Method for preparing high calorific value fuel from municipal sludge and biomass synergistically

A technology of biomass fuel and municipal sludge, which is applied in the field of municipal sludge synergizing biomass to prepare high calorific value fuel, can solve the problems of high cost, poor effect and long processing time, achieve high water content and reduce secondary pollution , the effect of increasing the calorific value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

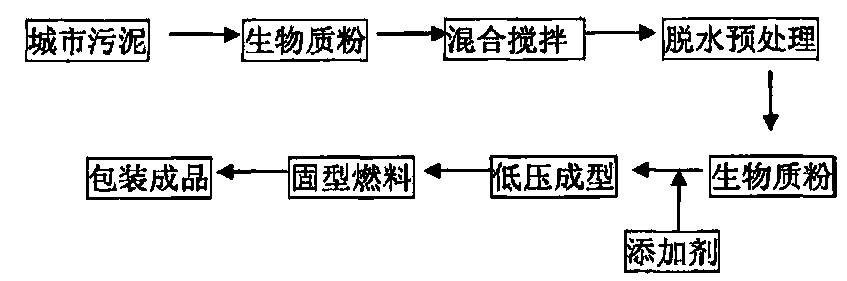

Method used

Image

Examples

Embodiment 1

[0021] A method for preparing high calorific value fuel from municipal sludge with biomass, comprising the following steps:

[0022] The moisture content of the garden waste is 38%, and it is crushed in situ. After crushing, the sawdust particles are 3mm. The urban landscaping waste is crushed, packaged, and directly transported to the sewage treatment plant by car, and dried in the sludge conditioning tank according to the sawdust and sludge. The basis weight is 1:1 mass percentage, and at the same time add 3 / 10,000 of the dry basis sludge and cationic PAM to stir evenly, then perform ordinary plate and frame mechanical dehydration, and the moisture content of the sludge is 58%; the compressed multi-stage heat energy is used to recover the air source heat pump sewage The mud drying complete set, the dehumidification capacity of a single air source heat pump is 240kg / h, 1kwh electric energy can dry and evaporate 3.0kg, the wet mud is deeply dried to a moisture content of 15%, t...

Embodiment 2

[0024] The moisture content of the garden waste is 40%, and it is crushed in situ. After crushing, the sawdust particles are 4mm. The urban landscaping waste is crushed, packaged, and directly transported to the sewage treatment plant by car, and dried according to the sawdust and sludge in the sludge conditioning tank. The basis weight is 1:1 mass percentage, at the same time add 5 / 10,000 dry base sludge and cationic PAM and stir evenly, then carry out ordinary plate and frame mechanical dehydration, the sludge moisture content is 54%; adopt compressed multi-stage heat energy to recover air source heat pump sewage Complete set of mud drying equipment, single air source heat pump dehumidification capacity 260kg / h, 1kwh electric energy can dry and evaporate 3.2kg, wet mud can be deeply dried to moisture content 15%, comprehensive power consumption 170kw.h, moisture content 15% sludge addition Additives, wherein the sulfur-fixing agent is added in an amount of 1.5% of the sludge ...

Embodiment 3

[0026] Utilize described in embodiment 1, comprise the following steps:

[0027] The water content of the garden waste is 35%, and it is crushed in situ. After crushing, the sawdust particles are 5mm. The urban landscaping waste is crushed, packaged, and directly transported by car to the sewage treatment plant. The basis weight is 1:1 mass percentage, and at the same time add 7 / 10,000 dry base sludge and cationic PAM to stir evenly, then perform ordinary plate and frame mechanical dehydration, and the moisture content of the sludge is 54%; the compressed multi-stage heat energy is used to recover the air source heat pump sewage The mud drying complete set, the dehumidification capacity of a single air source heat pump is 280kg / h, 1kwh of electric energy can dry and evaporate 3.5kg, and the wet mud is deeply dried to a moisture content of 13%, the comprehensive power consumption is 160kw.h, and the moisture content is 15%. Sludge addition Additives, wherein the sulfur-fixing a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| crush indicators | aaaaa | aaaaa |

| crush indicators | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com