Modified steel slag based on steel dust mud and red mud as well as preparation method and application of modified steel slag

A technology of steel slag and dust sludge, applied in the field of comprehensive utilization of resources, can solve the problems of low comprehensive utilization rate of red mud, less than 40% comprehensive utilization rate, and less than output, and achieve large-scale utilization, improve gelling activity, The effect of high economic value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

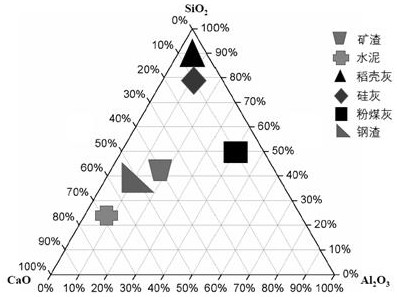

[0043] The invention uses industrial solid waste to modify steel slag, the modified steel slag includes steel slag and a composite modifier, the composite modifier includes coal gasification residue, red mud and steel dust, and the steel slag and composite modified The mass ratio of the agent is 65:35; the mass ratio of coal gasification residue, red mud and steel dust in the composite modifier is 1:2.5:3.5.

[0044] The mass percentage of each component in the steel slag mentioned above is SiO 2 10~20%, Al 2 o 3 1~7%, Fe 2 o 3 2~33%, MgO 3~12%, CaO 30~50%, FeO 3~15%, Na 2 O 0.01~3%, K 2 O 0.01~3%, SO 3 0.26%, P 2 o 5 1~6%, the mass percentage of each component in the gas residue is SiO 2 30~60%, Al 2 o 3 14~21%, Fe 2 o 3 12~24%, MgO 2~6%, CaO 8~20%, K 2 O 1~3%, Na 2 O 1~3%, SO 3 0.1~2%, P 2 o 5 0.01~1%, TiO 2 0.1~2%, loss on ignition 10~40%, the mass percentage of each component in the red mud is SiO 2 5~30%,Al 2 o 3 15~30%, Fe 2 o 3 10~40%, MgO 0...

Embodiment 2

[0062] The invention uses industrial solid waste to modify steel slag, the modified steel slag includes steel slag and a composite modifier, and the composite modifier includes coal gasification residue, red mud and steel dust; the steel slag and composite modified The mass ratio of the agent is 70:30; the mass ratio of coal gasification residue, red mud and steel dust in the composite modifier is 2:2:3.

[0063] The mass percent of each component in the steel slag is SiO 2 10~20%, Al 2 o 3 1~7%, Fe 2 o 3 2~33%, MgO 3~12%, CaO 30~50%, FeO 3~15%, Na 2 O 0.01~3%, K 2 O 0.01~3%, SO 3 0.26%, P 2 o 5 1~6%, the mass percentage of each component in the gas residue is SiO 2 30~60%, Al 2 o 3 14~21%, Fe 2 o 3 12~24%, MgO 2~6%, CaO 8~20%, K 2 O 1~3%, Na 2 O 1~3%, SO 3 0.1~2%, P 2 o 5 0.01~1%, TiO 2 0.1~2%, loss on ignition 10~40%, the mass percentage of each component in the red mud is SiO 2 5~30%,Al 2 o 3 15~30%, Fe 2 o 3 10~40%, MgO 0.1~2%, CaO 10~20%, K 2...

Embodiment 3

[0081] The invention uses industrial solid waste to modify steel slag, the modified steel slag includes steel slag and a composite modifier, and the composite modifier includes coal gasification residue, red mud and steel dust; the steel slag and composite modified The mass ratio of the modifier is 75:25; the mass ratio of coal gasification residue, red mud and steel dust in the composite modifier is 1.5:3:4.

[0082] The mass percent of each component in the steel slag is SiO 2 10~20%, Al 2 o 3 1~7%, Fe 2 o 3 2~33%, MgO 3~12%, CaO 30~50%, FeO 3~15%, Na 2 O 0.01~3%, K 2 O 0.01~3%, SO 3 0.26%, P 2 o 5 1~6%, the mass percentage of each component in the gas residue is SiO 2 30~60%, Al 2 o 3 14~21%, Fe 2 o 3 12~24%, MgO 2~6%, CaO 8~20%, K 2 O 1~3%, Na 2 O 1~3%, SO 3 0.1~2%, P 2 o 5 0.01~1%, TiO 2 0.1~2%, loss on ignition 10~40%, the mass percentage of each component in the red mud is SiO 2 5~30%,Al 2 o 3 15~30%, Fe 2 o 3 10~40%, MgO 0.1~2%, CaO 10~20%,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com