Preparation method of Ti2AlNb alloy material

A technology for alloy materials and alloy ingots, which is applied in the field of preparation of Ti2AlNb alloy materials, can solve problems such as processing difficulties, and achieve the effects of improving composition uniformity, small melting current and small molten pool.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

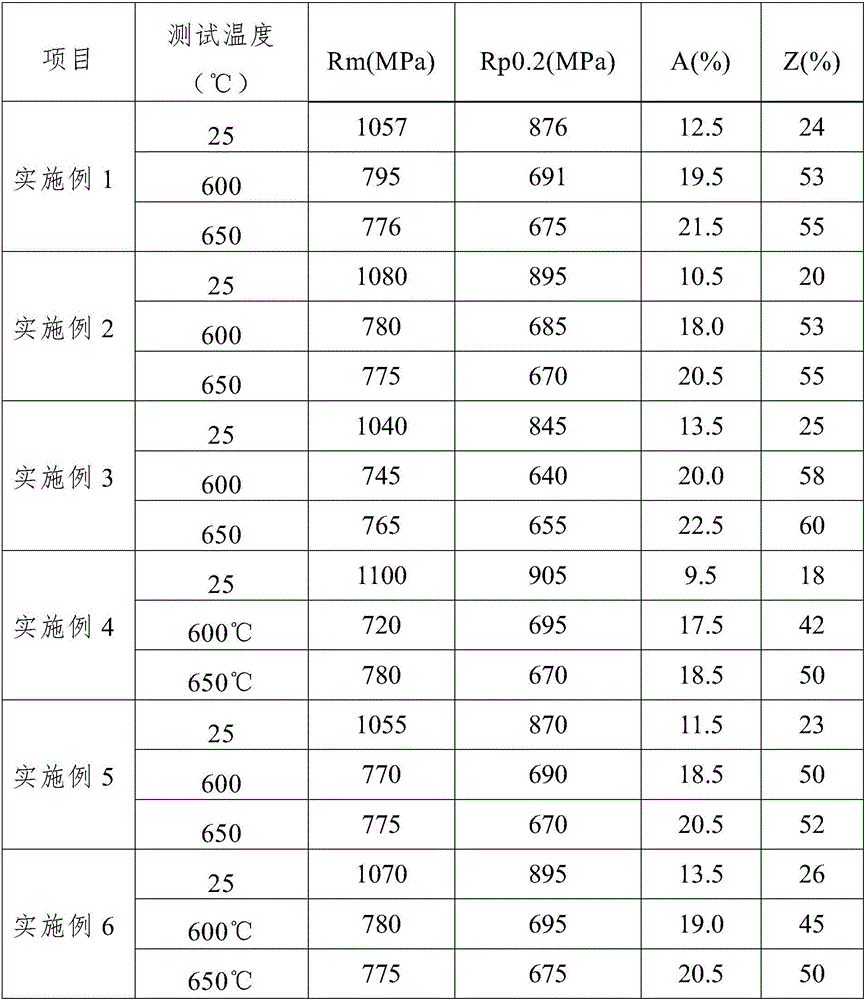

Embodiment 1

[0026] The method for preparing Ti2AlNb alloy rods in this embodiment comprises the following steps:

[0027] Step 1, preparing Ti2AlNb alloy ingot, the specific process is:

[0028] Step 101, mixing Ti-Nb master alloy, aluminum beans and zero-grade titanium sponge, and pressing them into electrodes, and then smelting them in a vacuum consumable electric arc furnace to obtain a primary ingot of Φ160mm;

[0029] Step 102, placing the primary ingot in step 101 on a shell furnace for smelting, and pouring it into a graphite mold after smelting to obtain a secondary ingot of Φ160 mm;

[0030] Step 103, after turning the surface of the secondary ingot described in step 102 by 3 mm, melting in a vacuum electric arc furnace to obtain a Ti2AlNb alloy ingot of Φ220 mm;

[0031] Step 2: Carry out surface peeling and riser cutting treatment on the Ti2AlNb alloy ingot described in step 103, then place it in a heat treatment furnace with a temperature of 750°C for 55 minutes, then raise t...

Embodiment 2

[0036] The method for preparing Ti2AlNb alloy rods in this embodiment comprises the following steps:

[0037] Step 1, preparing Ti2AlNb alloy ingot, the specific process is:

[0038] Step 101, mixing Ti-Nb master alloy, aluminum beans and zero-grade titanium sponge, and pressing them into electrodes, and then smelting them in a vacuum consumable electric arc furnace to obtain a primary ingot of Φ160mm;

[0039] Step 102, placing the primary ingot in step 101 on a shell furnace for smelting, and pouring it into a graphite mold after smelting to obtain a secondary ingot of Φ160 mm;

[0040] Step 103, turning 4 mm on the surface of the secondary ingot described in step 102, and melting in a vacuum electric arc furnace to obtain a Ti2AlNb alloy ingot of Φ220 mm;

[0041] Step 2: Perform surface peeling and riser cutting on the Ti2AlNb alloy ingot described in step 103, then place it in a heat treatment furnace with a temperature of 780°C for heat preservation for 45 minutes, then...

Embodiment 3

[0046] The method for preparing Ti2AlNb alloy rods in this embodiment comprises the following steps:

[0047] Step 1, preparing Ti2AlNb alloy ingot, the specific process is:

[0048] Step 101, mixing Ti-Nb master alloy, aluminum beans and zero-grade titanium sponge, and pressing them into electrodes, and then smelting them in a vacuum consumable electric arc furnace to obtain a primary ingot of Φ160mm;

[0049] Step 102, placing the primary ingot in step 101 on a shell furnace for smelting, and pouring it into a graphite mold after smelting to obtain a secondary ingot of Φ160 mm;

[0050] Step 103, turning 4 mm on the surface of the secondary ingot described in step 102, and melting in a vacuum electric arc furnace to obtain a Ti2AlNb alloy ingot of Φ220 mm;

[0051] Step 2: Carry out surface peeling and riser cutting treatment on the Ti2AlNb alloy ingot described in step 103, then place it in a heat treatment furnace with a temperature of 780°C for heat preservation for 65 m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com