Vanadium tailings and cement blended material and preparation method and application thereof

A technology of cement admixture and vanadium tailings, applied in cement production, etc., can solve the problem that the activity of tailings is difficult to be fully exerted, and achieve the effect of low price, simple preparation method, and increased added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

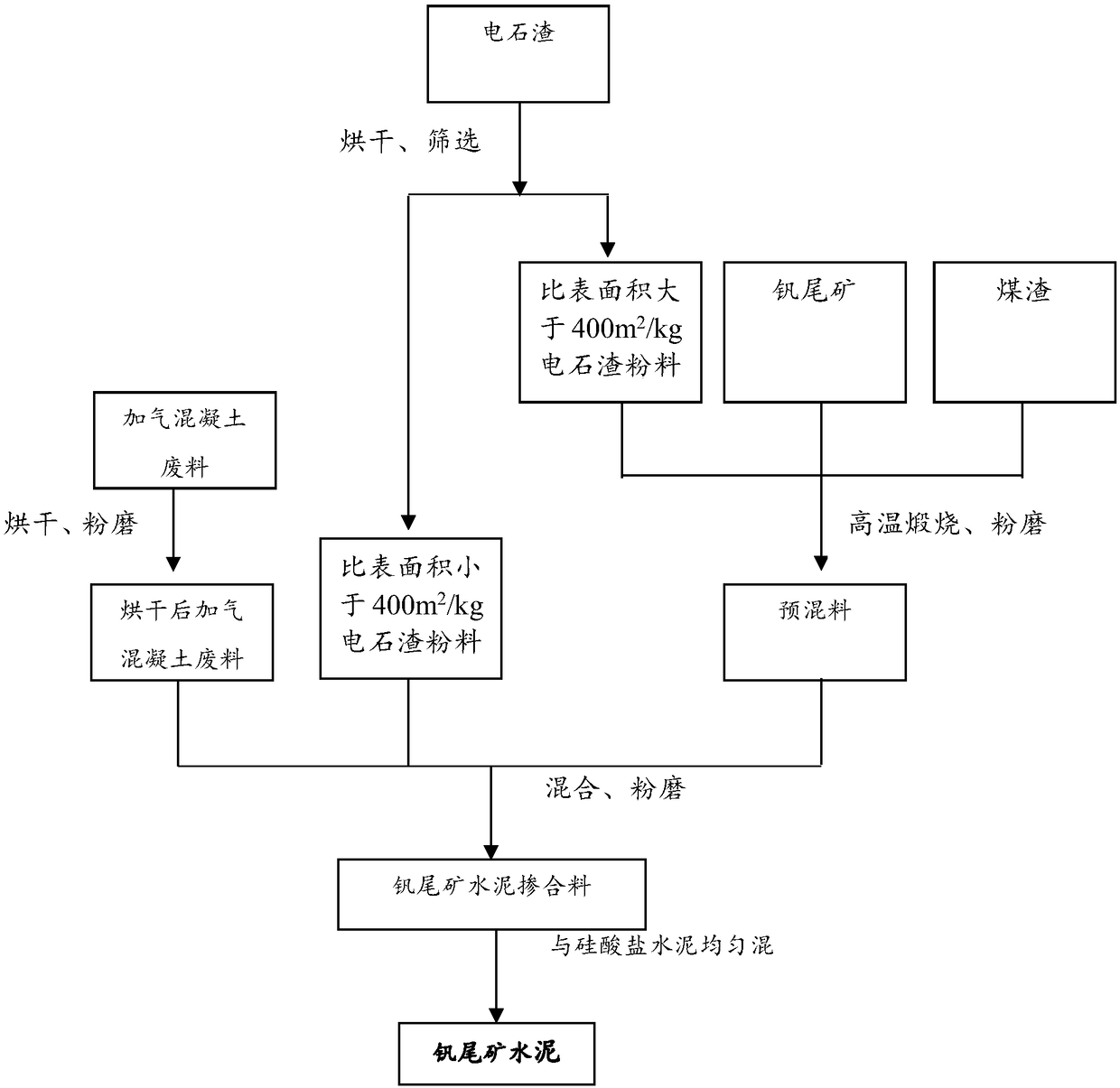

[0031] The invention discloses a preparation method of vanadium tailings cement admixture, comprising the following steps:

[0032] Step 1. Dry the calcium carbide slag, and use a powder classifier to screen the powder with a specific surface area greater than 400m 2 / kg and less than 400m 2 / kg of calcium carbide slag powder;

[0033] Among them, the chemical composition of calcium carbide slag is calculated as: SiO 2 2%~4%, Al 2 o 3 1.5%~2.5%, CaO 70%~72%, Fe 2 o 3 +FeO 0.2%~0.6%, SO 2 0.3%~0.6%, K 2 O 0.10%~0.18%, Na 2 O0.25%~0.30%, loss on ignition 22.00-22.30%.

[0034] Step 2, will be greater than 400m 2 / kg of calcium carbide slag powder, vanadium tailings and coal slag are mixed and calcined at high temperature. The mass ratio of coal slag to the total amount of vanadium tailings after high temperature calcination is 5:95~15:85; the high temperature calcination temperature is 600~1000℃ , the high temperature calcination time is 0.5~3hh;

[0035] Wherein, th...

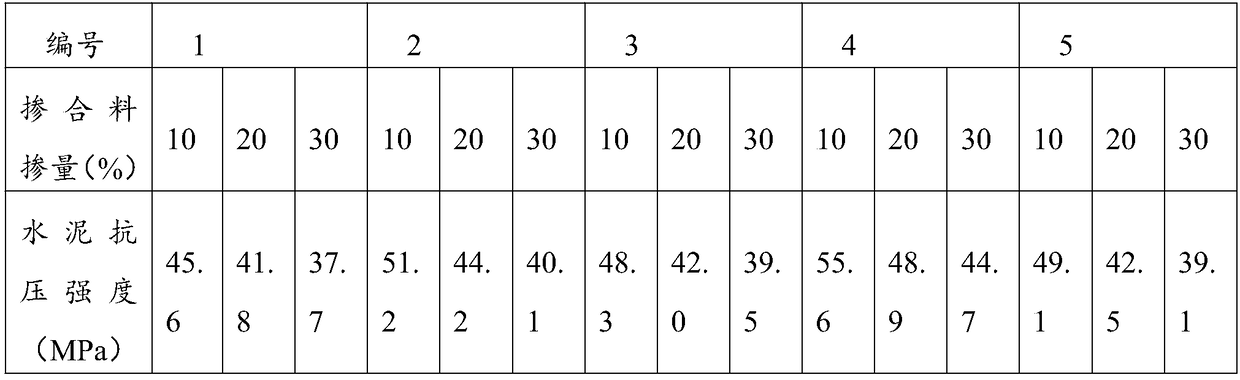

Embodiment 1

[0045] Dry the calcium carbide slag, and select the powder with a specific surface area greater than 400m3 with a powder separator 2 / kg and less than 400m 2 / kg of calcium carbide slag powder; will be greater than 400m 2 / kg calcium carbide slag powder mixed with vanadium tailings and coal slag and then calcined at high temperature, the mass ratio of coal slag to the total amount of vanadium tailings after high temperature calcination is 10:90, the high temperature calcination temperature is 750°C, and the high temperature calcination time is 1h ; Its SiO of the selected vanadium tailings of present embodiment 1 2 The content is 64.3%. The calcined powder is ground for 40 minutes with an SM 500mm×500mm cement mill to obtain a ground premix; the aerated concrete waste is dried at a temperature of 40-70°C, and then ground to 450m 2 / kg; will be less than 400m 2 / kg calcium carbide slag powder and dried aerated concrete waste were added to the premix, and SM 500mm×500mm cem...

Embodiment 2

[0051] Dry the calcium carbide slag, and select the powder with a specific surface area greater than 400m3 with a powder separator 2 / kg and less than 400m 2 / kg of calcium carbide slag powder; will be greater than 400m 2 / kg calcium carbide slag powder mixed with vanadium tailings and coal slag and then calcined at high temperature, the mass ratio of coal slag to the total amount of vanadium tailings after high temperature calcining is 5:95; the high temperature calcining temperature is 500°C, and the high temperature calcining time is 3h ; Its SiO of the selected vanadium tailings of present embodiment 2 2 The content is 64.3%. Grind the calcined powder with SM 500mm×500mm cement mill for 50 minutes to obtain the ground premix; dry the aerated concrete waste at 40°C, and then grind it to 300m 2 / kg; will be less than 400m 2 / kg calcium carbide slag powder and dried aerated concrete waste were added to the premix, and SM 500mm×500mm cement mill was used for grinding for 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com