High-hardness steel cut wire shot heat treatment technology

A steel wire cutting shot, high hardness technology, applied in the direction of heat treatment furnace, heat treatment equipment, metal material coating process, etc., to achieve the effect of compact internal structure, saving use cost and improving wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

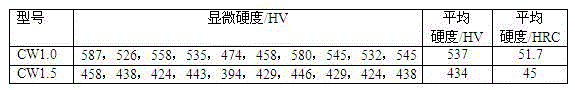

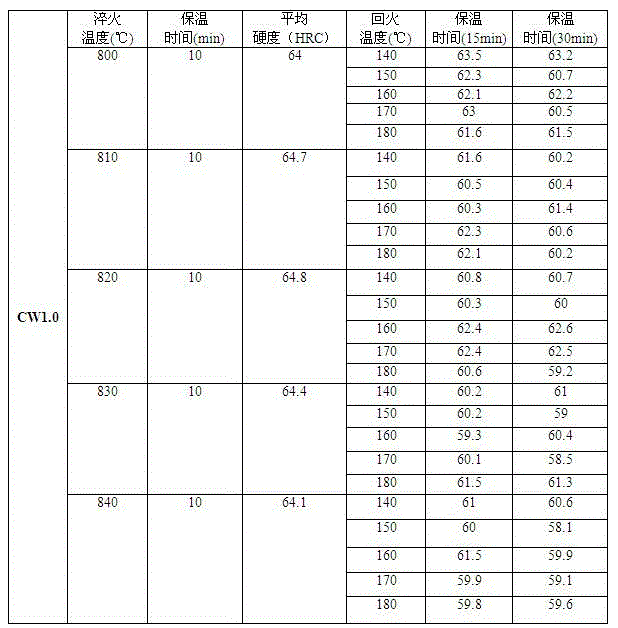

[0027] Select the same batch of CW1.0 high-carbon steel cut shot, heat the CW1.0 high-carbon steel cut shot to 800°C, 810°C, 820°C, 830°C, 840°C, keep it warm for 15 minutes, and quickly immerse it in water to cool it. Its hardness reaches above 64HRC; then tempering treatment, the tempering conditions are: heat the quenched CW1.0 high carbon steel wire cut shot to 140°C, 150°C, 160°C, 170°C, 180°C in a resistance furnace ℃, heat preservation for 15-30min, then cool naturally in the air, and the tempered high-carbon steel wire cut shot is subjected to gas nitriding treatment, and its hardness is tested by Vickers hardness tester. After the CW1.0 high-carbon steel wire cut shot is quenched, tempered and nitrided in sequence, the hardness test results are shown in Table 2.

[0028] The conditions of the above heat treatment are: quenching heating to 800°C, heat preservation for 15min, quenching medium is water; heating to 140°C, 150°C, 160°C, 170°C, 180°C for tempering, heat pre...

Embodiment 2

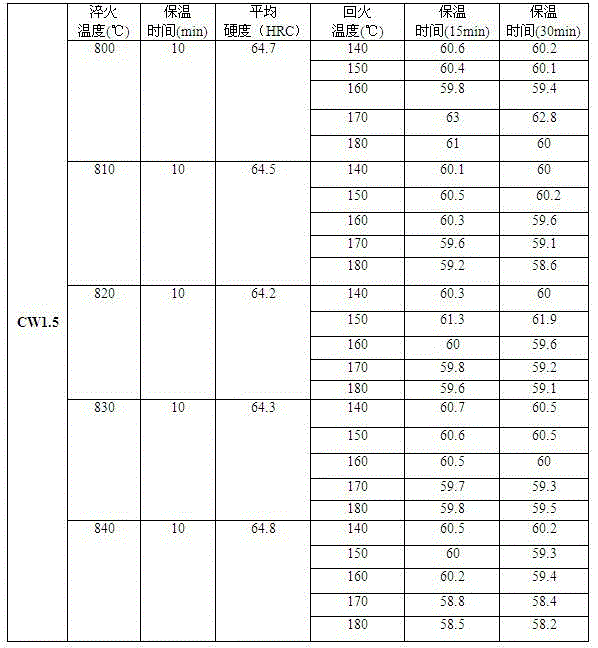

[0038] Select the same batch of CW1.5 high-carbon steel wire cut shots, heat the CW1.5 high-carbon steel wire cut shots to 800°C, 810°C, 820°C, 830°C, 840°C, and then quickly immerse them in water to cool them to make their hardness reach Above 64HRC; then tempering treatment, the tempering conditions are: heat the quenched CW1.0 high-carbon steel wire cut shot to 140°C, 150°C, 160°C, 170°C, 180°C in a resistance furnace, keep warm After 15-30 minutes, cool naturally in the air, and carry out nitriding treatment, and use Vickers hardness tester to test its hardness. After the CW1.5 high-carbon steel wire cut shot is quenched, tempered and nitrided in sequence, the hardness test results are shown in Table 3.

[0039] table 3

[0040]

[0041] It can be seen from Table 3: CW1.5 high-carbon steel wire cut shot is quenched at 800°C, tempered at 170°C for 15 minutes, and can reach 63HRC after nitriding treatment.

Embodiment 3

[0043] Select the same batch of CW1.0 high-carbon steel wire cut shot for the following treatment:

[0044] High-temperature quenching: Quenching the CW1.0 type of high-carbon steel cut shot within the temperature range of 800°C-840°C. The holding time is 15 minutes. After quenching, the hardness reaches above 64HRC, and then tempering;

[0045] Heating to 800°C for quenching, holding for 15 minutes, the quenching medium is water; heating to 140°C, 150°C, 160°C, 170°C, 180°C for tempering, holding for 15-30 minutes, cooling in air.

[0046] Heating to 810°C for quenching, holding for 15 minutes, quenching medium is water; heating to 140°C, 150°C, 160°C, 170°C, 180°C for tempering, holding for 15-30 minutes, cooling in air.

[0047] Heating to 820°C for quenching, holding for 15 minutes, the quenching medium is water; heating to 140°C, 150°C, 160°C, 170°C, 180°C for tempering, holding for 15-30 minutes, cooling in air.

[0048] Heating to 830°C for quenching, holding for 15 mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com