Flow dividing element and fluid distributor

A technology of fluid distributor and shunt element, which is applied in fluid circulation arrangement, refrigeration components, refrigeration and liquefaction, etc., can solve the problems of high cost of liquid distributor, large installation environment restrictions, etc., achieve uniform and stable mixing, and low processing cost , the effect of even distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

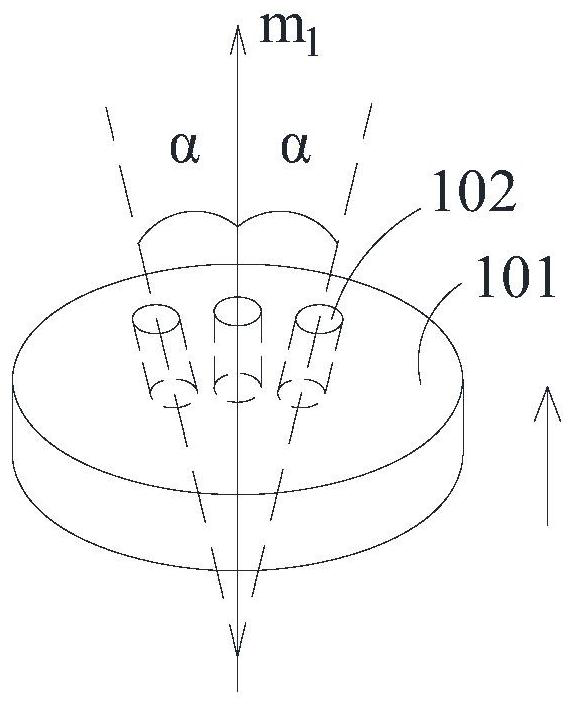

[0167] A fluid distributor 200, in which the flow distribution element 100 is a cap-shaped flow separation element 120, the axial length H of the distribution cavity 210 is 30 mm, and the axial length C (ie, the first axial distance) of the front cavity 211 is 15 mm , the installation height h (that is, the second axial distance) of the flow splitting element 100 is 0mm. The height A of the cap-shaped shunt element 120 is 15 mm, and the characteristic length B of the port is 16.8 mm. The number of distribution branch pipes 230 is four. For other parameters, refer to the above related content.

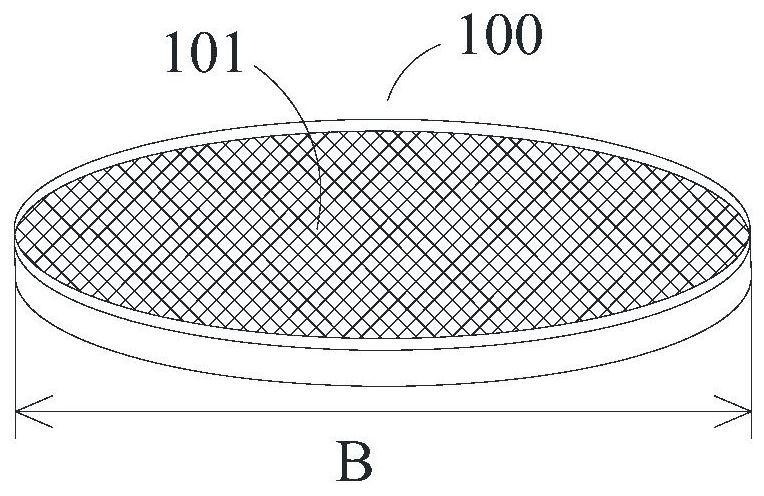

[0168] In the fluid distributor 200 of Embodiment 1, the first characteristic ratio of the cap-shaped flow dividing element 120 is 0.9, the first ratio is 0.5, and the second ratio is 0. The molding method of the cap-shaped flow distribution element 120 can be any of the above three molding methods, for example, the wire mesh flow distribution element 100 obtained by braiding metal wi...

Embodiment 2

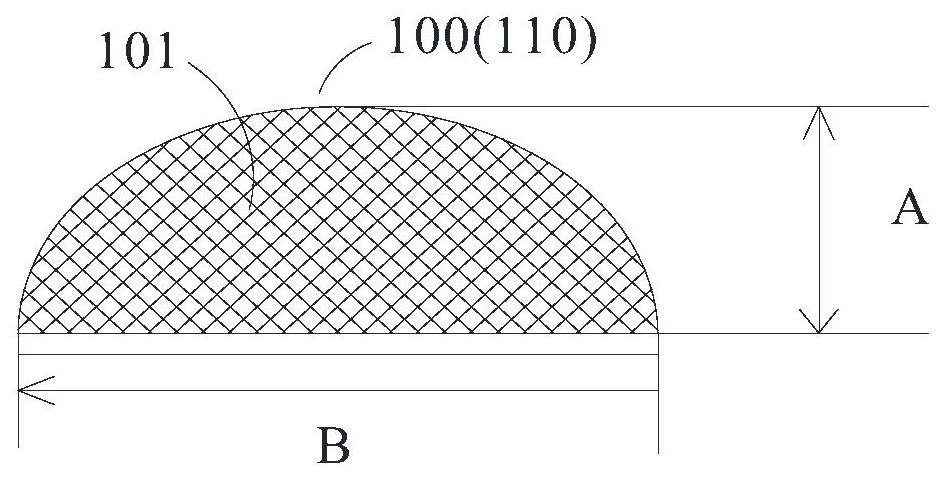

[0180] A fluid distributor 200, in which the flow distribution element 100 is a curved flow separation element 110, the axial length H of the distribution chamber 210 is 30mm, and the axial length C (that is, the first axial distance) of the front chamber 211 is 13mm , the installation height h (that is, the second axial distance) of the flow splitting element 100 is 10mm. The porosity of the curved flow splitting element 110 is 69%, the height A is 3 mm, and the characteristic length B of the port is 16.8 mm. The number of distribution branch pipes 230 is four. For other parameters, refer to the above related content.

[0181] In the fluid distributor 200 of this embodiment, the first characteristic ratio of the curved flow dividing element 110 is 0.18, the first ratio is 0.43, the second ratio is 0.3, and the third ratio is 0.66. The above-mentioned three molding methods can be used for forming the curved flow distribution element 110 , for example, the wire mesh flow dist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com