Improved cereal short biscuit and preparing method thereof

A technology for crisp biscuits and cereals, applied in the field of improved cereal biscuits and their preparation, biscuits, can solve the problems of high oil, high oil content, insufficient dietary fiber content, etc., achieves low oil content, low sugar content, improved Effects of sensory qualities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

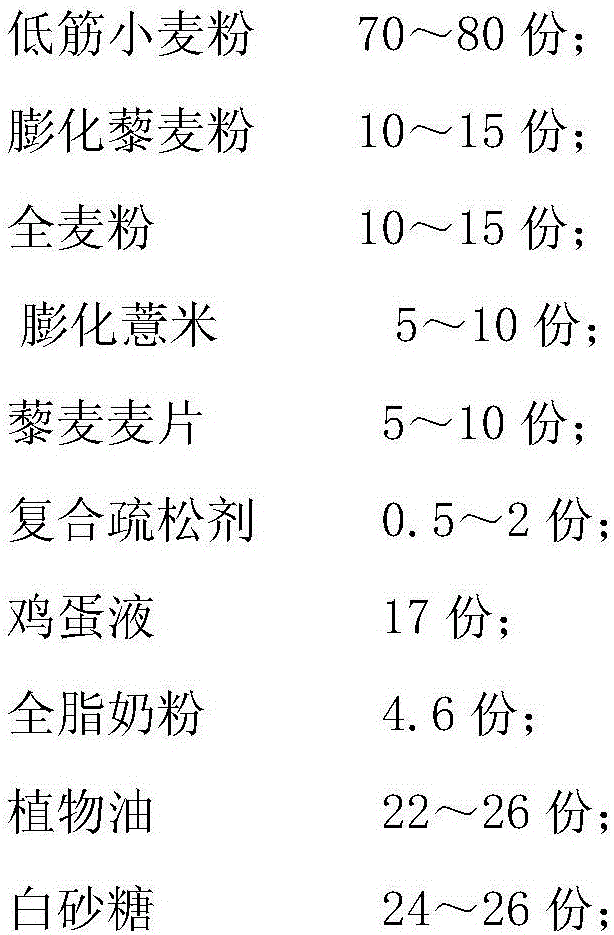

[0048] An improved cereal crisp biscuit, calculated according to the weight of the dry powder, its raw material composition and content are as follows:

[0049]

[0050] The composite bulking agent is calculated by weight ratio and is compounded by sodium bicarbonate: ammonium bicarbonate: gluconate-δ-lactone: citric acid: starch = 3:4:3:2:1

[0051] The specifications of the low-gluten wheat flour meet the national standard GB / T8607-1988;

[0052] The above-mentioned raw materials are all powdery solids with good flowability, and all pass the CQ20 sieve specified by the national standard GB5507;

[0053] The above-mentioned puffed quinoa flour and puffed barley are prepared as follows:

[0054] (1) Preparation of puffed quinoa powder

[0055] Select quinoa grains with full grains, add water in a ratio of 1:0.03 according to the quality of the quinoa grains: the quality of water is 1:0.03, mix well, air puff at 250℃ for 25s, and use a flour mill for the puffed quinoa Crush and pass a 10...

Embodiment 2

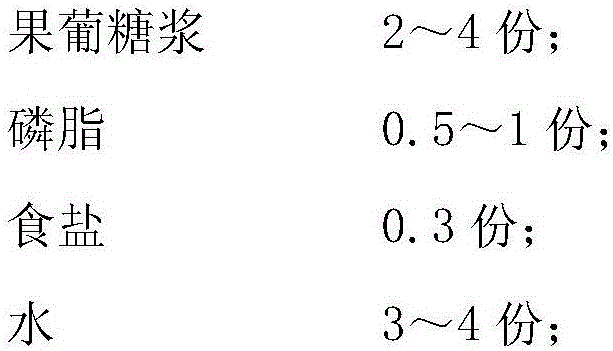

[0074] An improved cereal crisp biscuit, calculated according to the weight of the dry powder, its raw material composition and content are as follows:

[0075]

[0076]

[0077] The composite bulking agent is calculated by weight ratio and is compounded by sodium bicarbonate: ammonium bicarbonate: gluconate-δ-lactone: citric acid: starch = 3:4:3:2:1

[0078] The specifications of the low-gluten wheat flour meet the national standard GB / T8607-1988;

[0079] The above-mentioned raw materials are all powdery solids with good flowability, and all pass the CQ20 sieve specified by the national standard GB5507;

[0080] The preparation methods of the puffed quinoa powder and puffed barley are as follows:

[0081] (1) Preparation of puffed quinoa powder

[0082] Select quinoa grains with full grains, add water in a ratio of 1:0.03 according to the quality of the quinoa grains: the quality of water is 1:0.03, mix well, air puff at 250℃ for 25s, and use a flour mill for the puffed quinoa Crush a...

Embodiment 3

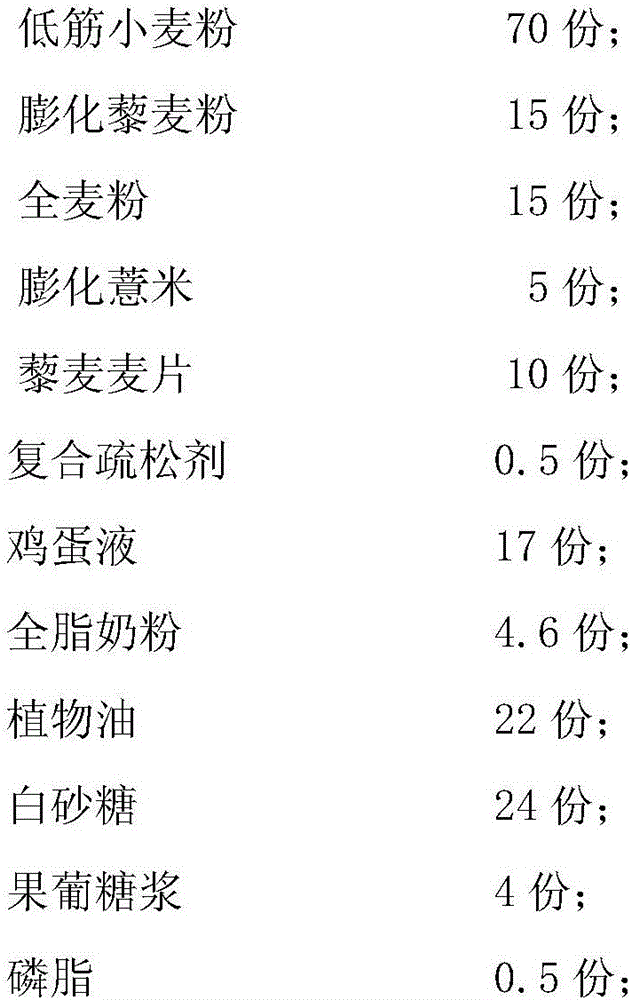

[0101] An improved cereal crisp biscuit, calculated according to the weight of the dry powder, its raw material composition and content are as follows:

[0102]

[0103]

[0104] The composite bulking agent is calculated by weight ratio and is compounded by sodium bicarbonate: ammonium bicarbonate: gluconate-δ-lactone: citric acid: starch = 3:4:3:2:1

[0105] The specifications of the low-gluten wheat flour meet the national standard GB / T8607-1988;

[0106] The above-mentioned raw materials are all powdery solids with good flowability, and all pass the CQ20 sieve specified by the national standard GB5507;

[0107] The above-mentioned puffed quinoa flour and puffed barley are prepared as follows:

[0108] (1) Preparation of puffed quinoa powder

[0109] Select quinoa grains with full grains, add water in a ratio of 1:0.03 according to the quality of the quinoa grains: the quality of water is 1:0.03, mix well, air puff at 250℃ for 25s, and use a flour mill for the puffed quinoa Crush and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com