Coal gangue-based mine filling material and preparation method thereof

A technology of mine filling and coal gangue, which is applied in the field of filling material ratio prepared from spontaneous combustion coal gangue, can solve the problems of unstable performance and high cost, achieve good mechanical properties, reduce costs, and improve resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

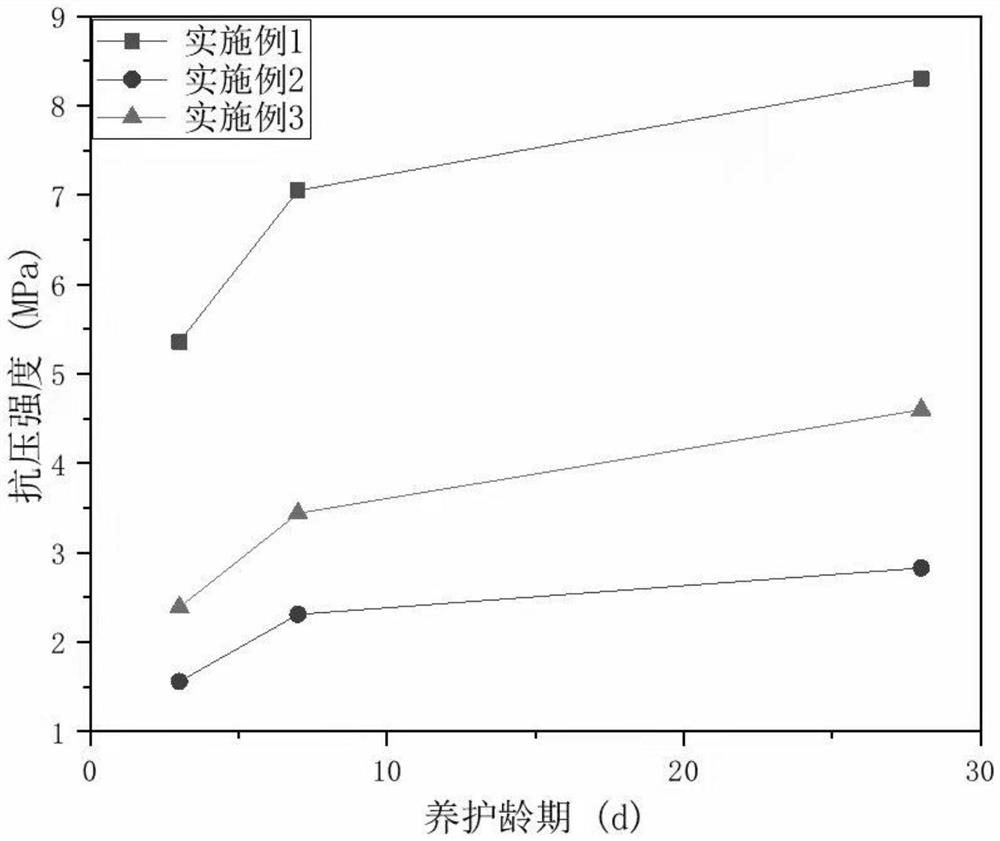

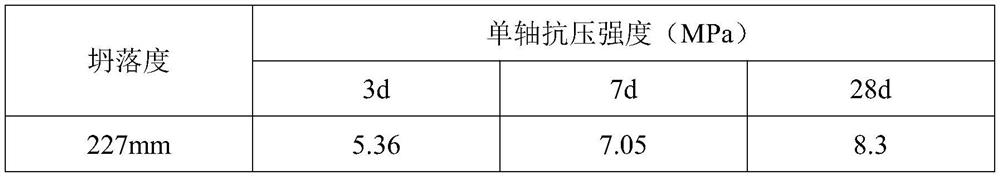

Embodiment 1

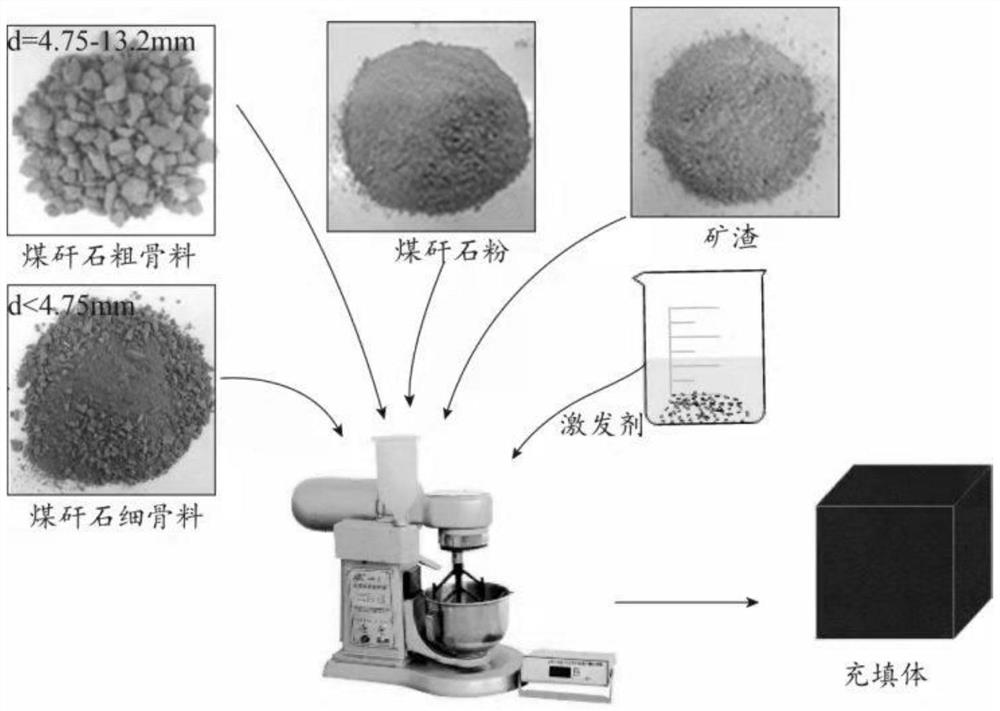

[0023] (1) First crush and screen the large pieces of coal gangue with a jaw crusher, so that the particle size of the screened coal gangue is distributed in the range of 0-13.2mm, wherein the particle size range is 4.75-13.2mm Coal gangue is used as coarse aggregate, and coal gangue with a particle size range of less than 4.75 mm is used as fine aggregate; the effective chemical composition of the coal gangue is: SiO 2 : 55.19%, Al 2 o 3 : 13.64%.

[0024] (2) Weigh 7kg of fine aggregate in step (1), put it into a ball mill and grind it for 30min, then sieve it with 270 mesh and 300 mesh standard sieves, and obtain the coal gangue powder with particle diameter less than 300 mesh for subsequent use;

[0025] (3) Weighing 3 kg of slag and mixing it with the gangue powder in step (2) and stirring for 2 minutes, and obtaining the gelled material after thorough mixing.

[0026] (4) Weigh 12 kg of coal gangue with coarse particle size and 18 kg of coal gangue with fine particle ...

Embodiment 2

[0032] (1) First crush and screen the large pieces of coal gangue with a jaw crusher, so that the particle size of the screened coal gangue is distributed in the range of 0-13.2mm, wherein the particle size range is 4.75-13.2mm Coal gangue is used as coarse aggregate, and coal gangue with a particle size range of less than 4.75 mm is used as fine aggregate; the effective chemical composition of the coal gangue is: SiO 2 : 55.19%, Al 2 o 3 : 13.64%.

[0033] (2) Weigh 8.5kg of fine aggregate in step (1), be placed in ball mill and grind for 30min, then sieve with 270 mesh, 300 mesh standard sieve, obtain particle diameter less than 300 mesh coal gangue powder for subsequent use;

[0034] (3) Weighing 1.5 kg of slag and mixing it with the gangue powder in step (2) and stirring for 2 minutes, and obtaining the gelled material after thorough mixing.

[0035] (4) Weigh 12 kg of coal gangue with coarse particle size and 18 kg of coal gangue with fine particle size in step (1), mi...

Embodiment 3

[0041] (1) First crush and screen the large pieces of coal gangue with a jaw crusher, so that the particle size of the screened coal gangue is distributed in the range of 0-13.2mm, wherein the particle size range is 4.75-13.2mm Coal gangue is used as coarse aggregate, and coal gangue with a particle size range of less than 4.75 mm is used as fine aggregate; the effective chemical composition of the coal gangue is: SiO 2 : 55.19%, Al 2 o 3 : 13.64%.

[0042] (2) Weigh 7kg of fine aggregate in step (1), put it into a ball mill and grind it for 30min, then sieve it with 270 mesh and 300 mesh standard sieves, and obtain the coal gangue powder with particle diameter less than 300 mesh for subsequent use;

[0043] (3) Weighing 3 kg of slag and mixing it with the gangue powder in step (2) and stirring for 2 minutes, and obtaining the gelled material after thorough mixing.

[0044] (4) Weigh 12 kg of coal gangue with coarse particle size and 18 kg of coal gangue with fine particle ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com