Low-temperature hydro-thermal synthesis method for high-viscosity and high-transparency aluminium-magnesium silicate

A magnesium aluminum silicate, high light transmittance technology, applied in the direction of silicon compounds, chemical instruments and methods, inorganic chemistry, etc., can solve the poor performance of light transmittance, thixotropy and viscosity, and the influence of magnesium aluminum silicate on performance Poor, poor application quality and other problems, to achieve the effect of high thixotropy, stable and uniform batches, and high product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

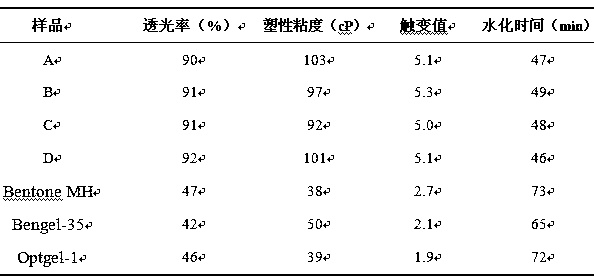

Examples

Embodiment 1

[0025] A magnesium aluminum silicate with high viscosity and high light transmittance is prepared from the following raw material components in parts by mass according to the following steps:

[0026] (1) First mix 0.5 parts of sodium fluoride and 5 parts of Ce(NO 3 ) 3 Add to 500 parts of pure water and stir well, then add 100 parts of aluminum chloride;

[0027] (2) Next, add 1 part of zinc chloride and 10 parts of magnesium chloride to 500 parts of pure water and stir well, then add to the solution in step (1); then continue to add 50 parts of sodium hydroxide;

[0028] (3) Heat the solution in step (2) to 60°C, then slowly add 100 parts of water glass (modulus n=3.1) dropwise, and control the dropping time to 30 minutes; after the dropping is completed, continue to keep stirring for 2 hours;

[0029] (4) Finally, the solution in step (3) was filtered and fully washed, and then fully dried at 65°C to obtain magnesium aluminum silicate A.

Embodiment 2

[0031] A magnesium aluminum silicate with high viscosity and high light transmittance is prepared from the following raw material components in parts by mass according to the following steps:

[0032] (1) First, 0.5 parts of sodium fluoride, 1 part of lithium fluoride, 5 parts of Ce 2 (SO4 ) 3 , 5 copies of Dy(NO 3 ) 3 Add to 500 parts of pure water and stir well, then add 100 parts of aluminum sulfate and 100 parts of aluminum nitrate;

[0033] (2) Next, add 2 parts of zinc sulfate, 3 parts of zinc nitrate, 10 parts of magnesium sulfate, and 10 parts of magnesium nitrate into 500 parts of pure water and stir well, then add to the solution in step (1); continue to add 50 parts Part sodium hydroxide and 50 parts sodium carbonate;

[0034] (3) Heat the solution in step (2) to 90°C, then slowly add 200 parts of water glass (modulus n=3.4) dropwise, and control the dropping time to 60 minutes; after the dropping is completed, continue to keep stirring for 4 hours;

[0035] (4...

Embodiment 3

[0037] A magnesium aluminum silicate with high viscosity and high light transmittance is prepared from the following raw material components in parts by mass according to the following steps:

[0038] (1) First, 0.3 parts of sodium fluoride, 0.3 parts of lithium fluoride, 0.3 parts of sodium fluorosilicate, 3 parts of CeCl 3 , 3 copies of Dy 2 (SO 4 ) 3 , 3 parts of Sr(NO 3 ) 2 Add to 500 parts of pure water and stir well, then add 50 parts of aluminum chloride, 50 parts of aluminum sulfate, and 50 parts of aluminum nitrate;

[0039] (2) Next, add 1 part of zinc chloride, 1 part of zinc sulfate, 1 part of zinc nitrate, 5 parts of magnesium chloride, 5 parts of magnesium sulfate, and 5 parts of magnesium nitrate into 500 parts of pure water and stir well, then add to Step (1) in the solution; Continue to add 40 parts of sodium hydroxide and 40 parts of sodium carbonate again;

[0040] (3) Heat the solution in step (2) to 70°C, then slowly add 150 parts of water glass (mod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com