Method of rapidly predicting smoking uniformity of cigarette

A technology of uniformity and cigarettes, applied in the field of sensory quality evaluation of cigarettes, can solve the problems of inability to achieve quantitative, horizontal, rapid comparison, large influence of subjective factors, inability to test online, etc., achieving simple judgment methods and low equipment requirements , The results are accurate and reliable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

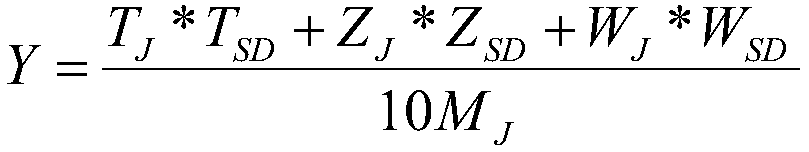

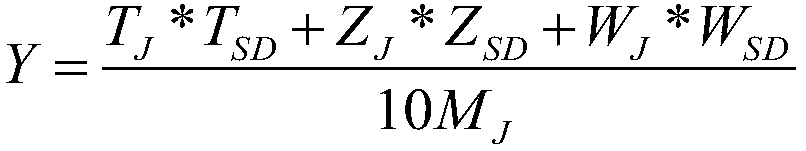

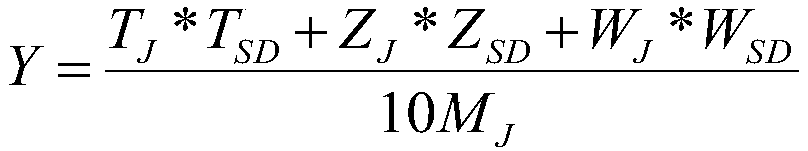

Method used

Image

Examples

Embodiment 1

[0023] Example 1: Prediction of the smoking uniformity of four cigarette samples with shredded widths of 0.9, 1.0, 1.1, and 1.2 mm.

[0024] Four kinds of cigarette samples with shredded widths of 0.9, 1.0, 1.1, and 1.2mm are rolled into cigarettes with a circumference of 24.2±0.2mm and a length of (24.0+60.0)±0.5mm according to the weight of the same cigarette . The arc length of the leveling groove of the leveling disc of the cigarette machine used is 24 mm, of which the end section is 12 mm, the non-compacted section is 36 mm, and the end section is 12 mm.

[0025] Take a number of mixed shredded cigarette samples with a cut width of 0.9 (number: sample 1), and randomly divide the cigarette samples into three groups, each group has 50 cigarettes, and the first group of cigarette samples is according to the standard The method of YC / T476-2013 measures and calculates the average density T of the tip of the cigarette respectively J and standard deviation T SD , the average ...

Embodiment 2

[0034] Example 2: Prediction of smoking uniformity of three kinds of cigarette samples whose blending ratios of cut stems are 8wt%, 12wt%, and 16wt%.

[0035] Take 8wt%, 12wt%, and 16wt% mixed cut stem samples, and roll them respectively according to the same cigarette weight to make cigarettes with a circumference of 24.2±0.2mm and a length of (30.0+54.0)±0.5 mm cigarettes. The arc length of the leveling groove of the leveling disc of the cigarette machine used is 22mm, of which the end section is 11mm, the non-compacted section is 32mm, and the end section is 11mm.

[0036] Take a number of rolled cigarette samples with a cut stem blending ratio of 8wt%, and randomly divide the cigarette samples into three groups. The number of cigarettes in each group is 40. The first group follows the standard YC / T 476-2013 The method is used to measure and calculate the average density T of the end section of the cigarette respectively J and standard deviation T SD , the average densit...

Embodiment 3

[0045] Example 3: Prediction of smoking uniformity of D brand cigarette samples produced by three cigarette factories A, B and C.

[0046] The circumference of the D brand cigarette sample produced by the three cigarette factories A, B and C is 24.2±0.2mm, and the length of the cigarette is (27.0+57.0)±0.5mm. The arc length of the flattened groove of the flattened disc of the cigarette machine used is 22 mm, of which the length of the end section is 11 mm, the non-compacted section is 35 mm, and the end section is 11 mm.

[0047] Take several cigarette samples of brand D cigarettes produced by A Cigarette Factory, and divide the cigarette samples into three groups at random, and the number of cigarettes in each group is 50. The same as in Example 1, the first group of cigarette samples is measured and calculated according to the YC / T 476-2013 method for the characteristic value Y value of the cigarette density distribution, and the second group of cigarette samples is measured...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com