Method for reduction and detoxification of stainless steel acid pickling sludge

A technology for pickling sludge and stainless steel, which is applied in the fields of metallurgy and environmental protection, and can solve problems such as impact on ironmaking production, difficulty in implementation, and low added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention can be better understood from the following examples. However, those skilled in the art will readily understand that the specific material ratios, process conditions and results described in the examples are only used to illustrate the description, and should not and will not limit the present invention described in detail in the claims .

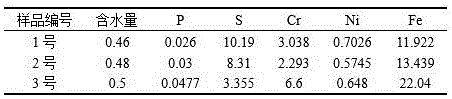

[0022] The main components of stainless steel pickling sludge in an enterprise are shown in Table 1:

[0023] Table 1 Main components of stainless steel pickling sludge in an enterprise

[0024]

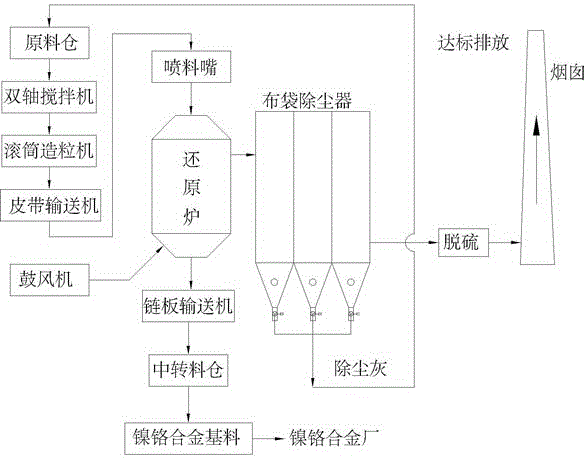

[0025] The specific implementation steps of the present invention are as follows:

[0026] 1) After the stainless steel pickling sludge is generated, it is first filtered to about 60% of the water content, and the water content can be reduced to 50% after being transferred and stored for natural drying;

[0027] 2) Qualified sludge is transported by the loader to the batching bin for batching, and then transporte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com