Preparation process of multifunctional artificial board

A preparation process and multi-functional technology, applied in the direction of manufacturing tools, wood processing appliances, and the joining of wooden veneers, etc., can solve the problems of single function of wood-based panels, related physical and chemical indicators cannot meet relevant standards at the same time, and related characteristics are incompatible. , to achieve the effect of environmental protection of home environment and improvement of performance and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

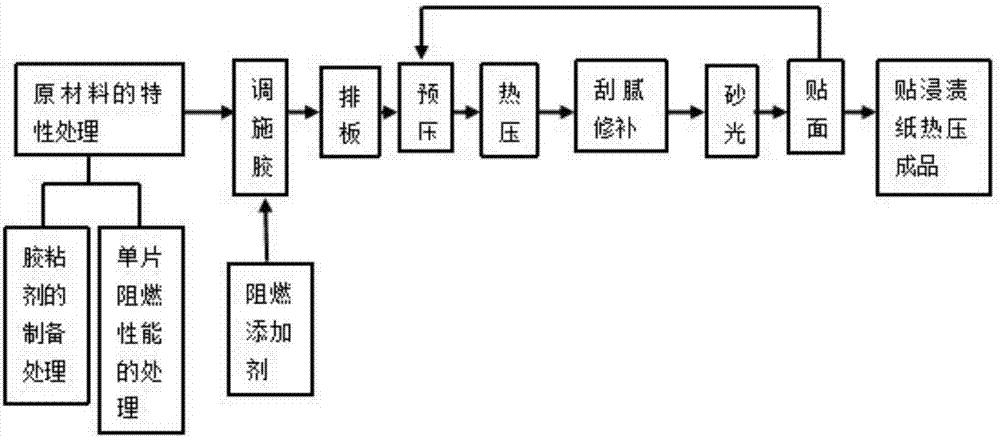

[0036] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

[0037] Such as figure 1 Shown, a kind of preparation technology of multifunctional artificial board comprises the following steps:

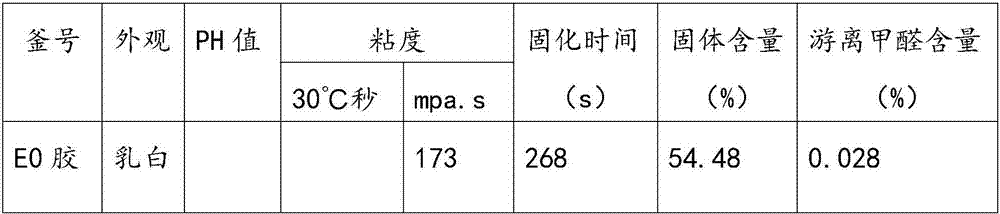

[0038] Step S1: prepare the modified urea-formaldehyde resin adhesive according to the following steps, and set aside:

[0039] (1) Weigh the following components respectively: formaldehyde: 1000-1350kg, urea: 1000-1600kg, melamine: 45-130kg, high-efficiency compounding agent: 10-50kg, PVA: 5-10kg, sodium hydroxide: 12 -28kg and formic acid: 1-3kg, and divide the weighed urea into four parts to be fed. 150-250kg.

[0040] (2) Add formaldehyde and the first portion of urea to the reaction kettle, open the steam valve to raise the temperature to 40-60°C, add 10-35kg of melamine, then ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com