Method and device for producing firedamp

A technology of production device and production method, which is applied in fertilization device, biological organic part treatment, organic fertilizer and other directions, can solve problems such as inability to produce gas, environmental pressure, and fermentation temperature affected by the outside world, achieve good economic benefits, and solve environmental pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] specific implementation plan

[0015] The present invention will be further described below according to the accompanying drawings.

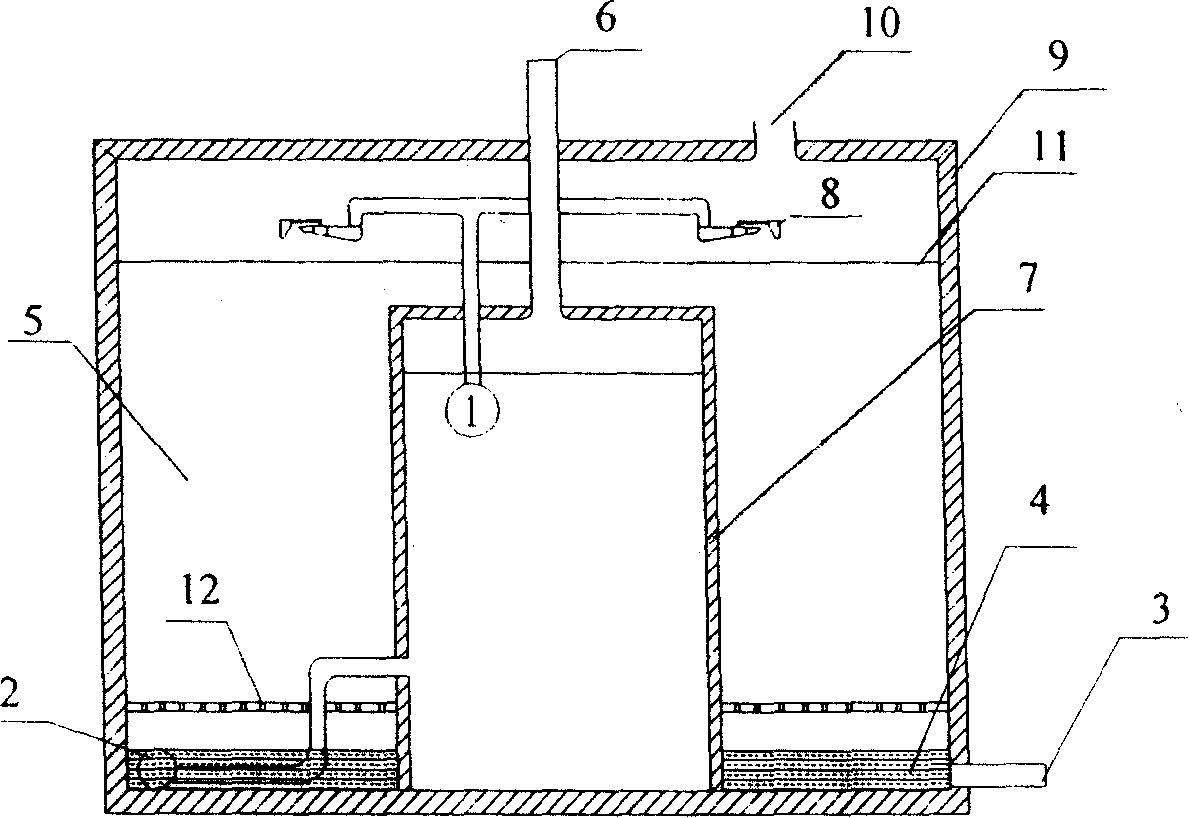

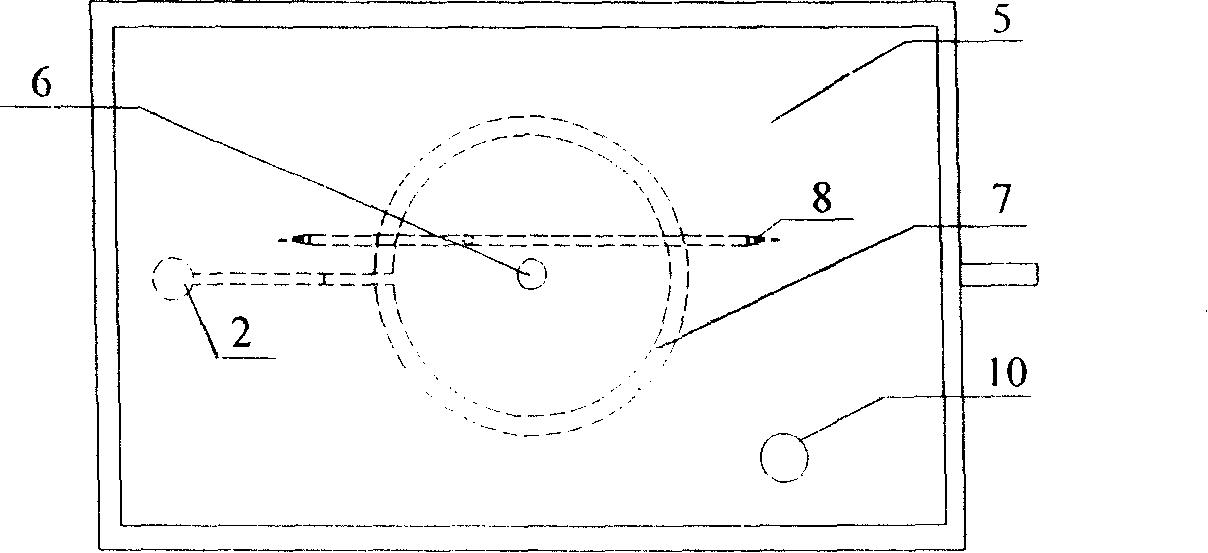

[0016] Such as figure 1 As shown, 1 is the submersible pump I, which has a filter device, 2 is the submersible pump II, 3 is the water outlet, 4 is the hot water and anaerobic nutrients flowing down from the aerobic zone, 5 is the aerobic zone, and 6 is the water outlet. Biogas outlet, 7 is a biogas digester, i.e. anaerobic fermentation tank, 8 is a rotary nozzle, 9 is a shell, 10 is an air outlet, 11 is the top of the compost, and 12 is the bottom plate of the compost filter. The submersible pump 1 is located at the upper part of the biogas digester, and is connected to the rotary nozzle 8 through a PVC pipe. In this embodiment, two nozzles are arranged. Drench evenly over the aerobic zone. The submersible pump II is located at the bottom of the aerobic zone, communicated with the bottom of the anaerobic fermentation tank through a PV...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com