Cement admixture prepared from tungsten tailings and application of cement admixture

A technology of tungsten tailings and mixed materials, applied in cement production and other directions, can solve problems such as limited quantity, and achieve the effects of low equipment requirements, wide sources and simple processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

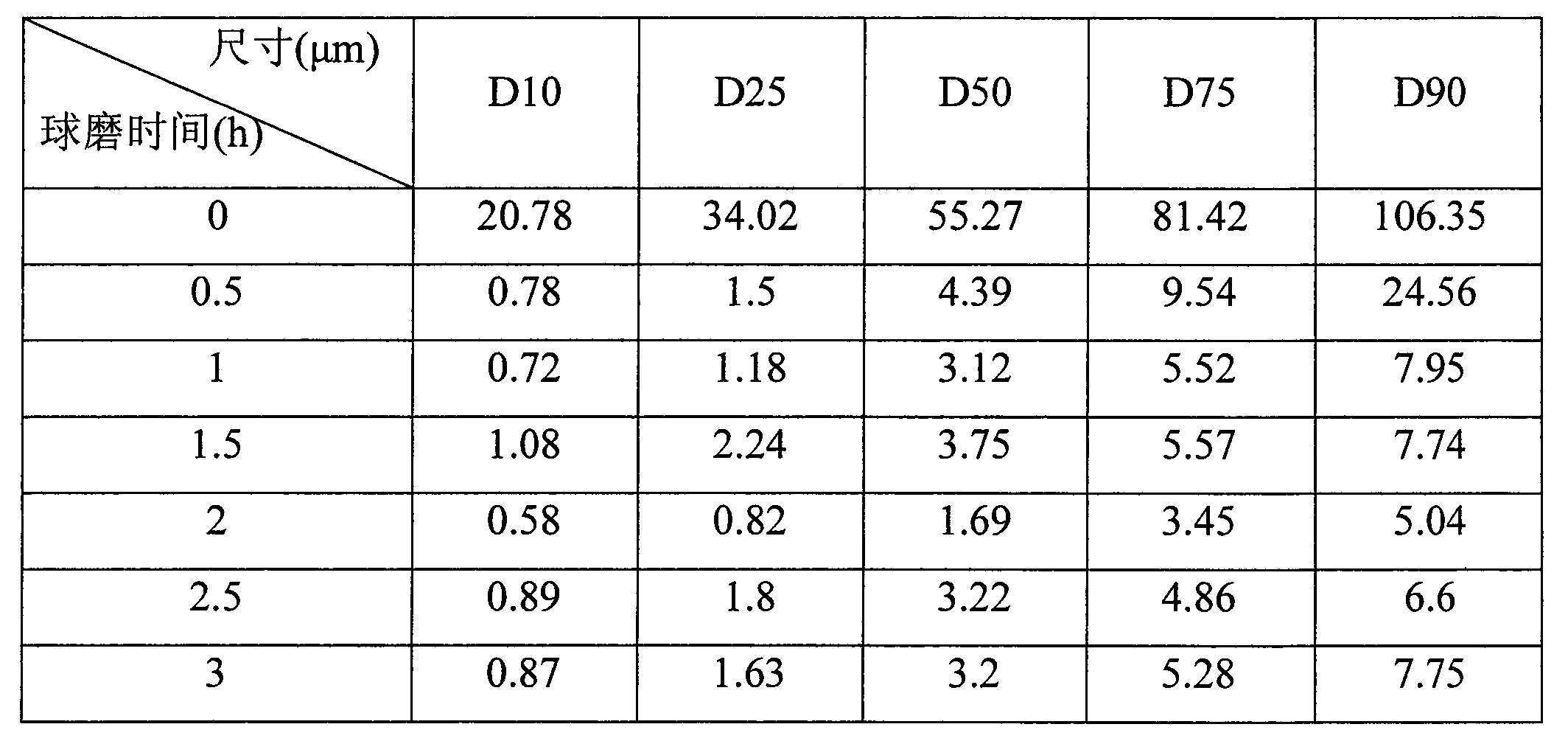

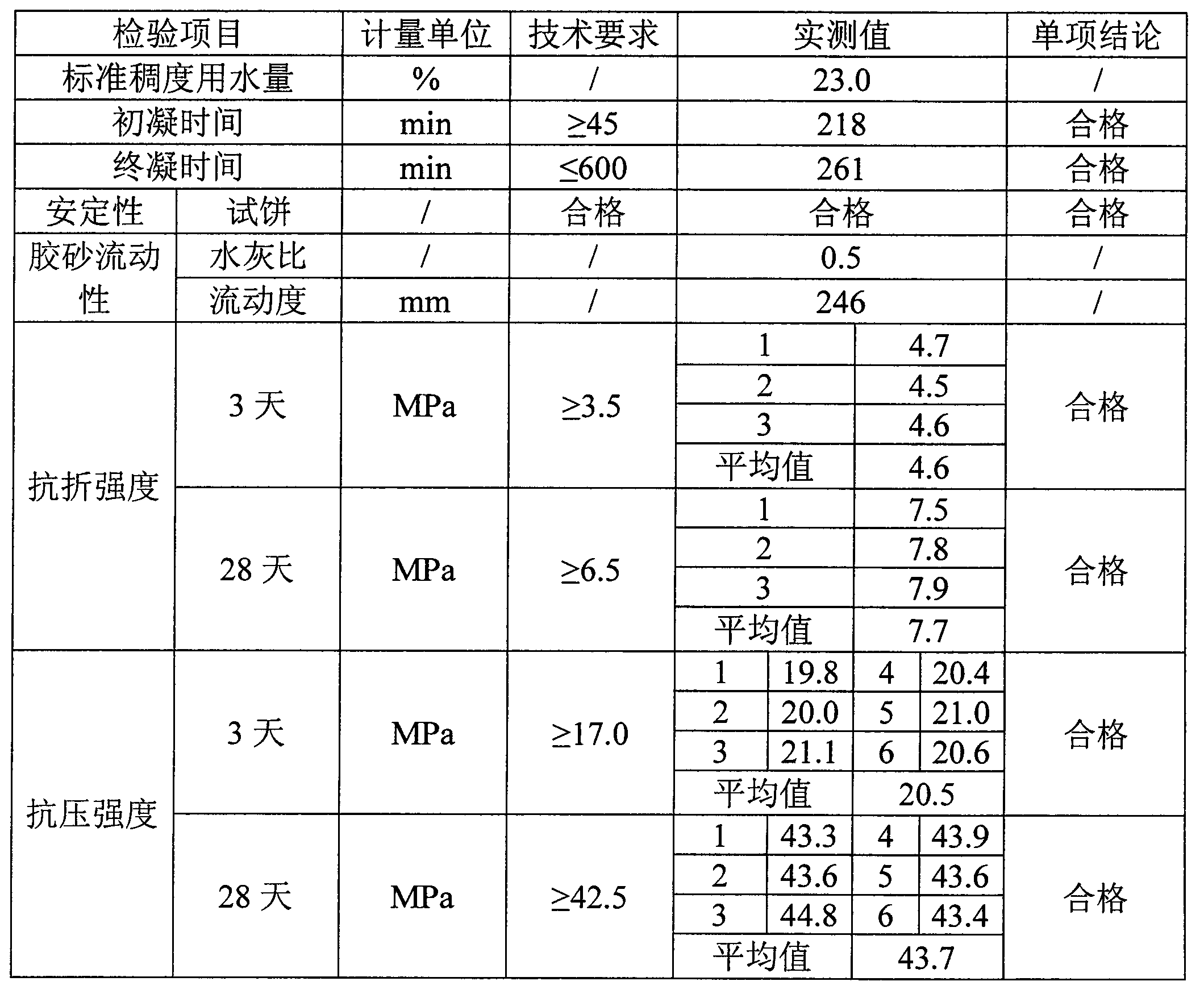

[0017] Preparation of cement mixture from tungsten tailings, the ultra-fine processing method of tungsten tailings, the operation steps include: drying the tungsten tailings to a moisture content below 5%, grinding the ore with a cylindrical ball mill, and using steel balls as the ball milling medium , the ball-to-material ratio is 6:1, each batch of grinding is 30kg, and the particle size distribution of tungsten tailings at different ball milling times is as follows.

[0018] Table 1 Particle size distribution of tungsten tailings at different milling times

[0019]

Embodiment 2

[0021] Preparation of cement mixture with tungsten tailings, the ultra-fine processing method of tungsten tailings, the operation steps include: drying the tungsten tailings to a moisture content below 5%, performing ultra-fine processing by ball mill classification, and using corundum balls as ball milling media , ultra-fine processing test parameters are as follows.

[0022] Table 2 Test parameters of tungsten tailings products with different particle sizes

[0023] product product one product two product three Grading rotor frequency (Hz) 11.5 24 34 Productivity of finished product(kg / h) 1500 600 350 Finished particle size (D90 / μm) 30.03 17.33 8.47

Embodiment 3

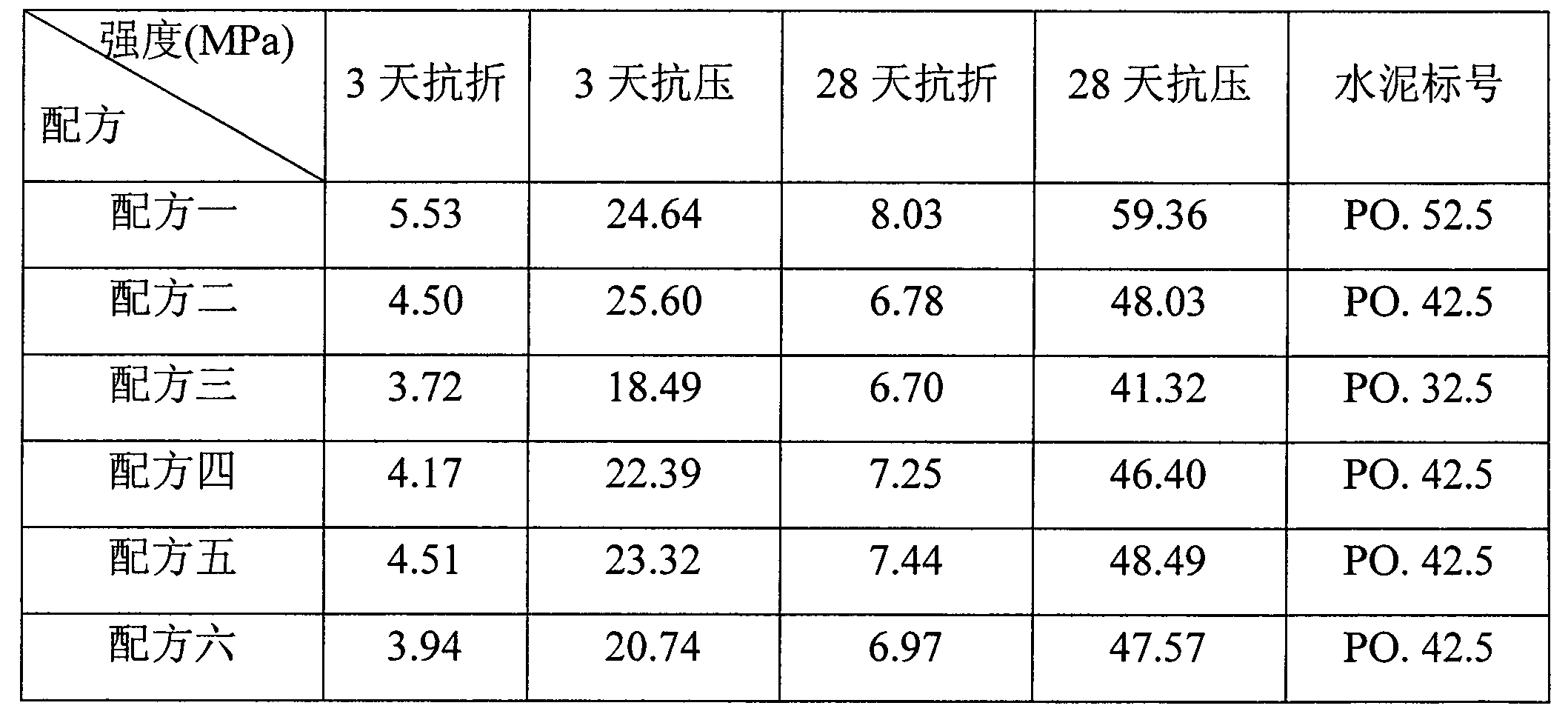

[0025] For the application of cement mixture prepared from tungsten tailings, different amounts of tungsten tailings cement mixture are added to prepare different grades of cement. The formula and strength are as follows.

[0026] Table 3 Cement formula prepared by tungsten tailings cement mixture

[0027] formula Clinker (%) plaster(%) Tungsten tailings (%) quicklime(%) Tungsten tailings -400 mesh content (%) recipe one 87.5 2.5 10 0 82.88 recipe two 77.5 2.5 20 0 82.88 Recipe three 67.5 2.5 30 0 82.88 Recipe four 77.5 2.5 20 0 66.57 Recipe five 77.5 2.5 20 0 92.32 Recipe six 77.5 2.5 18 2 82.88

[0028] Table 4 Strength of cement prepared with tungsten tailings cement mixture

[0029]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com