A device for extracting indium by microwave chlorination of waste liquid crystal panels

The technology of a liquid crystal panel and a microwave heating device is applied in the field of indium material devices, which can solve the problems of high requirements for equipment and devices, failure to realize industrial application, and high energy consumption, and achieves reduction of energy consumption waste, avoidance of shadow effects, and reduction of volatilization loss. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

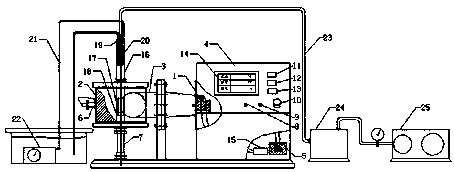

[0038] Please refer to figure 1 , figure 1 It is a structural diagram of a device for extracting indium by microwave chlorination of waste liquid crystal panels of the present invention. As shown in the figure, the device for extracting indium by microwave chlorination of waste liquid crystal panels includes a microwave generator 1, a microwave heating chamber 2, a microwave connecting pipe 3, an electric control panel 4, a frequency conversion high-voltage driver 5, an infrared temperature sensor 6, and a lifting rod 7 , microwave start button 8, microwave pause button 9, emergency power off button 10, temperature controller 11, time controller 12, power controller 13, digital display panel 14, microwave heating device composed of electromagnetic relay 15; by quartz reaction tube 16. Quartz reaction device composed of material crucible 17, quartz sand core layer 18, and ground sealing plug 19; condensation recovery device composed of quartz condensation pipe 20, condensation...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com