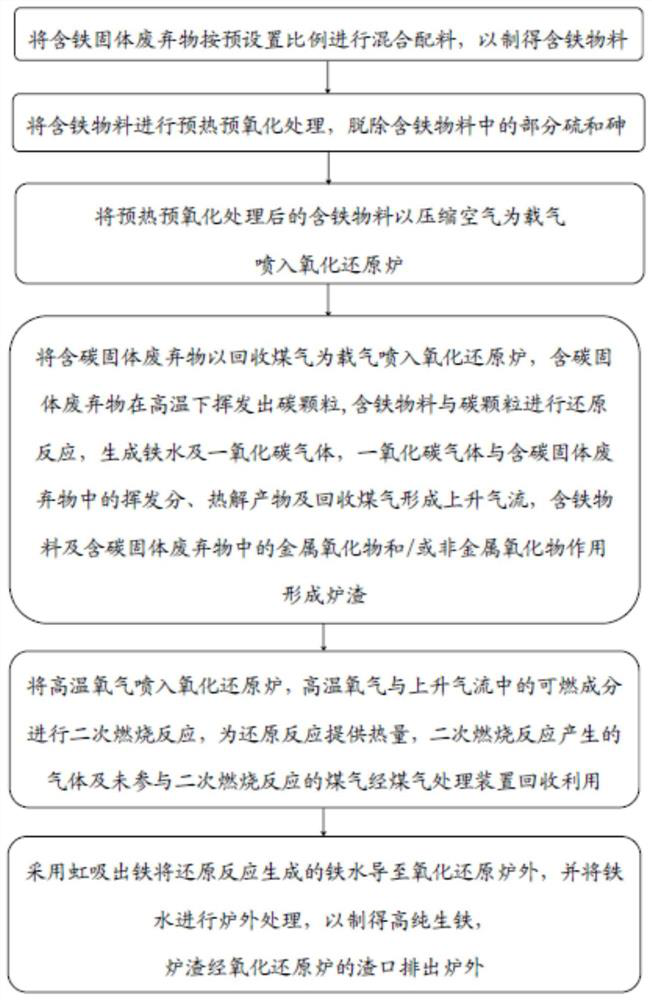

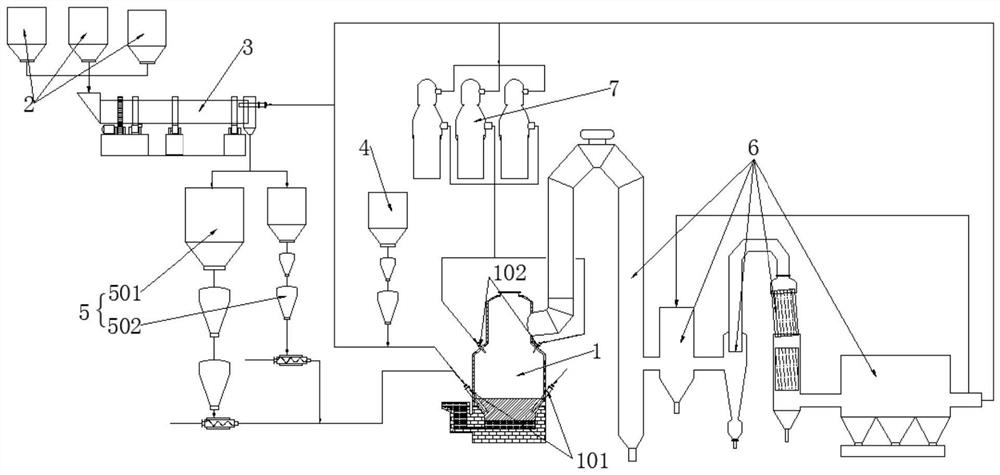

Method and system for treating solid waste through smelting reduction process

A solid waste and process technology, applied in the field of solid waste treatment by smelting reduction process, can solve the problems of decentralized utilization, secondary pollution, high fuel consumption, etc., reduce flue gas emissions, suppress NOx generation, improve transmission The effect of thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0119] In this embodiment, the iron-containing solid waste in step (1) is selected from iron scale, blast furnace cyclone dust removal, blast furnace dry dust removal, converter slag, vanadium-titanium tailings; and the preset ratio is iron-containing solid waste The mass ratio of iron oxide, calcium oxide, silicon dioxide, magnesium oxide and aluminum oxide is 100:14:8.5:2.6:2.3.

[0120] In step (2), oxygen-enriched hot air is used for preheating and pre-oxidation treatment. The oxygen content in the oxygen-enriched hot air is 28%.

[0121] The injection volume of compressed air in step (3) is 8000~10000Nm 3 / h, the injection rate of iron-containing materials is 140t / h.

[0122] The carbon-containing solid waste in step (4) includes semi-coke and sludge, the particle size of the carbon-containing solid waste is less than 3mm, and the moisture content is ≤2.5%.

[0123] The high-temperature oxygen in step (5) adopts industrial oxygen with a purity exceeding 95%, and the tem...

Embodiment approach 2

[0128] In this embodiment, the iron-containing solid waste in step (1) is selected from iron oxide scale, steelmaking secondary dedusting ash, converter slag, electric furnace slag; and the preset ratio is iron oxide, calcium oxide in iron-containing solid waste The mass ratio of silicon dioxide, magnesium oxide and aluminum oxide is 100:8.4:5.0:1.7:0.8.

[0129] In step (2), oxygen-enriched hot air is used for preheating and pre-oxidation treatment. The oxygen content in the oxygen-enriched hot air is 23%.

[0130] The injection volume of compressed air in step (3) is 15000~21000Nm 3 / h, the injection rate of iron-containing materials is 280t / h.

[0131] The carbon-containing solid waste in step (4) includes semi-coke, sludge, blast furnace ash, and coal gangue. The carbon-containing solid waste has a particle size of less than 2mm and a moisture content of ≤2.0%.

[0132] The high-temperature oxygen in step (5) adopts industrial oxygen with a purity of 98.5%, and the tempe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com