Alcohol fermentation anaerobic high temperature bacterium culture medium, preparation and use thereof

A technology of ethanol fermentation and culture medium, which is applied in the biological field and can solve the problem of no bean curd residue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

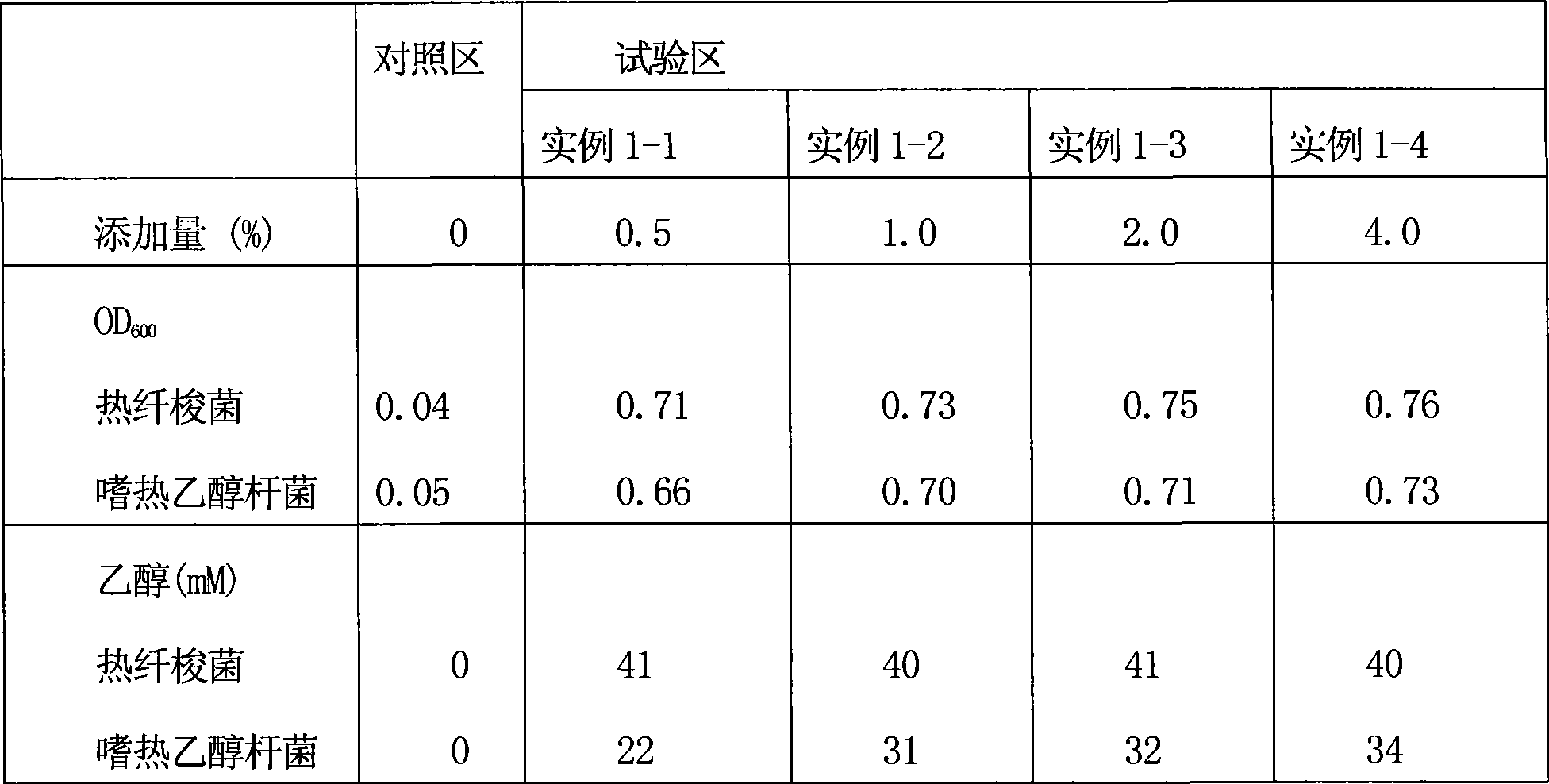

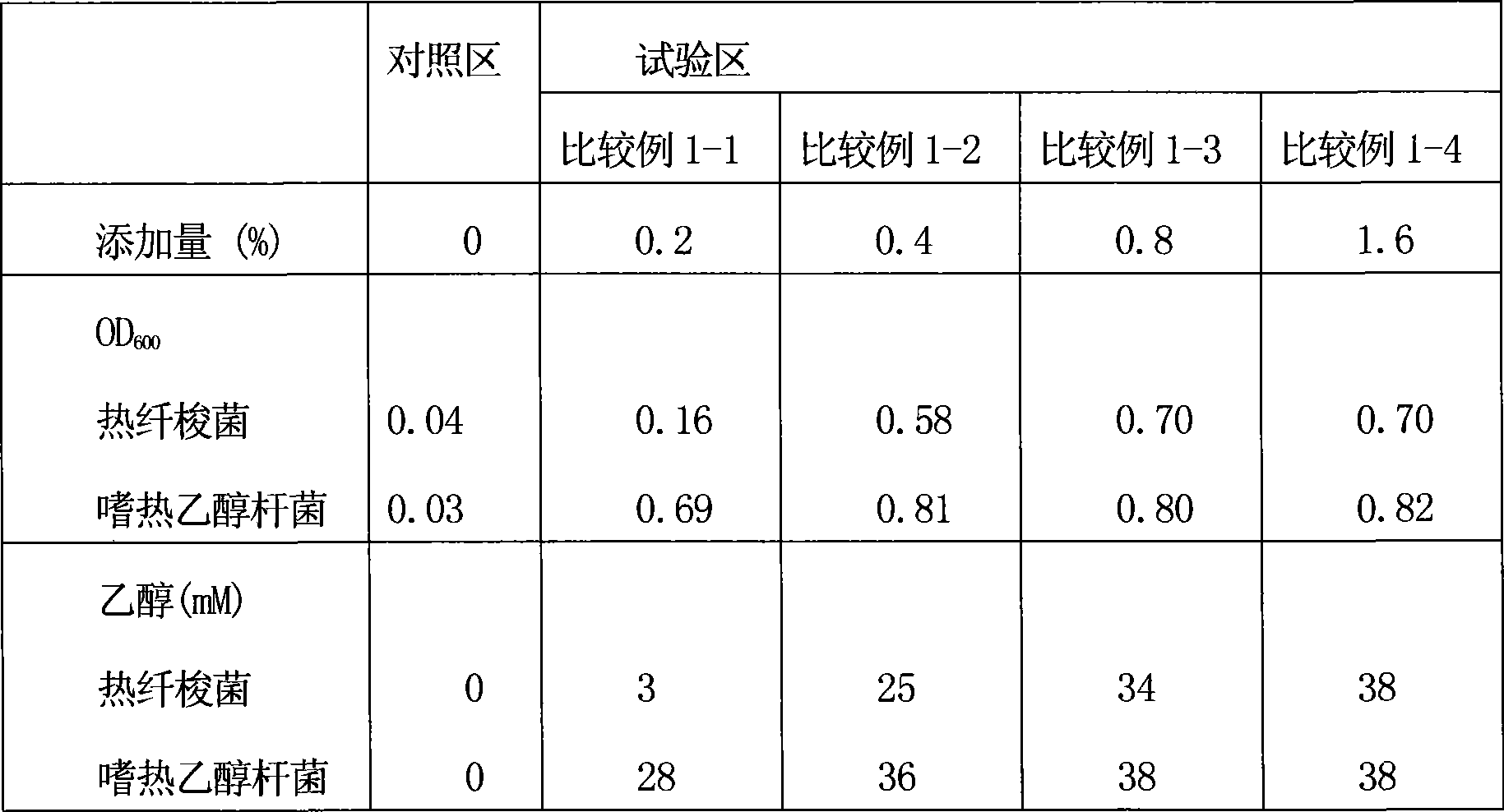

[0024] The cultivation effect of bean curd residue as a nutrient substance:

[0025] Preparation of bean curd dregs nutrient stock solution: weigh 20 g bean curd dregs (wet weight), add 80 ml of pure water, stir evenly, adjust the pH value to 7 with an appropriate amount of NaOH solution, and use it as a bean curd dregs nutrient stock solution for later use. The bean curd residue used in this test is a raw material without any processing or treatment, and its moisture content is 75%.

[0026] The preparation of the basal medium of ethanol fermenting high-temperature anaerobic bacteria: the following components are dissolved in 1 liter of pure water, and the pH value is adjusted to 7 with NaOH solution, which is used as the basal medium solution of the high-temperature bacteria culture test for subsequent use.

[0027] Medium components: peptone (peptone): 10g; yeast extract (Yeast extract): 0g; microcrystalline cellulose (Avicel) or glucose (Glucose): 5g; magnesium chloride he...

Embodiment 2

[0035] The method used is the same as in Example 1, except that the content of each component in every liter of medium is: peptone: 5g; microcrystalline cellulose or glucose 50g; magnesium chloride hexahydrate 2g; calcium chloride dihydrate 0.3g; hexahydrate 2.5 mg of ferrous sulfate; 3.0 g of potassium dihydrogen phosphate; 6.0 g of dipotassium hydrogen phosphate; 1.0 g of cysteine hydrochloride; 2.0 mg of resazurin; The culture medium with a concentration of 4.0% by weight of slag.

Embodiment 3

[0037] The method used is the same as in Example 1, except that the content of each component in every liter of medium is: peptone: 10g; microcrystalline cellulose or glucose 100g; magnesium chloride hexahydrate 1g; calcium chloride dihydrate 0.15g; 1.25 mg of ferrous sulfate; 0.75 g of potassium dihydrogen phosphate; 5.0 g of dipotassium hydrogen phosphate; 0.5 g of cysteine hydrochloride; 1.0 mg of resazurin; Slag 3.0% weight ratio concentration of medium.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com