High temperature carburizing gear steel with fine grains and narrow hardenability bandwidth

A high-temperature carburizing and hardenability technology, applied in the field of carburizing gear steel, can solve the problems of no public stability control, no provision of high-temperature carburizing gear steel, etc., so as to achieve difficult mass production application, less performance fluctuation, and save raw materials cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

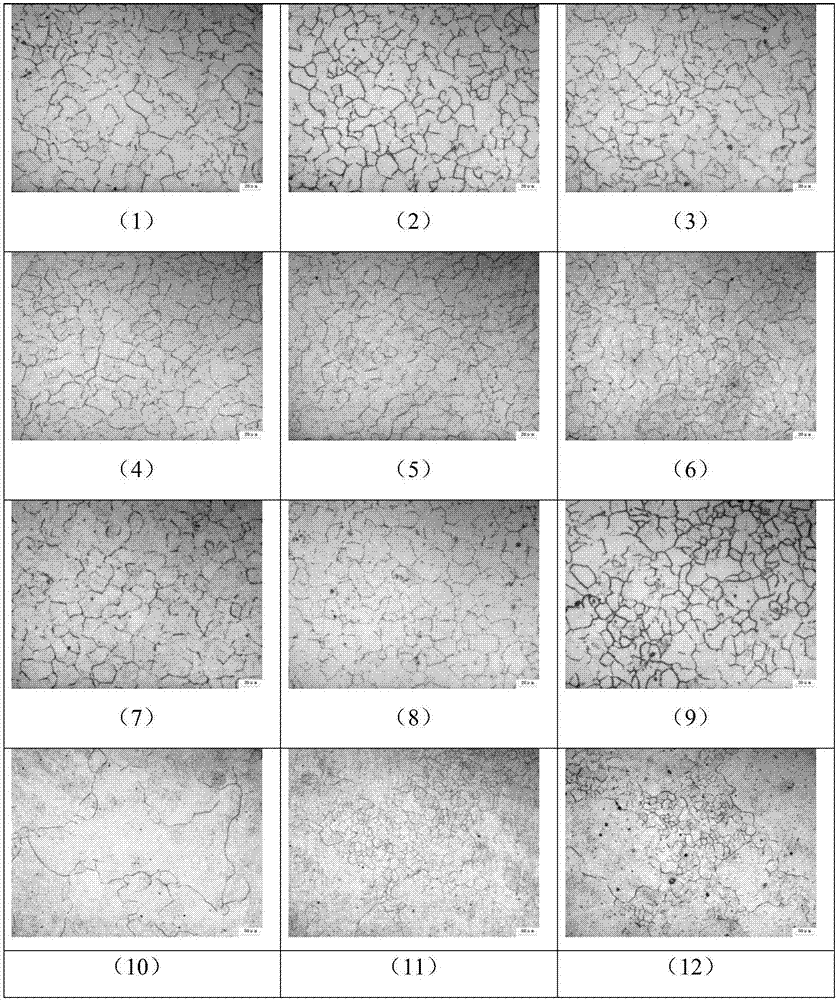

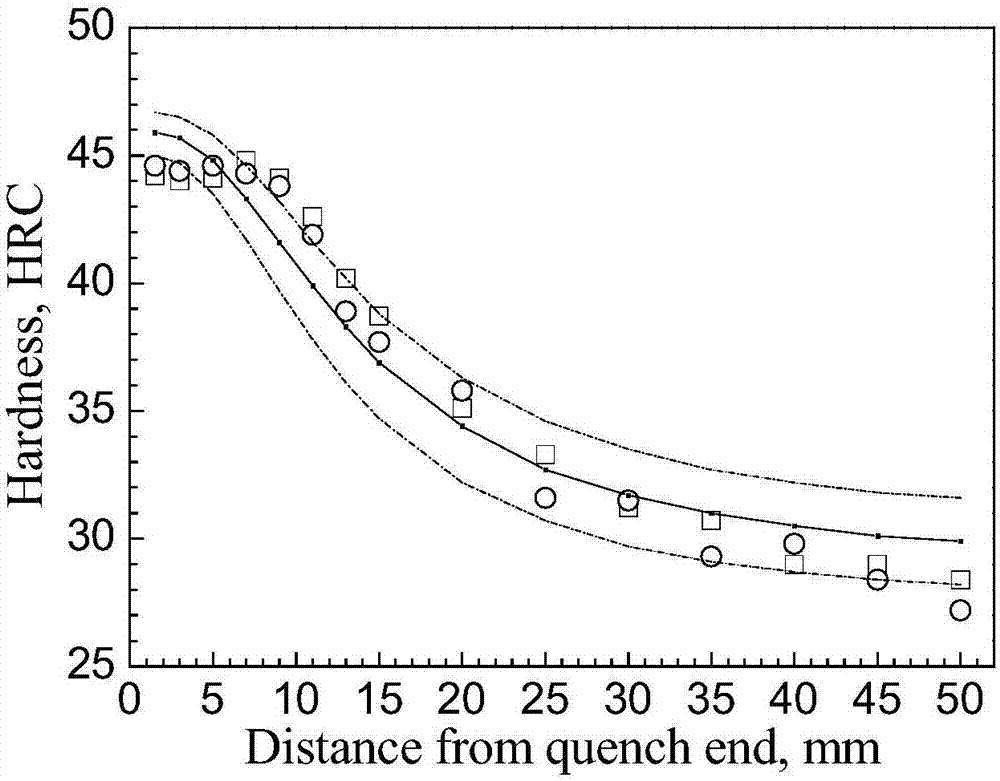

[0021] Example 1: Invention steel with heat number 1 (C, Si, Mn, Cr, and Mo components are on the line, Al, N is on the lower limit) and comparison steel hot-rolled bar samples are compared at 980 ° C for 6 hours after high-temperature carburization. Grain size of original austenite, take another hardenability sample, normalize at 925°C / 1 hour, and end quench at 925°C to compare its hardenability bandwidth.

Embodiment 2

[0022] Example 2: Invention steel with heat number 2 (C, Si, Mn, Cr, and Mo components on the line, Al, N partial to the middle limit) and comparison steel hot-rolled bar samples were compared at 980°C for 6 hours after high-temperature carburization For the original austenite grain size, take another hardenability sample, normalize at 925°C / 1 hour, and end-quench at 925°C to compare the hardenability bandwidth.

Embodiment 3

[0023] Example 3: Invention steel with heat number 3 (C, Si, Mn, Cr, Mo components on the line, Al, N partial upper limit) and comparison steel hot-rolled bar samples were compared at 1000 ° C for 6 hours after high-temperature carburization Grain size of original austenite, take another hardenability sample, normalize at 925°C / 1 hour, and end quench at 925°C to compare its hardenability bandwidth.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com