A method for preparing cement admixture by utilizing engineering spoil, cement admixture and cement composition

A cement admixture and cement composition technology, which is applied in the field of solid waste resource utilization, can solve the problems of unsatisfactory load-bearing member strength, complex sediment separation process, and insufficient utilization of engineering spoils, and achieve operability Strong sex and reproducibility, good economic and social effects, and the effect of realizing large-scale utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

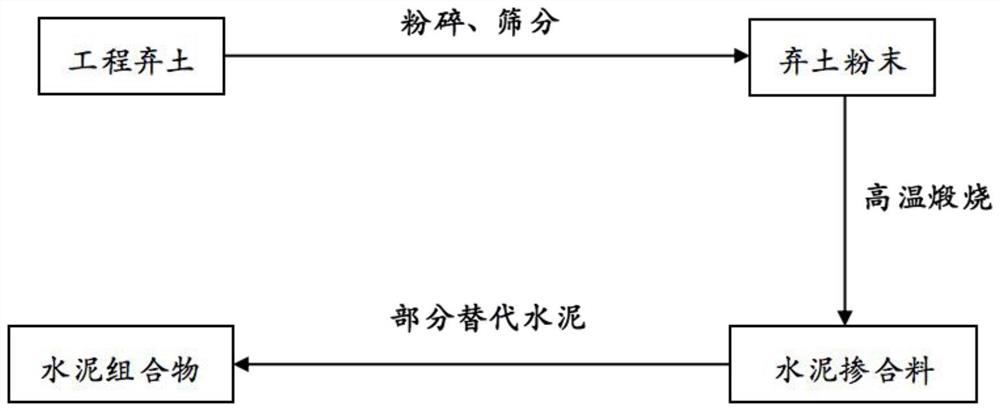

Method used

Image

Examples

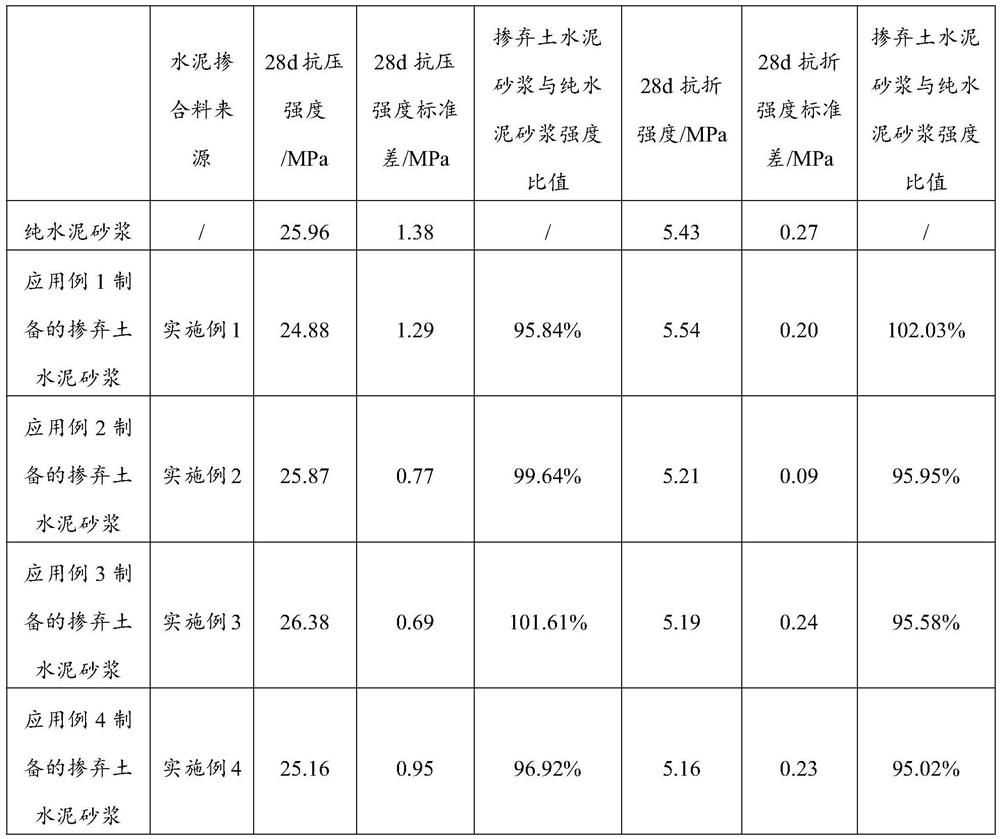

Embodiment 1

[0036] Grinding the granite residual soil (containing 50wt.% quartz and 30-35wt.% kaolin) and sieving through a 0.3mm sieve to obtain spoil powder with a particle size below 0.3mm;

[0037]The spoil powder is placed in a muffle furnace, heated from room temperature (25°C) to 650°C at a heating rate of 10°C / min for calcination, and kept at this temperature for 2 hours, and the muffle furnace is closed after the heat preservation is completed. After the temperature in the muffle furnace cavity is naturally cooled to room temperature (25° C.), the cement admixture is obtained.

Embodiment 2

[0039] Grinding the granite residual soil (containing 50wt.% quartz and 30-35wt.% kaolin) and sieving through a 0.3mm sieve to obtain spoil powder with a particle size below 0.3mm;

[0040] The spoil powder is placed in a muffle furnace, heated from room temperature (25°C) to 700°C at a heating rate of 10°C / min for calcination, and kept at this temperature for 2 hours, and the muffle furnace is closed after the heat preservation is completed. After the temperature in the muffle furnace cavity is naturally cooled to room temperature (25° C.), the cement admixture is obtained.

Embodiment 3

[0042] Grinding the granite residual soil (containing 50wt.% quartz and 30-35wt.% kaolin) and sieving through a 0.3mm sieve to obtain spoil powder with a particle size below 0.3mm;

[0043] Put the spoil powder in a muffle furnace, heat it from room temperature (25° C.) to 650° C. at a heating rate of 10° C. / min for calcination, and keep it at this temperature for 3 hours. After the heat preservation is completed, close the muffle furnace. After the temperature in the muffle furnace cavity is naturally cooled to room temperature (25° C.), the cement admixture is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com