Mask and fabrication method thereof

A manufacturing method and a technology of a mask, which are applied in the direction of photolithography, optics, instruments, etc. on a patterned surface, can solve the problems of reduced mask precision and low production efficiency, and achieve improved production efficiency, avoiding shadow effects, The effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, but not to limit the present invention. In addition, it should be noted that, for the convenience of description, only some structures related to the present invention are shown in the drawings but not all structures.

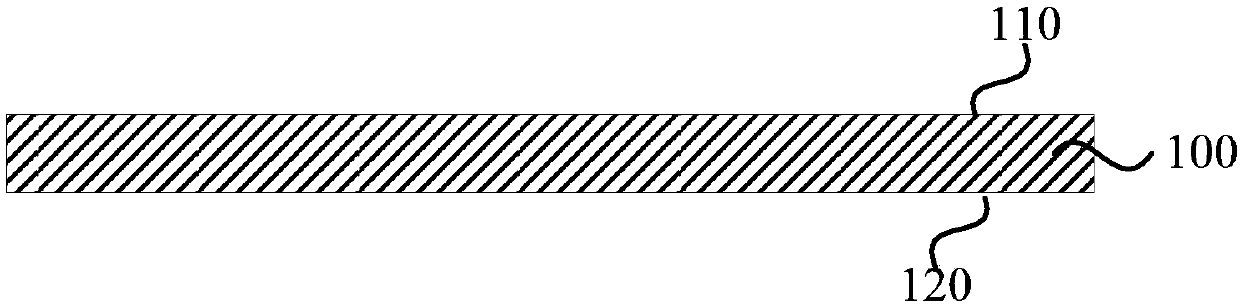

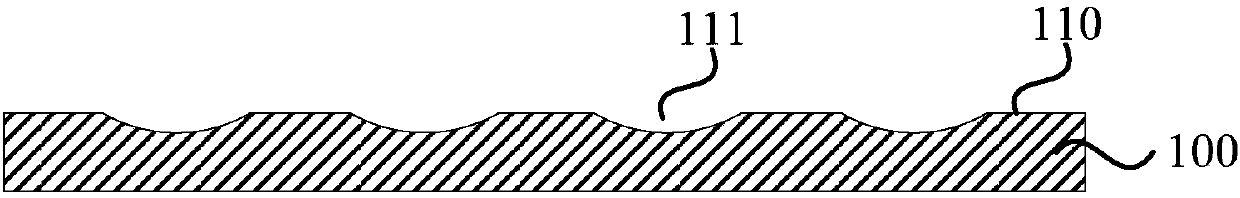

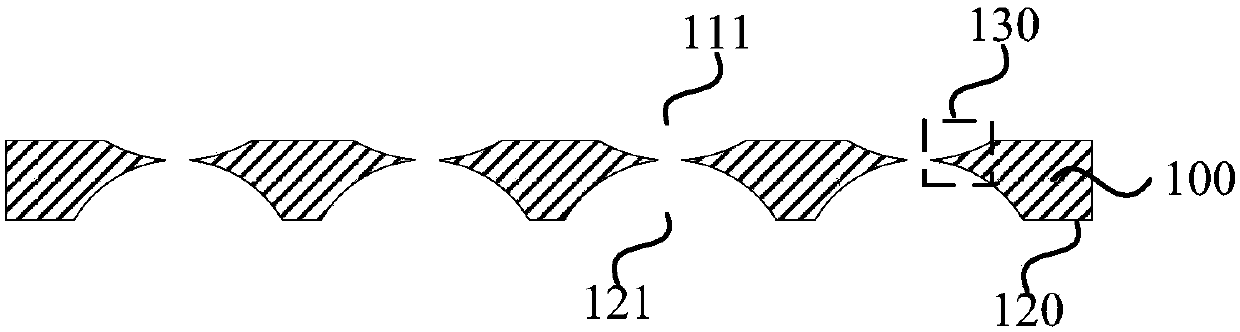

[0019] Figure 1a-Figure 1c It is a schematic diagram of the manufacturing method of the mask plate in the prior art. like Figure 1a As shown, a mask substrate 100 is provided, and the mask substrate 100 includes a glass surface 110 and an evaporation surface 120 opposite to each other. A plurality of grooves 111 are formed on the glass surface 110 side of the mask substrate 100 by using a yellow light process, such as Figure 1b shown. Then again use the yellow light process to form a plurality of openings 12...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com