A kind of composite tailings cementitious material and its preparation method and application

A technology of cementitious materials and tailings, which is applied in the field of composite tailings cementitious materials and its preparation, can solve the problems of difficult mining and selection, high production costs, and few rich ores, and achieve low prices, low equipment requirements, and preparation methods simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

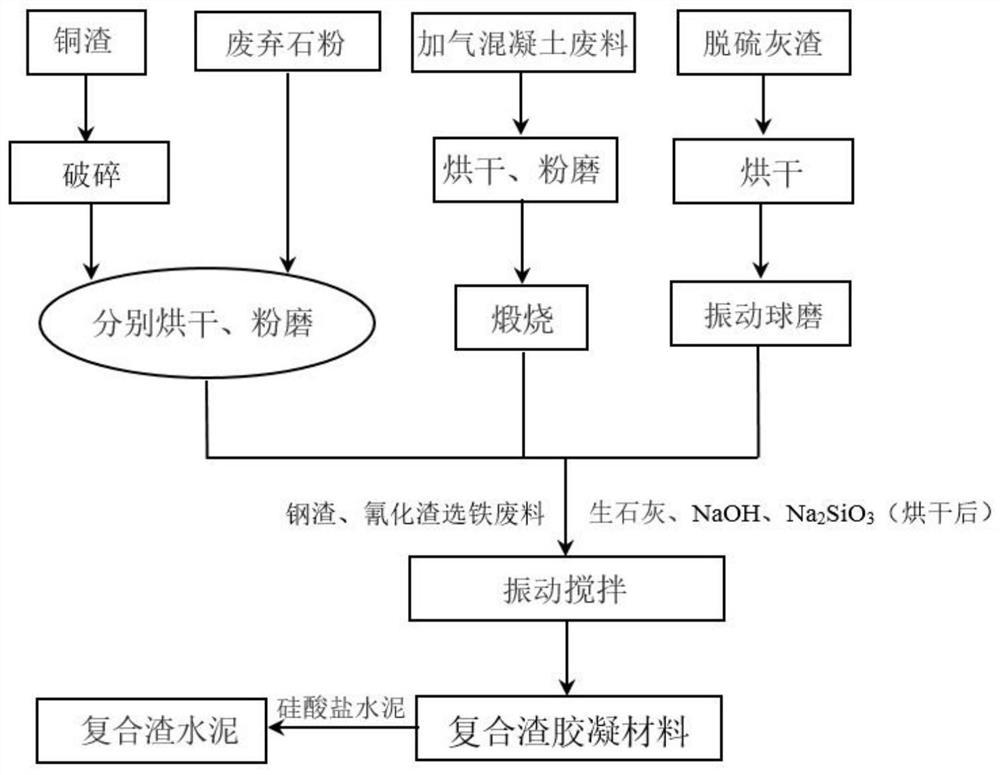

[0035] The present invention also includes a method of preparing the composite tail desear gelling material, the preparation method comprising the steps of:

[0036] Step 1, use the jaw crusher to break the copper slag to <2 mm, dry, then powder to <0.08 mm by the ball mill; the agglomerate refiner is dried, and the ball mill is powdered to <0.08 mm, then placed in 300 ~ 500 ° C high temperature calcination 1 to 3 hours, naturally cooled; after desulfurization ash slag, pollen to <0.08 mm was dried with a vibrating ball mill; after discarding stone powder was dried with a ball mill powder to <0.08 mm; the drying temperature is 80 ~ 110 ° C, drying to a water content of less than 0.1%; the powder mill is SMφ500 mm × 500 mm type cement grinding.

[0037] Step 2, select the material and steel slag and cyanide residue obtained in step 1 (400 to 800m specific surface area) 2 / kg), raw lime, naoh, na 2 SiO 3 Based on proportion, then placed in a vibrating mixer, stir well, and finally ob...

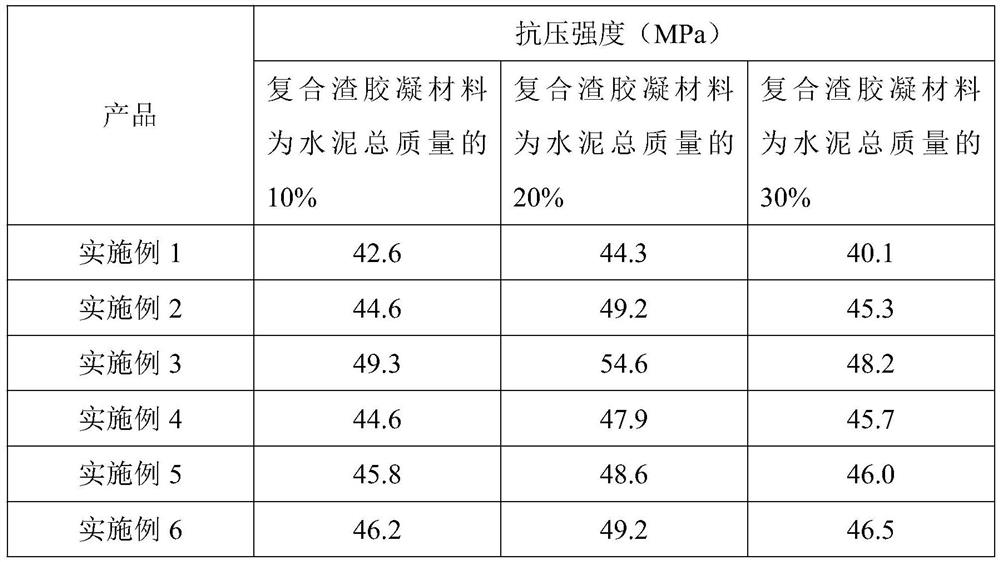

Embodiment 1

[0040] A composite degeneration gelling material consists of various substances of the following mass:

[0041] Steel slag and cyanide residue selection iron waste 80, aerated concrete waste 10, copper residue 10, raw lime 10, desulfurization ash 6, NaOH1, NA 2 SiO 3 0.75, abandoned stone powder 0.5.

[0042] The preparation method of the above composite tail slag gelling material includes the following steps:

[0043] The copper slag was broken to <2 mm, dried, and then powdered with a ball mill powder to dry with a ball mill. The agglomerate gas was dried, and the ball mill was powdered to <0.08 mm, then placed at 300 ° C high temperature calcination. 1H, and naturally cooled; after desulfurization ash slag, grinds to <0.08 mm by the vibrating ball mill; after the abandonment stone is dried, the ball mill is powdered with the ball mill; the drying temperature is 80 ° C, dried to aqueous water The rate is less than 0.1%; the powder mill is SMφ500mm × 500 mm cement grinding.

[00...

Embodiment 2

[0047] A composite degeneration gelling material consists of various substances of the following mass:

[0048] Steel slag and cyanide residue selection iron waste 70, aerated concrete waste 20, copper residue 10, raw lime 12, desulfurization ash, NaOH1.5, NA 2 SiO 3 1. Waste stone powder 0.5.

[0049] The preparation method of the above composite tail slag gelling material includes the following steps:

[0050] The copper slag was broken to <2 mm, dried, and then powdered with a ball mill to dry with a ball mill. The aggressive refiner was dried, and the ball mill was powdered to <0.08 mm, then placed in a high temperature calcination of 500 ° C. 2H, and naturally cooled; after desulfurization ash slag, grinds to <0.08 mm; after the dry stone is dried, the grinding machine is grinded to <0.08 mm; the drying temperature is 80 ° C, dried to aqueous water The rate is less than 0.1%; the powder mill is SMφ500mm × 500 mm cement grinding.

[0051] Select the above materials and steel s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com