Narrow-hardenability high-temperature fine grain MnCr gear steel and preparation method thereof

A technology of hardenability and gear steel, applied in the direction of temperature control, metal rolling, etc., can solve the problems of narrow hardenability bandwidth of fine-grained gear steel, excessive workpiece size, coarse steel grains, etc., to achieve hardenability. The effect of narrow bandwidth, small deformation and stable production performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0054] Table 1 chemical composition (Wt, %)

[0055] element C Si mn P S Cr Al N O H Example 1 0.19 0.28 1.28 0.010 0.012 1 .25

0.039 0.014 0.0013 0.0001 Example 2 0.20 0.26 1.26 0.012 0.014 1.27 0.038 0.019 0.0012 0.0001 Example 3 0.21 0.23 1.24 0.009 0.015 1.23 0.034 0.017 0.0010 0.0002

[0056] The steel grade of the invention has narrow chemical composition range, low oxygen content and high purity.

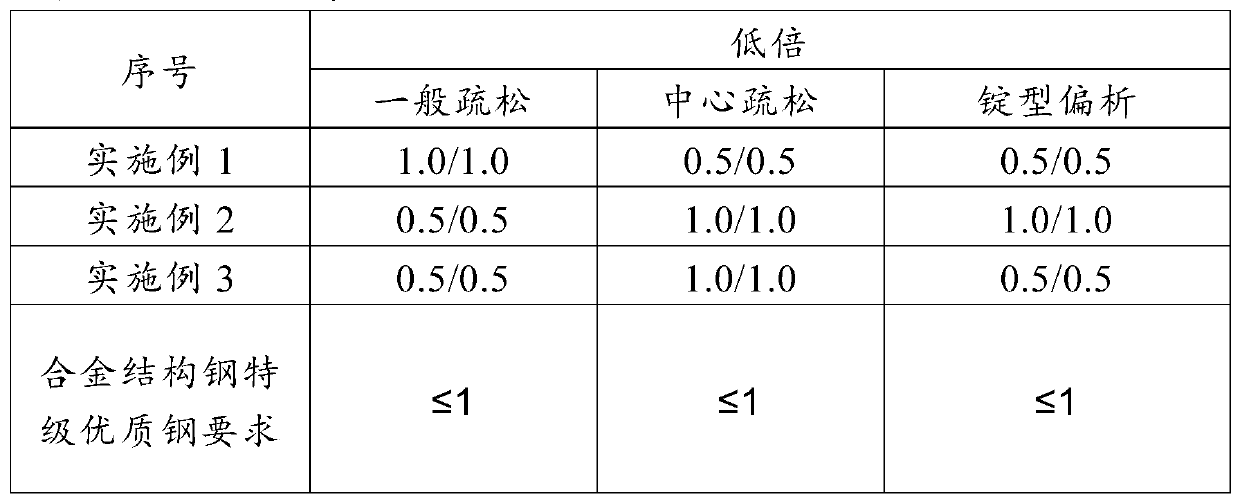

[0057] Table 2 Low-magnification tissue properties

[0058]

[0059] The low-magnification structure level of the steel grade of the present invention is better, reaching the level of the special-grade high-quality alloy structural steel specified in GB / T 3077-2015.

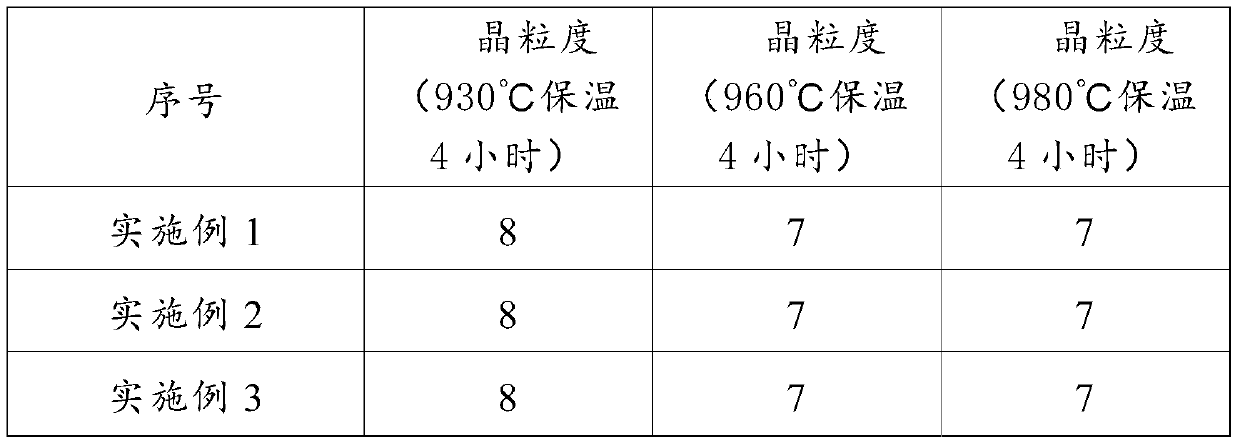

[0060] Table 3 grain size

[0061]

[0062]

[0063] The steel grade of the present invention has a grain size of grade 8 when it is kept at 930° C. for 4 hours, and the grain size is fine and uniform, meeting the requirements of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com