Patents

Literature

195results about How to "Reduce risk factor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

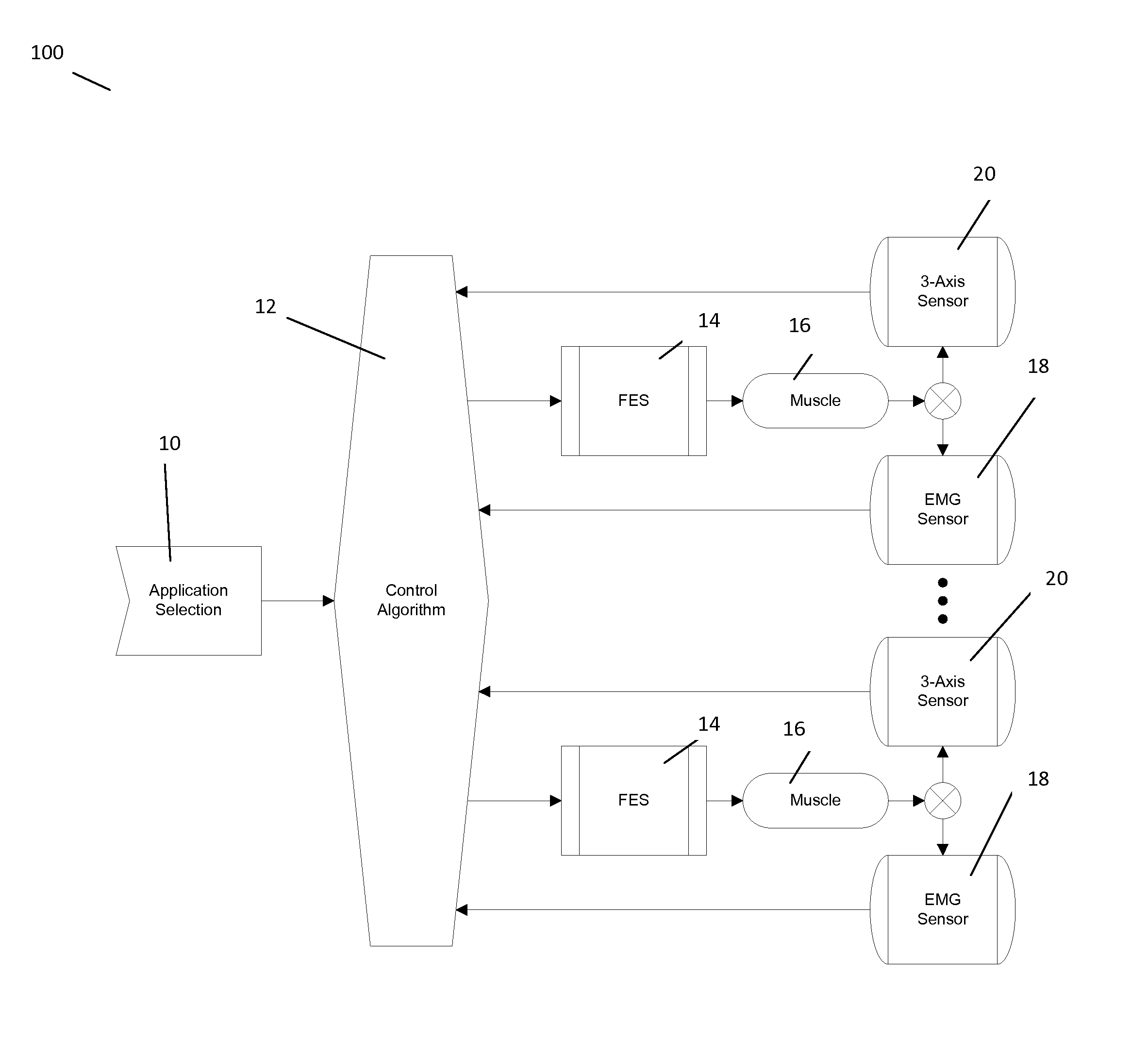

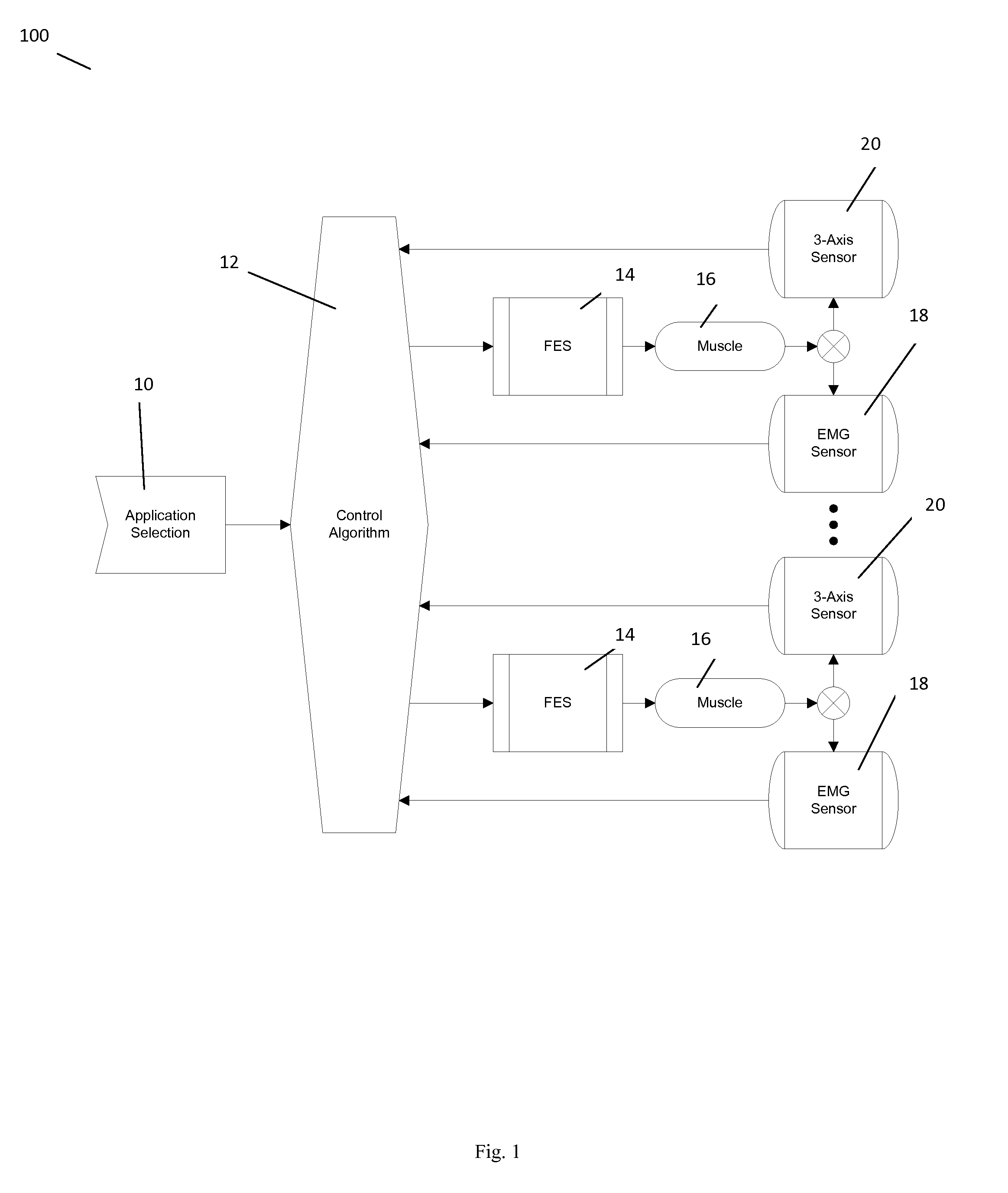

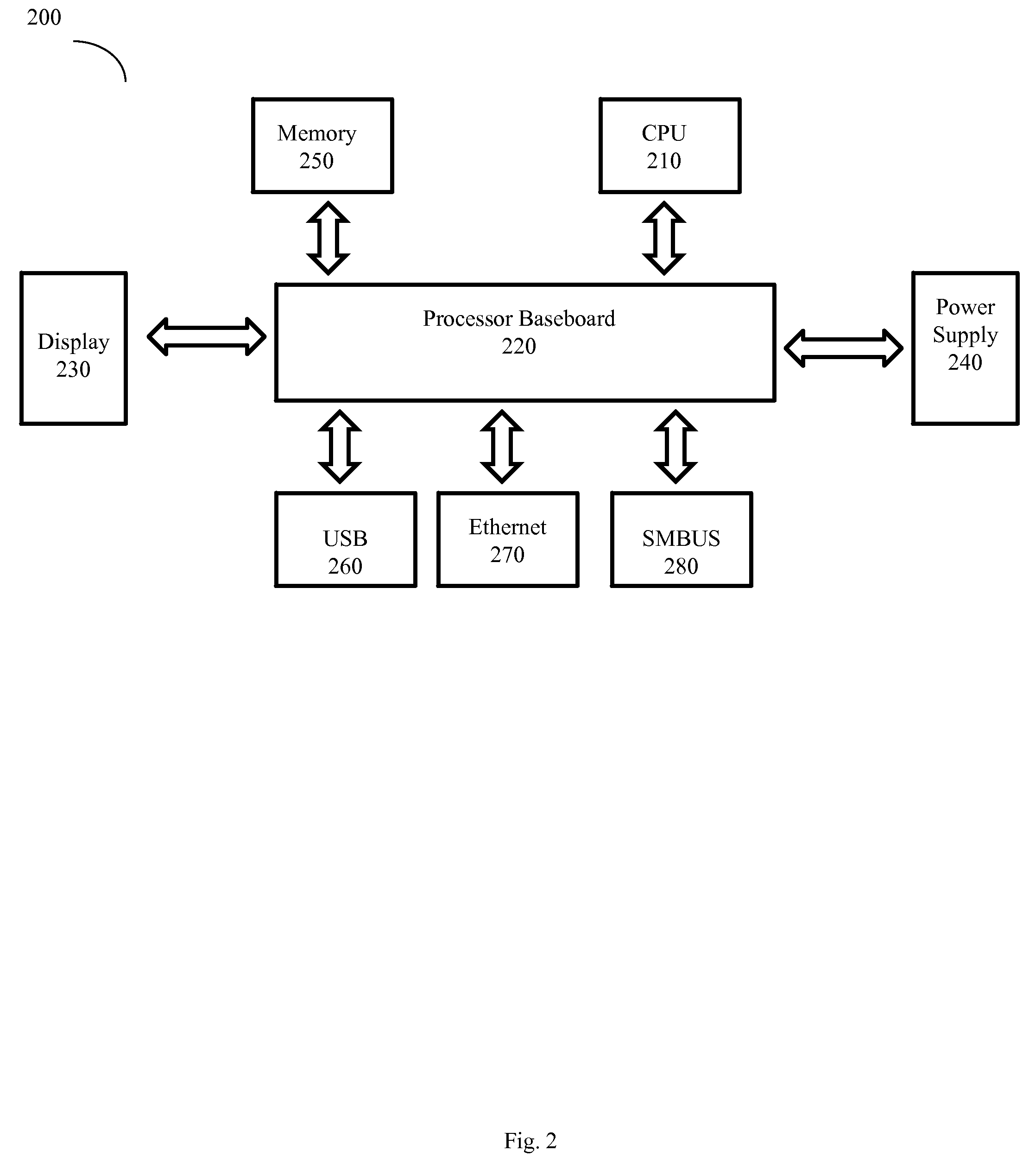

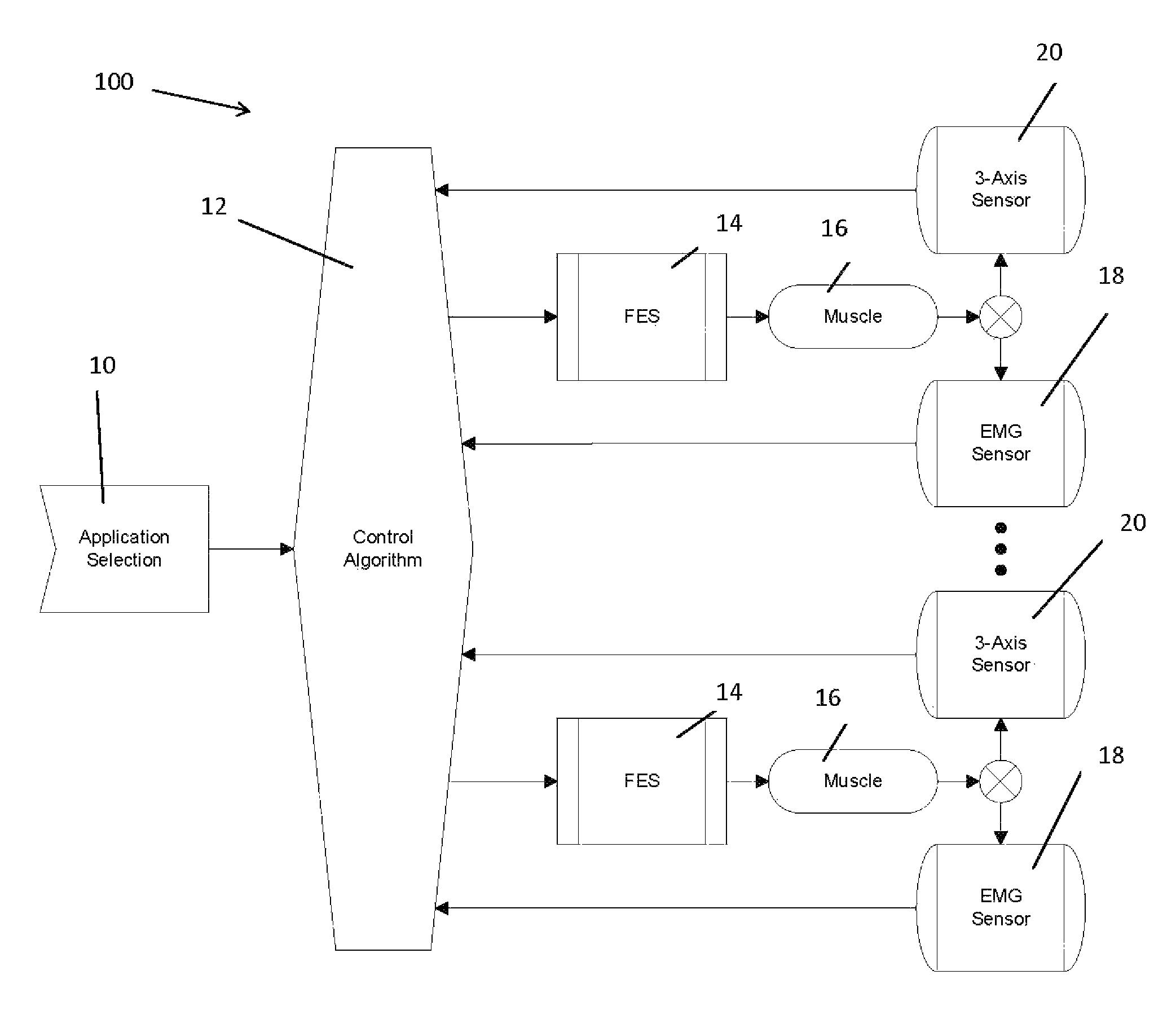

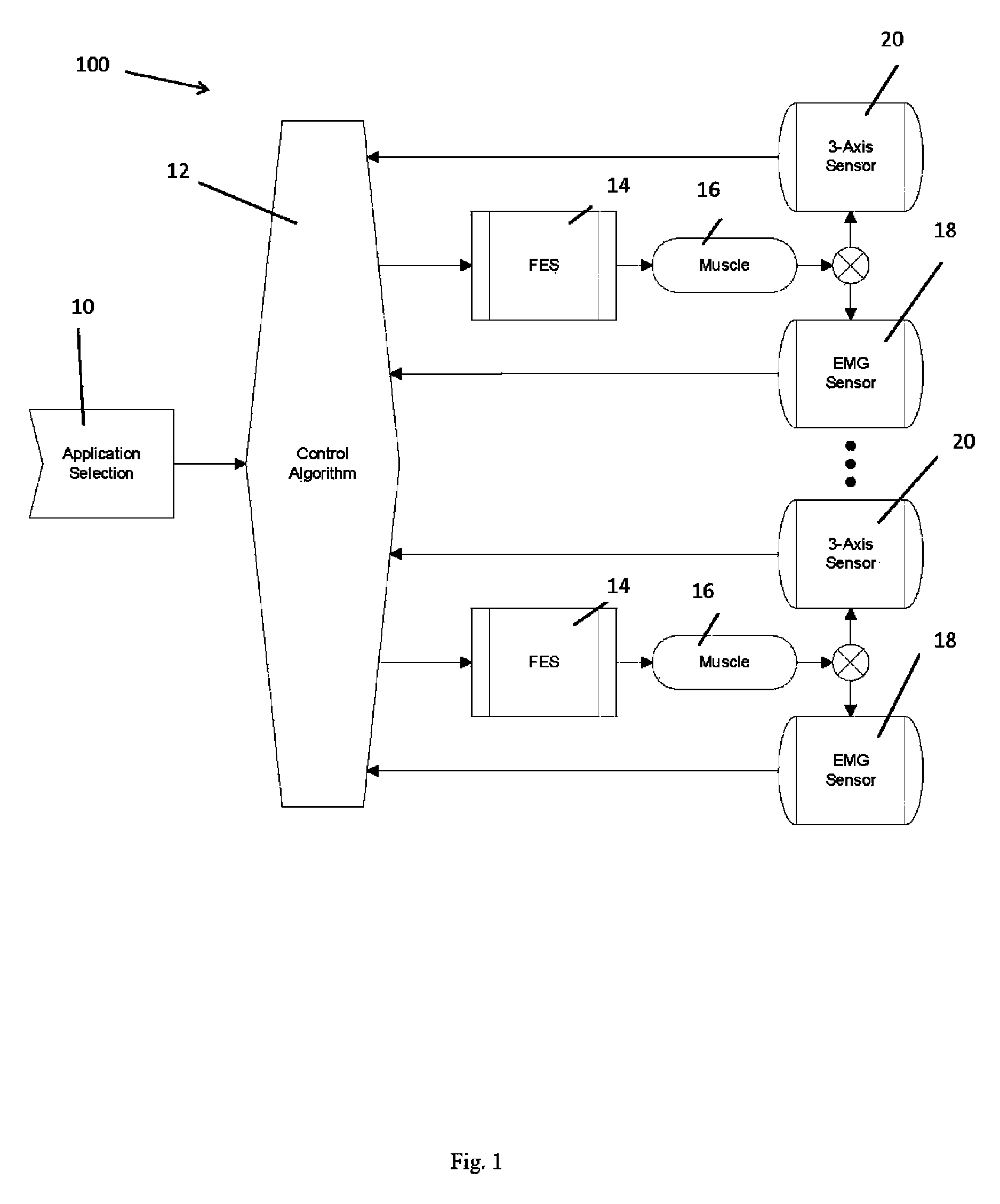

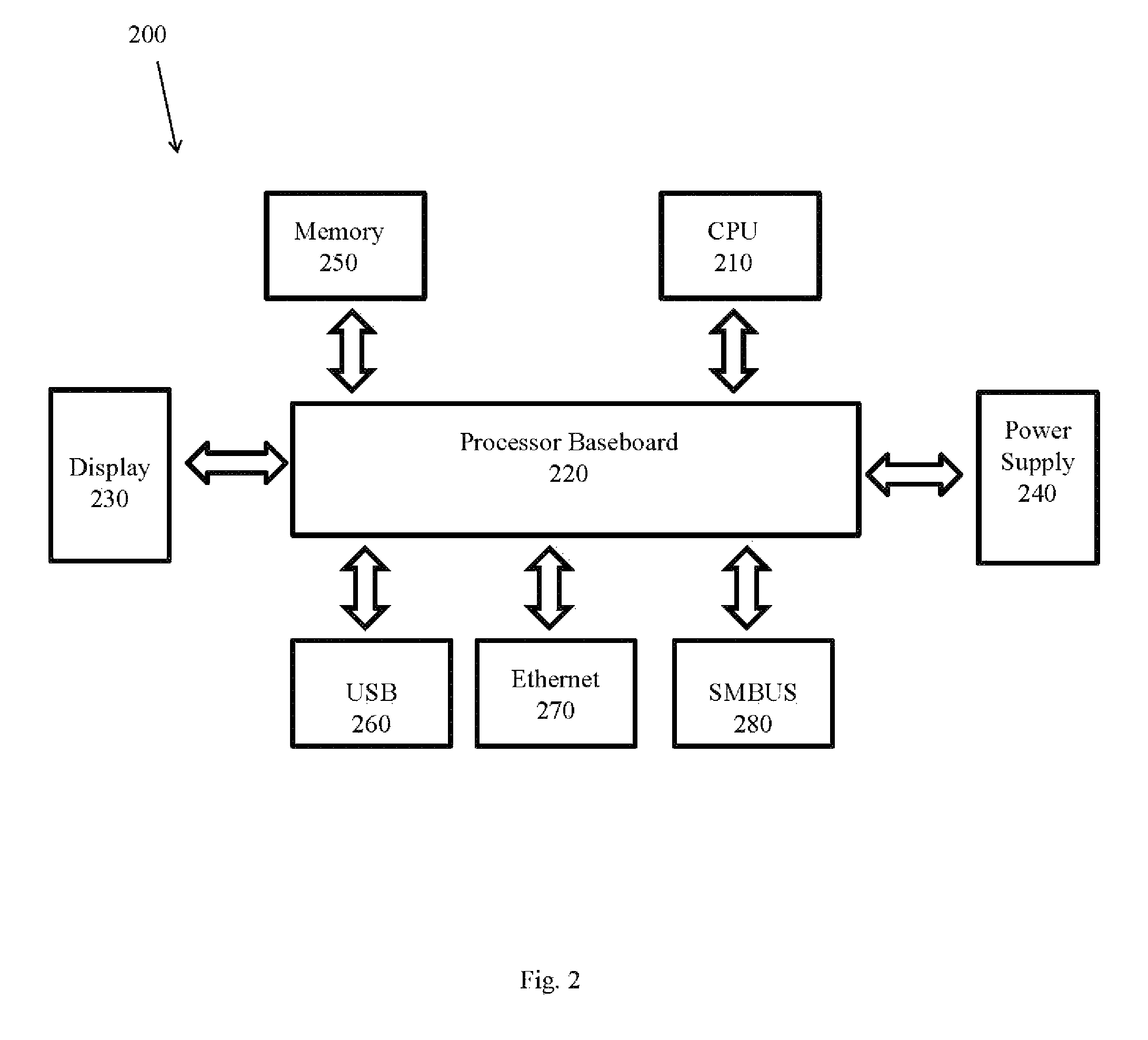

Universal closed-loop electrical stimulation system

ActiveUS20130123568A1Restore motor functionReduce hyperlipidemiaElectrotherapyMagnetotherapy using coils/electromagnetsNervous systemClosed loop

A universal closed-loop functional electrical stimulation system comprising at least one electrode assembly adapted to deliver an electrical stimulation signal to the central nervous system, peripheral nervous system, or muscles of a user, a sensor system adapted to detect a mechanical response to a muscle stimulation signal of at least one muscle associated with a muscle group stimulated through the nervous system or proximate to the electrode assembly. An electrical stimulation device operably coupled to at least one electrode assembly and the sensor system, the electrical stimulation device including a control system to automatically receive feedback from at least one characteristic of the muscle from the detected muscle response and adjust at least one parameter of the muscle stimulation signal in real-time and in response thereto and a programmed microprocessor for controlling said electrical stimulation and receiving input from said sensor system.

Owner:HAMILTON MARILYN J +1

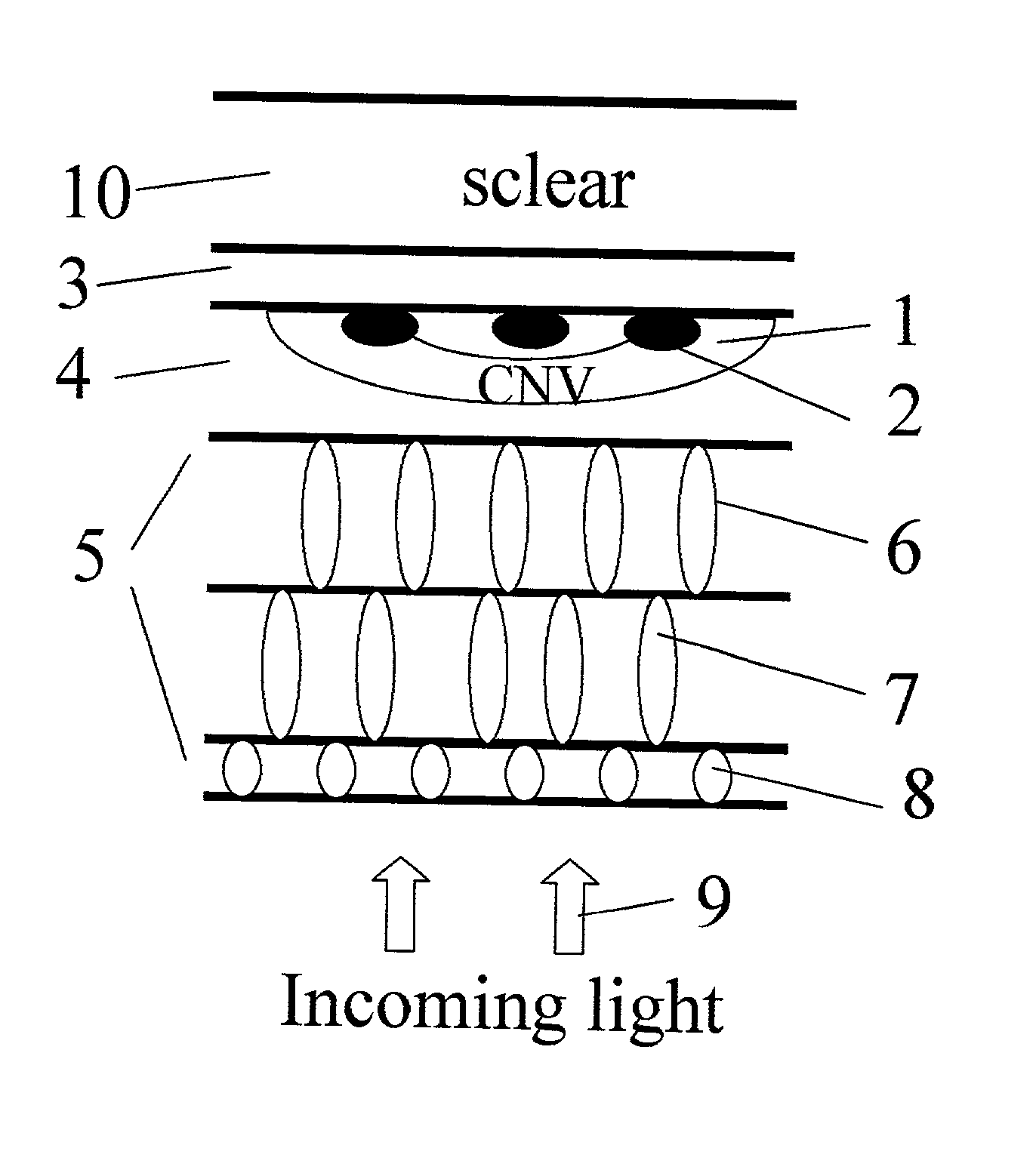

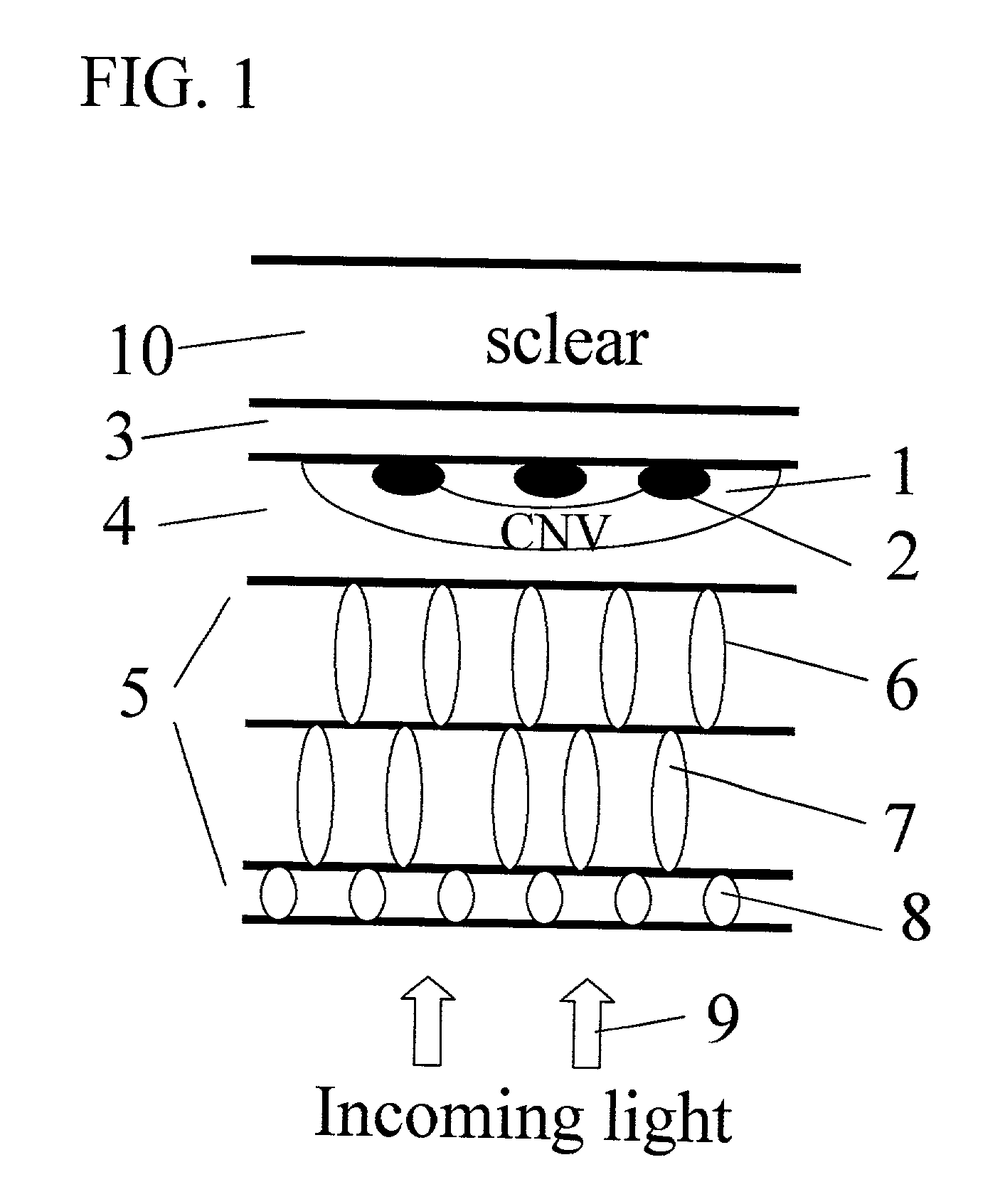

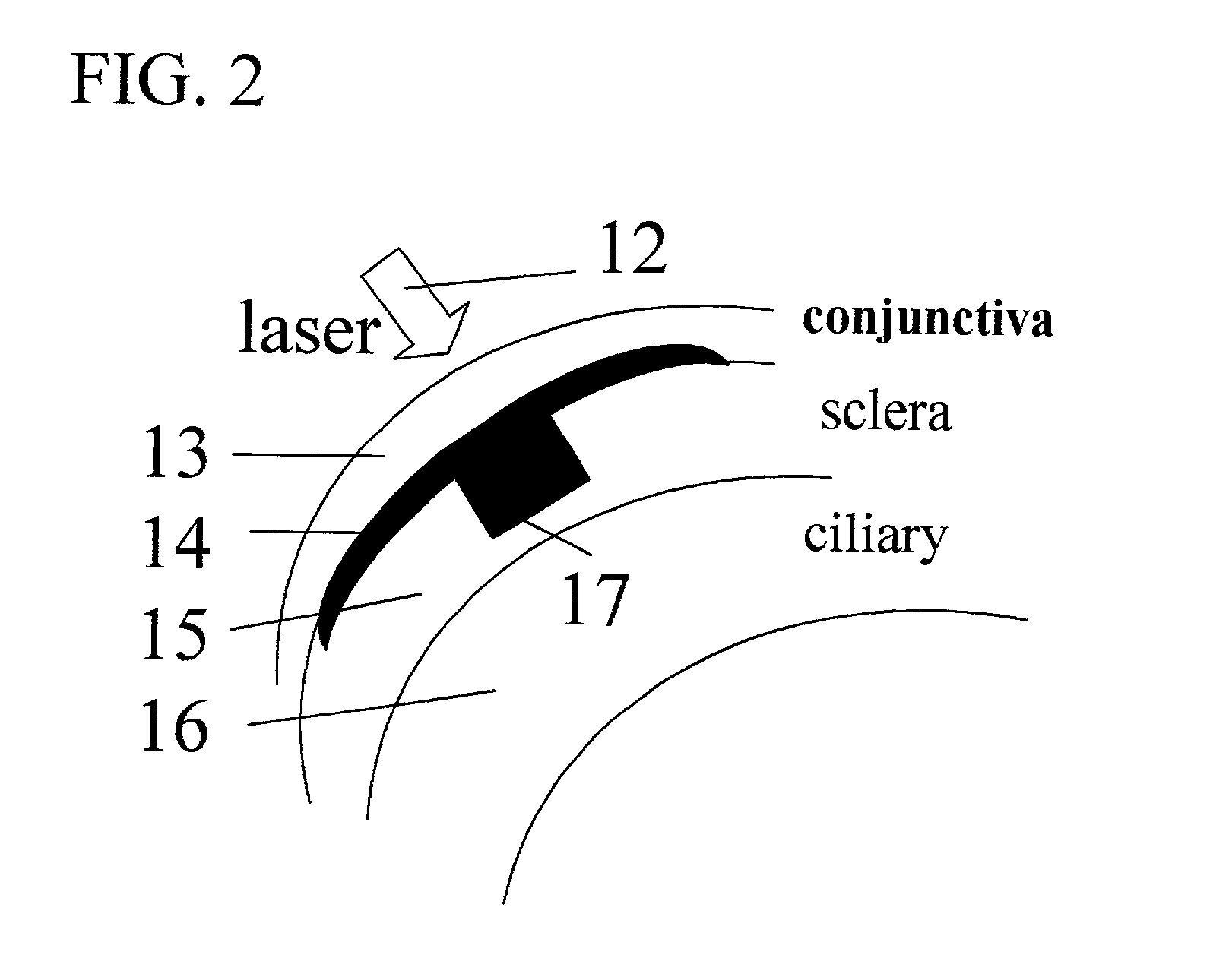

Apparatus and methods for prevention of age-related macular degeneration and other eye diseases

InactiveUS20030105456A1Minor side effectsIncrease flexibilityLaser surgerySurgical instruments for heatingRadio frequencyLaser beams

Surgical apparatus and surgical methods are proposed for the prevention of age-related macular degeneration (AMD) and choroidal neovascularization (CNV), and other eye diseases such as glaucoma by removal of the sclera tissue to reduce its rigidity and increase the flood flow and decrease pressure in the choriocapillaris. The disclosed preferred embodiments of the system consists of a tissue ablation means and a control means of ablation patterns and a fiber delivery unit. The basic laser beam includes UV lasers and infrared lasers having wavelength ranges of (0.15-0.36) microns and (0.5-3.2) microns and diode lasers of about 0.98, 1.5 and 1.9 microns. AMD and CNV are prevented, delayed or reversed by using an ablative laser to ablate the sclera tissue in a predetermined patterns outside the limbus to increase the elasticity of the sclera tissue surrounding the eye globe The surgery apparatus also includes non-laser device of radio frequency wave, electrode device, bipolar device and plasma assisted device

Owner:LIN J T

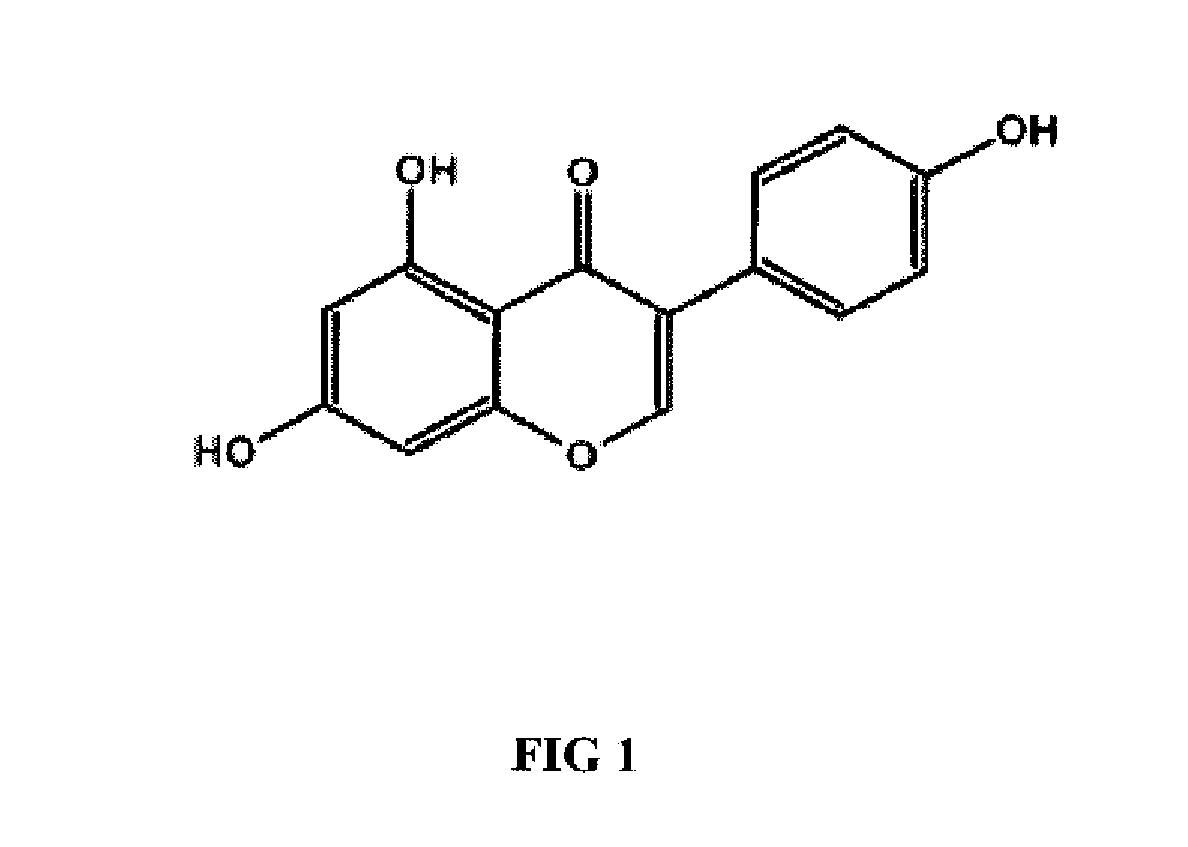

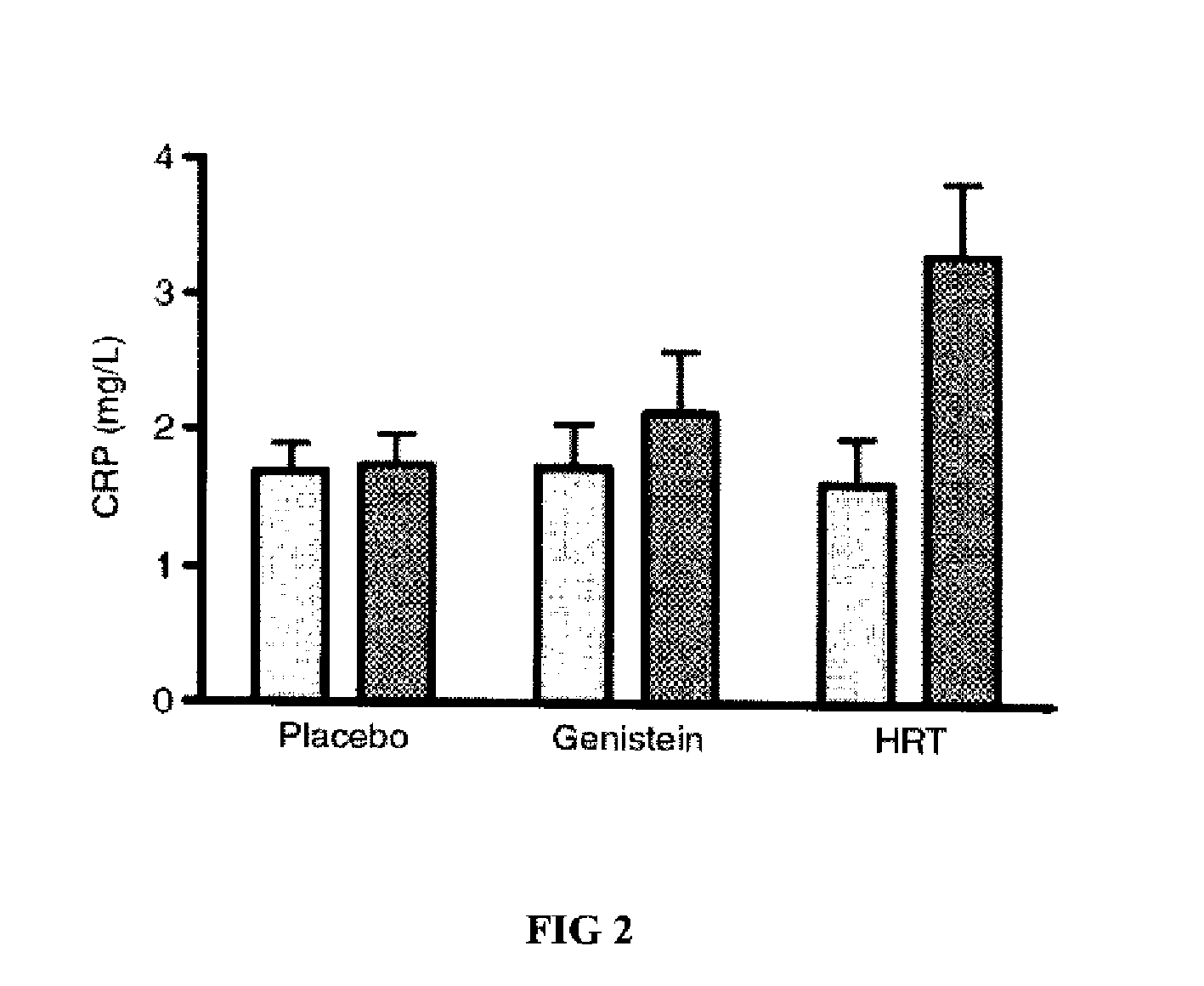

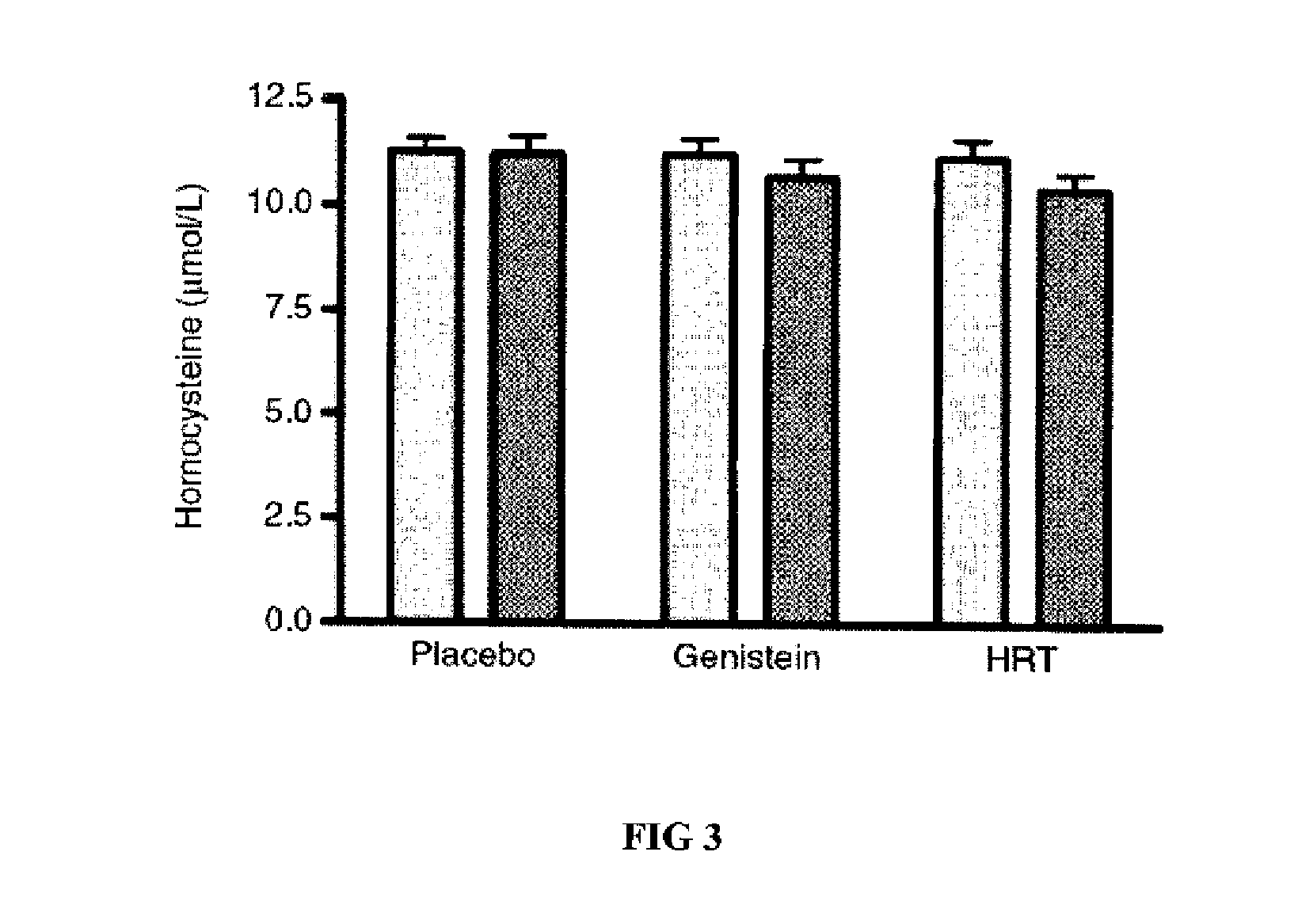

Genistein modulated reduction of cardiovascular risk factors

InactiveUS20070207225A1Reducing cardiovascular risk factorReduce risk factorBiocideAnimal repellantsFasting glucoseFibrinogen

The disclosed methods and compositions for reducing cardiovascular risk factors in mammals generally includes using genistein to modulate various inflammatory and cardiovascular risk markers including: homocysteine, C-reactive protein, fibrinogen, sex hormone-binding globulin, fasting glucose, insulin, insulin resistance, and osteoprotegerin.

Owner:PRIMUS PHARM INC

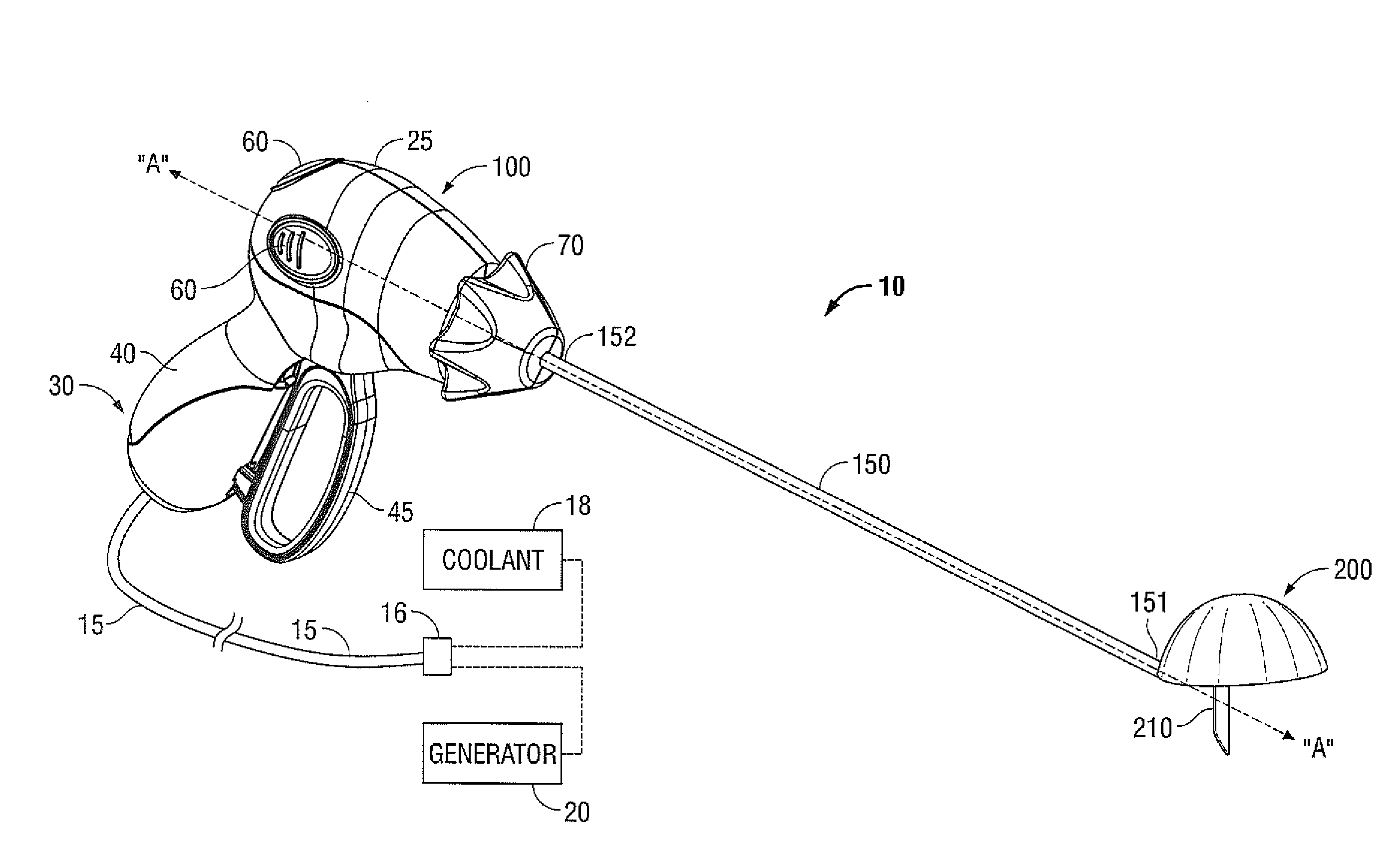

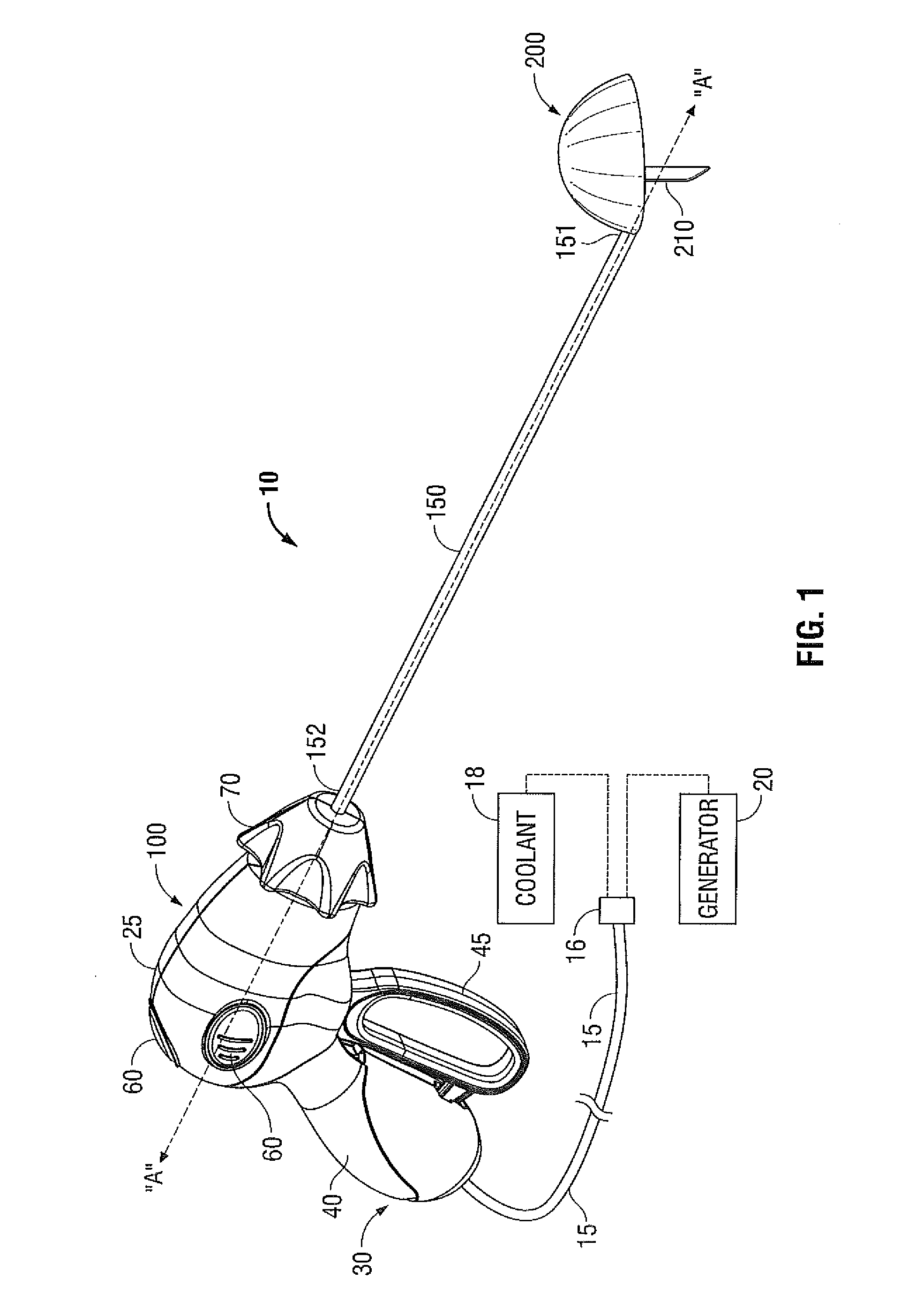

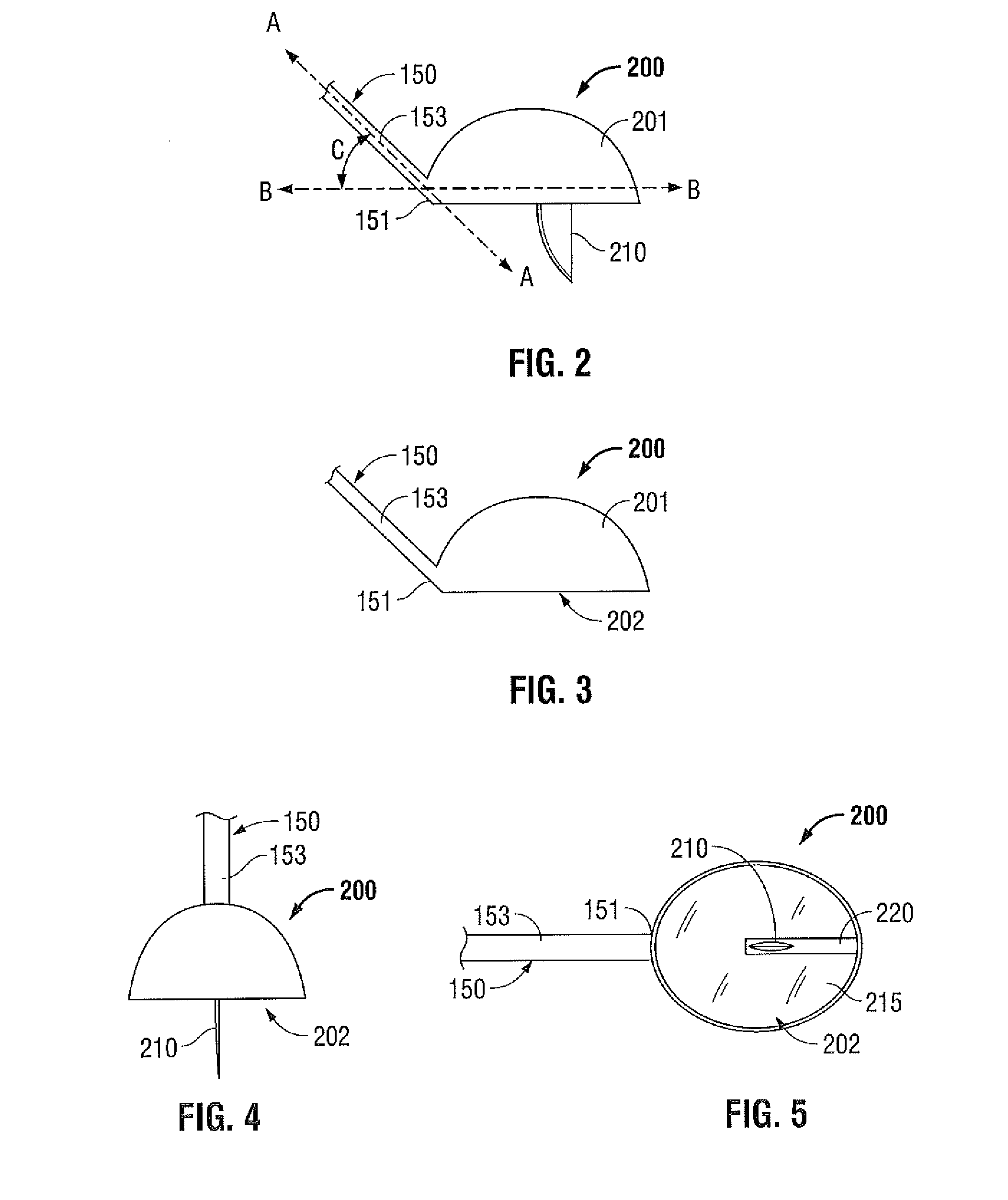

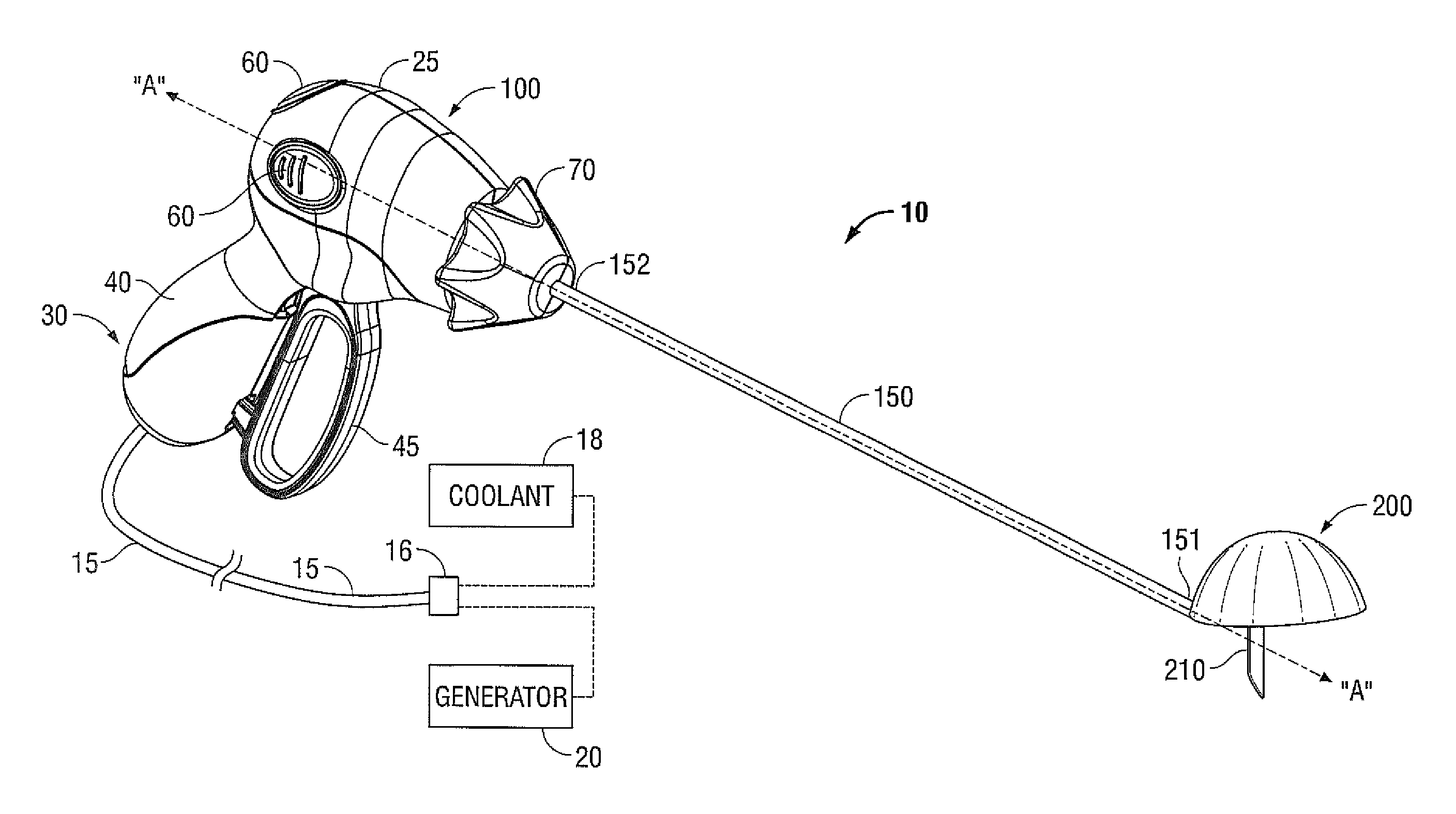

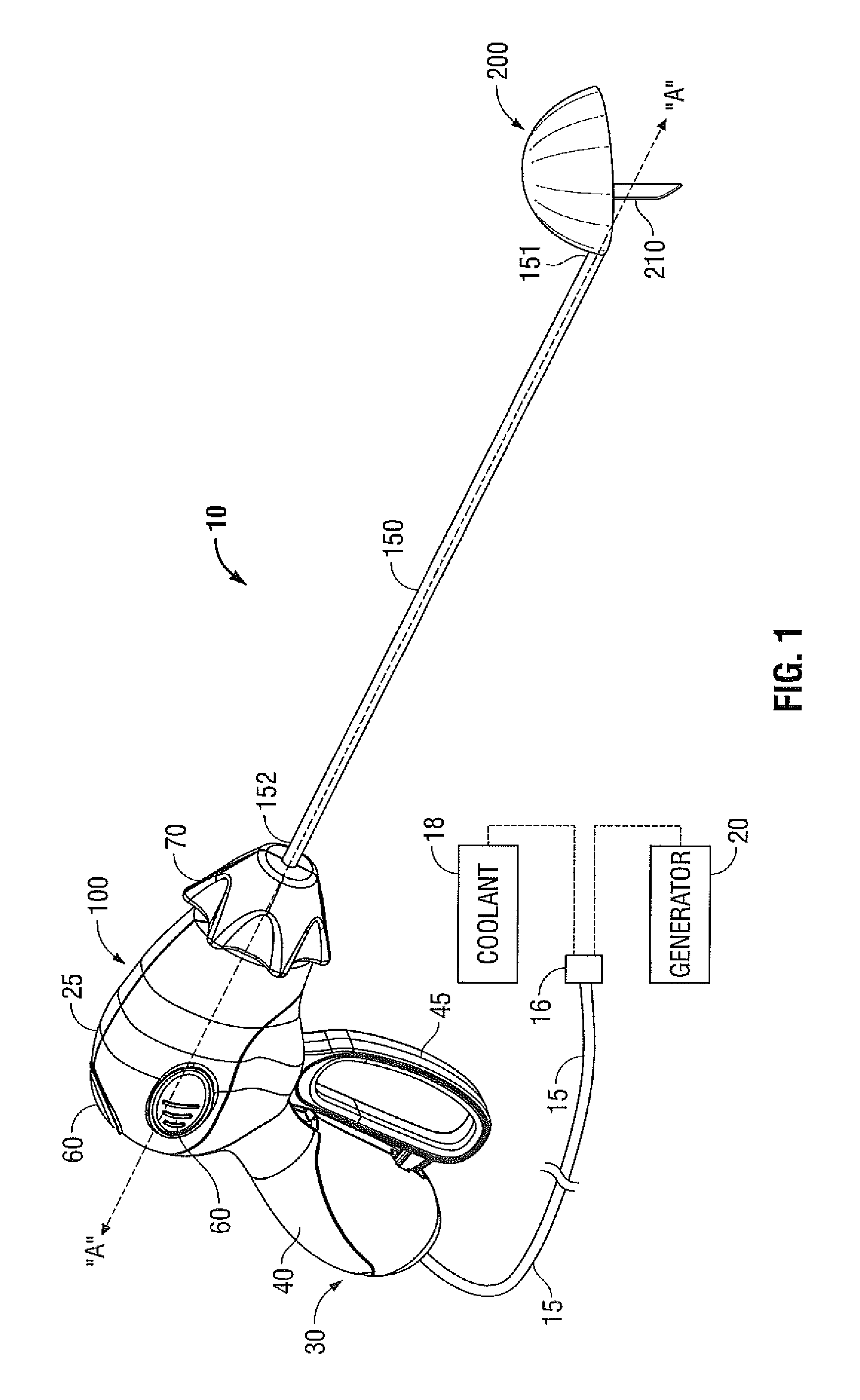

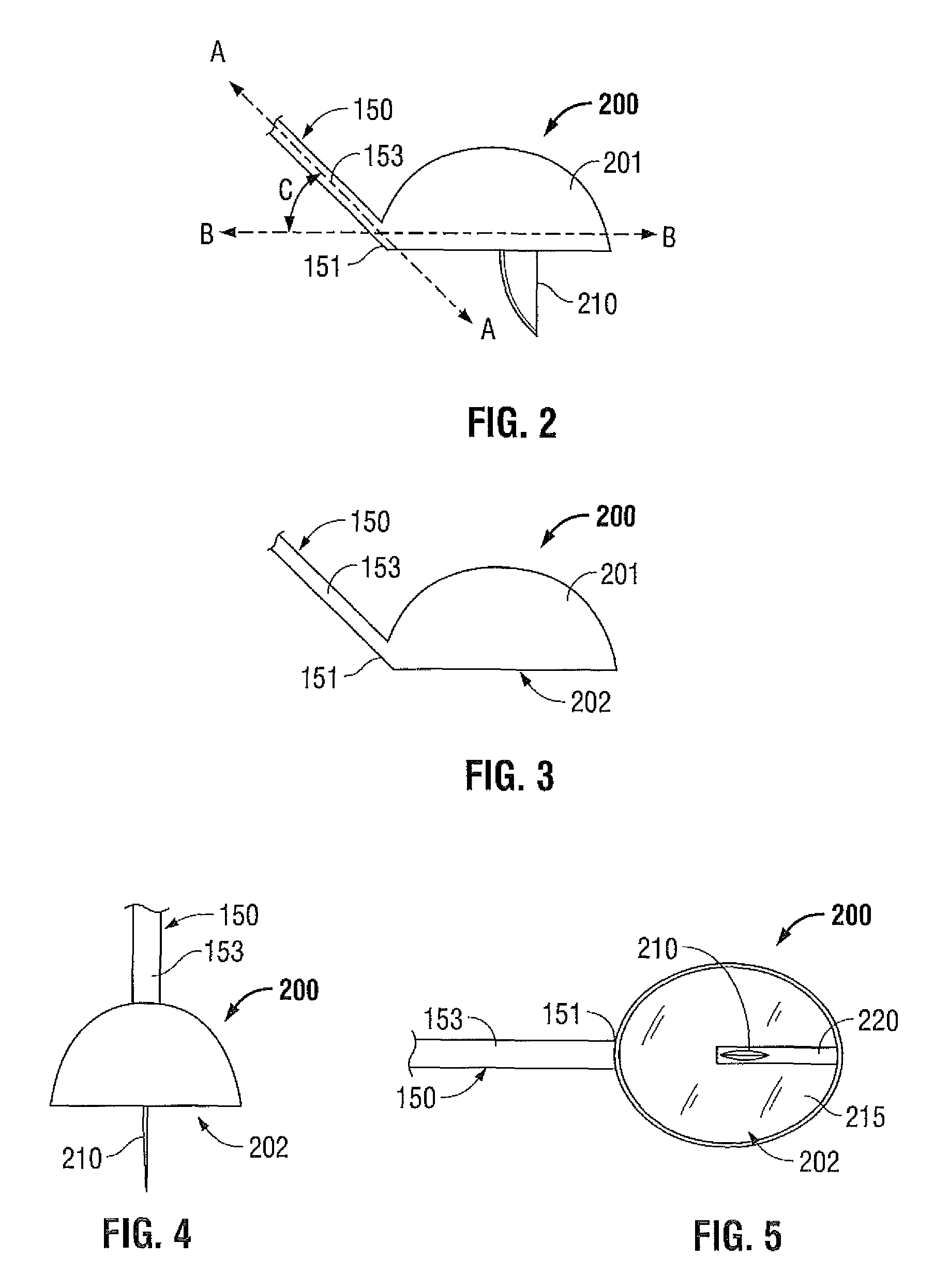

Microwave Surface Coagulator with Retractable Blade

ActiveUS20110238053A1Shorten operation timeDissect the targeted tissueIncision instrumentsCatheterMicrowaveCatheter

An ablation instrument having an ergonomic handle that includes an actuator adapted to selectively extend and retract a blade that is pivotably mounted within an aperture assembly coupled to the housing by a shaft. The shaft extends distally from the handle and includes a coaxial feedline, a wire conduit disposed along a longitudinal axis of the shaft, and a pull wire disposed within the wire conduit and having a proximal and a distal end, wherein a proximal end of the pull wire is operably coupled to the actuator. The aperture assembly is coupled to a distal end of the shaft and includes a reflector having a closed upper portion, and an open lower portion from which the blade may be extended for use. Also disclosed is an ablation system that includes the above-described ablation instrument, a source of ablation energy, and optionally, a source of coolant for cooling the shaft and aperture assembly.

Owner:TYCO HEALTHCARE GRP LP

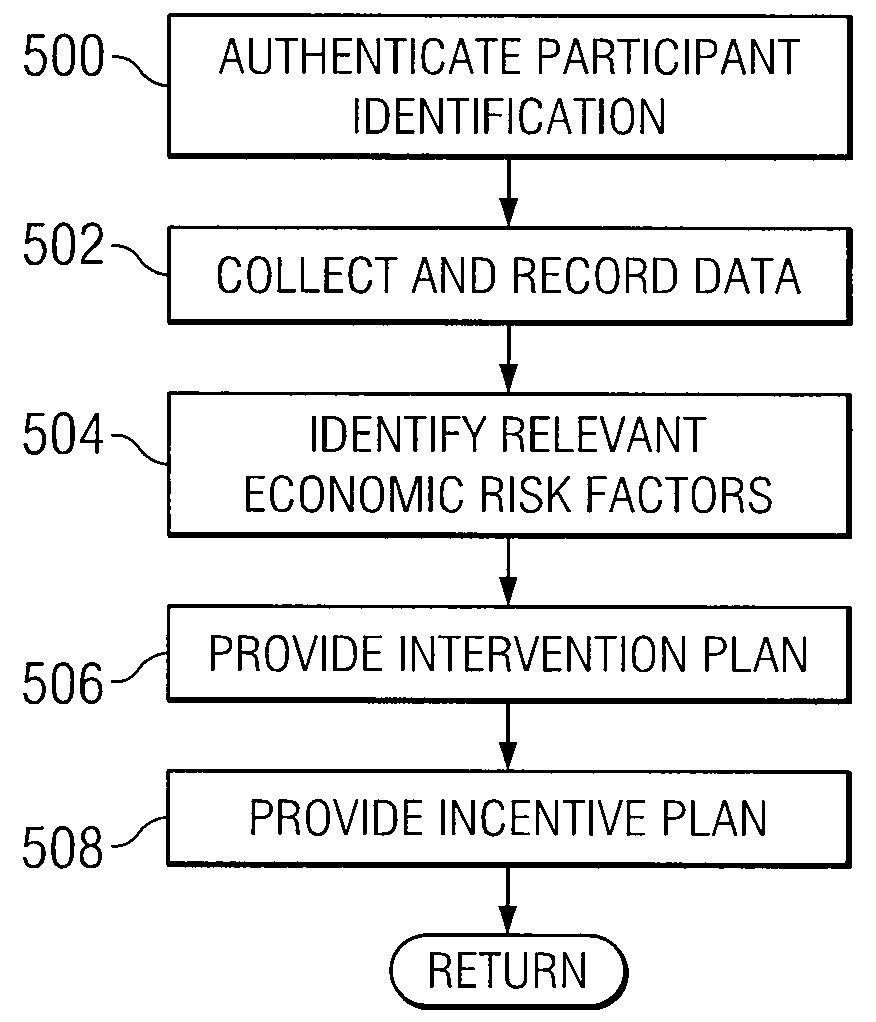

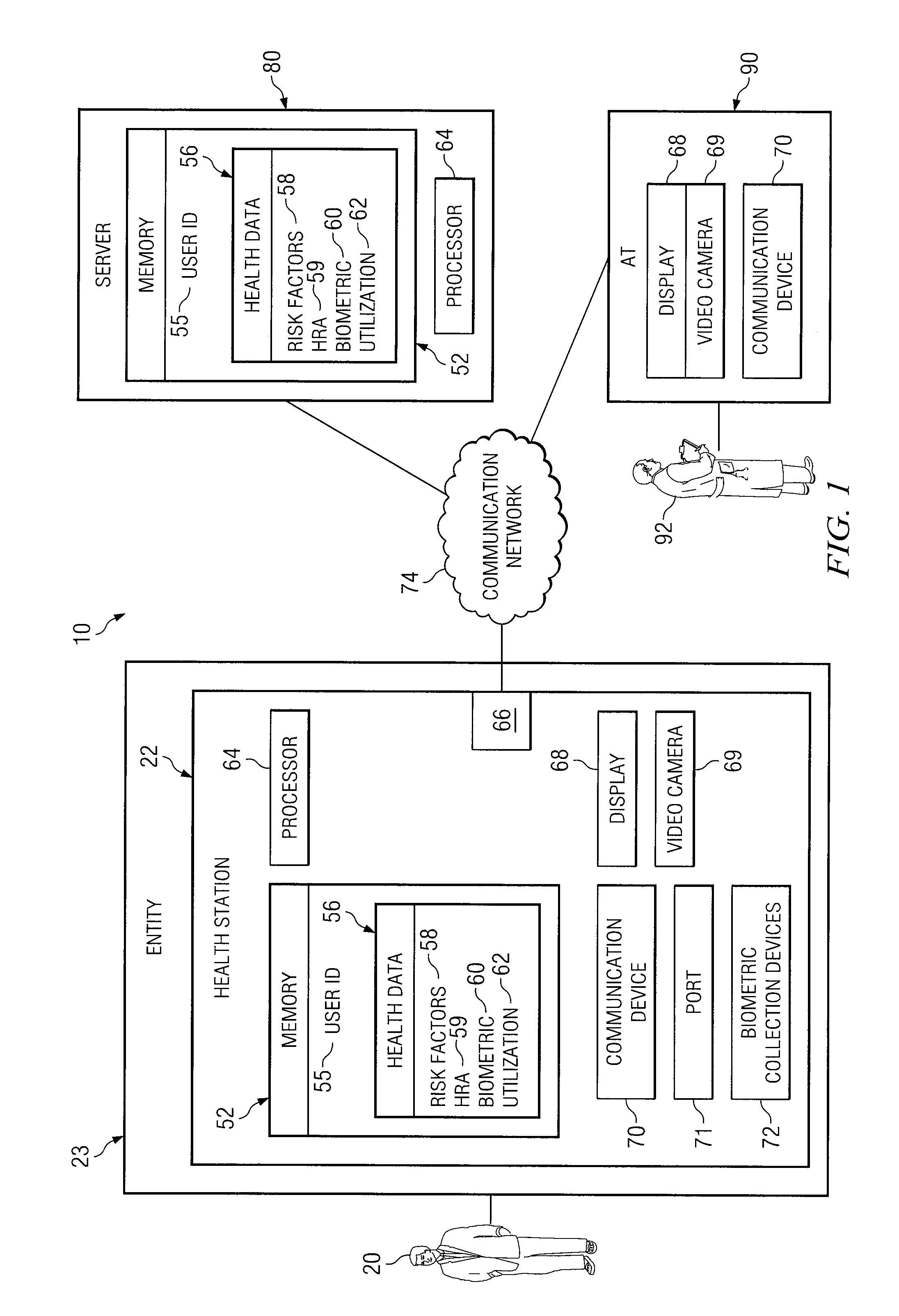

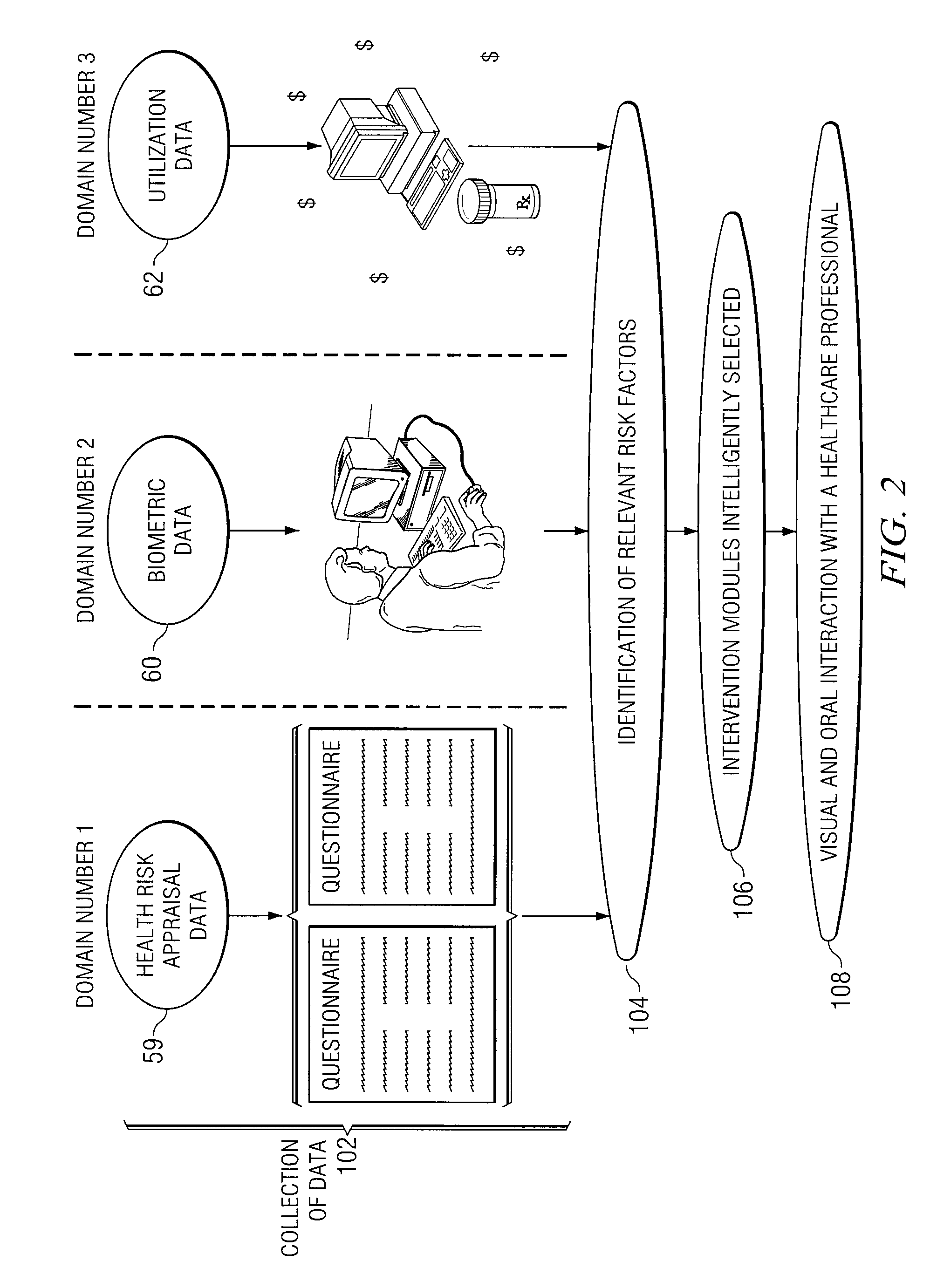

System and Method for Modifying Risk Factors by a Healthcare Individual at a Remote Location

InactiveUS20080306763A1Efficient and cost-effectiveReduce probabilityMedical communicationData processing applicationsLive videoRisk factor

A method for modifying risk factors by a healthcare individual at a remote location includes interacting with a participant at a remote location to obtain health-related data, such that the interaction occurs during a live video session. The healthcare individual determining an intervention plan to the participant based on the health-related data. The healthcare individual communicating data associated with the intervention plan to the participant during the live video session.

Owner:JAMES TERRY L

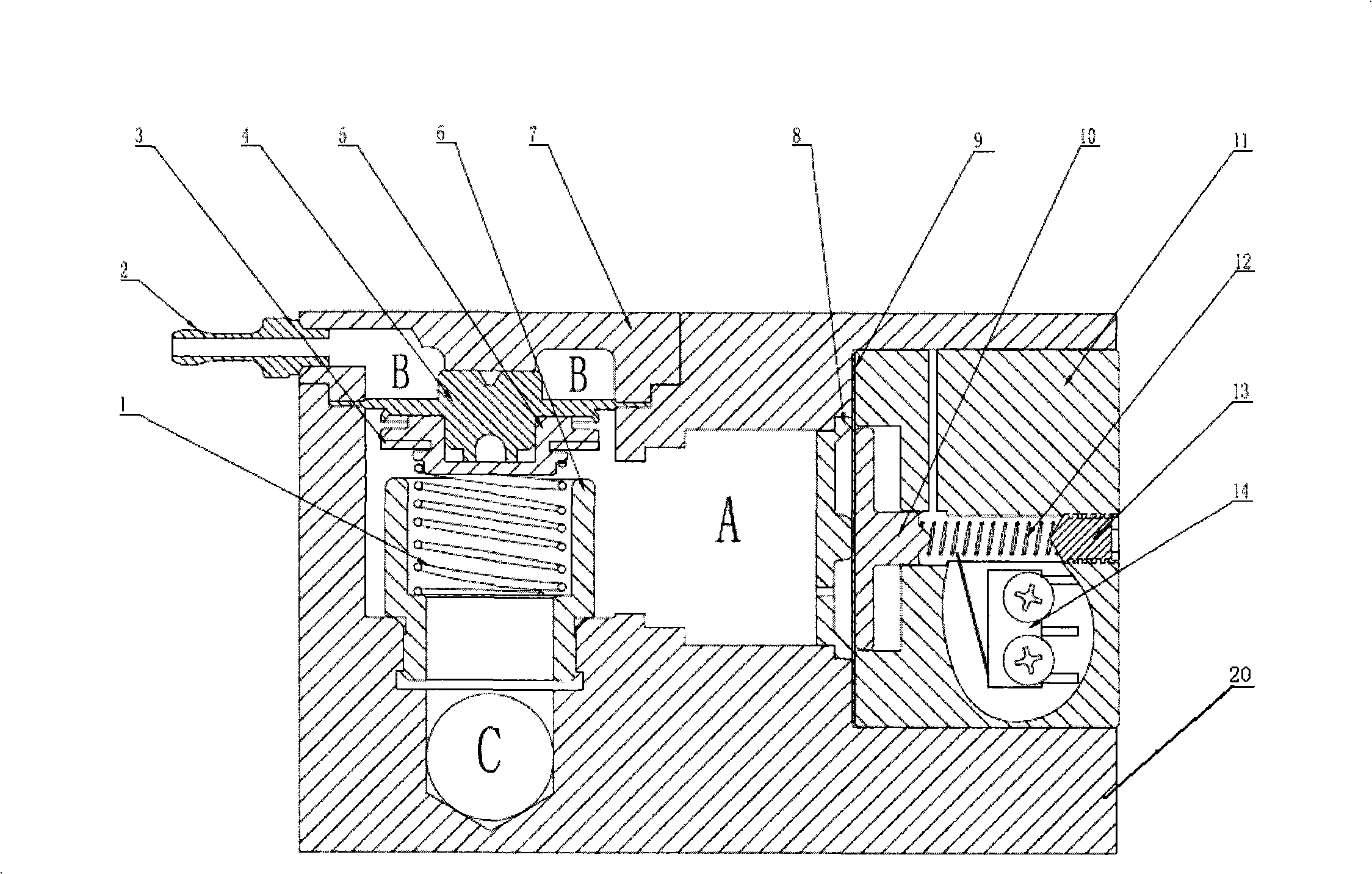

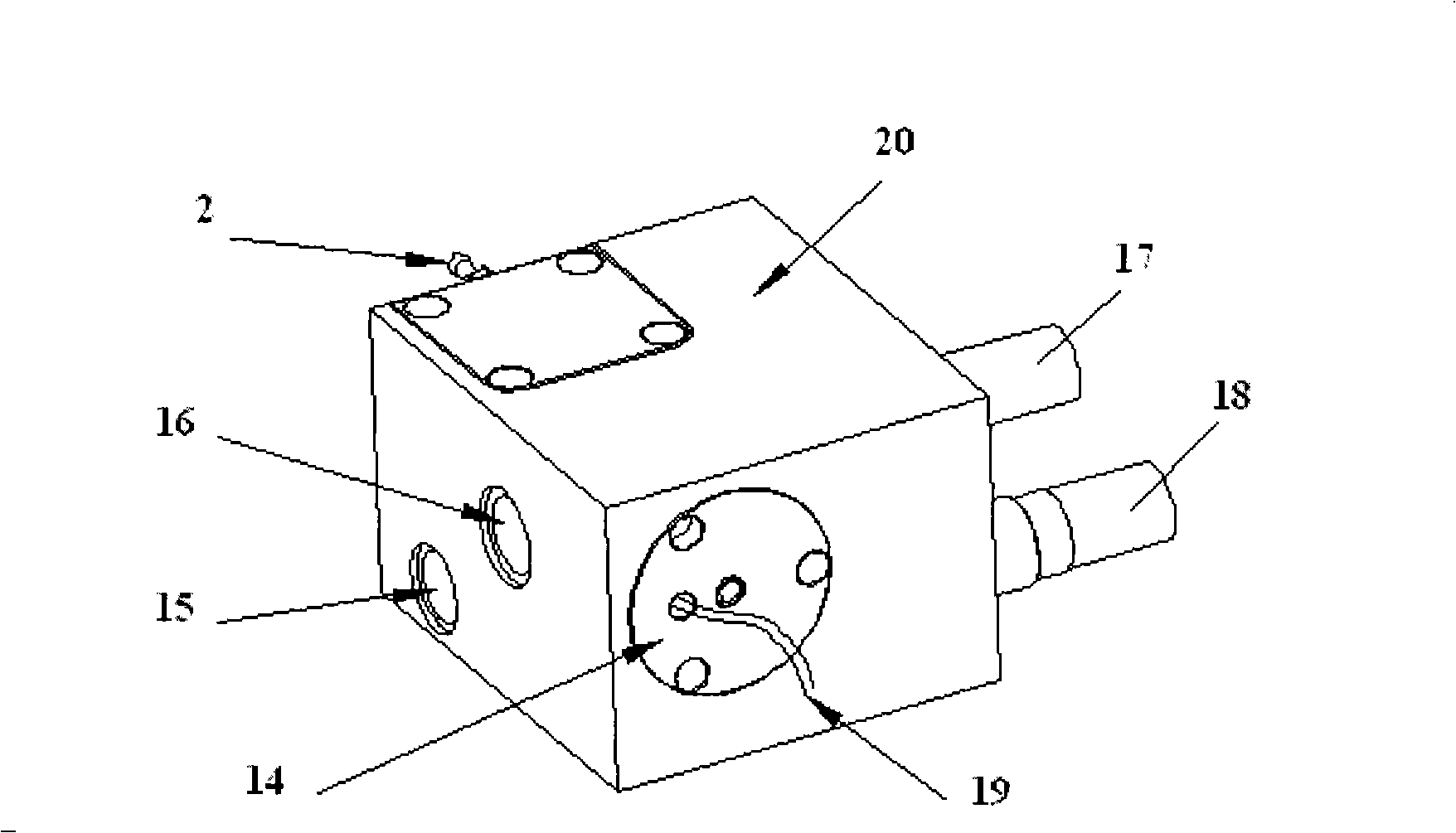

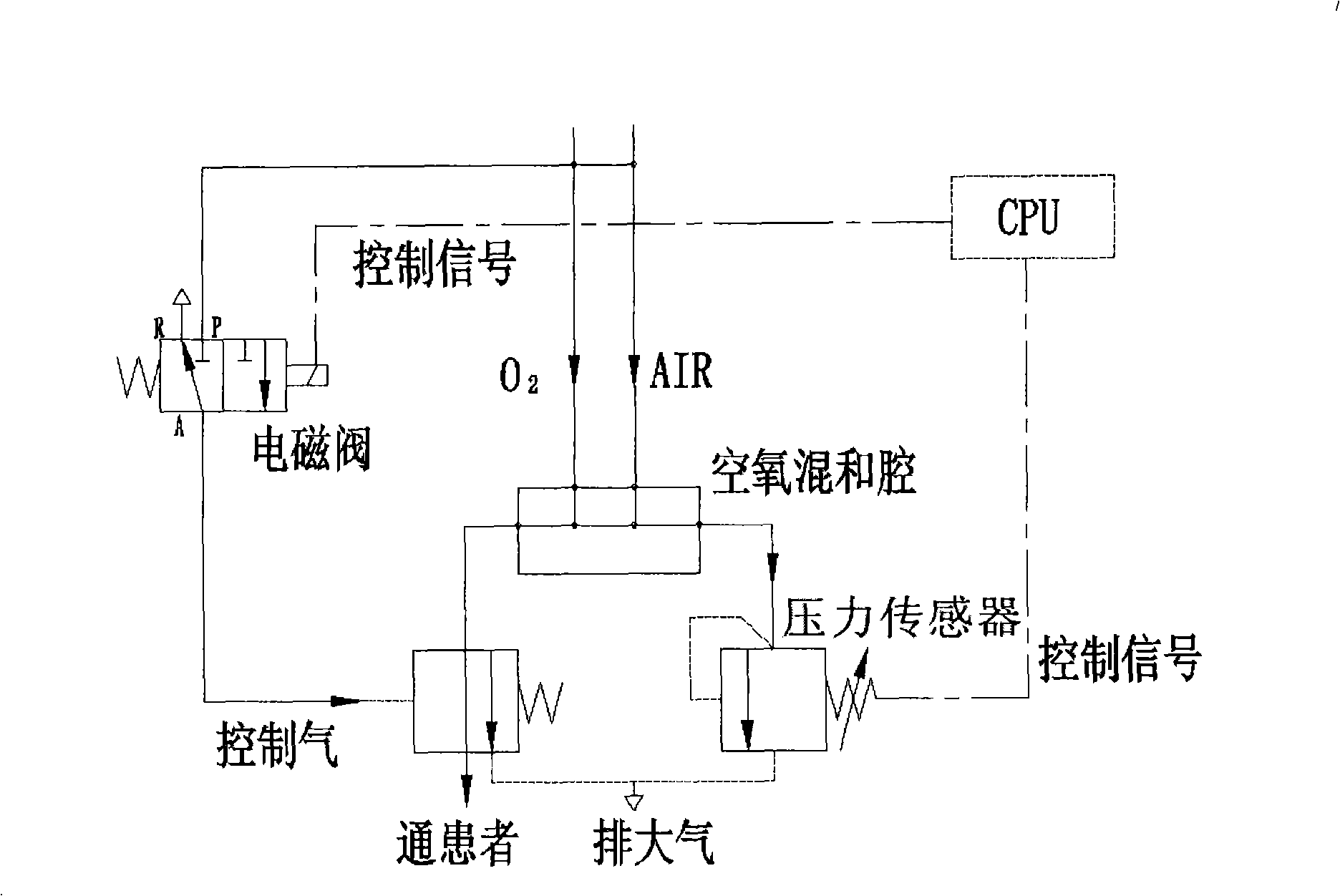

Multifunctional safety valve

ActiveCN101310790AReduce risk factorBreathing automatically communicates with the atmosphereRespiratorsValvesEngineeringOxygen

A multi-functional safety valve comprises a valve body, an air-oxygen mixing cavity, a control gas chamber and an exhaust chamber, an air-oxygen input, an air suction port, an exhaust port and a gas control port are arranged on the valve body, the air-oxygen input and the air suction port are communicated with the air-oxygen mixing cavity, the exhaust port is communicated with the exhaust chamber, the gas control port is communicated with the control gas chamber; an air suction valve and a pressure reducing valve are arranged in the body, the air suction valve is sealed or the air-oxygen mixing cavity and the exhaust chamber are conducted by the action of the pressure reducing valve, the multi-functional safety valve further comprises: a two-position three-way electromagnetic valve, a first end thereof is connected with a gas source, a second end is connected with the gas control port and a third end is communicated with atmosphere; a pressure sensor, which is arranged in the air-oxygen mixing cavity and transmits a signal to a microprocessor according to the gas pressure in the air-oxygen mixing cavity; and a microprocessor, which controls the on-off of the two-position three-way electromagnetic valve according to the signal which is transmitted by the pressure sensor. Therefore, when the air suction pressure is super high or super low, a power supply is switched off and other accidents occur, the multi-functional safety valve can form the automatic protection, thus protecting the safety of a user of a respirator.

Owner:BEIJING AEONMED

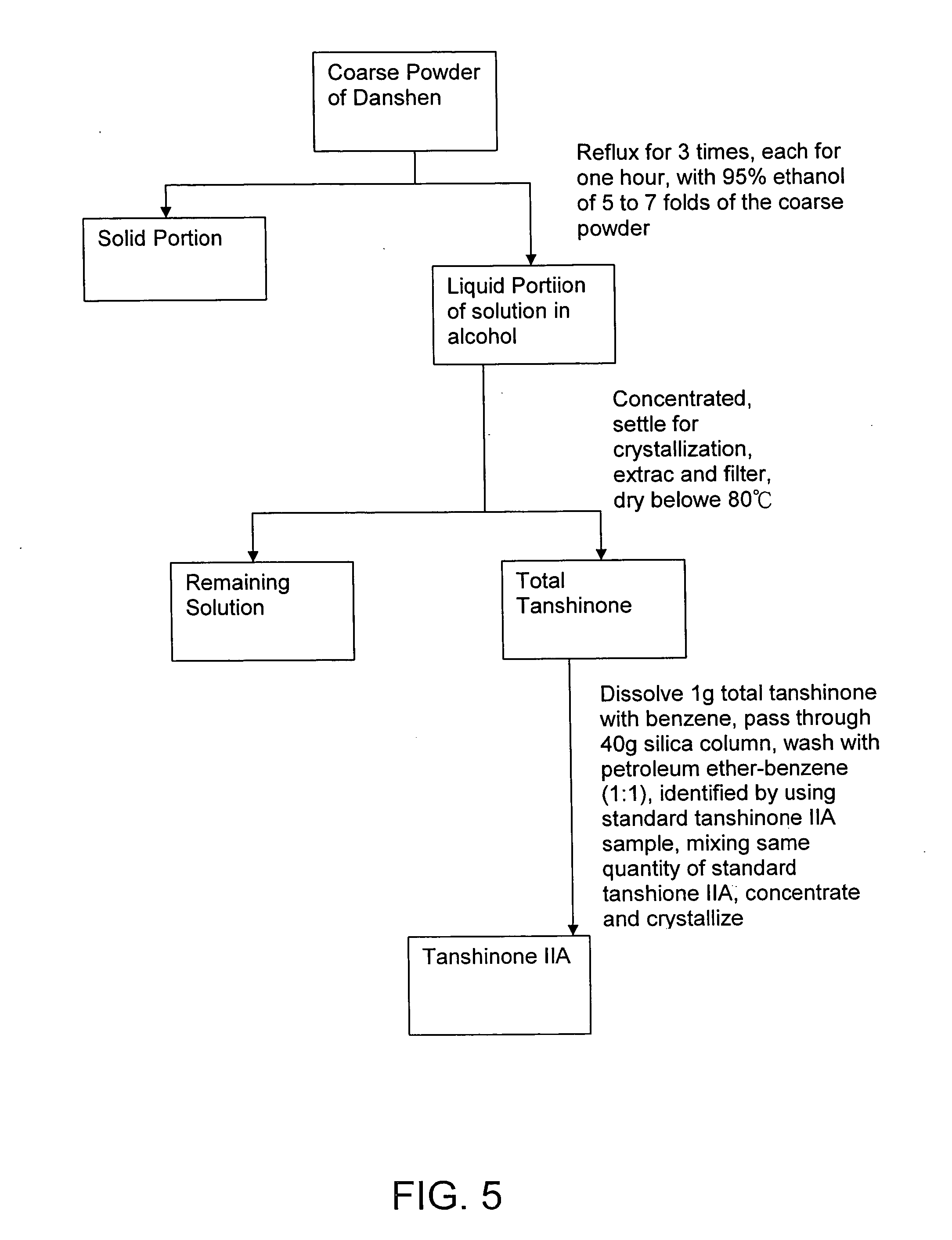

Composition of natural herb extract for treating cardiovascular disease and its method of preparation thereof

InactiveUS20060083798A1Reduce risk factorReduce accumulationBiocideAnimal repellantsSide effectAdditive ingredient

A composition of natural herb extract for treating cardiovascular disease or vascular disorder and its method of preparation and separation, and particularly to a composition prepared from natural herb extract comprising constituents of Danshensu, Tanshinone IIA, matrine, oxymatrine and puerarin for lowering the risk factors of heart disease or treating the heart disease that side effects are minimized. The working ranges of Danshensu, Tanshinone IIA, matrine, oxymatrine and puerarin are between 5 and 40 mg / kg per day and a ratio of Danshensu, Tanshinone IIA, matrine, oxymatrine, and puerarin is 1:1:1:1:1. The extraction and separation method of the five active ingredients are also illustrated. The composition can be exhibit in different forms for administration.

Owner:YOUNG JEFFREY

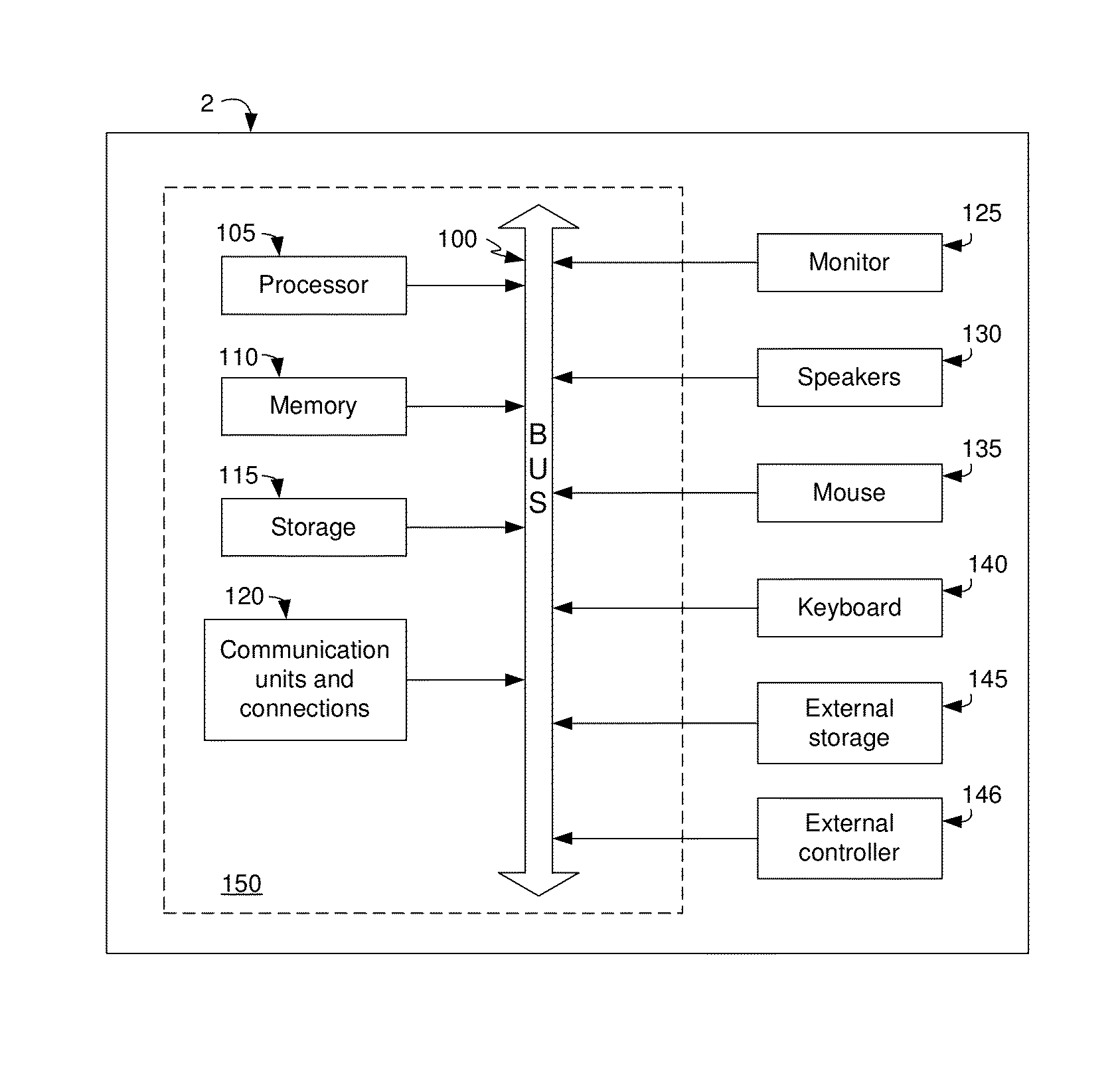

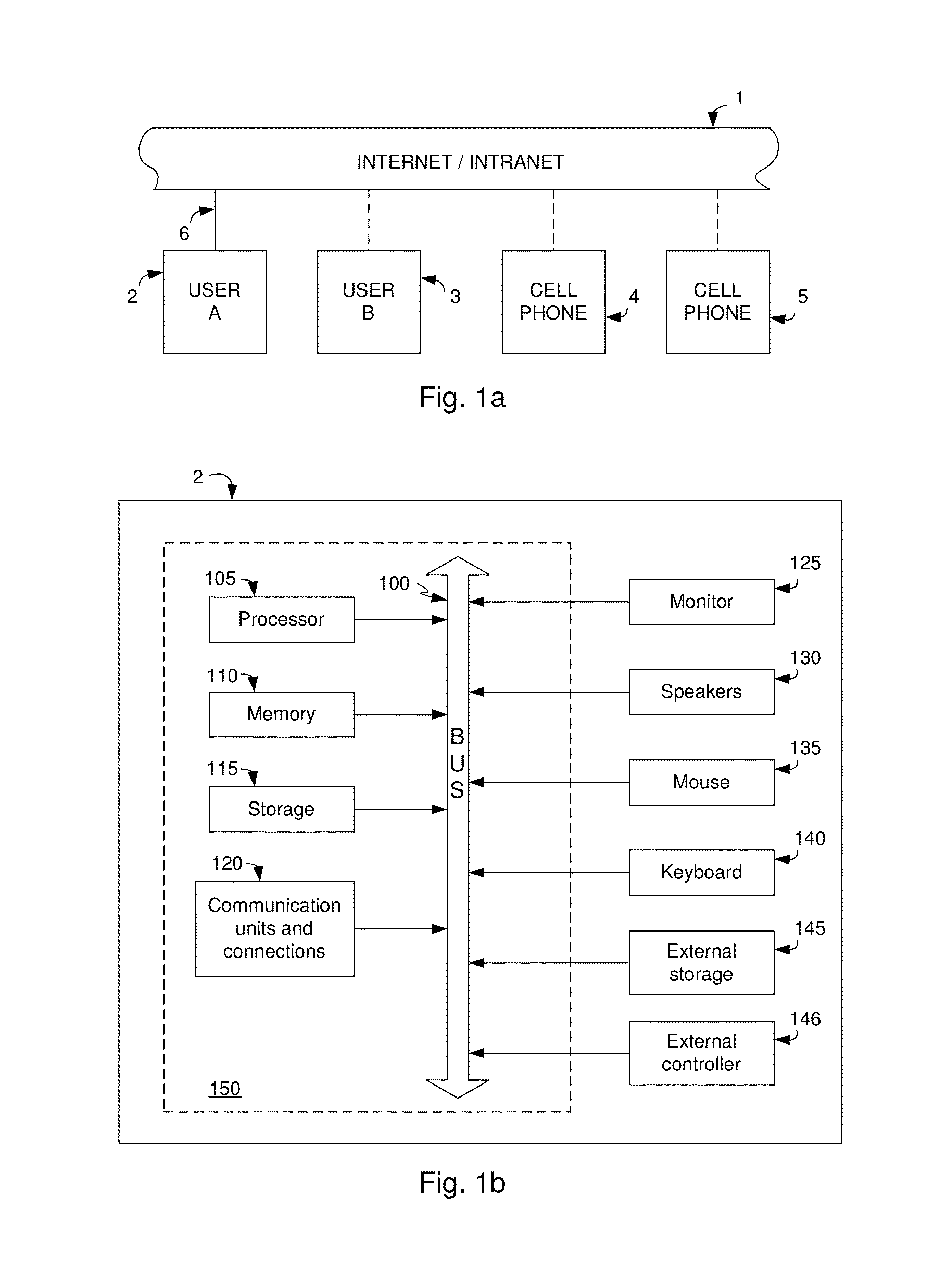

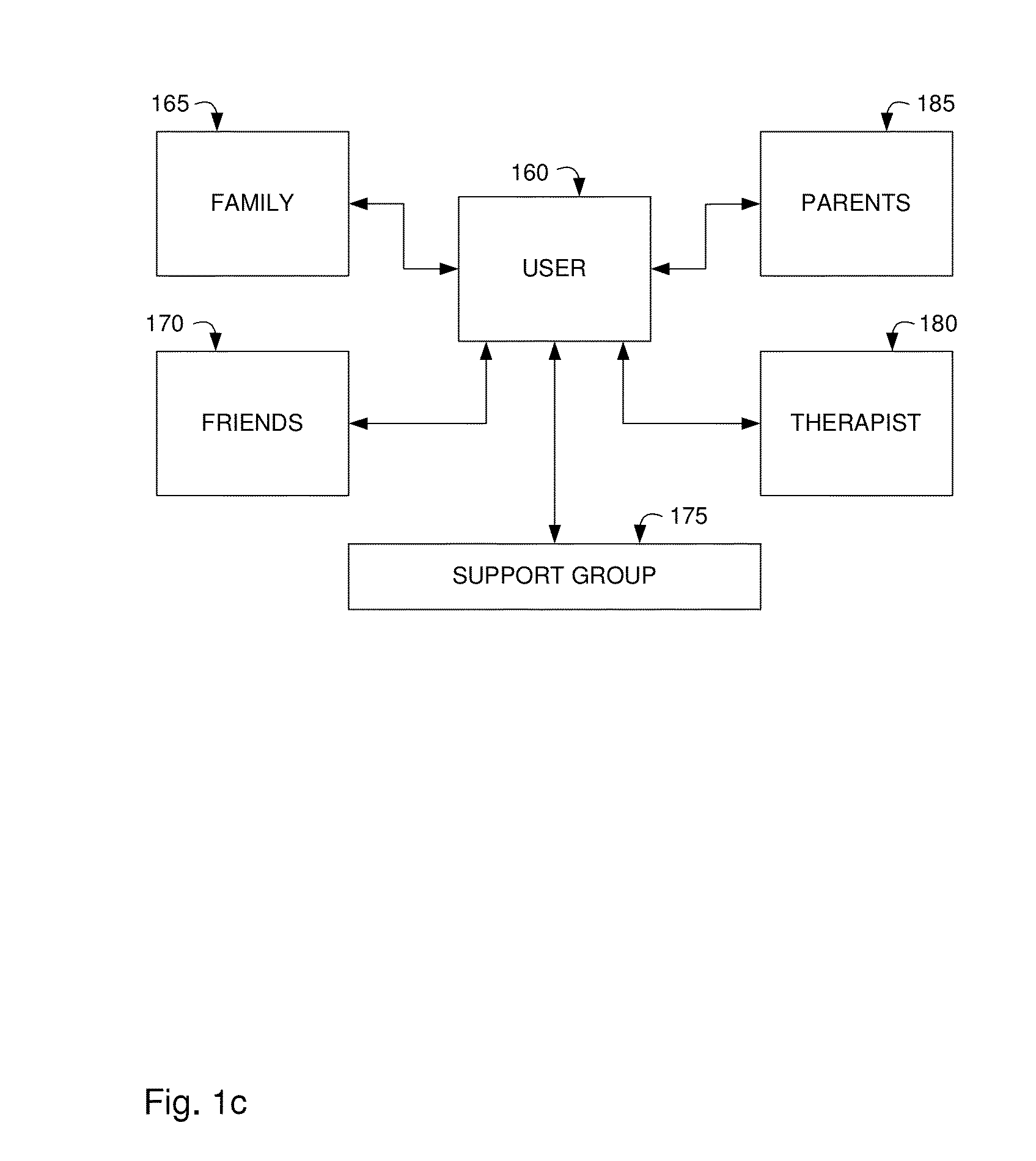

Method and system for identify, treatment and weaning from internet and computer addiction

ActiveUS20140045157A1Reduce risk factorPrevent addictionData processing applicationsDiagnostic recording/measuringPositive feedbackThird party

Self controlled method and system for identified, treatment and weaning from computer and Internet addiction. On one embodiment of the invention, the system analyzed user activity on the computer and while surfing the Internet, and presents results of his addictive level visually on user's interface. Supporting the whole information of addictive level to the user, give him the power to fight against the phenomena and prevent to increase it.The user can decide whether he wants treatment and act to have it by personal actions or by involvement of third parties such as parents, therapist, support group or even a specific social website. For weaning from the addiction the system can provide positive feedbacks, special treatment and even presents and prizes if the user reduced dramatically his addictive level.

Owner:GROSS DAVID

Universal closed-loop electrical stimulation system

ActiveUS9272139B2Extend your lifeRestore motor functionMagnetotherapy using coils/electromagnetsExternal electrodesNervous systemClosed loop

A universal closed-loop functional electrical stimulation system comprising at least one electrode assembly adapted to deliver an electrical stimulation signal to the central nervous system, peripheral nervous system, or muscles of a user, a sensor system adapted to detect a mechanical response to a muscle stimulation signal of at least one muscle associated with a muscle group stimulated through the nervous system or proximate to the electrode assembly. An electrical stimulation device operably coupled to at least one electrode assembly and the sensor system, the electrical stimulation device including a control system to automatically receive feedback from at least one characteristic of the muscle from the detected muscle response and adjust at least one parameter of the muscle stimulation signal in real-time and in response thereto and a programmed microprocessor for controlling said electrical stimulation and receiving input from said sensor system.

Owner:HAMILTON MARILYN J +1

Dietary composition containing conjugated linoleic acid and calcium for improved health

InactiveUS20060105033A1Reduce risk factorLower Level RequirementsBiocideCarbohydrate active ingredientsVitamin CDietary supplement

The invention provides a composition for oral administration comprising a mixture of conjugated linoleic acid (CLA), docosahexaenoic acid “DHA”, vitamin E, vitamin C, vitamin B6, vitamin B12, folic acid, and calcium together with a suitable carrier. These compositions are particularly useful as dietary supplements administered to reduce the risk factors of cardiovascular disease, such as elevated serum cholesterol levels and high blood pressure.

Owner:SMITHKLINE BECKMAN CORP

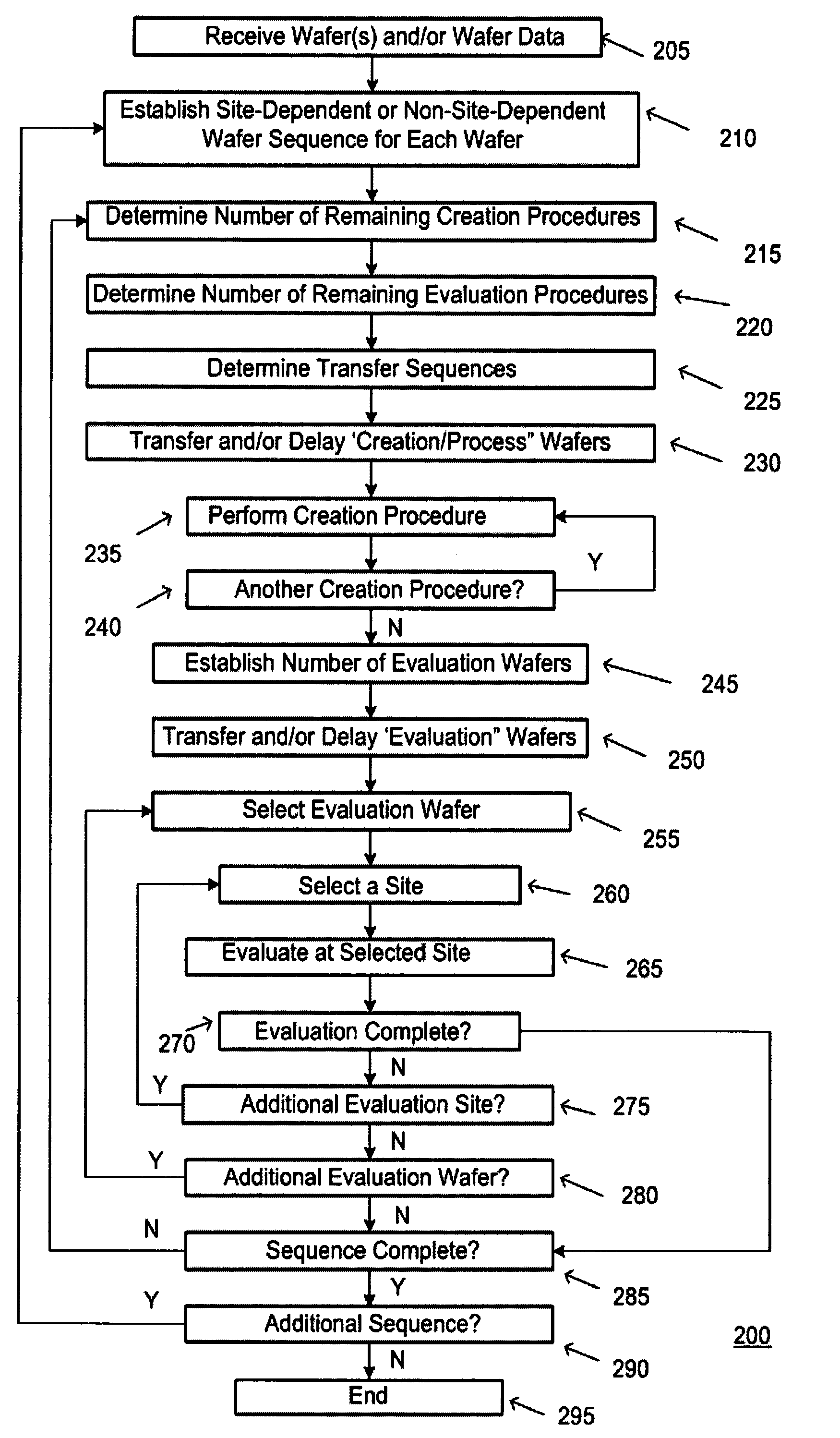

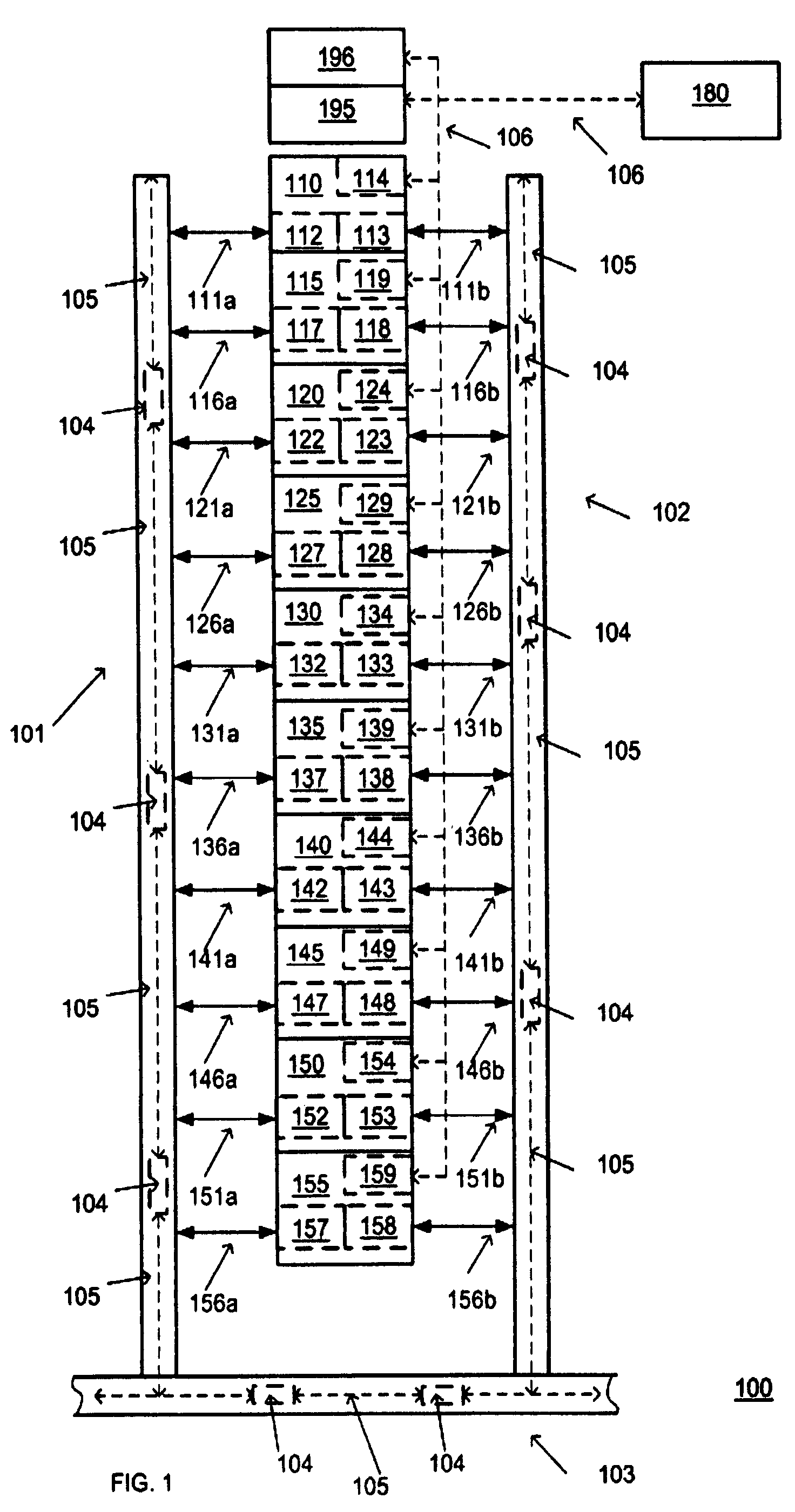

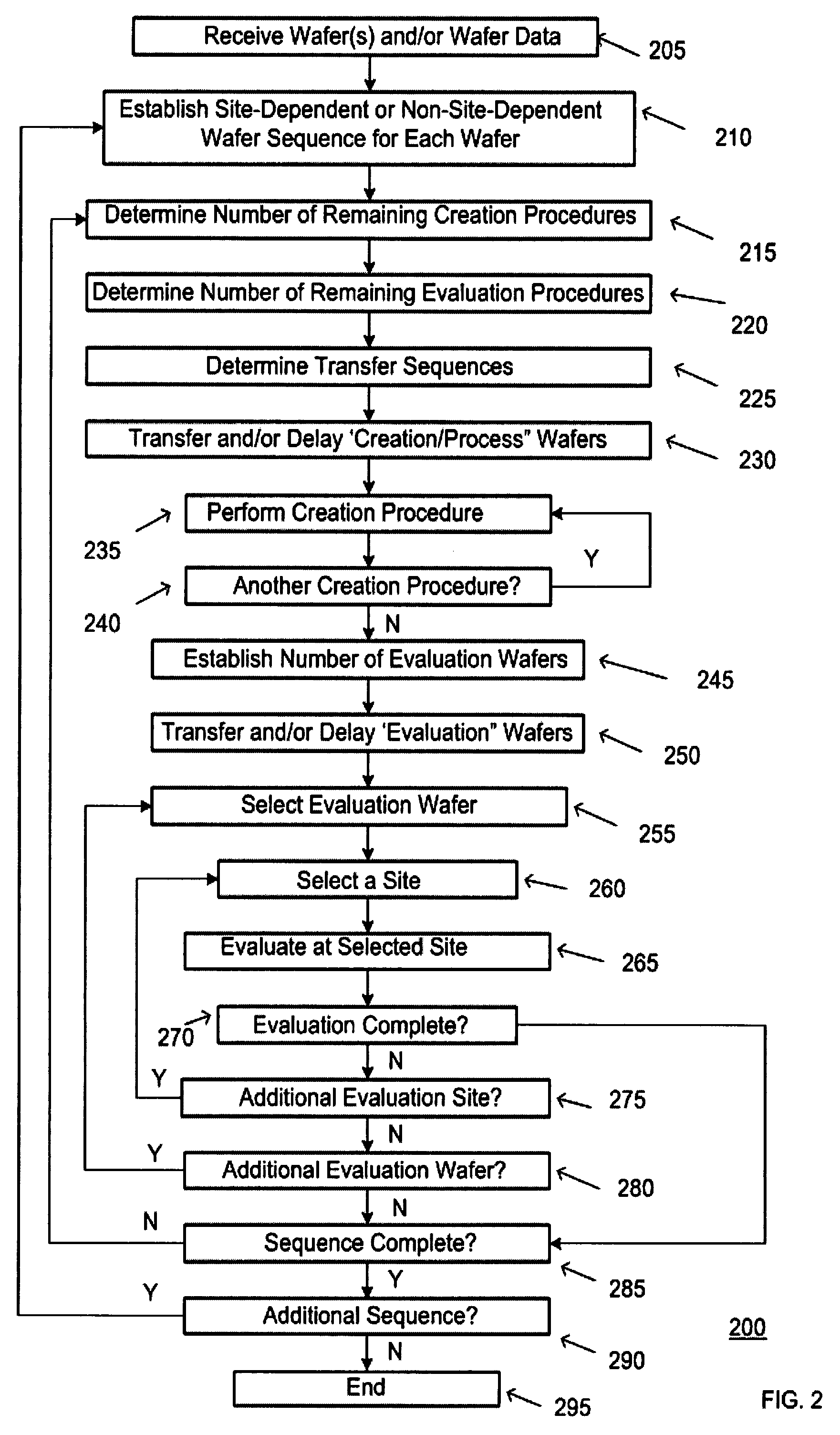

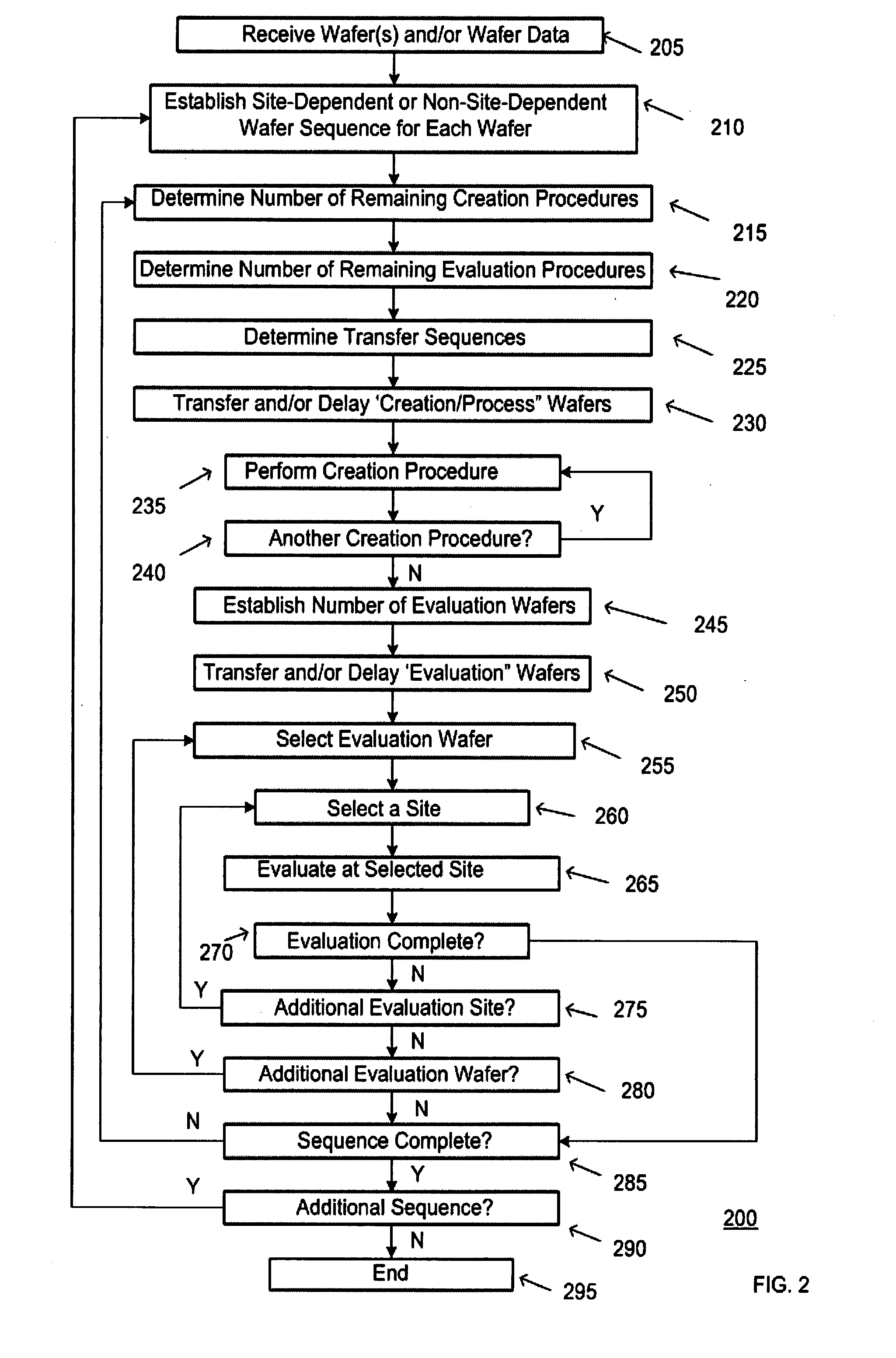

Method and apparatus for verifying a site-dependent procedure

InactiveUS7596423B2Speed up the processReduce risk factorProgramme controlMaterial analysis by optical meansComputer architectureTransfer system

Owner:TOKYO ELECTRON LTD

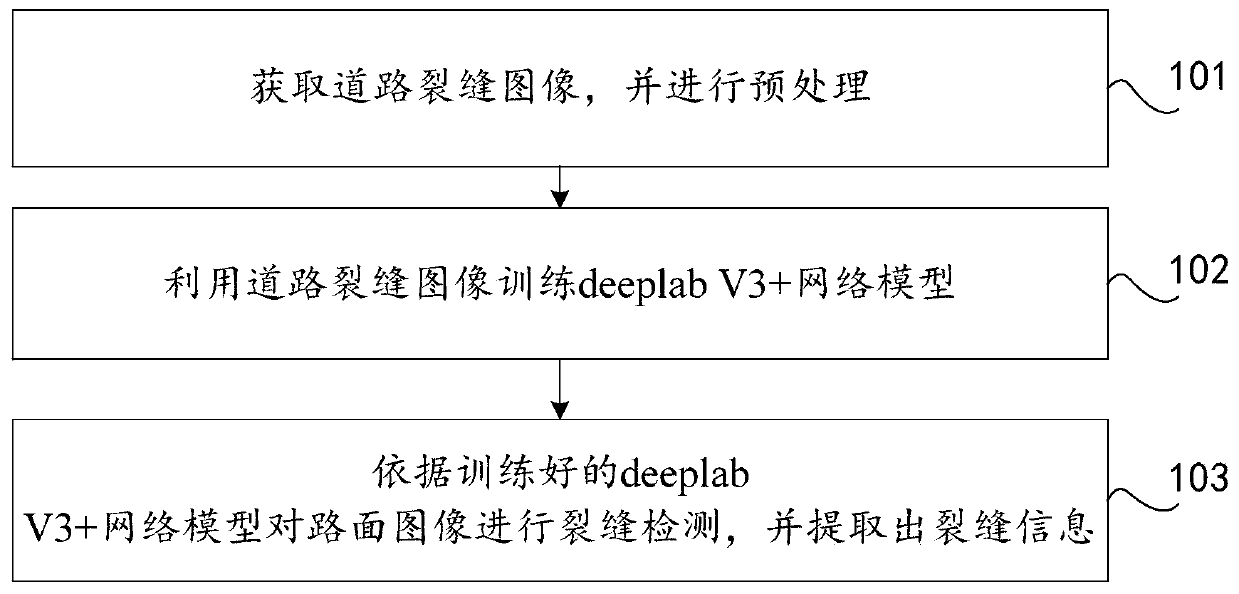

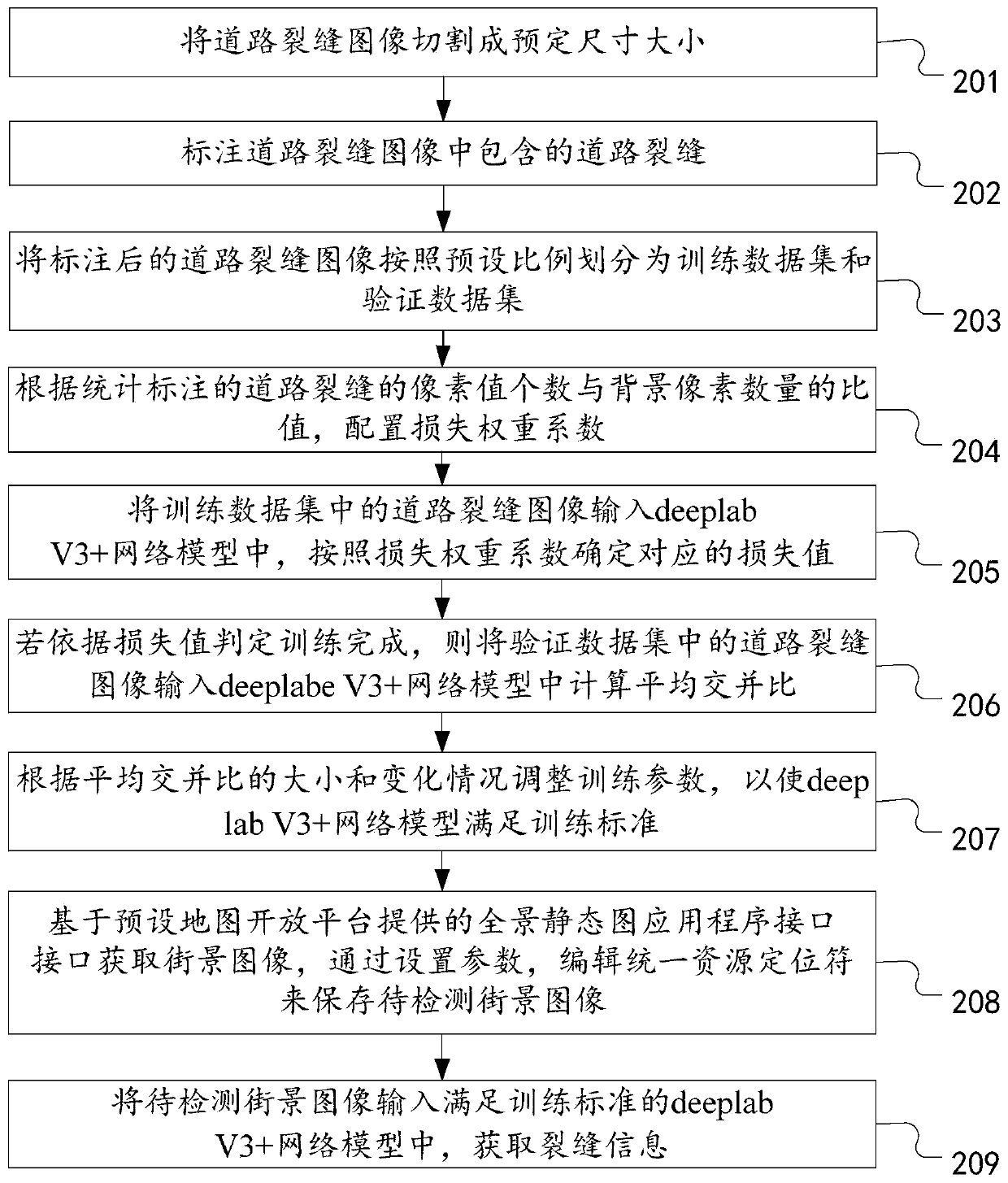

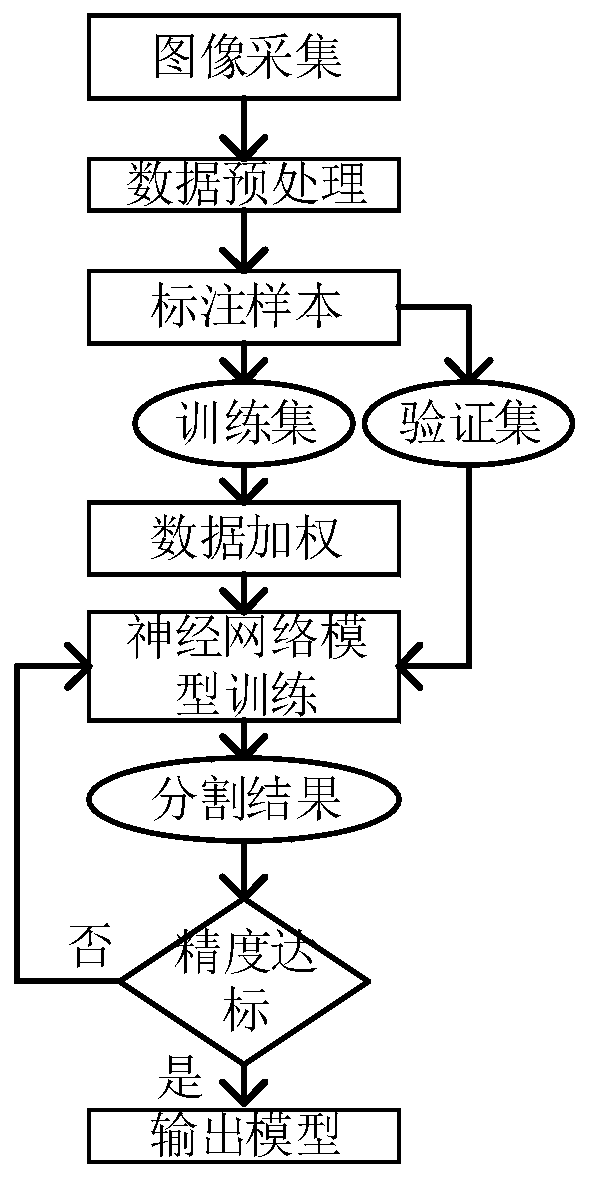

Pavement crack detection method and device and computer equipment

PendingCN110910343AAccurate identificationEnsure safetyImage enhancementImage analysisComputer graphics (images)Engineering

The invention discloses a pavement crack detection method, a pavement crack detection device and computer equipment, relates to the technical field of computers, and can solve the problems of low detection efficiency, low accuracy and strong environmental interference which are easily generated when pavement cracks are detected. The method comprises the steps of acquiring and preprocessing a roadcrack image; training a deeplab V3 + network model by using the road crack image; and performing crack detection on the pavement image according to the trained deeplab V3 + network model, and extracting crack information. The method is suitable for detecting the crack area in the pavement.

Owner:BEIJING UNIV OF CIVIL ENG & ARCHITECTURE

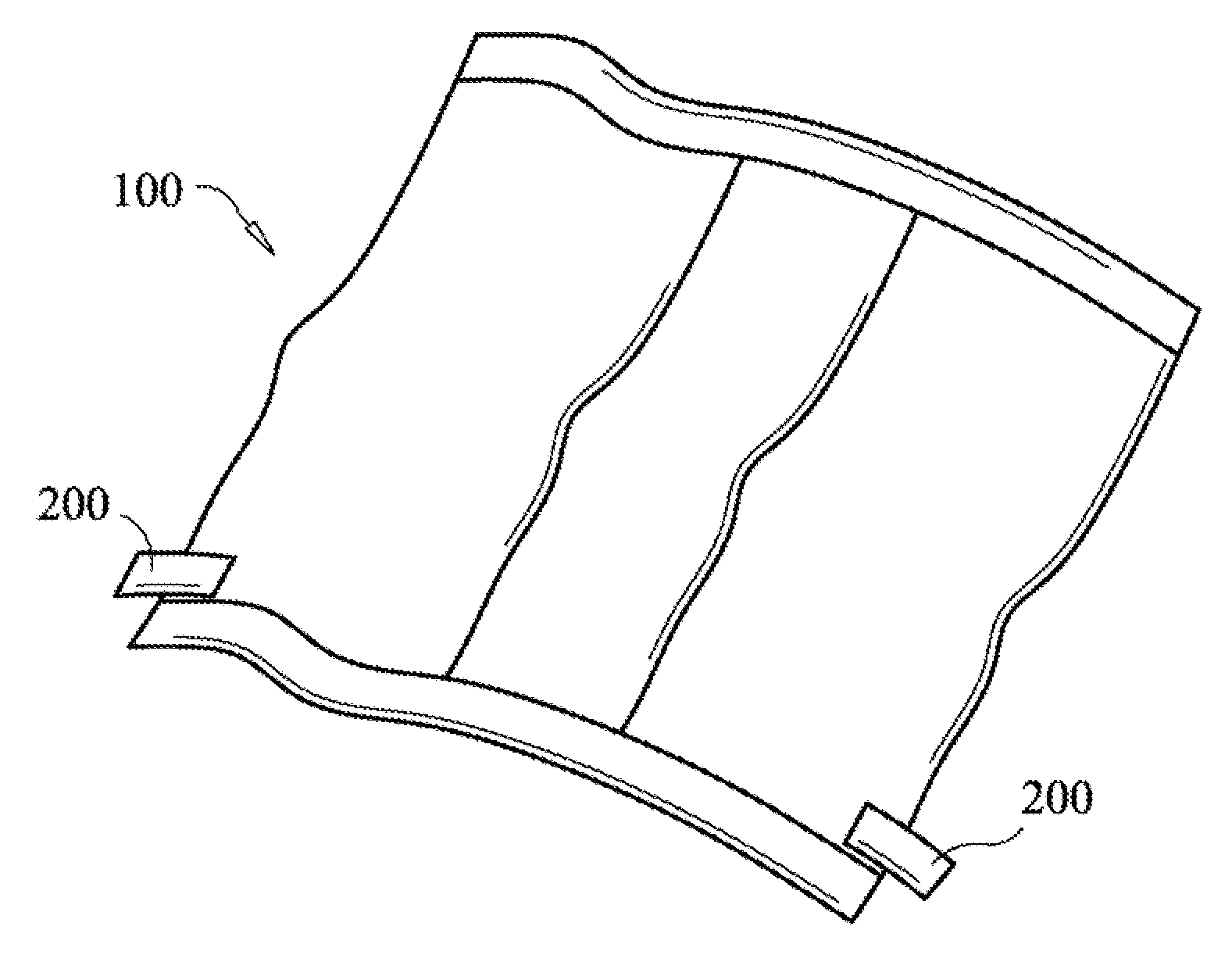

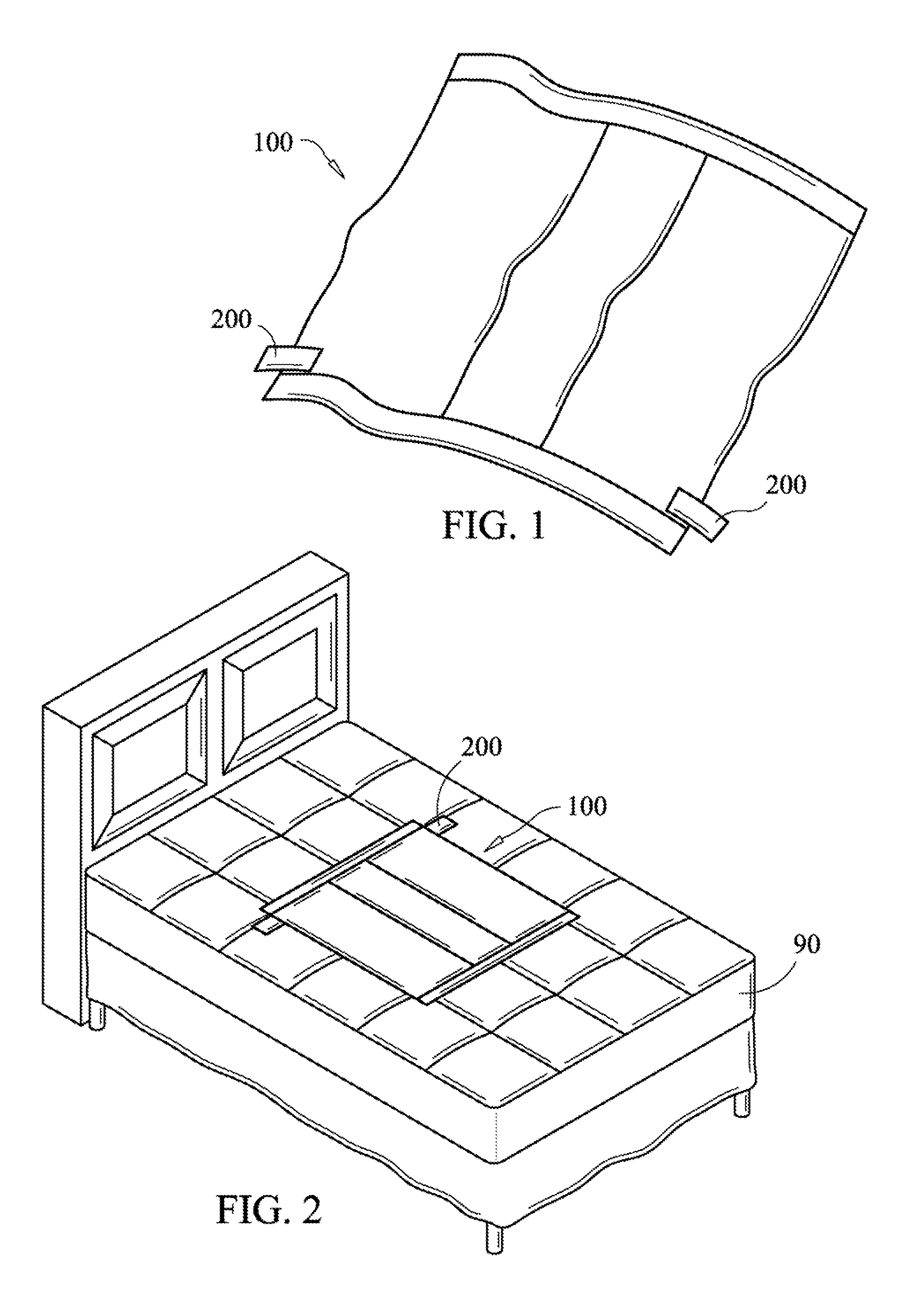

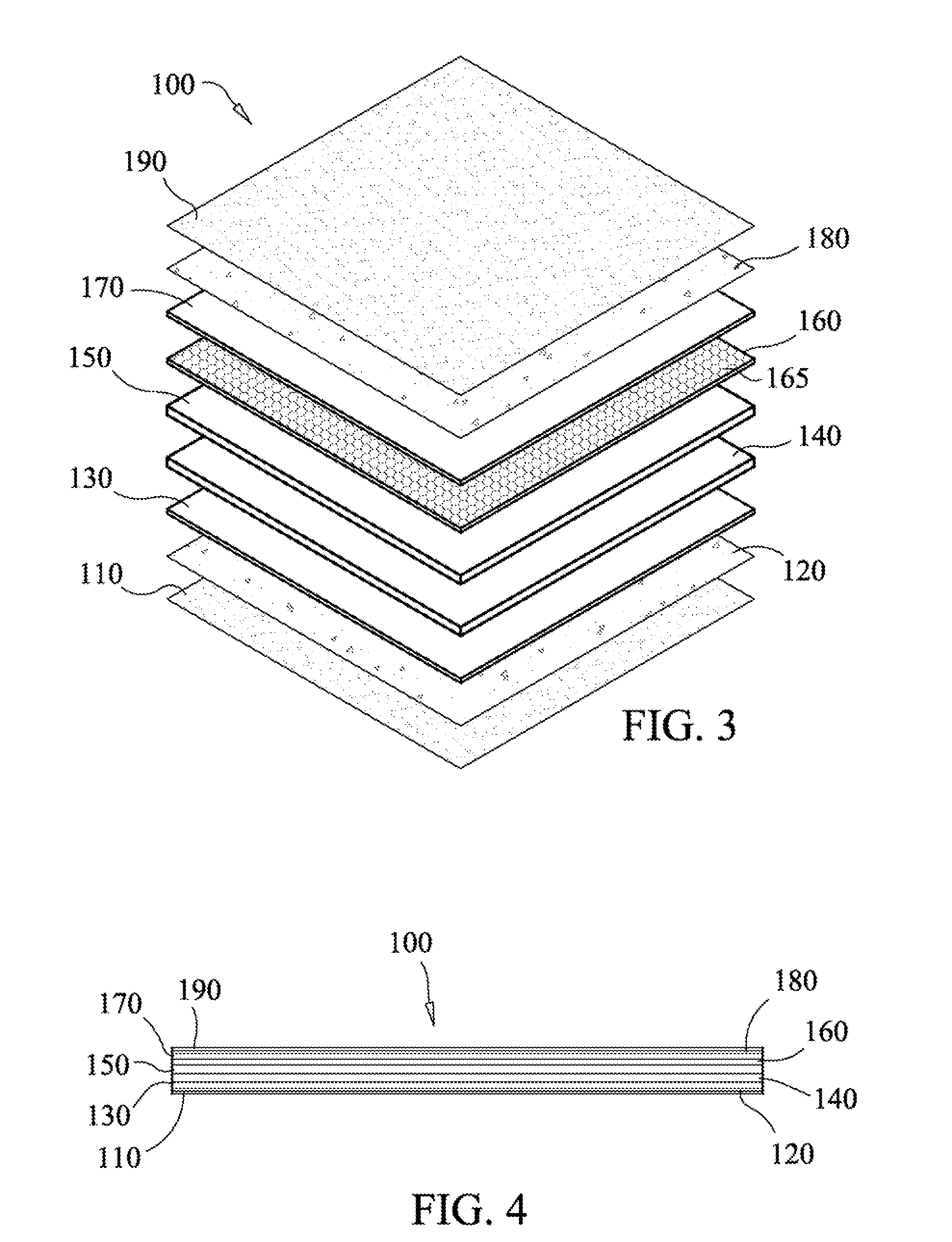

Disposable multilayered low friction double lubricated bed pad

InactiveUS20080306462A1Reducing and preventing bedsoreImprove disposablePlastersBaby linensEngineeringBody fluid

A disposable multilayered double lubricated bed pad is disclosed. Specifically, a lubricated pad for preventing and treating bedsores on a person's body and for managing discharged body fluids is disclosed. Among other things, the disclosed pad has absorbing layers and means for managing discharged body fluids away from a person's body to the absorbing layers. The disclosed pad also has a lubricating layer and is constructed to minimize friction between a person's body and a supporting surface. The disclosed pad is also treated with a lubricating, skin protecting, and moisturizing emollient for the treatment and prevention of pressure sores The emollient can be microencapsulated in the lubricating layer.

Owner:BRUCKNER ARNOLD +3

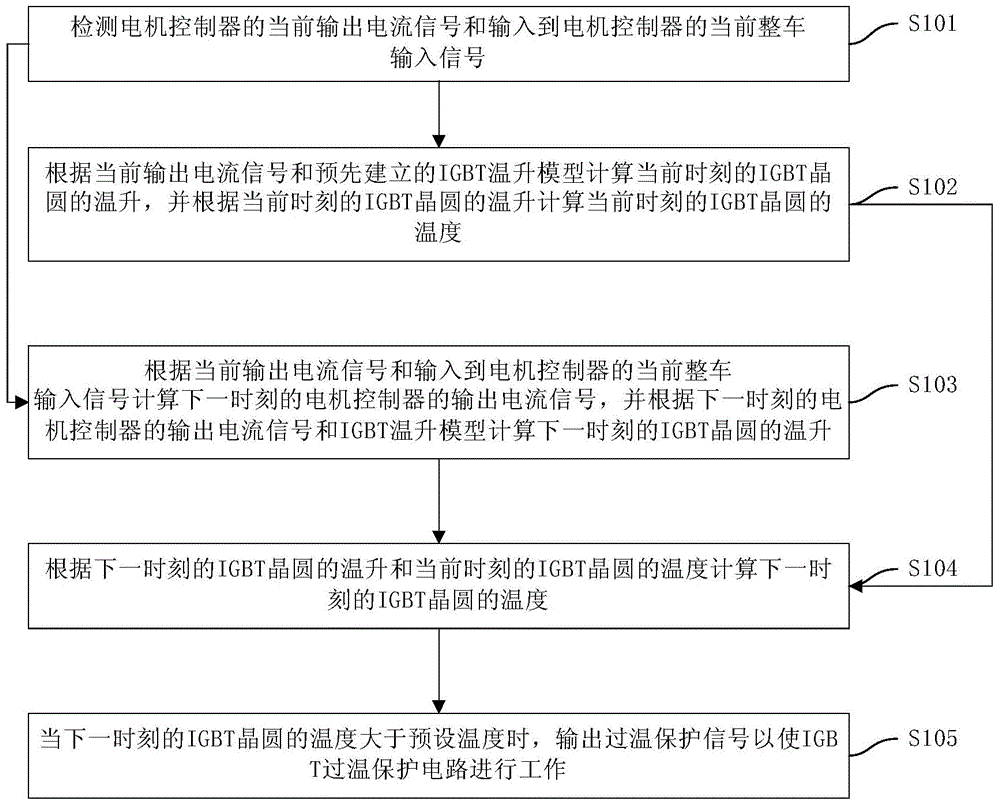

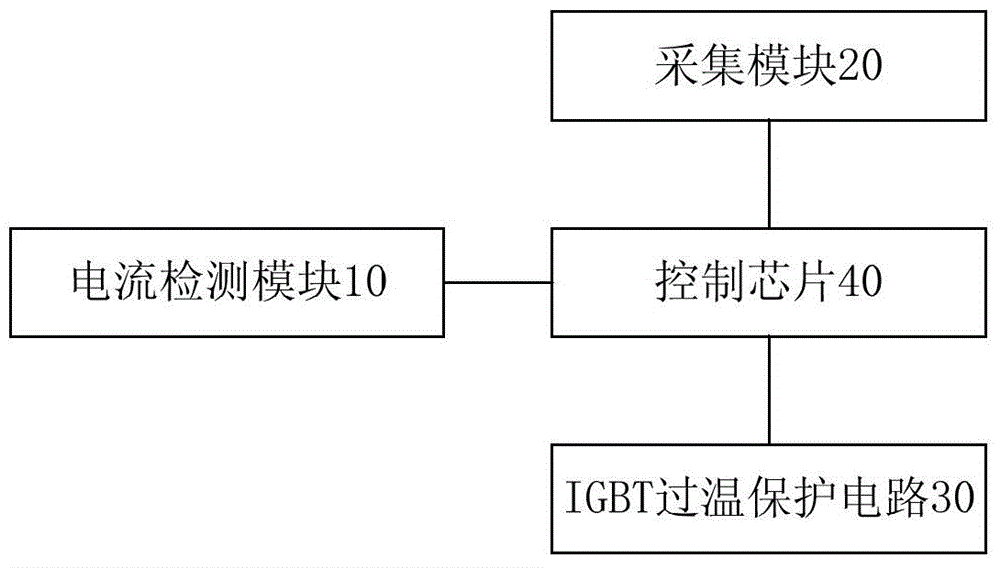

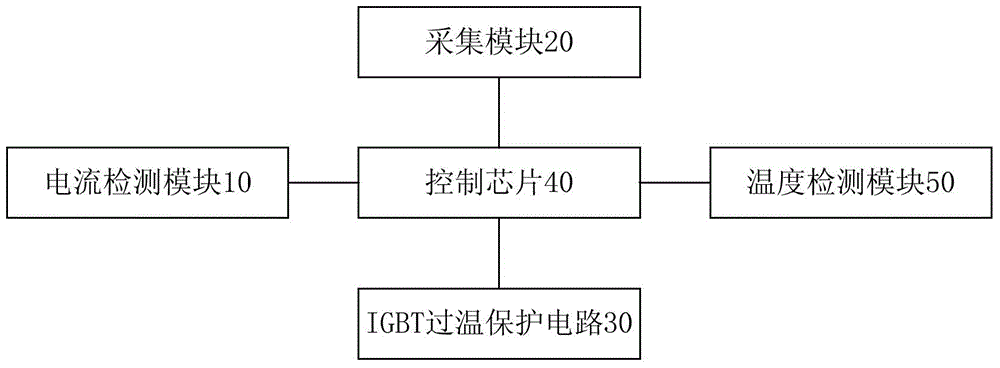

Motor controller, IGBT over-temperature protection method and apparatus for same

The invention discloses an IGBT over-temperature protection method and apparatus for a motor controller and a motor controller are provided. The method comprises steps of detecting a current output current signal of the motor controller and a current whole-vehicle input signal input to the motor controller, calculating current time IGBT temperature rise according to the current output current signal and a pre-set IGBT temperature rising model and calculating corresponding temperature according to the temperature rise, calculating an output current signal of the motor controller of next time according to the current output current signal and the current whole-vehicle signal, calculating temperature rise of the IGBT of the next time according to the signal and the above model, calculating the temperature of the IGBT of the next time according to the next time temperature rise and the current temperature, and outputting an over-temperature protection signal to enable an IGBT over-temperature circuit to work when the next time temperature is larger than the preset temperature. IGBT over-temperature damage risk can be reduced and reliability can be improved, by the use of the IGBT over-temperature protection method and apparatus.

Owner:BYD CO LTD

Specialized flour for nutrition meals for diabetes and preparation method and use thereof

ActiveUS20170224001A1Reduce the burden onDecrease increaseDough treatmentMetabolism disorderAtmospheric pressureFat content

Disclosed are specialized flour for nutrition meals for diabetes and a preparation method and use thereof. The flour is based on cereal meal as a basic material and is added to a defatted soybean vegetable protein powder and a soybean tissue isolated dietary fiber power, wherein in the dry flour base, the content of protein is 20-26 weight %, the content of the dietary fiber is 4-10 weight %, the content of carbohydrate is no more than 65 weight %, and the content of fat is no more than 4% of the weight. The method comprises physically mixing the cereal meal, the defatted soybean vegetable protein powder and the soybean tissue isolated dietary fiber power under atmospheric pressure. Food and semi-finished products made from the flour are used for preventing and / or treating diabetes.

Owner:TIAN JIANHUA

Therapy system and method for treating and reducing risk factors associated with overweight and obesity

InactiveUS20080046284A1Reduce risk factorPhysical therapies and activitiesData processing applicationsMedical emergencyRisk factor

A therapy system and method for treating and reducing risk factors associated with overweight and obesity in patients, especially children in a medical clinic setting having facilities for personal training of patients, and personnel including at least one physician who is also a certified personal trainer.

Owner:FISHER MARIA C +1

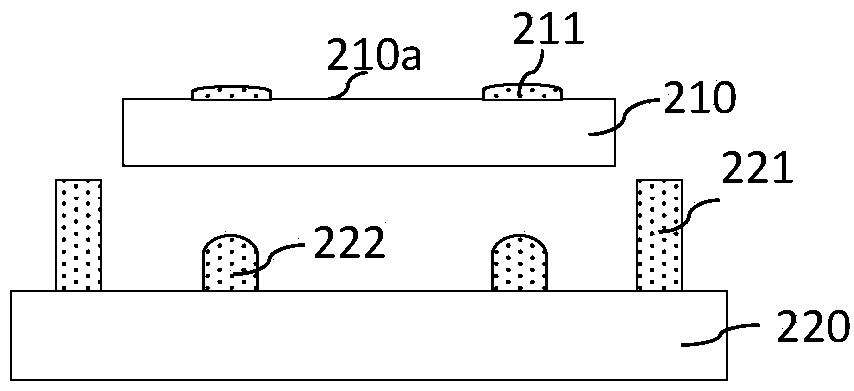

Method for manufacturing color filter with pixel end difference height improved through half tone mask

InactiveCN104280805AReduce workflowIncrease productivityOptical filtersOriginals for photomechanical treatmentColor filter arrayOptoelectronics

The invention discloses a method for manufacturing a color filter with the pixel end difference height improved through a half tone mask. The method comprises the steps that firstly, a substrate is coated with a black matrix material; secondly, exposing, developing and high-temperature baking and solidifying are carried out on the material through the half tone mask, four areas are formed, T-shaped black matrix patterns with the height difference are formed in the first area, the second area and the third area and are reserved on the substrate; thirdly, the four areas of the substrate are coated with color films; fourthly, exposing, developing and solidifying are carried out on the color films so that a needed color film pattern can be formed, wherein the needed color film pattern is located on the first area, the third area and the fourth area, and the operation is repeatedly carried out three times; fifthly, a transparent conductive layer ITO is splashed after all color film layers are formed; sixthly, the substrate is coated with a transparent insulation material layer; seventhly, the substrate is wholly exposed, developed and solidified, and a PS layer with the needed height is formed and serves as a common column for supporting Gaps between two LCD substrate layers. The method has the advantages that the material does not need to be changed, the production efficiency is improved, and the production procedures are simplified.

Owner:南京中电熊猫液晶材料科技有限公司

Machine-transplanted rice seedling raising ground substance

ActiveCN101507410BGood qualityNo soreBio-organic fraction processingOrganic fertiliser preparationOryza sativaRaw material

The invention relates to a rice seedling raising substrate, in particular to a rice seedling raising substrate taking agricultural and forestal wastes as materials and mechanically transplanting rice seedlings. The forming steps of the rice seedling raising substrate of the invention are as follows: organic wastes such as straws are taken as raw materials, fermented by various beneficial microorganisms, and prepared into an organic substrate with a fertilizer slow release and caking agent and a water retention agent. The rice seedling raising substrate has strong stress resistance and strong compatibility with mechanical rice transplanting technology, and makes the rice seedlings have good quality; and the technology of raising the rice seedlings by the substrate is simple, and has low cost and high success ratio.

Owner:HUNAN CHAIMIHE AGRI TECH DEV

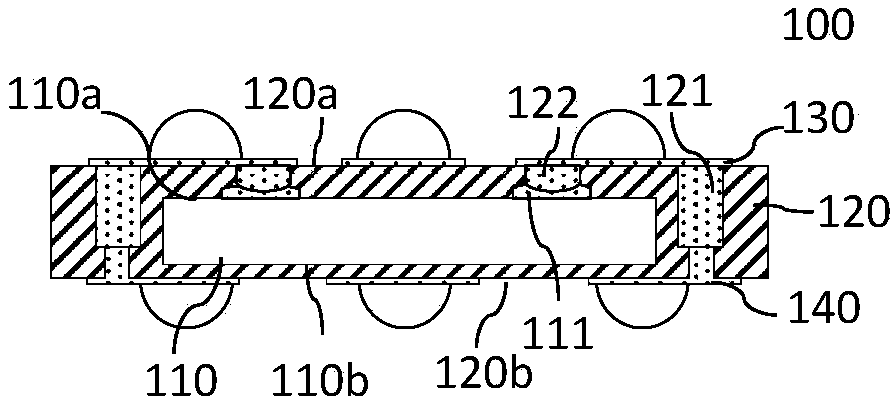

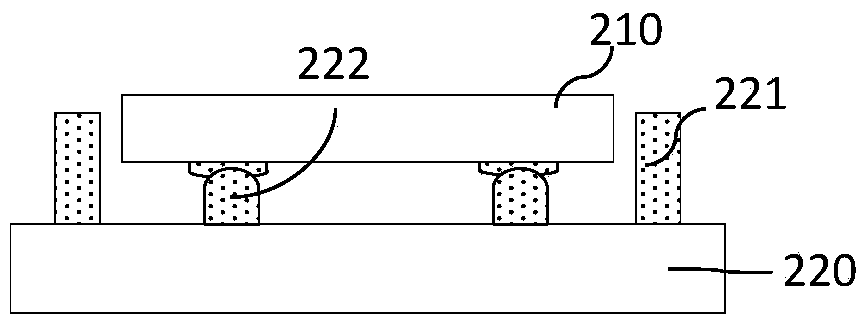

Fan-out type packaging structure and manufacturing method thereof

InactiveCN108962773AHigh precisionAvoid Welding TolerancesSemiconductor/solid-state device detailsSolid-state devicesPlastic packagingEngineering

The invention discloses a fan-out type packaging structure comprising a chip and a plastic packaging layer that wraps the chip; the chip has a first surface that includes a conductive pad; the plasticpackaging layer comprises a first surface and a second surface, wherein the second surface is opposite to the first surface; the first surface is provided with a first rewiring structure, and the second surface is provided with a second rewiring structure; the plastic packaging layer also comprises a first conductive pillar that penetrates the first and second surfaces; the first conductive pillar forms an electric connection between the first rewiring structure and the second rewiring structure; the plastic packaging layer also comprises a second conductive pillar that extends from the firstsurface to the conductive pad of the chip; the electric connection is formed between the chip and the first rewiring structure.

Owner:NAT CENT FOR ADVANCED PACKAGING

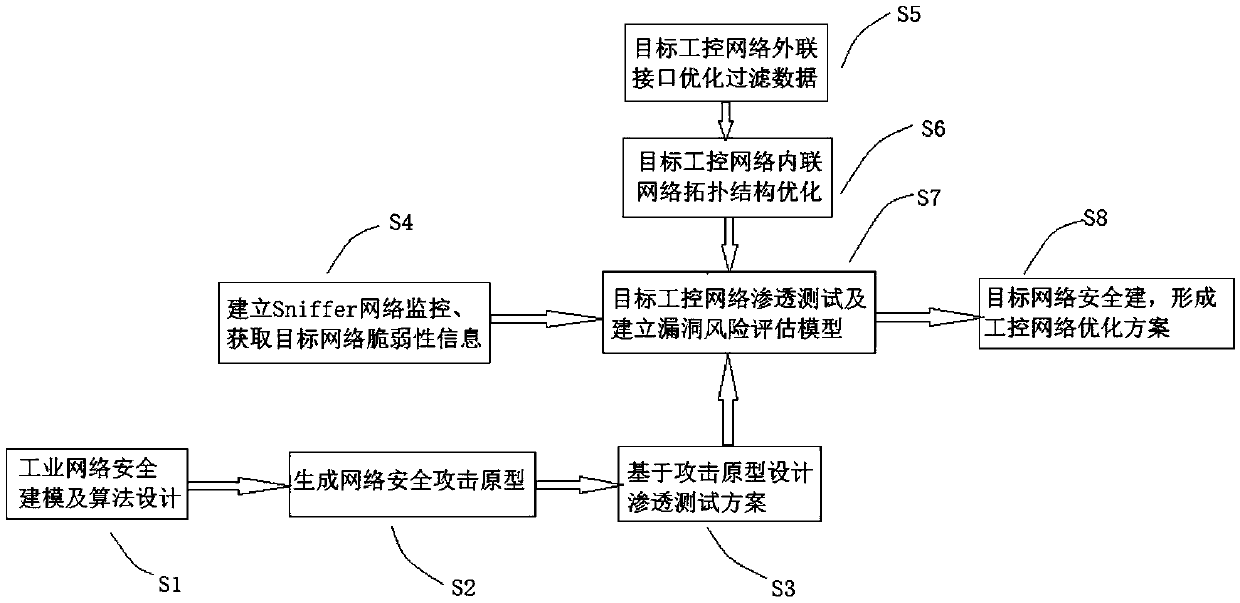

A prototype modeling method of network security attack based on industrial control

InactiveCN109543301AOptimize topologyDeny illegal intrusionDesign optimisation/simulationTransmissionSecurity solutionVulnerability

The invention discloses an industrial control network security method based on industrial network attack prototype modeling, which comprises the following steps: S1, industrial network security modeling and algorithm design; S2, designing an industrial control network security attack prototype; S3, taking an attack model of an attacker in an algorithm of the attack prototype in S1 as an attack source, and converting the network vulnerability information obtained in S4 into an attack set of an attacker according to attack rules to form an attack prototype; S4: Designing penetration test schemebased on attack prototype; 5, establishing a Sniffer network monitoring system; 6, optimizing and filtering that data through the external interface of the target industrial control network; 7, optimizing that topology structure of the intranet of the target industrial control network; S8: Establishing vulnerability risk assessment and modeling; S9: Forming an industrial network security defense solution. The network optimization and safety solution provided by the invention will effectively solve the safety problem of the industrial control of the enterprise, can timely carry out the risk assessment on the system, reduce the risk factors to the maximum extent, and improve the network operation efficiency and the safety reliability of the production management.

Owner:SUZHOU CHIEN SHIUNG INST OF TECH

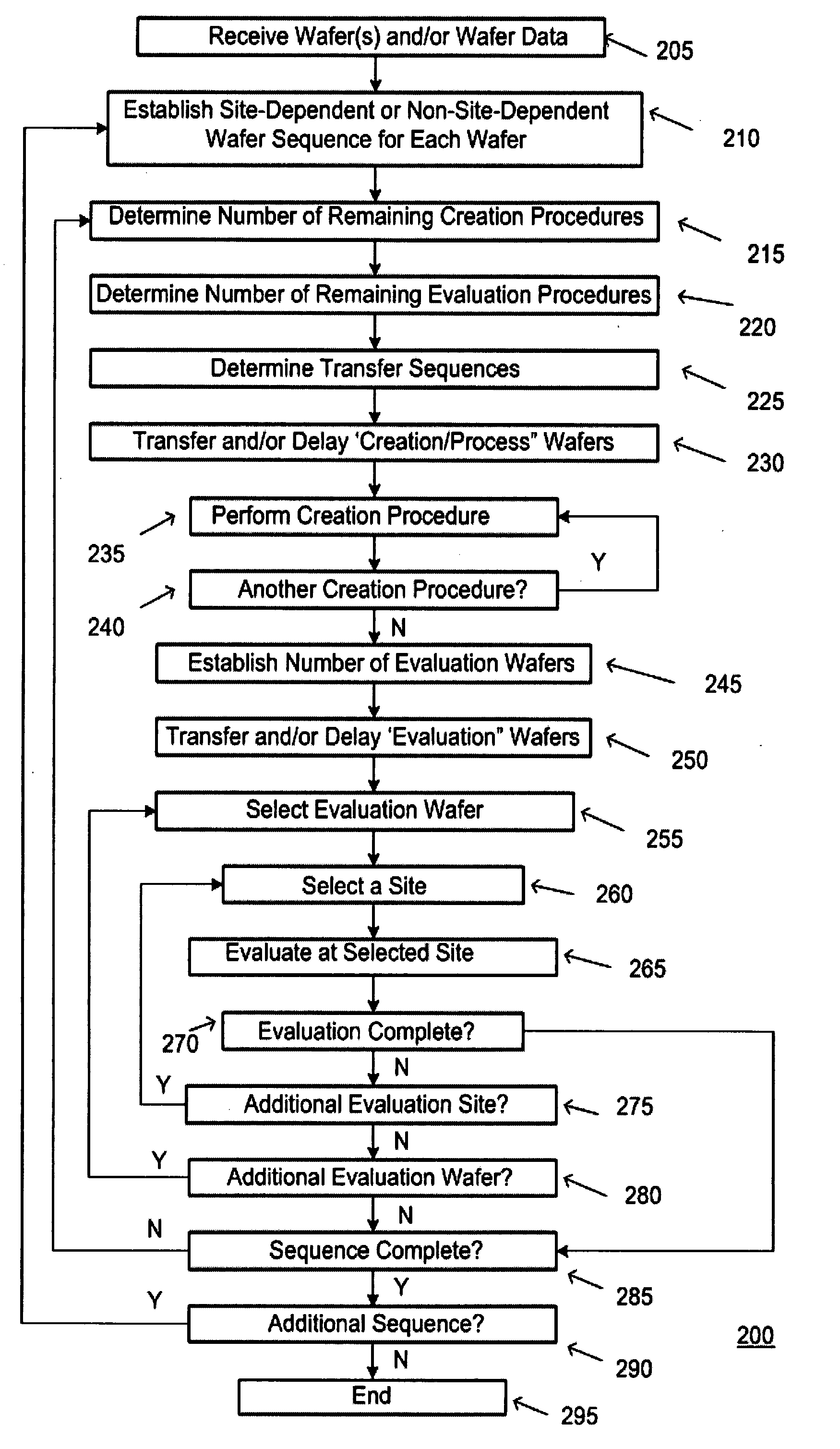

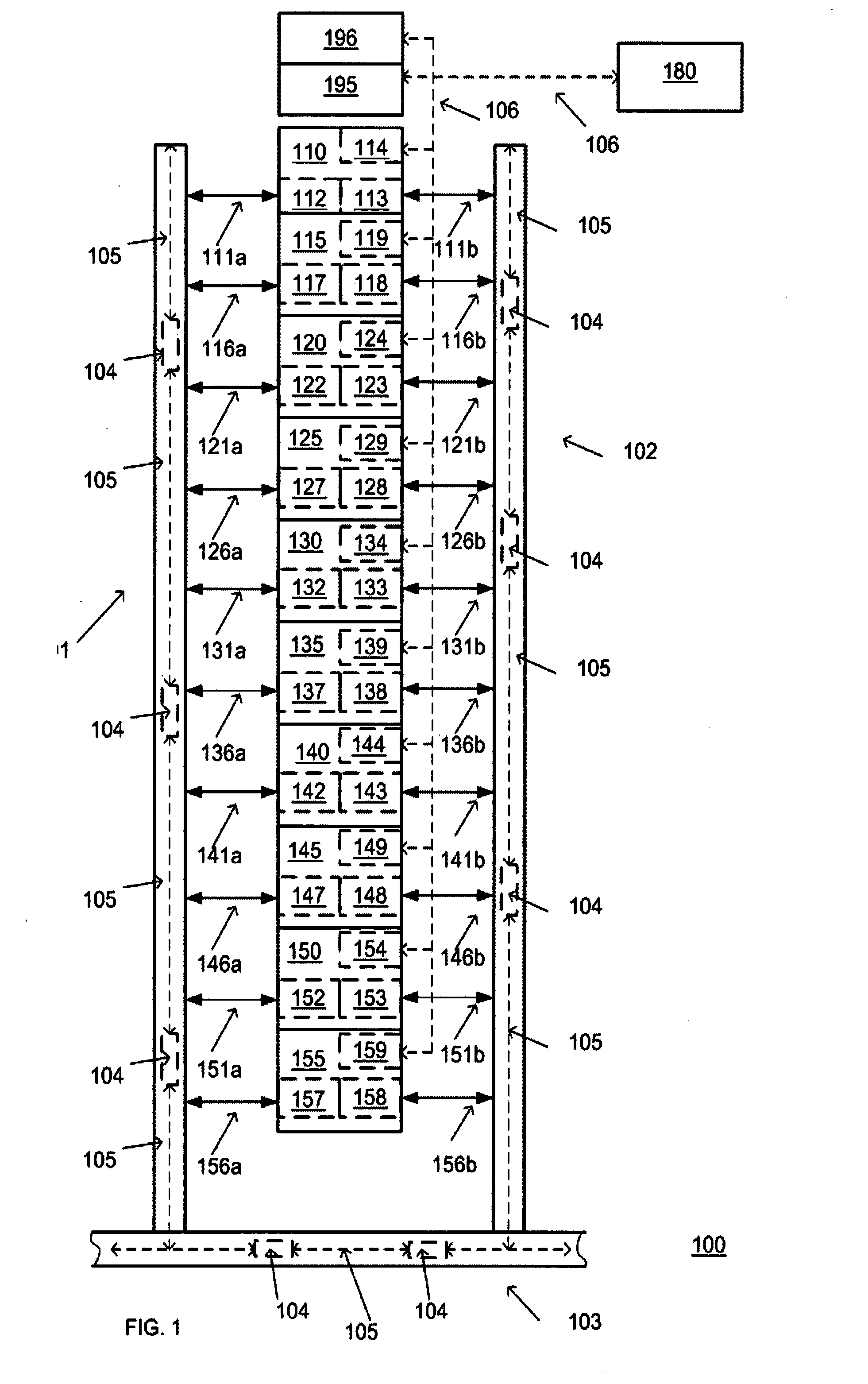

Method and apparatus for verifying a site-dependent procedure

InactiveUS20080243294A1Improving wafer processingImprove throughputProgramme controlMaterial analysis by optical meansComputer architectureTransfer system

The present invention includes a method of verifying a Site-Dependent (S-D) processing procedure, the method including receiving a plurality of wafers by a S-D transfer system, determining S-D wafer state data for each wafer; establishing a first set of verification wafers, determining a number of required verification sites for each verification wafer, determining a number of visited verification sites, determining a number of remaining verification sites for each verification wafer, establishing a first procedure-verification sequence, determining a first S-D verification procedure, transferring the first verification wafer to a first S-D processing element and delaying the first verification wafer for a first period of time.

Owner:TOKYO ELECTRON LTD

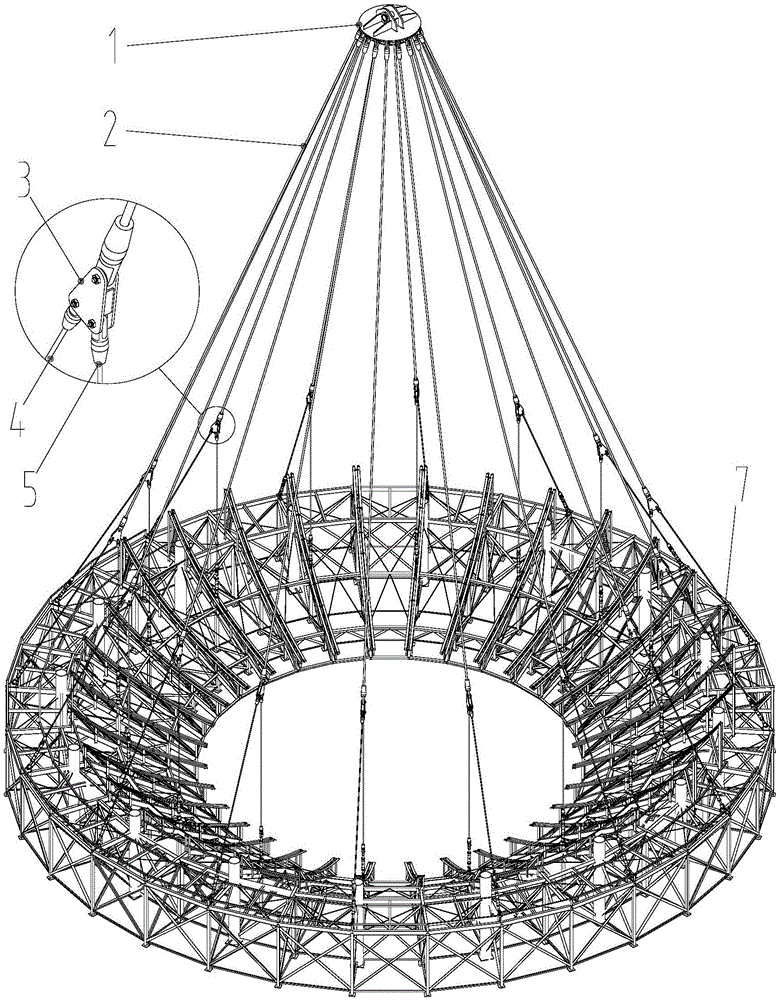

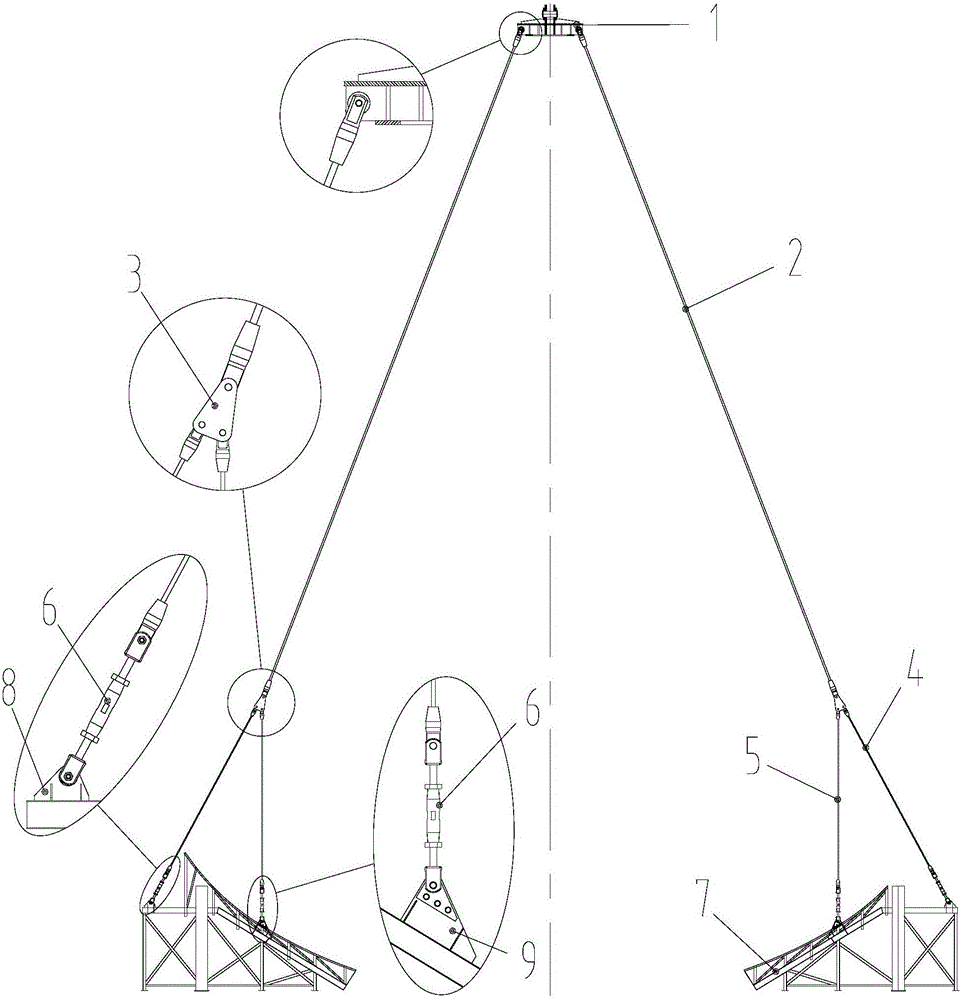

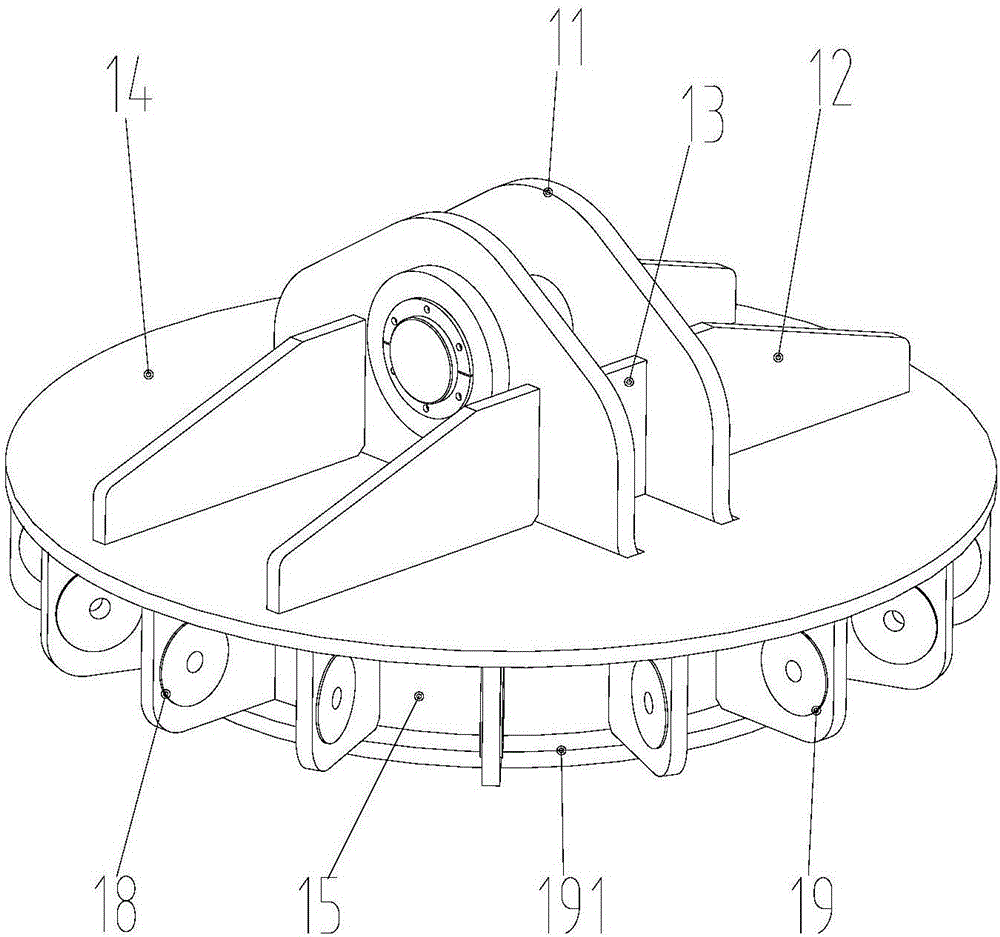

Special hoisting sling and hoisting method for nuclear power station CR10 and reinforcing steel bar composite module

ActiveCN106429791ASimple structureReasonable structureLoad-engaging elementsNuclear powerEngineering

The invention relates to a special hoisting sling and a hoisting method for a nuclear power station CR10 and reinforcing steel bar composite module. The special hoisting sling comprises a transition beam, main slings, sling distributors, outside auxiliary slings, inside auxiliary slings and adjustable pull rods. According to the special hoisting sling and the hoisting method for the nuclear power station CR10 and reinforcing steel bar composite module provided by the invention, the special hoisting sling is adopted as connection between a hoist and the CR10 and reinforcing steel bar composite module, the special hoisting sling is connected before hoisting, the transition beam is connected with the hoist, and the adjustable pull rods are connected with inside and outside lifting lugs on the CR10 and reinforcing steel bar composite module. A center-of-gravity position of the CR10 and reinforcing steel bar composite module is adjusted through applying balance weight and adjusting the adjustable pull rods, so that the level degree of a lower port is ensured. The CR10 and reinforcing steel bar composite module is in position through hook-lifting, rotating, walking and hook-dropping of normal hoisting. According to the special hoisting sling and the hoisting method provided by the invention, the deformation of the CR10 and reinforcing steel bar composite module during a hoisting process can be effectively reduced, the level degree of the lower port of the CR10 and reinforcing steel bar composite module is ensured, and the construction safety is ensured.

Owner:DALIAN YILIY CONSTR MACHINERY

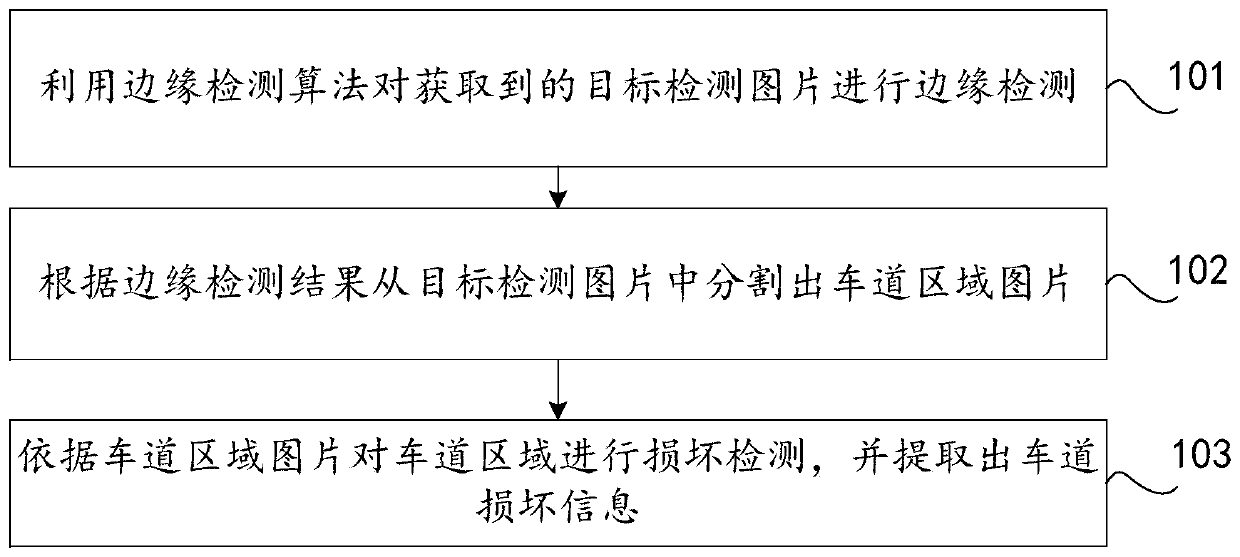

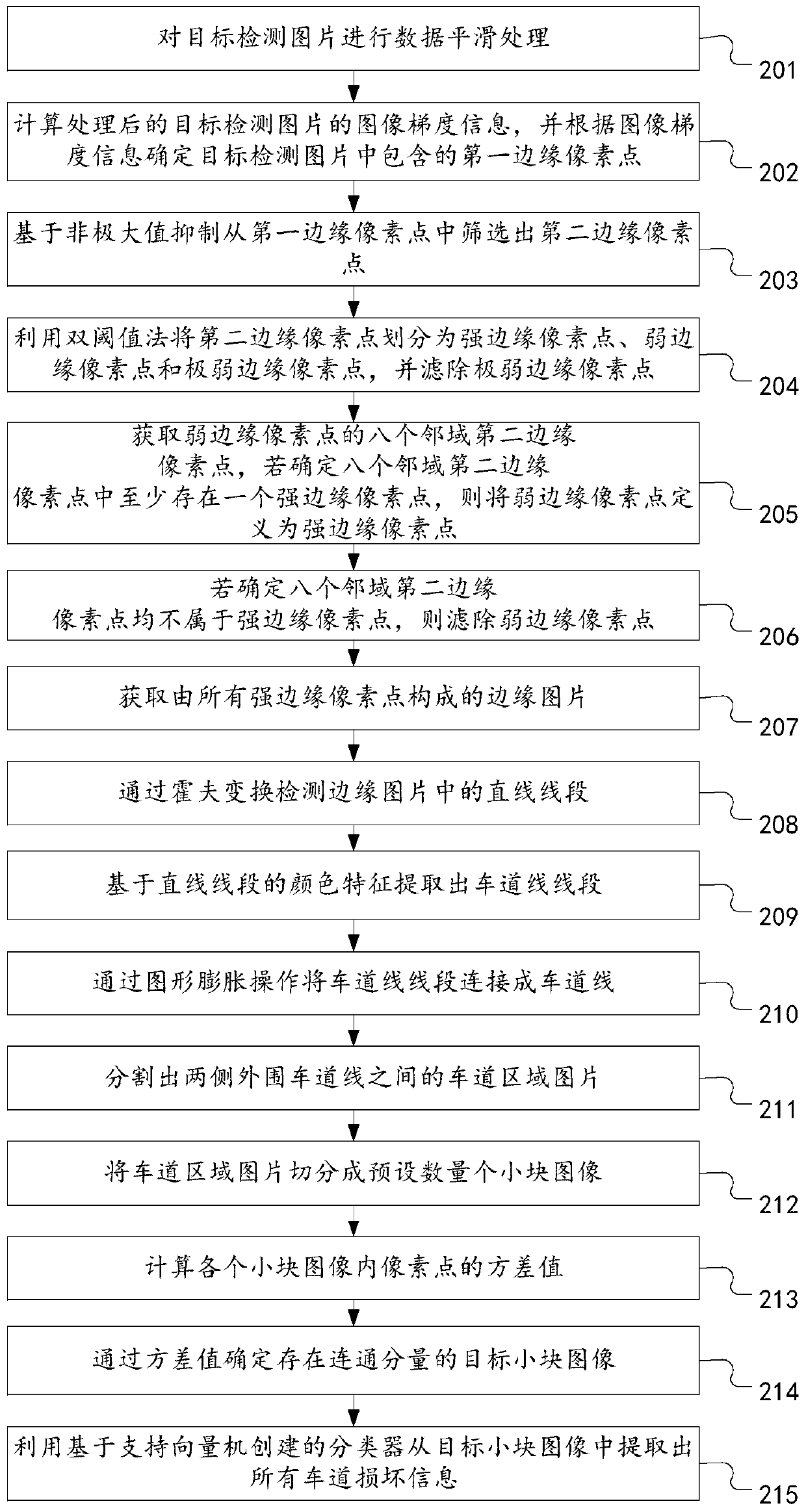

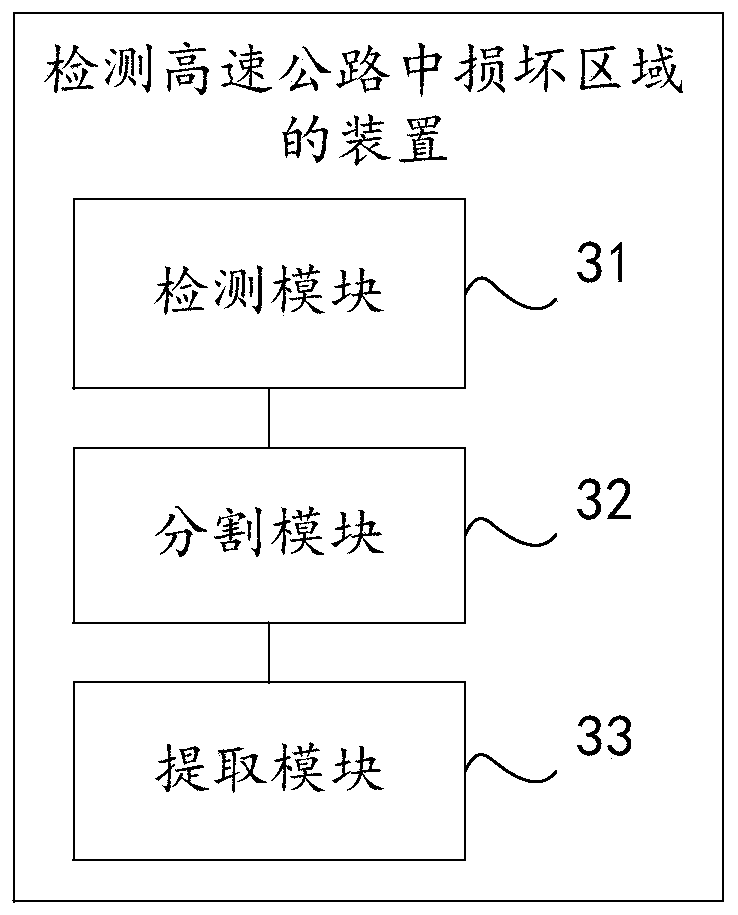

Method and device for detecting damaged area in expressway and computer equipment

PendingCN110490839AEnsure safetyShorten the timeImage enhancementImage analysisComputer graphics (images)Computer vision

The invention discloses a method and device for detecting a damaged area in an expressway and computer equipment, relates to the technical field of computers, and can solve the problems that when thedamaged area in the expressway is detected, the detection efficiency is low, the accuracy is low, and the danger coefficient is high. The method comprises the following steps: carrying out edge detection on an obtained target detection picture by utilizing an edge detection algorithm; segmenting a lane area picture from the target detection picture according to an edge detection result; and performing damage detection on the lane area according to the lane area picture, and extracting lane damage information. The application is suitable for detecting the damaged area in the expressway.

Owner:PING AN TECH (SHENZHEN) CO LTD

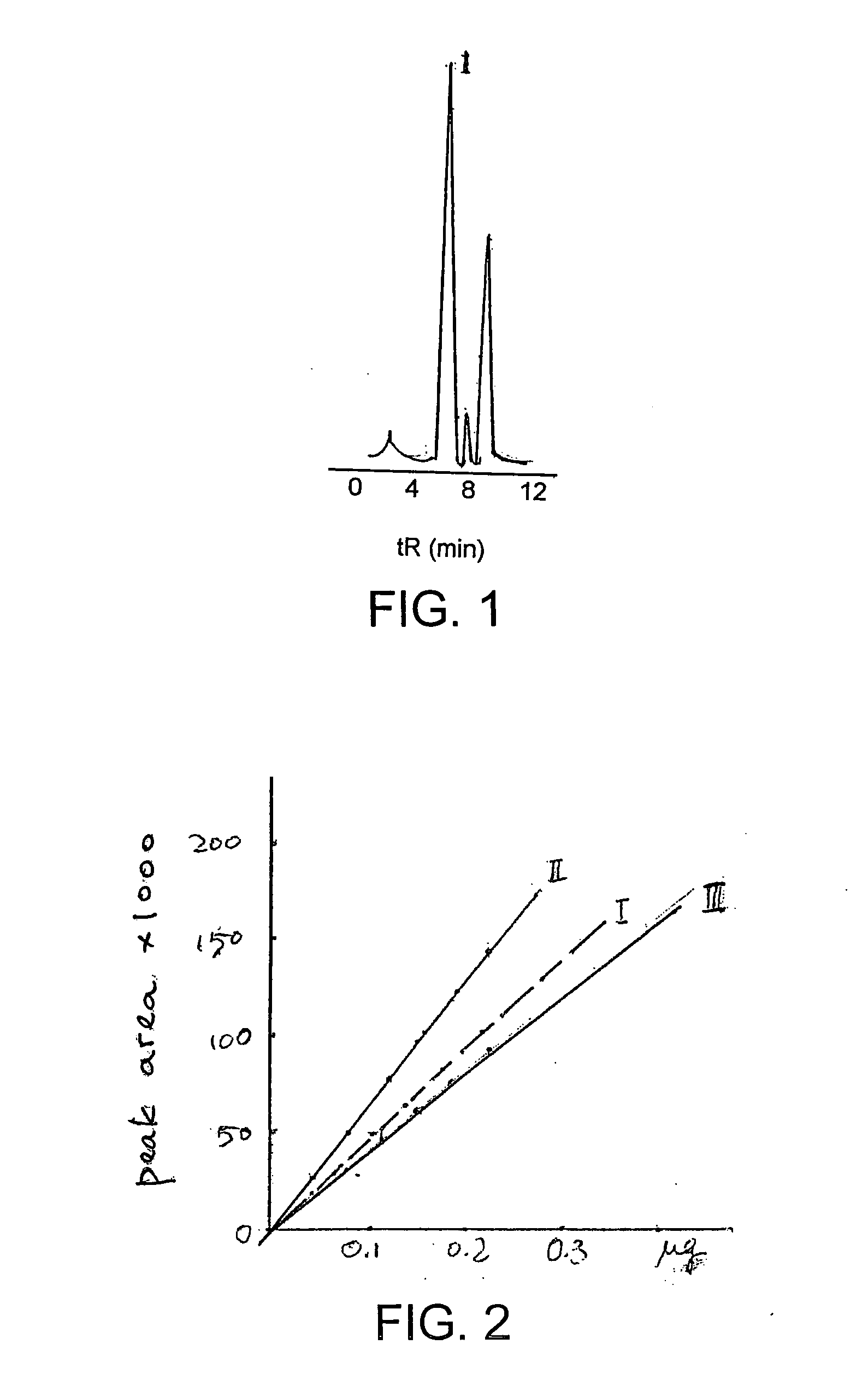

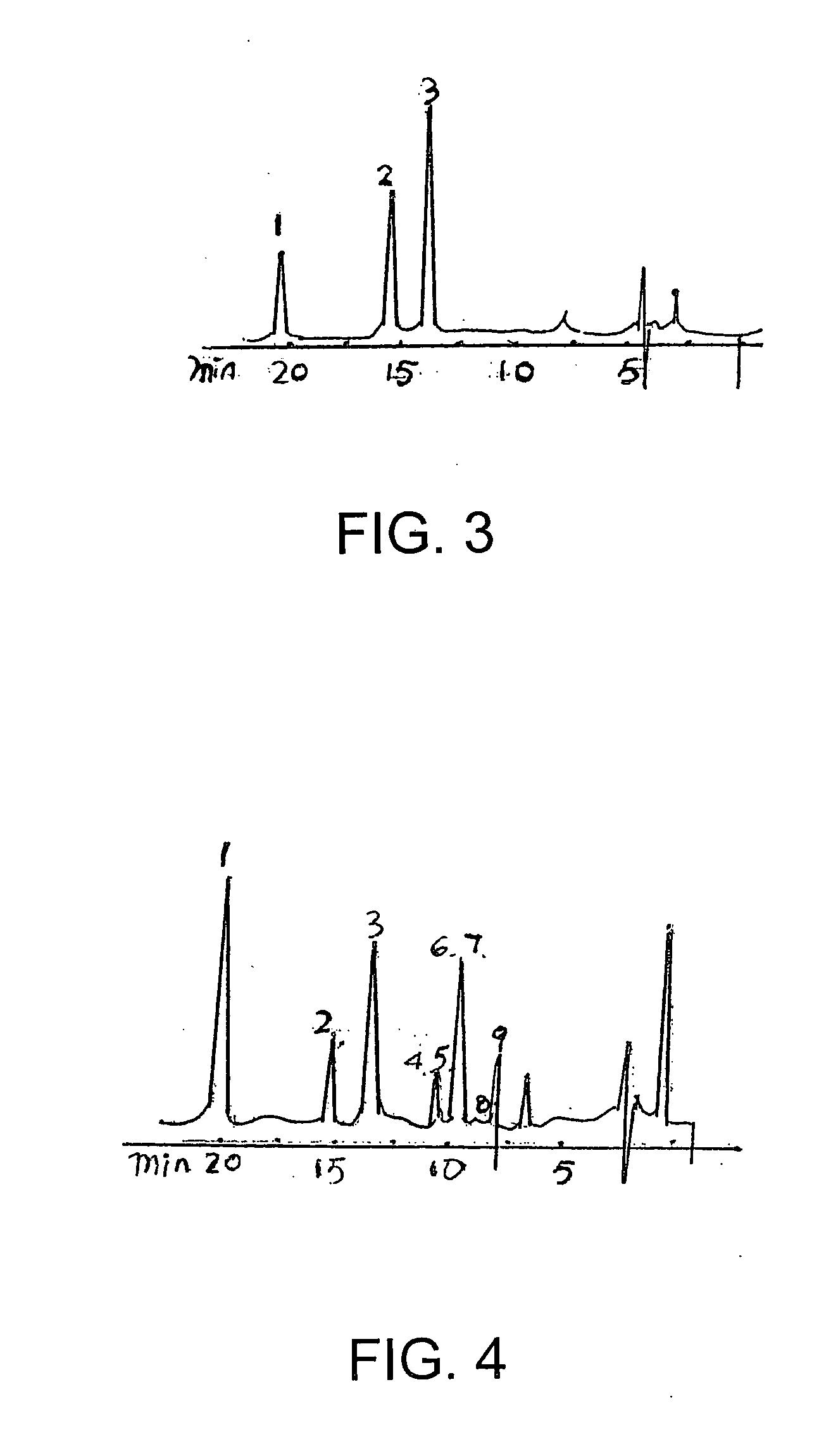

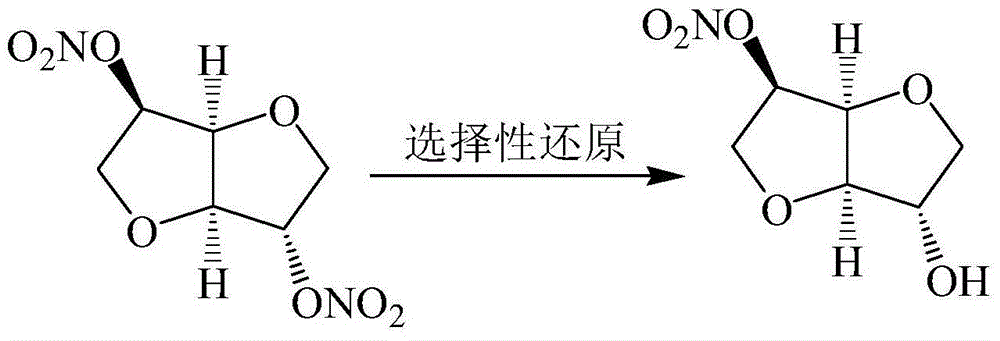

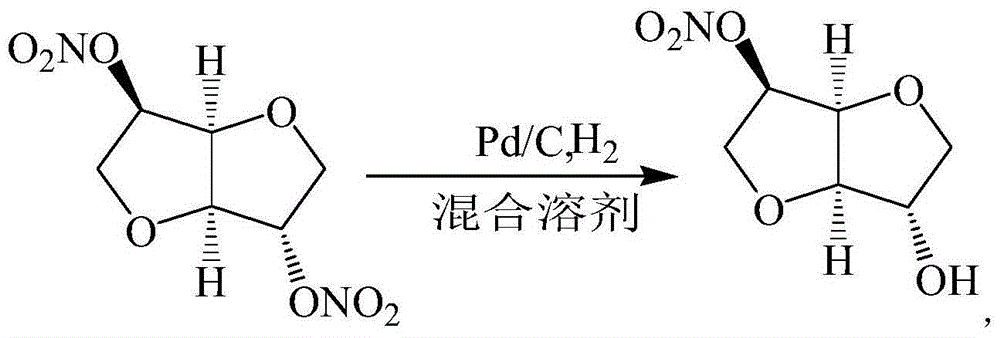

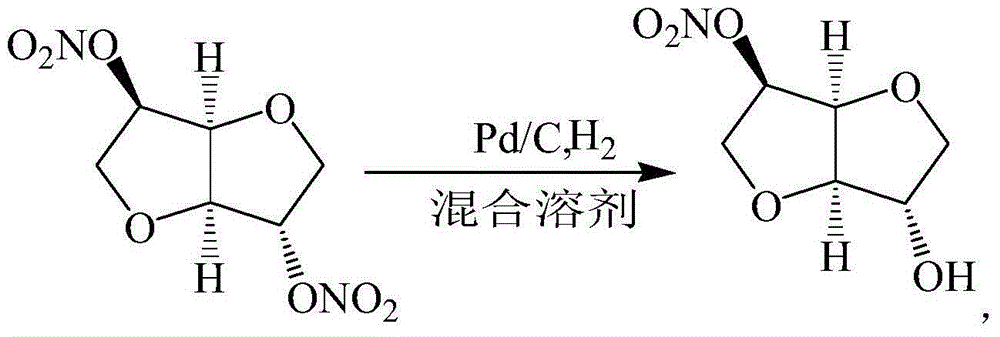

Preparation method for isosorbide 5-mononitrate

ActiveCN104892623AHigh yieldReduce manufacturing costOrganic chemistryIsosorbide-5-mononitrateSolvent

The invention provides a preparation method for isosorbide 5-mononitrate. The preparation method comprises the following steps: with isosorbide dinitrate as a raw materials and Pd / C as a catalyst in a special mixed solvent, carrying out selective hydrogenation reduction on 2-nitro, filtering after reaction, steaming to remove ethyl alcohol in filtrate, extracting residual concentrated liquid through ethyl acetate, washing extracting liquid through dilute acid, washing to be neutral through water, drying through anhydrous magnesium sulfate, filtering to remove a drying agent and steaming to remove ethyl acetate so as to obtain high-purity isosorbide 5-mononitrate. Compared with the prior art, the synthetic method provided by the invention is simple and easy to operate, impurities are easy to remove, the yield and purity are higher, the cost is reduced since the Pd / C and the solvent can be recycled and reused, isosorbide generated through over reduction can be recycled and the preparation method is suitable for industrial production.

Owner:SHANDONG NEWTIME PHARMA

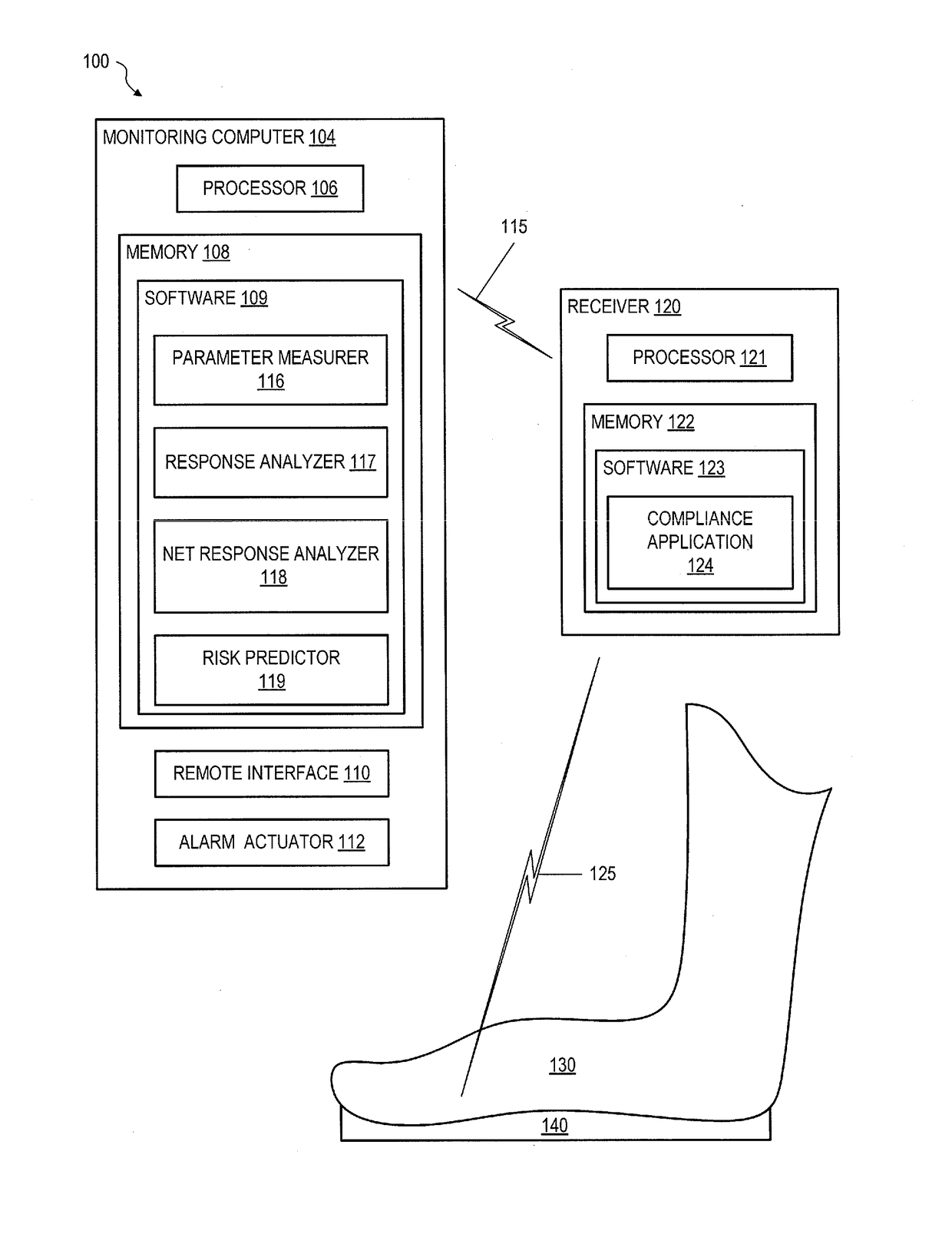

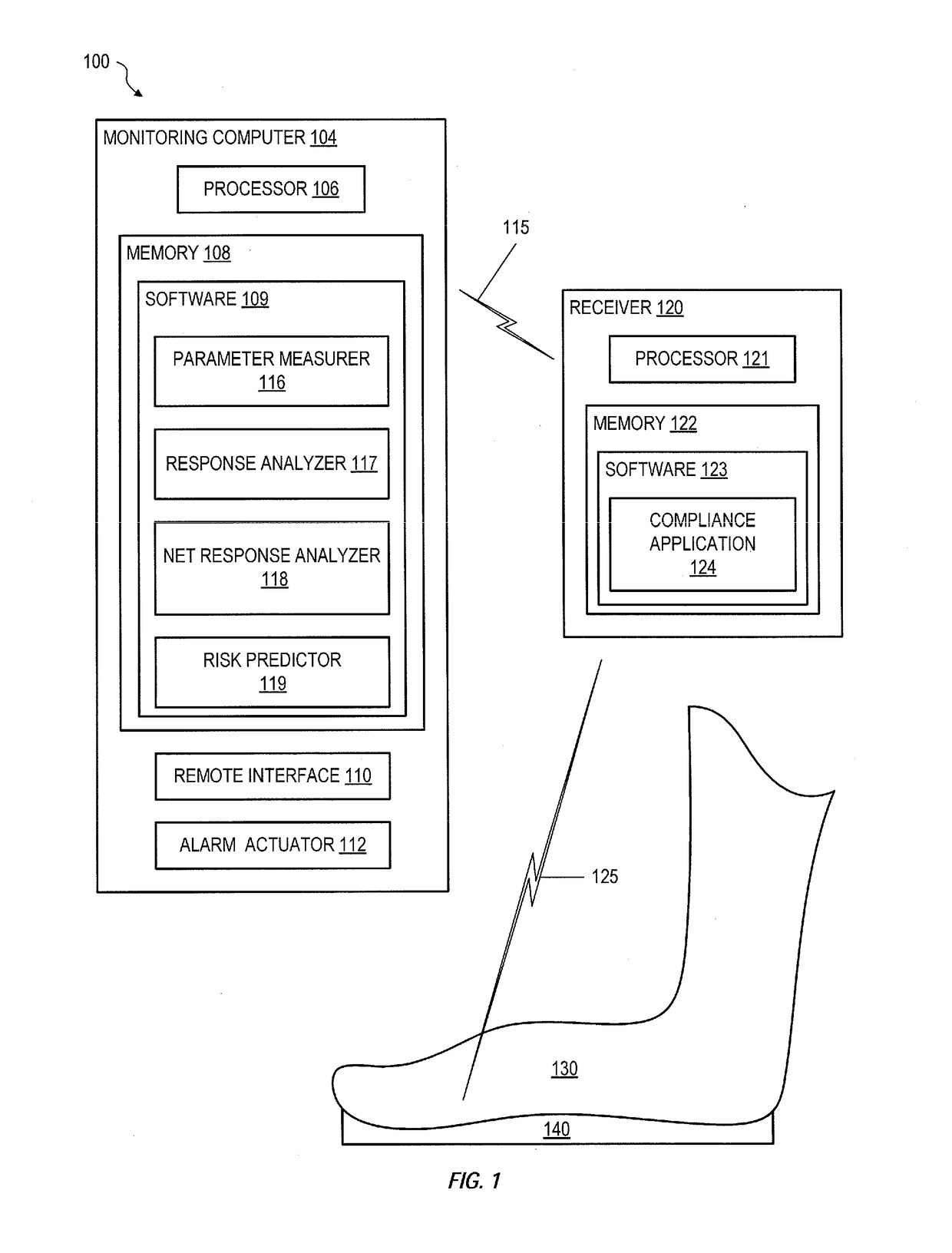

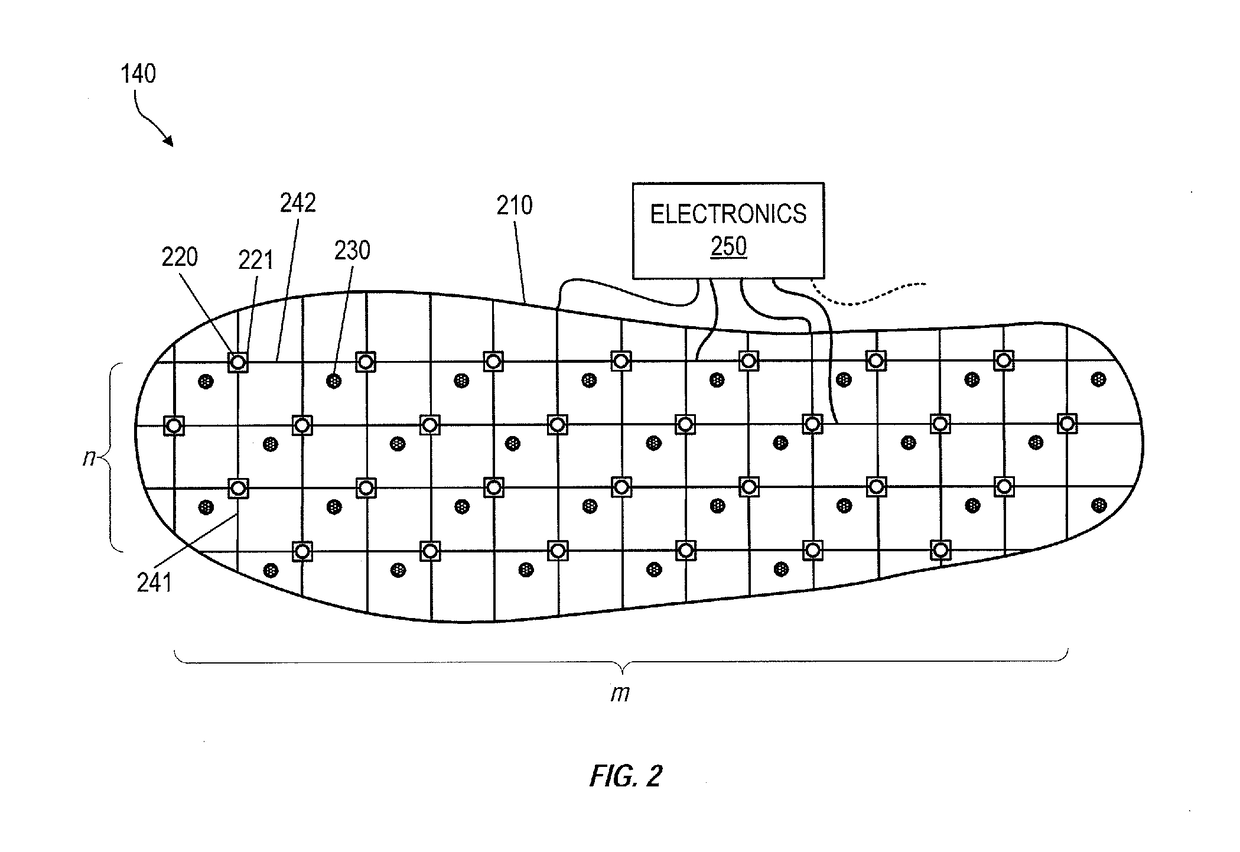

Smart Textile to Predict Risk of Diabetic Foot Ulcer

ActiveUS20180249945A1Easy to identifyEasy to manageDiagnostic recording/measuringSensorsFoot ulcersPhysical therapy

A system and a method predict risk of diabetic foot ulcer by automatically recognizing and tracking physiological activities of a person using a smart textile that has a plurality of pressure sensors and a plurality of temperature sensors. Pressure data indicative of plantar pressure applied to each of the pressure sensors by the person is received from the smart textile. Temperature data indicative of plantar temperature at each of the temperature sensors is received from the smart textile. Plantar parameters are determined from the pressure and temperature data and plantar responses to activity of the person are determined from the plantar parameters. A risk of the person developing a foot ulcer is determined based upon the plantar parameters and the plantar responses.

Owner:THE ARIZONA BOARD OF REGENTS ON BEHALF OF THE UNIV OF ARIZONA

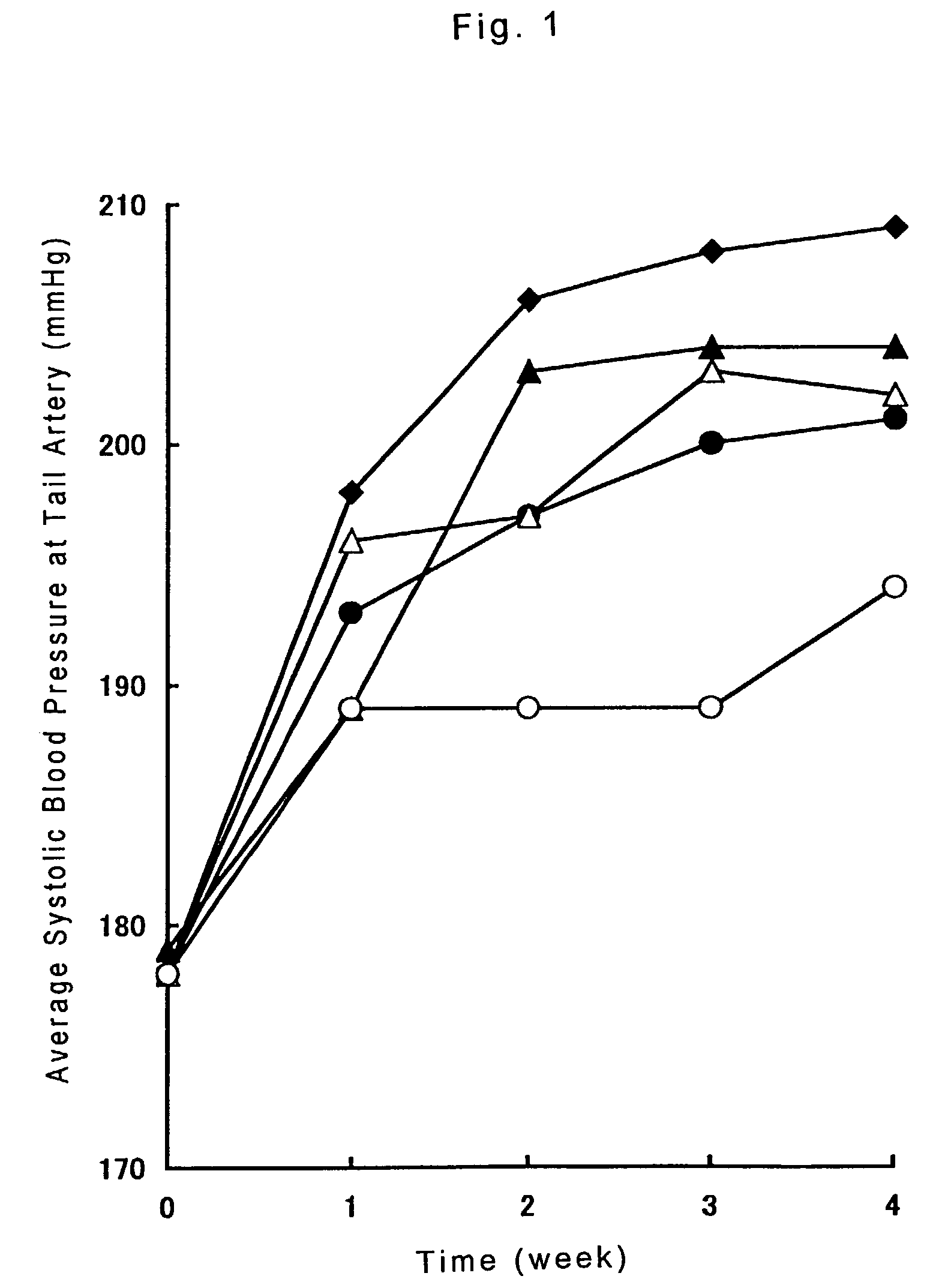

Compositions containing peptide and electrolyte excretion promoter and foods containing the same

InactiveUS7550436B2High activityImprovement of lifestyleHydrolysed protein ingredientsImmunoglobulinsAngiotensin-converting enzymeProteinase activity

A composition containing a peptide and an electrolyte excretion promoter, which comprises a peptide or a peptide mixture which is obtained by lysing a food-origin protein with a protease and has an activity of inhibiting angiotensin converting enzyme, and one or more electrolyte excretion promoters selected from chitosan, alginic acid or a salt thereof, and further relates to a food containing the same. Said composition has excellent inhibitory activity to rise of blood pressure by synergistic effects of both components.

Owner:KRACIE SEIYAKU

Microwave surface coagulator with retractable blade

ActiveUS9028474B2Shorten operation timeDissect the targeted tissueIncision instrumentsCatheterMicrowaveEngineering

An ablation instrument having an ergonomic handle that includes an actuator adapted to selectively extend and retract a blade that is pivotably mounted within an aperture assembly coupled to the housing by a shaft. The shaft extends distally from the handle and includes a coaxial feedline, a wire conduit disposed along a longitudinal axis of the shaft, and a pull wire disposed within the wire conduit and having a proximal and a distal end, wherein a proximal end of the pull wire is operably coupled to the actuator. The aperture assembly is coupled to a distal end of the shaft and includes a reflector having a closed upper portion, and an open lower portion from which the blade may be extended for use. Also disclosed is an ablation system that includes the above-described ablation instrument, a source of ablation energy, and optionally, a source of coolant for cooling the shaft and aperture assembly.

Owner:TYCO HEALTHCARE GRP LP

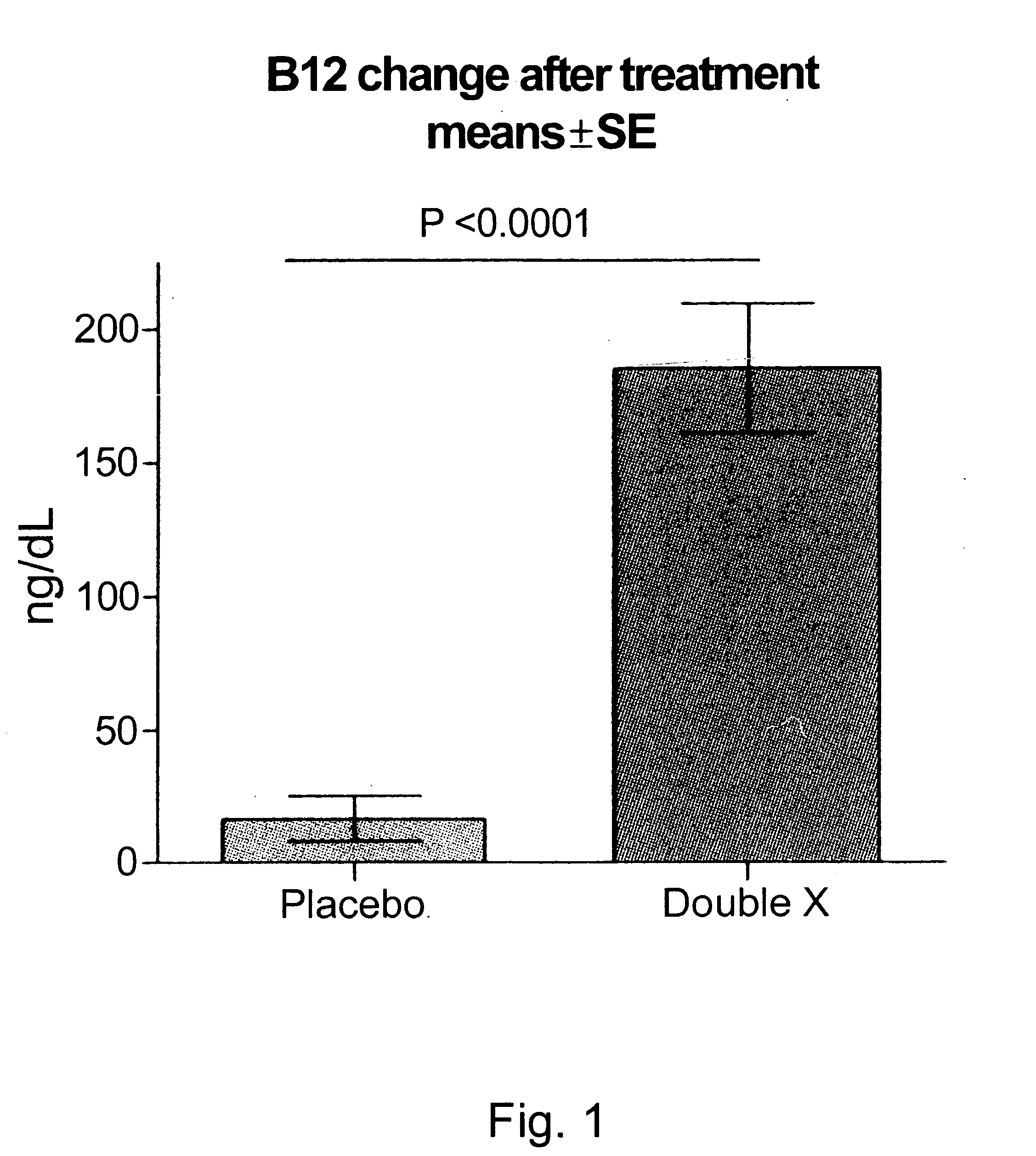

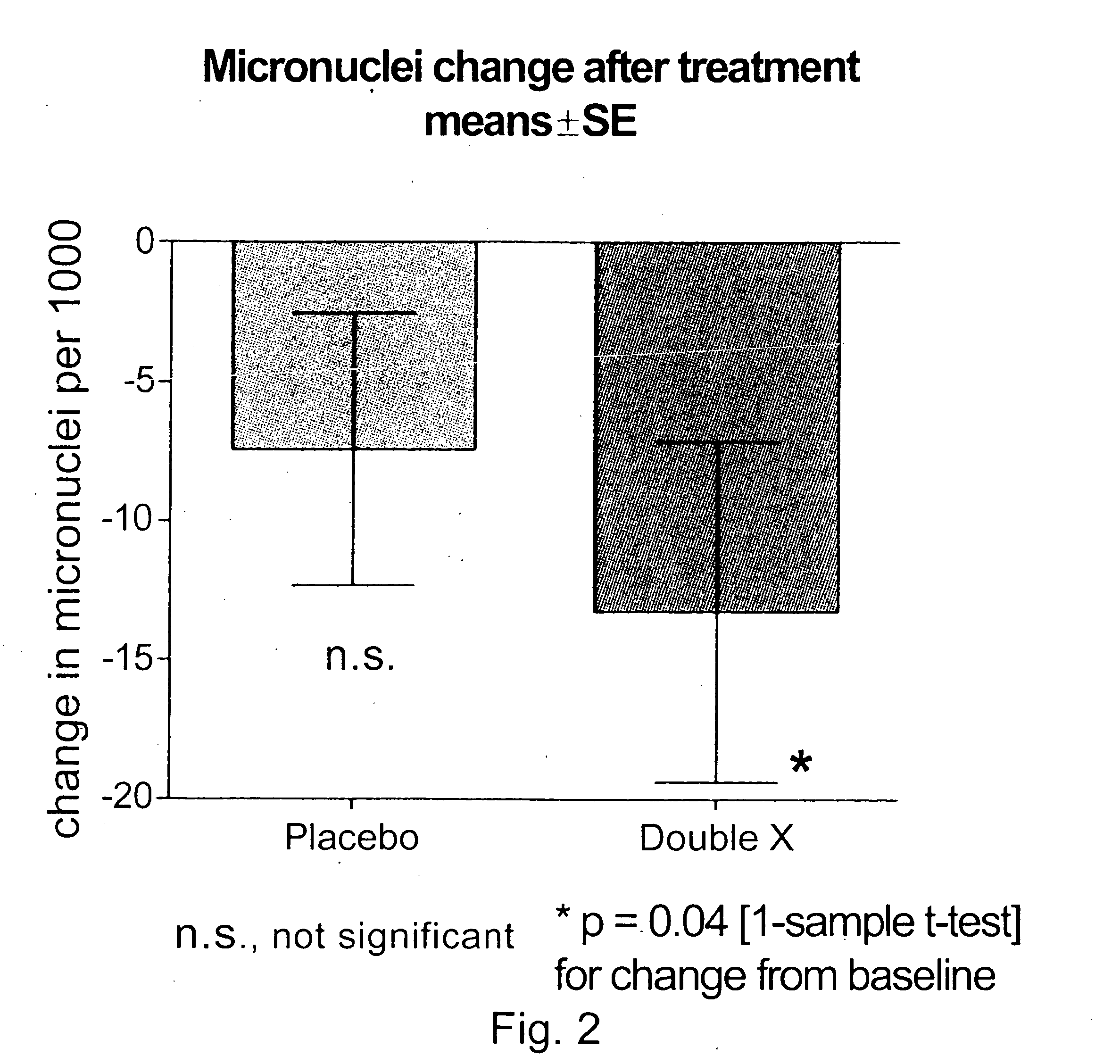

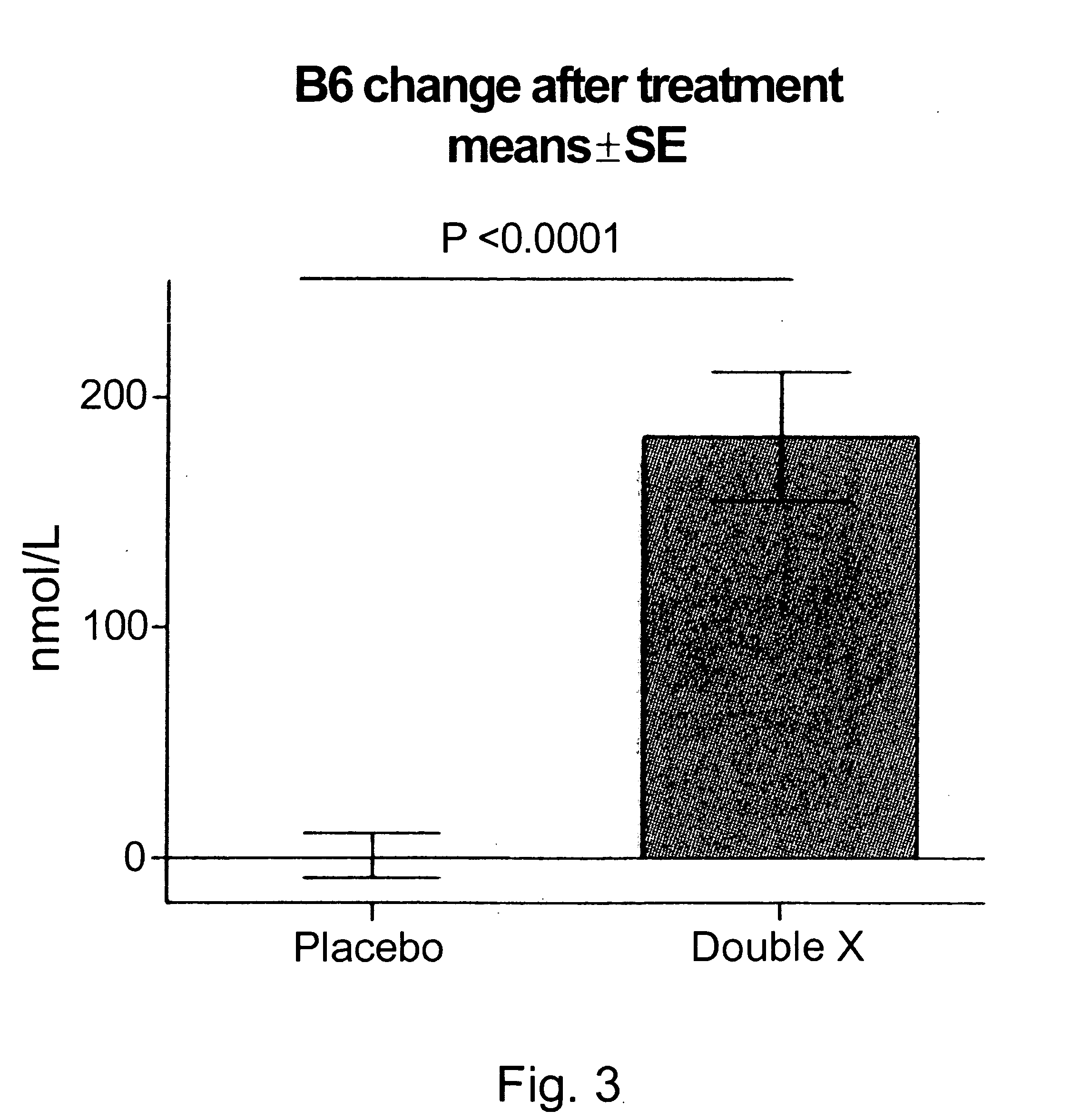

Dietary supplement and related method

InactiveUS20060147563A1Reduce risk factorReduce homocysteine levelBiocideOrganic active ingredientsBeta-CaroteneDietary supplement

A dietary supplement including a unique combination of fruits, vegetables, herbs, and optionally vitamins, minerals and specialty ingredients. The supplement can include a fruit ingredient, a vegetable ingredient and an herbal ingredient, wherein the fruit ingredient is at least one of pomegranate and citrus bioflavonoids, wherein the vegetable ingredient is at least one of asparagus, lutein, lycopene and watercress, and wherein the herbal ingredient is at least one of basil, oregano and rosemary. The supplement can be administered to subjects to reduce risk factors in a subject, for example, by lowering homocysteine levels and / or reducing DNA damage. The supplement can increase plasma levels of at least one of vitamin B6, Vitamin B12, folate, and beta-carotene and other vitamins or substances in the subject.

Owner:ACCESS BUSINESS GRP INT LLC

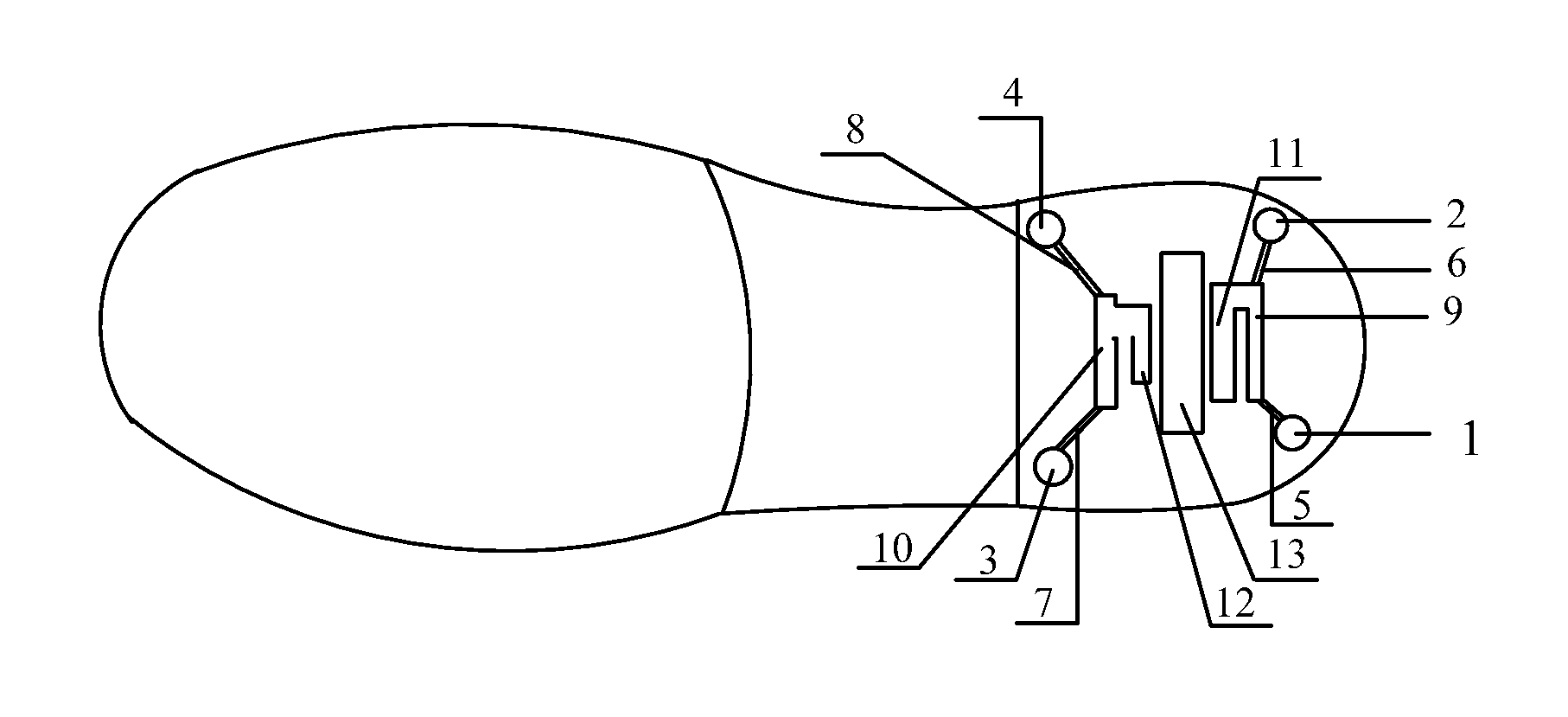

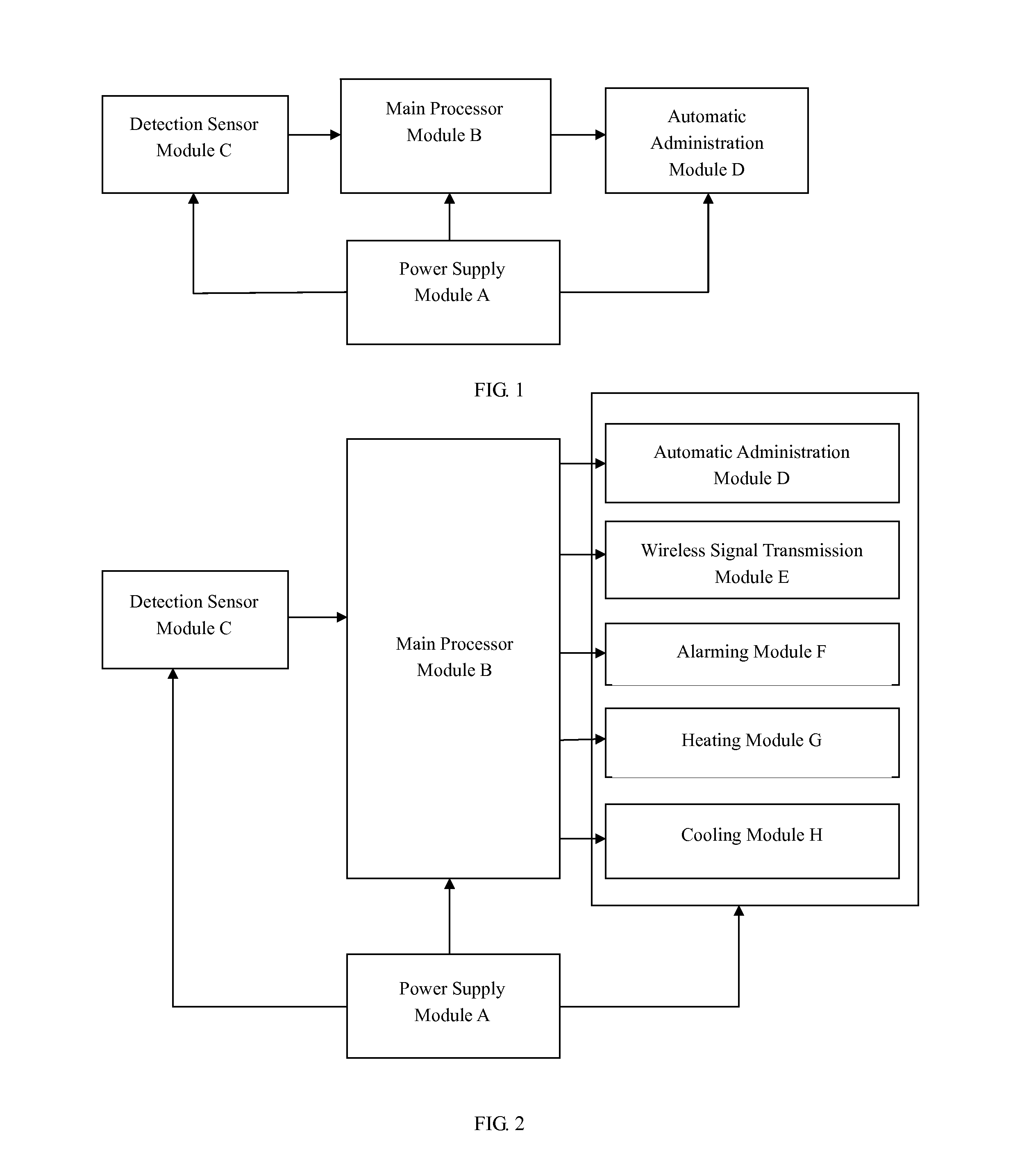

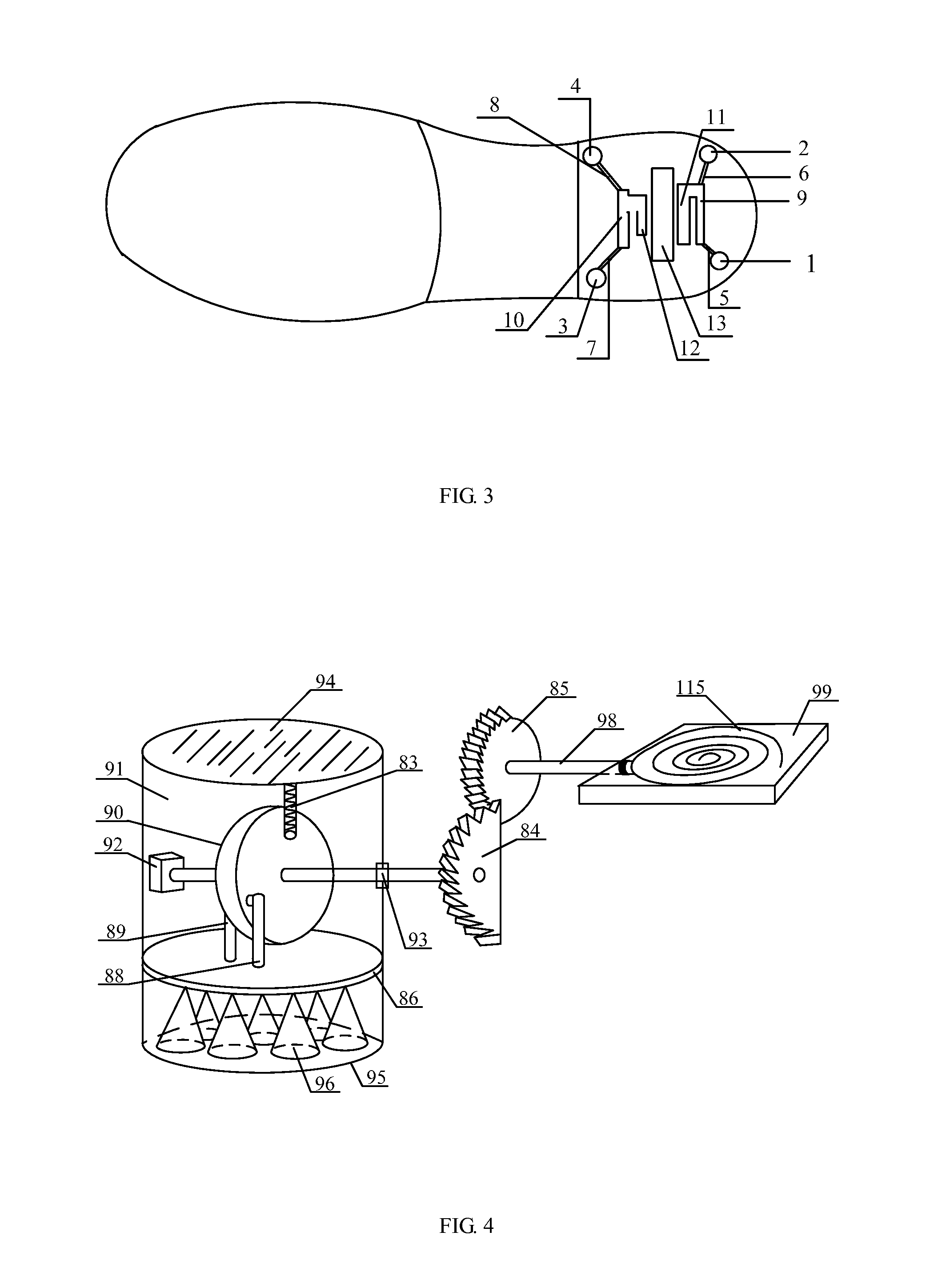

Disease testing and therapeutic device and remote monitoring shoes

ActiveUS20150088057A1Small sizeGuaranteed strongAutomatic syringesMedical devicesDiseaseTherapeutic Devices

The invention discloses a detection and therapeutic device and remote monitoring shoes. The detection and therapeutic device comprises a power supply module (a) which is connected with modules with electricity needs and used for powering the modules, a main processor module (b) which is used for collecting and processing signals from sensors and controlling working status of an automatic injection module (d), a detection sensor module (c) which comprises a plurality of sensors in connection with the main processor module (b) and is used for examining nerves, organs or secretions and sending back the results to the main processor module (b), an automatic injection module (d) which comprises a plurality of automatic injectors in connection with the main processor module (b) and is used for administrating according to signals for controlling from the main processor module automatically. The detection and therapeutic device can be used independently or can be paired with daily goods, such as shoes and the like. According to this arrangement, health condition can be detected at any time and automatic therapies can be achieved as sudden illnesses occur, and therefore, health risks can be reduced.

Owner:SU BO

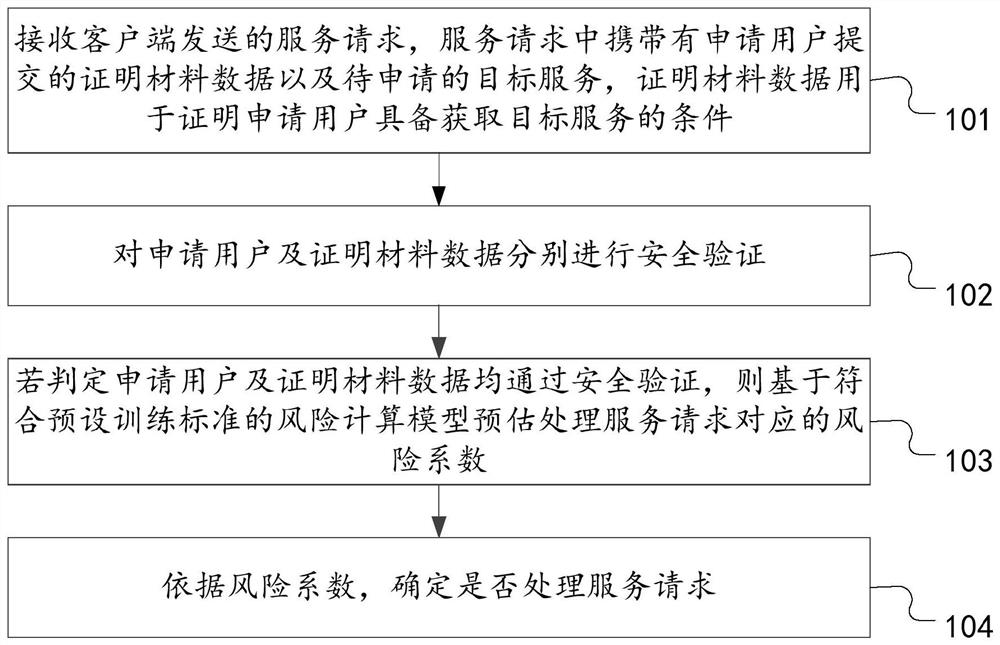

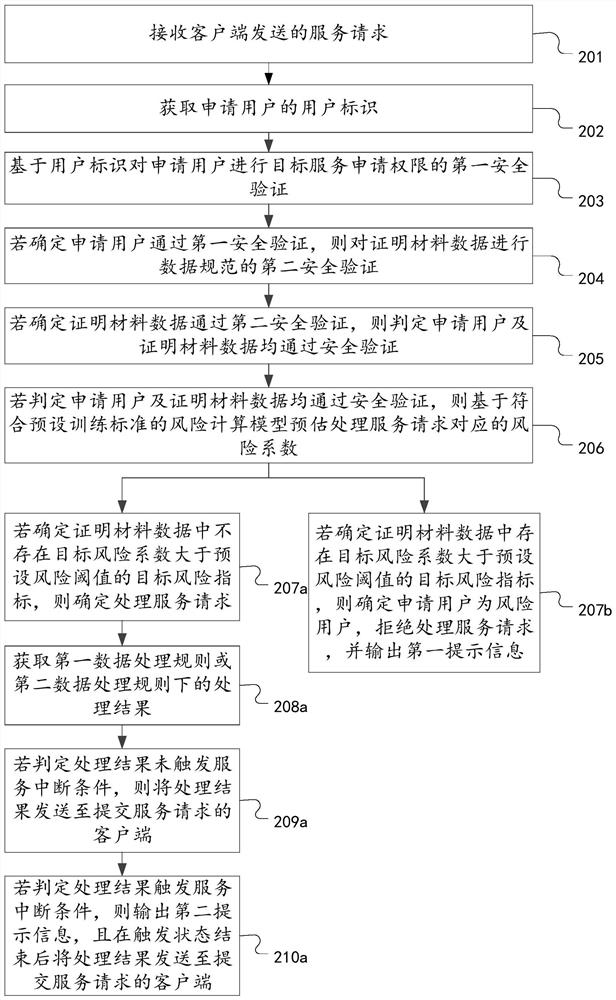

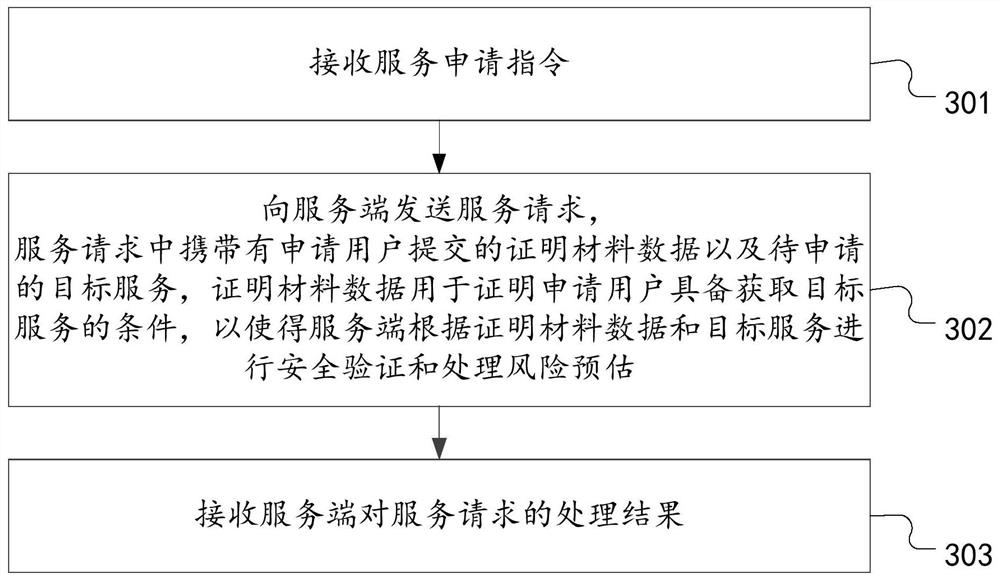

Risk control-based service request processing method, device and system

The invention discloses a risk control-based service request processing method, a device and a system, relates to the field of data processing, and can solve the problems of relatively low operation efficiency, high risk data leakage rate and relatively large potential safety hazards caused by consumption of a large amount of manpower in risk control analysis of service data processing. The methodcomprises the steps of receiving a service request sent by a client by a server, wherein the service request carries certification material data submitted by an application user and a to-be-applied target service, and the certification material data is used for certifying that the application user has a condition of obtaining the target service; performing safety verification on the application user and the certification material data respectively; if it is judged that the application user and the certification material data pass safety verification, estimating a risk coefficient corresponding to the processing service request based on a risk calculation model meeting a preset training standard; and determining whether to process the service request according to the risk coefficient. Themethod is suitable for risk control processing of the service request.

Owner:北京水滴科技集团有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com