Method for filling urban road roadbed with slag

A technology for steel slag and roadbed, which is applied in the field of filling urban road subgrades with steel slag, can solve the problems of limited consumption of steel slag, surrounding soil pollution, and the large-scale utilization of steel slag has not been effectively solved, so as to solve the shortage of fillers and realize large-scale utilization. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] It should be noted that the embodiments in the application and the features in the embodiments can be combined with each other if there is no conflict. Hereinafter, the present invention will be described in detail with reference to the drawings and in conjunction with the embodiments.

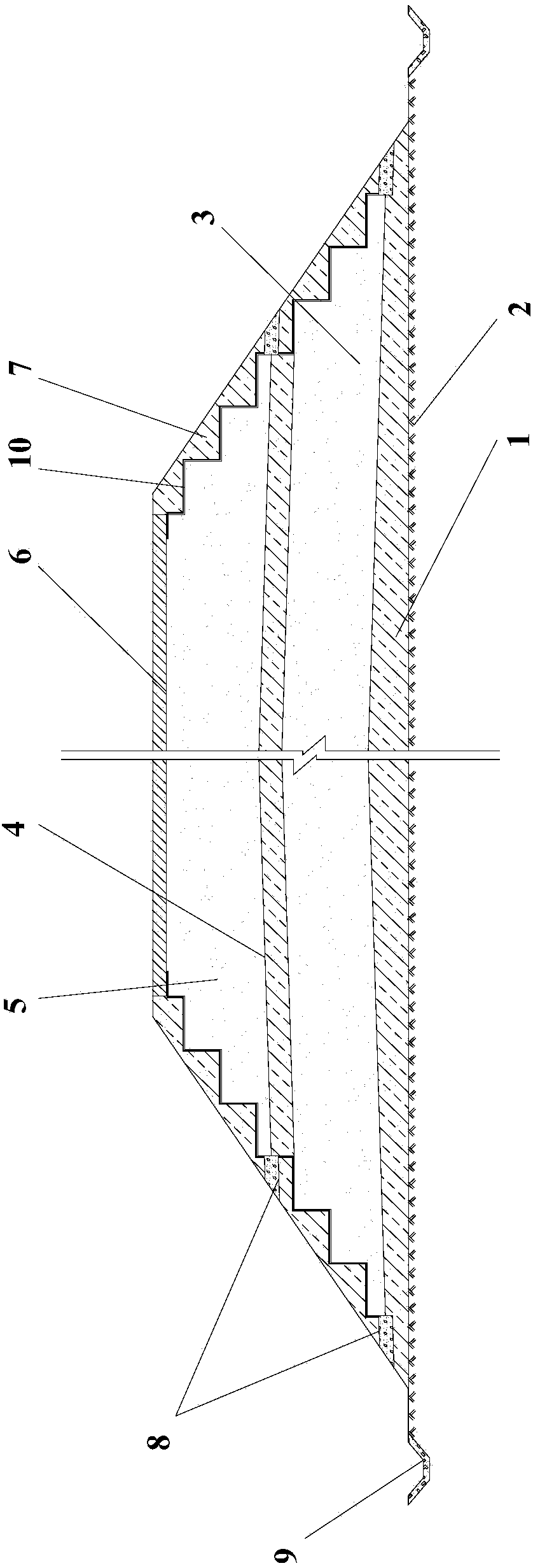

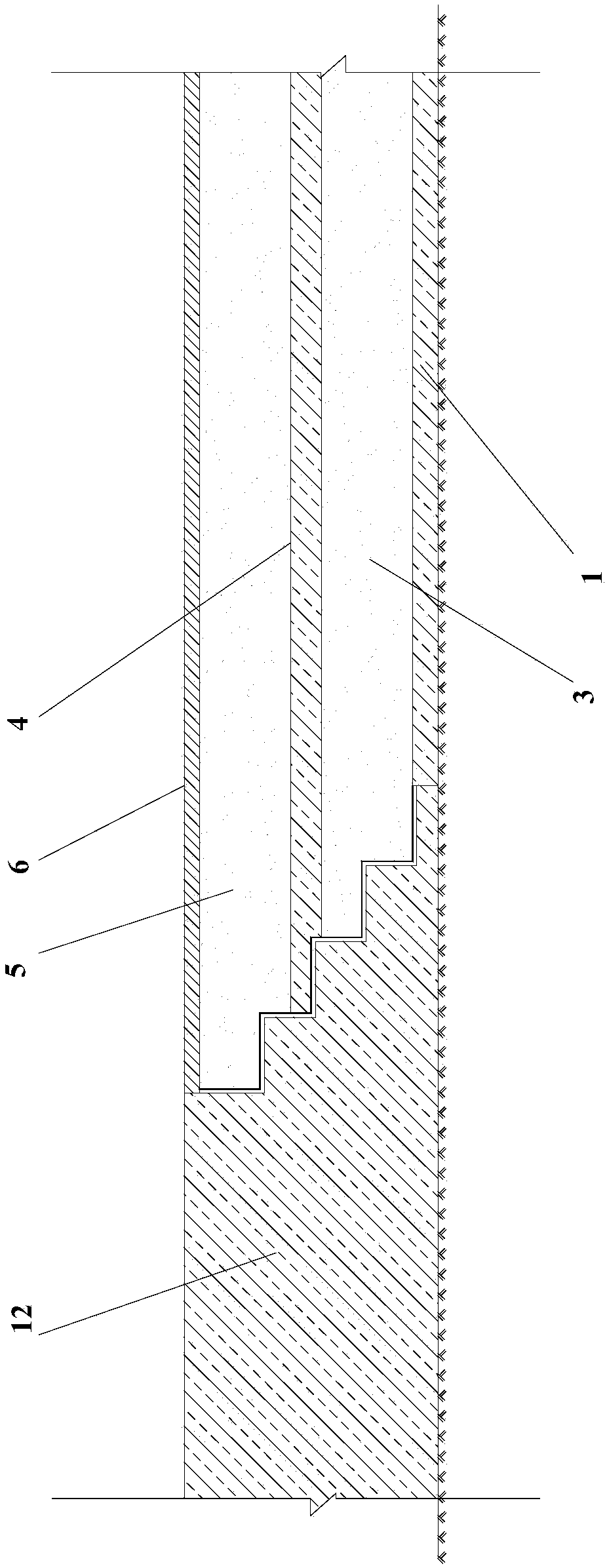

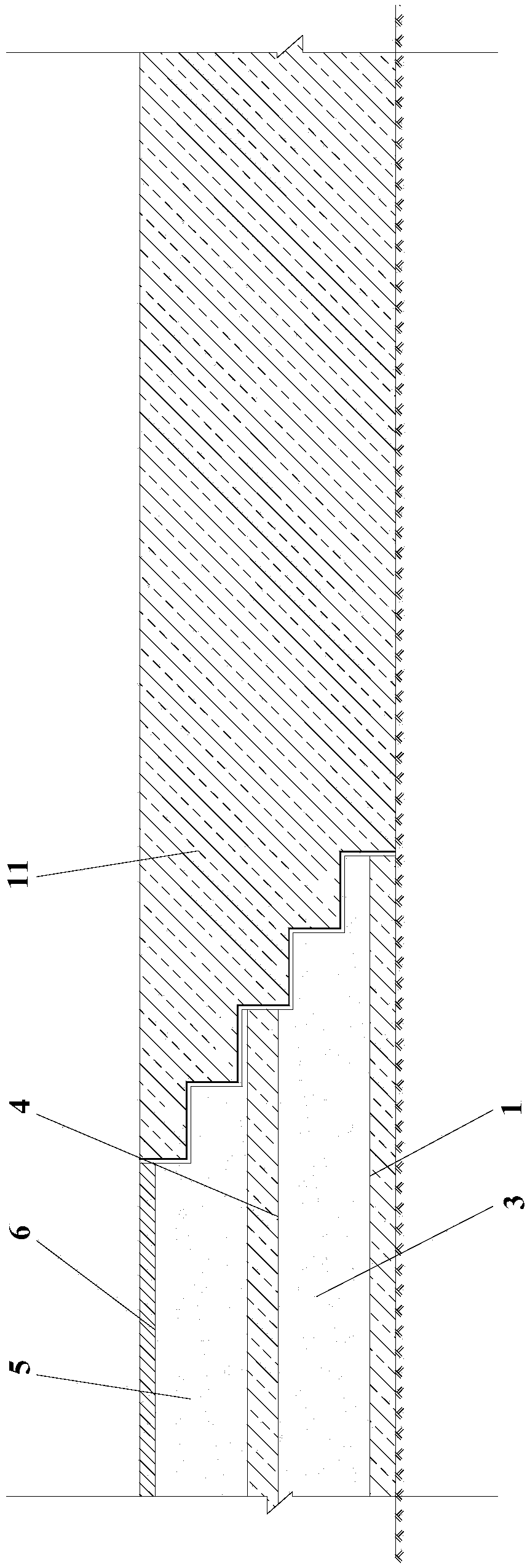

[0022] The embodiment of the present invention provides a method for filling urban road subgrade with steel slag, which includes the following steps:

[0023] Step 10. Lay cohesive soil with a plasticity index greater than or equal to 6 on the bottom of the roadbed to form a bottom seal;

[0024] Step 20: Lay the steel slag with stable performance after hot splash, water quenching, heat stuffing or aging treatment on the bottom seal layer to form a lower embankment;

[0025] Step 30: Lay the cohesive soil with a plasticity index greater than or equal to 6 on the top of the lower embankment to form an interlayer;

[0026] Step 40: Laying steel slag with stable performance after hot splashing, wat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com