High-fiber and low-sugar potato nutritional compound powder and preparation method thereof

A high-fiber, potato-based starch technology, applied in the field of food processing, can solve problems such as the loss of nutrients in whole powder, microbial spoilage, and troublesome processing of potato residues, and achieve the goals of improving quality, high dietary fiber content, and reducing drying energy consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

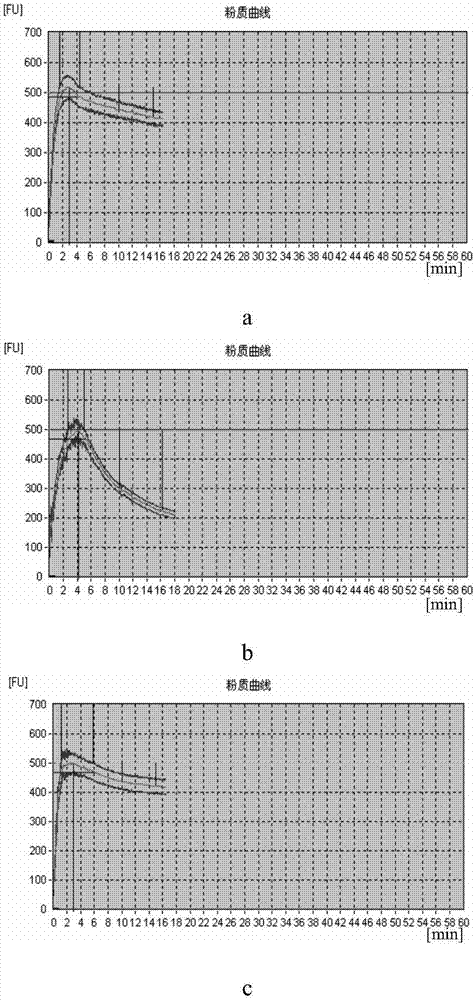

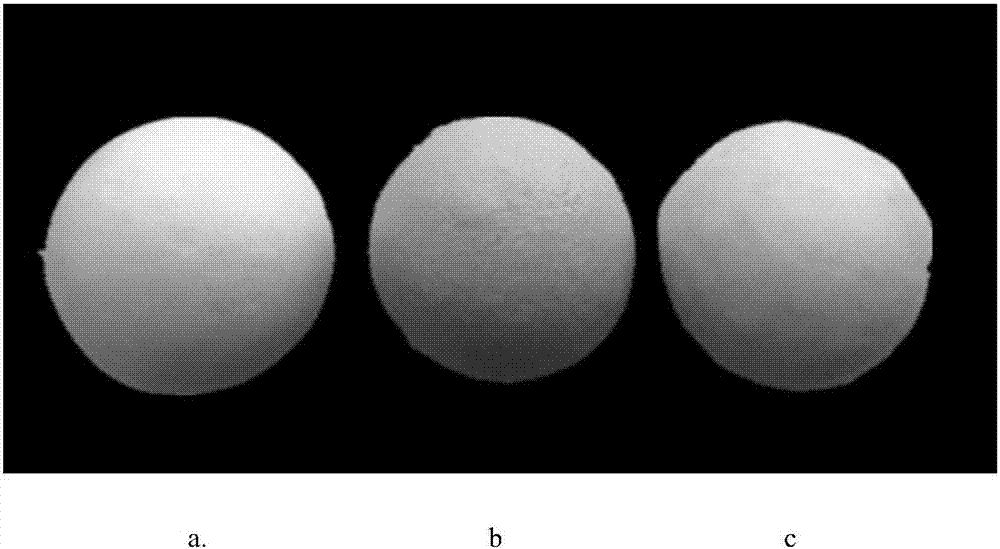

[0046] Example 1 Preparation of Sweet Potato Nutrition Compound Powder (backfilling process) and its application in making steamed bread

[0047] 1. Fresh sweet potato dregs are mixed evenly with water at a material-to-liquid ratio of 1:35. Use a shear emulsifier to process 25min under the condition of 7000r / min. Then use a suction filtration device to suction filter under a double-layer 400-mesh sieve until the suction filtration is complete, and collect the processed fresh potato residue.

[0048] 2. Weigh 1 kg of the above-mentioned fresh potato dregs (moisture content is about 90%), and then weigh the following raw materials respectively: cornstarch 75g (starch content is about 90%), ovalbumin 7.5g (crude protein content is about 82%) . Stir the above materials with a dough mixer for 10 minutes until the materials are completely mixed.

[0049] 3. The above-mentioned materials after mixing are vacuum-microwave-dried under the conditions of temperature ~60°C, microwave p...

Embodiment 2

[0093] Preparation of Example 2 High Calcium Potato Nutrition Compound Powder (non-backfilling process) and its application in cookie making

[0094] 1. Mix fresh potato residue with water at a material-to-liquid ratio of 1:20 and mix evenly. Use a homogenizer to process for 10 minutes under the condition of 12000r / min. Then use a suction filtration device to suction filter under a double-layer 400-mesh sieve until the suction filtration is complete, and collect the processed fresh potato residue.

[0095] 2. Under the conditions of temperature 40°C, microwave power 800W, and vacuum degree -0.5Mpa, vacuum microwave drying is carried out for 5 hours.

[0096] 3. Pulverize the above-mentioned potato dregs with an ultrafine pulverizer to obtain potato dregs powder.

[0097] 4. Take by weighing 100g of the above-mentioned dried potato residue powder (moisture content is about 8%), and then weigh the following raw materials respectively: wheat starch 55g (starch content is about ...

Embodiment 3

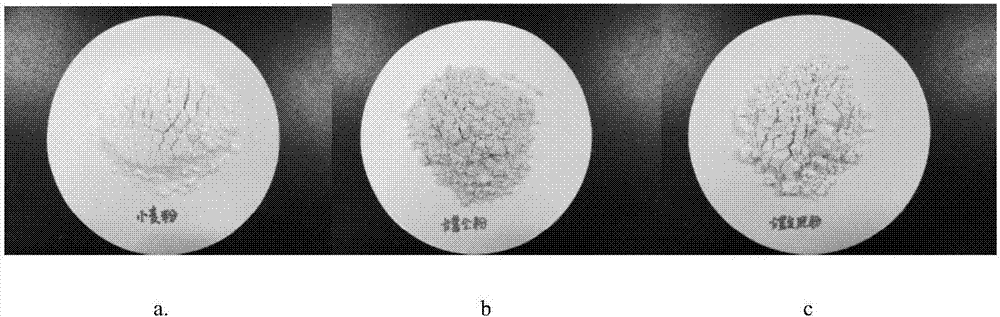

[0126] Example 3 Effect of Wet Ultrafine Grinding and Backfilling on Water Activity and Moisture Content of Potato Residue Material

[0127] The sample preparation method is as follows:

[0128] 1) Untreated wet potato residue (SPR): simulated fresh sweet potato residue obtained after industrial starch extraction;

[0129] 2) Potato residues treated by wet superfine grinding (WSG-SPR): Treat 1) medium potato residues with a shear emulsifier at 7000 r / min for 25 minutes. Then use a suction filtration device to suction filter under the double-layer 400-mesh sieve until the suction filtration is complete, and collect the processed fresh potato residue to obtain it;

[0130] 3) Backfill + wet superfine grinding material (FB+WSG-SPR): the material obtained by mixing potato residue in step 2) with corn starch and egg protein at 100:7:2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com