; and a group of synergistic low-molecular expelling agents is adopted in the hot-pressing process of the base material and the substrate, and a device with a specially reconstructed structure is combined, so organic volatile components are maximally removed from the blend composite material in a molten state. The composite material has the characteristics of good antistatic and antibacterial functions, low cost and environmental protection.

Owner:TAIZHOU HUALI PLASTIC

Micro-nano full bamboo shoot beverage and preparation method thereof

PendingCN113575810ARetain nutrientsGreat tasteFood ingredient as antioxidantFood freezingMicro nanoFreeze-drying

The invention discloses a micro-nano full bamboo beverage and a preparation method thereof. The method comprises the following steps: pretreating bamboo shoots, carrying out hot extraction for deastringency, carrying out freeze drying, carrying out grinding and crushing, carrying out superfine grinding, filtering and separating to obtain bamboo shoot superfine powder, uniformly blending the bamboo shoot superfine powder with purified water, carrying out curing treatment, carrying out primary homogenization on the cured material, adding an antioxidant, a sweetening agent and an active additive, performing secondary homogenization, filling after secondary homogenization, and performing sterilization treatment to obtain the micro-nano all-bamboo shoot beverage. The all-bamboo-shoot beverage prepared by processing fresh bamboo shoots as raw materials is purely natural, free of artificial pigments and preservatives, free of astringent taste of the bamboo shoots, fine and smooth in taste, tasty, refreshing, soft and smooth, rich in nutritional ingredients and dietary fibers and good in health-care effect, meets the positioning of 'nutrition and functionalization', meets the requirements of modern consumers, high-value utilization of the bamboo shoots is realized; meanwhile, the process is simple, and industrial production is easy.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

Modified steel slag based on steel dust mud and red mud as well as preparation method and application of modified steel slag

ActiveCN113979655AImprove gelling activityAchieving Scale UtilizationRecycling and recovery technologiesProcess efficiency improvementSlagPolluted environment

The invention discloses modified steel slag based on steel dust and mud and red mud as well as a preparation method and application of the modified steel slag, wherein the modified steel slag comprises steel slag and a composite modifier, and the composite modifier comprises coal gasification residues, the red mud and the steel dust mud; the preparation method comprises the following steps: pretreatment of steel slag, pretreatment of the coal gasification residues, pretreatment of the red mud, pretreatment of the steel dust mud, ball-milling mixing, compression molding, sintering modification and blast quenching. According to the modified steel slag and the preparation method and application thereof, the problems that steel slag, steel dust mud, red mud and coal gasification residues cannot be effectively utilized and pollute the environment can be solved, so that the steel slag, the coal gasification residues, the steel dust mud and the red mud are effectively utilized, and the gelling activity and stability of the steel slag are improved; and meanwhile, waste is turned into wealth, large-scale utilization of waste is achieved, high economic value is generated, and the purposes of green sustainable development, energy conservation, environmental protection and resource utilization of solid waste are achieved.

Owner:CHINA RAILWAY CONSTR GROUP +2

Environment-friendly straw PVC compound plate

InactiveCN108891100AAchieving Scale UtilizationImprove structural strengthSynthetic resin layered productsGlass/slag layered productsMolten stateCompound structure

The invention discloses an environment-friendly straw PVC compound plate which has a multilayer compound structure and comprises a wearing layer, a colorful film, a base plate and a substrate from topto bottom; straws are added into the substrate; the further improvement is as follows: a glass fabric is added into the substrate; SiC nanometer powder is added into the substrate; a transparent filmwith a UV coating layer serves as the wearing layer. According to the preparation technology of the environment-friendly straw PVC compound plate, a set of synergistic low-molecule repellents are combined with the device subjected to special structure improvement, so that the organic volatile components contained in the blended compound material can be removed under a molten state. The environment-friendly straw PVC compound plate has low smoke density, high strength and high toughness and is capable of realizing the large-scale utilization of crop straws.

Owner:郭新

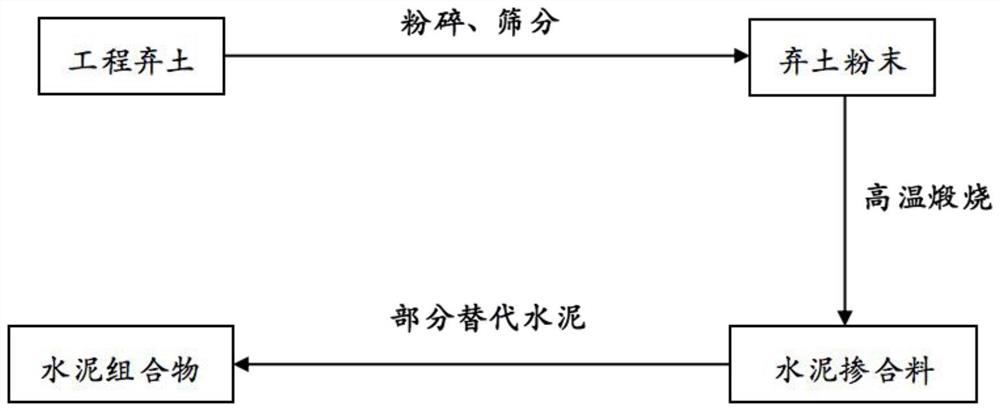

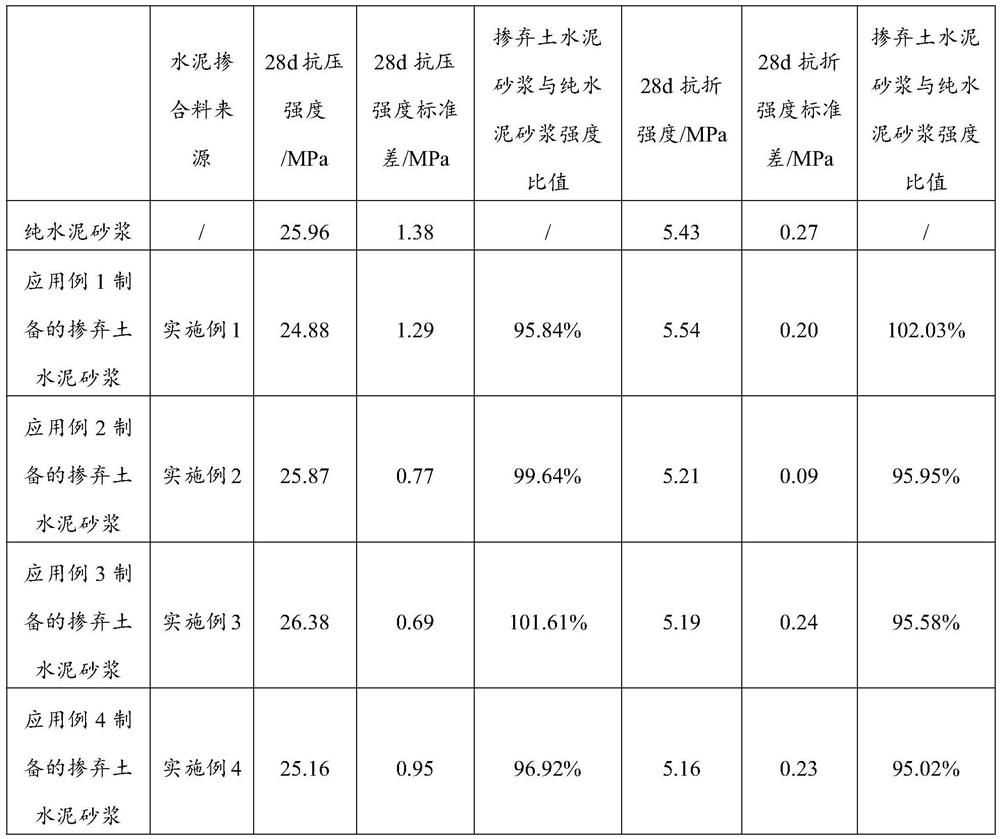

A method for preparing cement admixture by utilizing engineering spoil, cement admixture and cement composition

The invention belongs to the technical field of resource utilization of solid waste, and in particular relates to a method for preparing cement admixture by using engineering waste soil, a cement admixture and a cement composition. The method for preparing cement admixture from engineering spoil provided by the present invention comprises the following steps: crushing engineering spoil to obtain spoil powder; calcining the spoil powder to obtain cement admixture; The spoil includes kaolin, and the content of the kaolin is above 30wt.%. The calcining temperature is 650-700°C. The method for treating engineering spoils in the invention is simple and easy to operate, and the prepared cement admixture can meet the strength requirement of concrete for cementitious materials, and can realize large-scale utilization.

Owner:HARBIN INSTITUTE OF TECHNOLOGY SHENZHEN (INSTITUTE OF SCIENCE AND TECHNOLOGY INNOVATION HARBIN INSTITUTE OF TECHNOLOGY SHENZHEN)

Formula for wood flour filled PP

The invention discloses a formula for wood flour filled PP. The formula is that 11-14 parts of PPg-MAH and 90-100 parts of wood flour are added into every 100 parts of PP resin; and further improvement is that the wood flour has 200 mesh or more. The formula provided by the invention can realize large-scale utilization of the wood flour.

Owner:JIANGSU BAOJINLAI PIPELINE EQUIP

Technology utilizing agricultural waste resources for intelligent large-scale production of edible fungi

InactiveCN103190289AAchieving Scale UtilizationLabor savingHorticultureAgricultural engineeringPulp and paper industry

The invention provides a technology utilizing agricultural waste resources for intelligent large-scale production of edible fungi. The technology includes the steps of (1) material pretreatment, (2) stacking for fermentation, (3) stirring of matching auxiliary materials, (4) capping and bagging, (5) sterilization, (6) precooling, (7) undercarriage, (8) inoculation, (9) feeding into a cultivating warehouse, (10) bag opening and (11) fruiting growth management. The technology specifically includes: pre-wetting and fermenting wood dust; stacking for fermentation for more than three days to enable a wood dust pile to be completely fermented; adding the matching auxiliary materials into a boiler, and uniformly stirring; capping, bagging and sealing; feeding into a sterilizer for steam sterilization; after sterilization is finished, pushing into a cooling room for cooling treatment; when temperature in bags is lower than 25 DEG C, performing undercarriage; feeding into an inoculation room for inoculation; after inoculation, feeding fungi bags into a cultivation warehouse for cultivation; opening the bags when the fungi bags is delivered from the warehouse; and then well performing fruiting growth management. The technology achieves large-scale utilization of the agricultural waste resources, and capable of improving the environment and obtaining benefits.

Owner:HENAN BANGYOU AGRI ECOSYST CYCLE DEV

A kind of steel slag-cyanide tailings cementitious material and its preparation method and application

ActiveCN112408831BIncrease added valueEasy to prepareSolid waste managementMagnetic separationCyanidePortland cement

The invention proposes a steel slag-cyanide tailings cementitious material and its preparation method and application. The steel slag-cyanide tailings cementitious material is composed of the following substances in mass percentage: 30-60% of iron-selected waste slag, 10-20% of aerated concrete waste, 15-25% of calcium carbide slag, and 10-30% of desulfurized gypsum %. Carbide slag is calcined, cooled naturally, and ground; aerated concrete waste is crushed, dried, and ground; after desulfurization gypsum is ground, it is mixed with steel slag-cyanide tailings iron selection waste in proportion to prepare steel slag-cyanide tailings cementitious material. The cementitious material is mixed with portland cement to prepare steel slag-cyanide tailings cement. The preparation method of the invention is simple and easy to implement, can realize the coordinated utilization of various wastes, increase the added value of the wastes, reduce the production cost of cement, and has good social and economic effects.

Owner:HEBEI UNIV OF ENG +1

Natural fiber modified composite wrapping plate with low emission and low smoke density

InactiveCN109228576AAchieving Scale UtilizationIncrease filling volumeSynthetic resin layered productsEnvironmental resistanceSmoke

The invention discloses a natural fiber modified composite wrapping plate with low emission and low smoke density. The natural fiber modified composite wrapping plate comprises a wear-resistant layerand a substrate from outside to inside, wherein the substrate is formed by compositing natural fiber and a PVC base material, further improvement lies in that the natural fiber is wood meal or straw;the natural fiber surface is treated with a natural fiber surface composite treatment process (ethylene glycol / coupling); a group of synergistic low-molecular removers are adopted during preparation and combined with equipment subjected to specific structural transformation. The natural fiber modified composite wrapping plate has low emission and low smoke density and is environmentally friendly,and large-scale utilization of the natural fiber can be realized.

Owner:QIHANG PLASTIC JIANGSU

A kind of method for ammonia extraction and modification of electrolytic manganese residue

ActiveCN104529196BRealize cascade utilizationAchieving mass utilizationSolid waste managementSolid waste disposalBrickElectrolysis

Owner:UNIV OF SCI & TECH BEIJING

A kind of composite tailings cementitious material and its preparation method and application

ActiveCN111704374BAchieving Scale UtilizationIncrease added valueCement productionSocial benefitsCyanide

The invention proposes a composite tailings cementitious material and its preparation method and application. The composite tailings cementitious material is composed of steel slag and cyanide slag, iron selection waste, copper slag, aerated concrete waste, quicklime, desulfurization ash, NaOH, Na 2 SiO 3 It is prepared from waste stone powder. The preparation method is to crush, dry and grind copper slag; dry and grind aerated concrete waste, then calcinate and cool at high temperature; dry and grind desulfurized ash; dry and grind waste stone powder; Separation of iron waste, quicklime, NaOH, Na with steel slag and cyanide slag 2 SiO 3 Mix in proportion, and then place in a vibrating mixer and stir evenly to obtain a composite tailings cementitious material. The invention can effectively utilize steel slag and cyanide slag to select iron waste, aerated concrete waste and copper slag, realize turning waste into wealth, greatly reduce environmental pollution, and realize significant economic and social benefits.

Owner:HEBEI UNIV OF ENG +1

A method to replace natural gas with surplus electricity system

The invention discloses a method for utilizing electricity to gas (ETG). The method comprises the following steps: (1) preparing hydrogen by using water electrolyzed by surplus electricity, and collecting the produced oxygen as a by-product; (2) increasing the pressure of the hydrogen to 0.5-5MPa, and then heating up to 220-350 DEG C; (3) enabling the heated hydrogen to be divided into two parts, inputting one part of hydrogen into a gas mixer, and inputting the other part of hydrogen into a methanation reaction zone; (4) inputting carbon dioxide into the gas mixer to enabled the carbon dioxide to be mixed with the hydrogen; (5) arranging at least four methanation reactors which are connected in series and / or in parallel in the methanation reaction zone, and collecting natural gas at an outlet of the last methanation reactor, wherein the surplus electricity comes from the abandoned light, wind, water and / or nuclear power. According to the method, the reactant is taken as a diluent of the raw material gas, so that the situation that the product gas is needed to be introduced into the raw material gas for diluting the reactant concentration by a recycle compressor in the traditional methanation technology can be avoided; therefore, the compressor is omitted, and the power consumption of mechanical equipment is reduced.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com