Steel slag-cyaniding tailing cementing material as well as preparation method and application thereof

A technology for cyanide tailings and cementitious materials, which is applied in chemical instruments and methods, sustainable waste treatment, solid waste management, etc., can solve problems such as the utilization rate of less than 40%, achieve reuse, reduce production costs, Inexpensive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

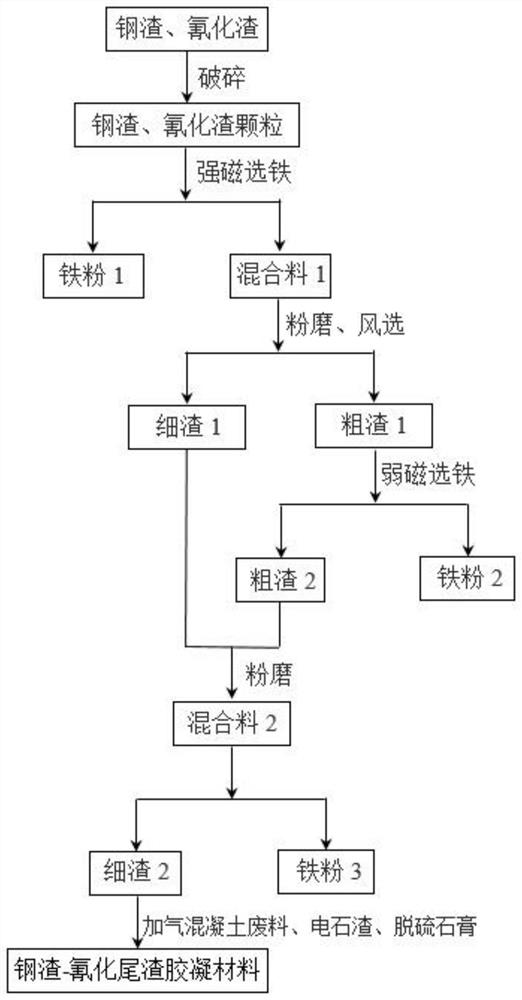

[0035] The preparation method of described iron selection waste slag comprises the following steps:

[0036] Step 1. After the original steel slag is carbonized in a concrete carbonization box for 24-72 hours, it is crushed by a jaw crusher, and then ground by a ball mill to a size smaller than 2 mm to form steel slag powder;

[0037] Step 2. Mix steel slag powder and cyanide tailings 1:1, and separate them into iron powder 1 and mixture 1 by dry strong magnetic roller; wherein, the magnetic field strength is 1.5-2T, and the magnetic separator speed is 10-20r / min;

[0038] Step 3. Grind the mixture 1 to 100-200m 2 / kg, divided into: 100~160m by winnowing 2 / kg of coarse slag 1 and 160~200m 2 / kg fine slag;

[0039] Step 4, continue to separate the coarse slag 1 by the dry weak magnetic roller into: coarse slag 2 and iron powder 2; wherein, the magnetic field strength is 50-80mT, and the magnetic separator speed is 10-20r / min;

[0040] Step 5. Mix fine slag and coarse sla...

Embodiment 1

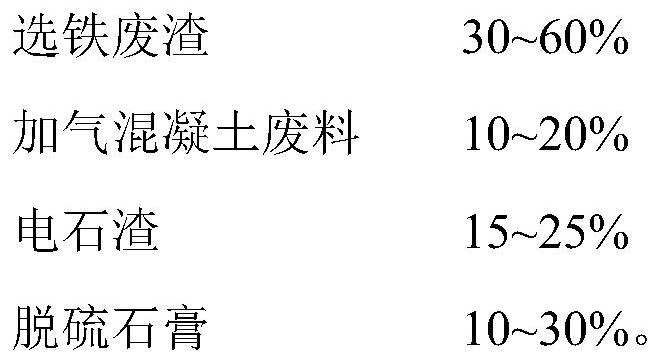

[0047] A steel slag-cyanide tailings cementitious material is composed of the following substances in mass percentage:

[0048]

[0049] The preparation method of the iron selection waste slag comprises the following steps: after the original steel slag is carbonized in a concrete carbonization box for 48 hours, it is crushed by a jaw crusher, and then ground by a ball mill to a size less than 2 mm to form steel slag powder; 1:1 mixing, the mixture is separated into iron powder 1 and mixture 1 by a magnetic field strength of 1.5T, and a magnetic separator with a speed of 10-20r / min. 200m 2 / kg, divided into: 100~160m by winnowing 2 / kg of coarse slag 1 and 160~200m 2 / kg of fine slag; the coarse slag 1 is separated into: coarse slag 2 and iron powder 2 by a dry weak magnetic roller with a magnetic field strength of 50mT and a magnetic separator rotating speed of 15r / min; after mixing the fine slag and coarse slag 2 Grind to 400-800m by vibrating ceramic mill 2 / kg to fo...

Embodiment 2

[0060] A steel slag-cyanide tailings cementitious material is composed of the following substances in mass percentage:

[0061]

[0062]

[0063] The preparation method of described iron selection waste slag comprises the following steps:

[0064] After the original steel slag is carbonized in the concrete carbonization box for 24 hours, it is crushed by a jaw crusher, and then ground by a ball mill to a size less than 2 mm to form steel slag powder; the steel slag powder and cyanide tailings are mixed at a ratio of 1:1, and the mixture is passed through a magnetic field with a strength of 1.8T, the speed of the magnetic separator is 10-20r / min, and the dry-type strong magnetic roller is separated into: iron powder 1 and mixture 1; the mixture 1 is ground to 100-200m 2 / kg, divided into: 100~160m by winnowing 2 / kg of coarse slag 1 and 160~200m 2 / kg of fine slag; the coarse slag 1 is separated into: coarse slag 2 and iron powder 2 by a dry weak magnetic roller with a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com