A kind of steel slag-cyanide tailings cementitious material and its preparation method and application

A technology for cyanide tailings and cementitious materials, which is applied in chemical instruments and methods, sustainable waste treatment, solid waste management, etc. Simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

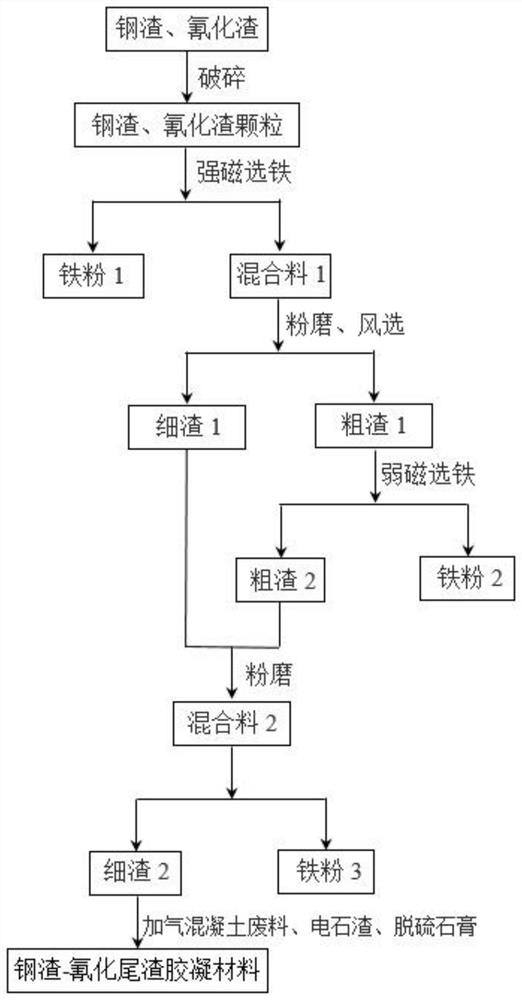

[0035] The preparation method of described iron selection waste slag comprises the following steps:

[0036] Step 1. After the original steel slag is carbonized in a concrete carbonization box for 24-72 hours, it is crushed by a jaw crusher, and then ground by a ball mill to a size smaller than 2 mm to form steel slag powder;

[0037] Step 2. Mix steel slag powder and cyanide tailings 1:1, and separate them into iron powder 1 and mixture 1 by dry strong magnetic roller; wherein, the magnetic field strength is 1.5-2T, and the magnetic separator speed is 10-20r / min;

[0038] Step 3. Grind the mixture 1 to 100-200m 2 / kg, divided into: 100~160m by winnowing 2 / kg of coarse slag 1 and 160~200m 2 / kg fine slag;

[0039] Step 4, continue to separate the coarse slag 1 by dry-type weak magnetic rollers into: coarse slag 2 and iron powder 2; wherein, the magnetic field strength is 50-80mT, and the magnetic separator speed is 10-20r / min;

[0040] Step 5. Mix fine slag and coarse s...

Embodiment 1

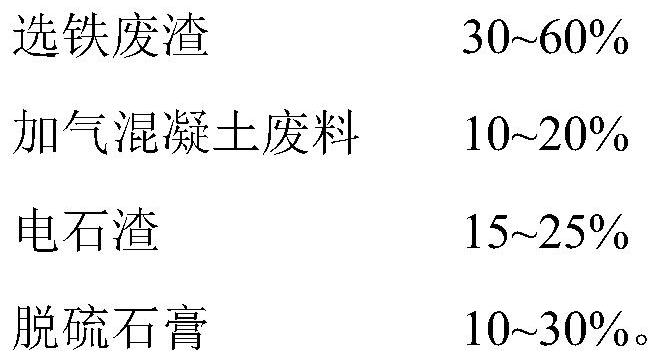

[0047] A steel slag-cyanide tailings cementitious material is composed of the following substances in mass percentage:

[0048]

[0049] The preparation method of the iron selection waste slag comprises the following steps: after the original steel slag is carbonized in a concrete carbonization box for 48 hours, it is crushed by a jaw crusher, and then ground by a ball mill to a size less than 2 mm to form steel slag powder; 1:1 mixing, the mixture is separated into iron powder 1 and mixture 1 by a magnetic field strength of 1.5T, and a magnetic separator with a speed of 10-20r / min. 200m 2 / kg, divided into: 100~160m by winnowing 2 / kg of coarse slag 1 and 160~200m 2 / kg of fine slag; the coarse slag 1 is separated into: coarse slag 2 and iron powder 2 by a dry weak magnetic roller with a magnetic field strength of 50mT and a magnetic separator rotating speed of 15r / min; after mixing the fine slag and coarse slag 2 Grind to 400-800m by vibrating ceramic mill 2 / kg to fo...

Embodiment 2

[0060] A steel slag-cyanide tailings cementitious material is composed of the following substances in mass percentage:

[0061]

[0062]

[0063] The preparation method of described iron selection waste slag comprises the following steps:

[0064] After the original steel slag is carbonized in the concrete carbonization box for 24 hours, it is crushed by a jaw crusher, and then ground by a ball mill to a size less than 2 mm to form steel slag powder; the steel slag powder and cyanide tailings are mixed at a ratio of 1:1, and the mixture is passed through a magnetic field with a strength of 1.8T, the speed of the magnetic separator is 10-20r / min, and the dry-type strong magnetic roller is separated into: iron powder 1 and mixture 1; the mixture 1 is ground to 100-200m 2 / kg, divided into: 100~160m by winnowing 2 / kg of coarse slag 1 and 160~200m 2 / kg of fine slag; the coarse slag 1 is separated into: coarse slag 2 and iron powder 2 by a dry weak magnetic roller with a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com