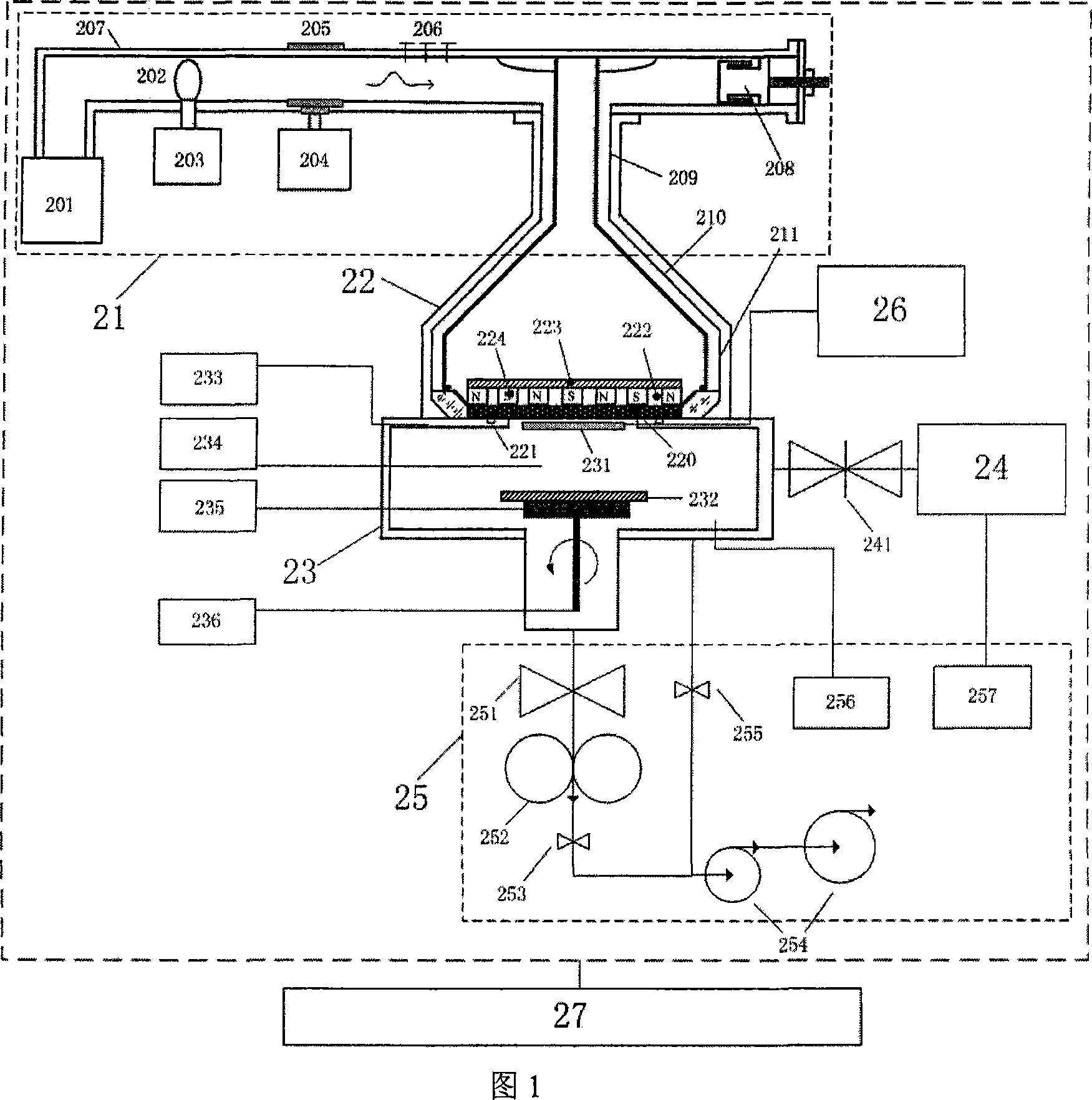

Method for chemical gaseous phase deposition of silicon nitride film by electron cyclotron resonance plasma

A technology of electron cyclotron resonance and chemical vapor deposition, which is applied in the field of microelectronics, can solve the problems of low deposition rate, poor uniformity of large area, high hydrogen content, etc., and achieve low deposition temperature, excellent uniformity and repeatability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

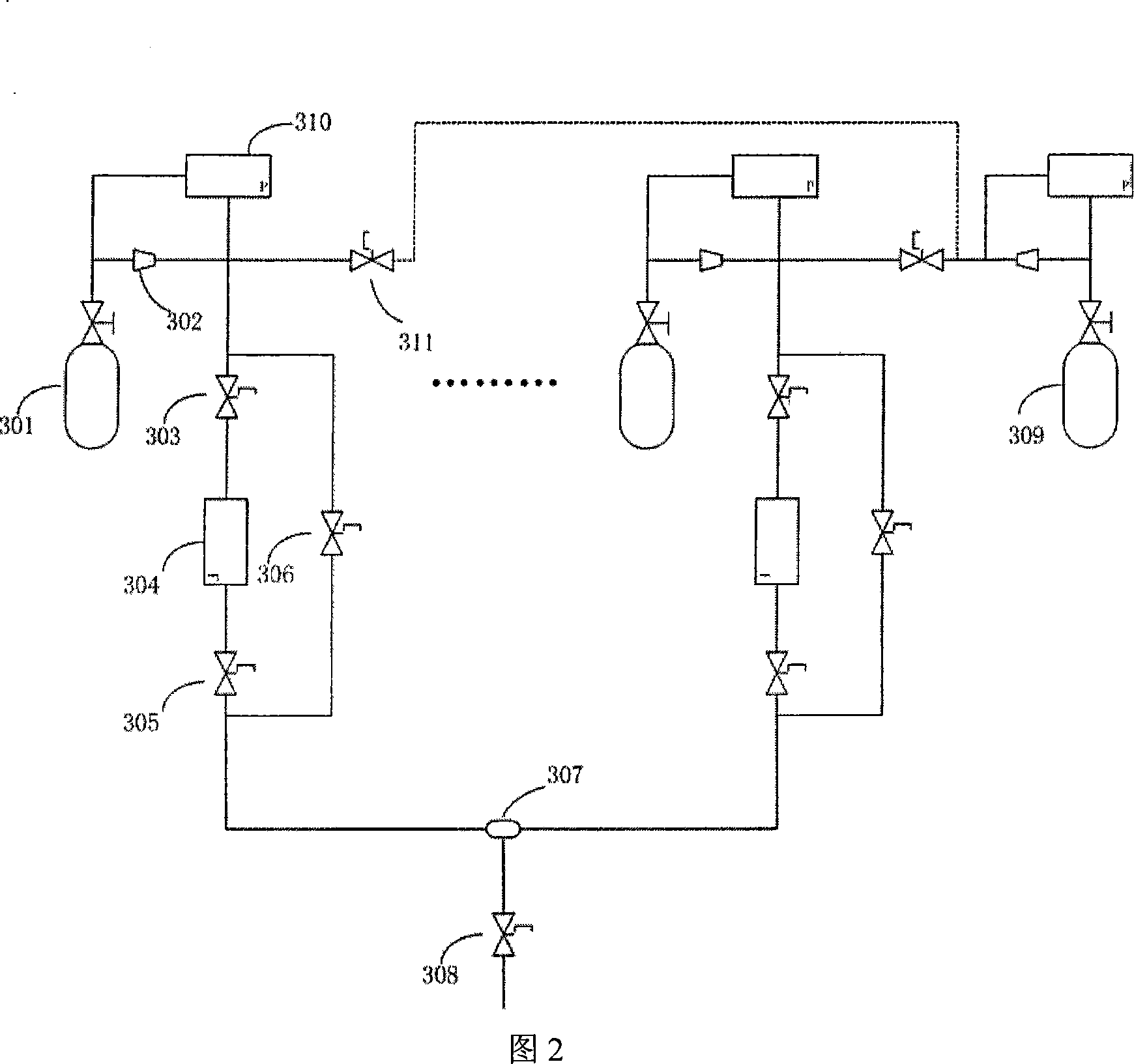

Method used

Image

Examples

Embodiment 1

[0060] The present invention selects a p(100) single crystal silicon chip with a substrate size of Φ150mm as the substrate.

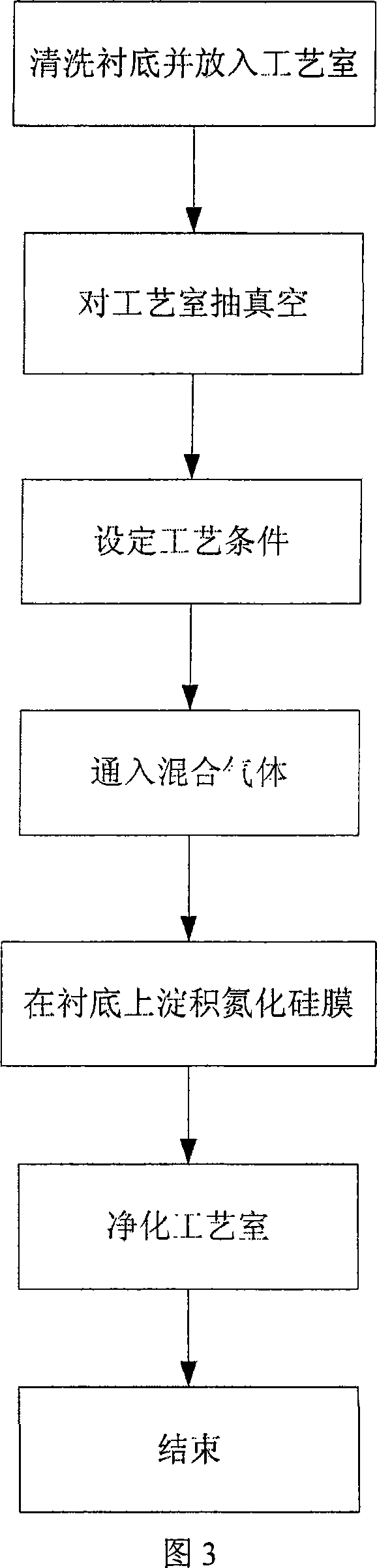

[0061] In the first step, the substrate is cleaned and placed in the process chamber.

[0062] Immerse the wafer in 4:1 H 2 SO 4 :H 2 o 2 The solution was cleaned for 10 minutes at a solution temperature of 90 ° C; the deionized water was cleaned for 5 minutes, including 6 cycles; the silicon wafer was immersed in 5:1:1 H 2 O:H 2 o 2 : Wash in HCl solution for 10 minutes at a solution temperature of 70°C; wash in deionized water for 5 minutes including 6 cycles; soak the wafer in a 50:1 HF solution for 15 to 30 seconds; wash in deionized water for 5 minutes including 6 cycles The second cycle: spin-drying treatment under the protection of nitrogen atmosphere, that is, washing with deionized water for 80 seconds, and spin-drying for 120 seconds. After cleaning, a clean silicon surface with a surface saturated by H-bonds is obtained. The cleaned s...

Embodiment 2

[0078] The present invention selects a p(100) single crystal silicon chip with a substrate size of Φ150mm as the substrate.

[0079] In the first step, the substrate is cleaned and placed in the process chamber.

[0080] Immerse the wafer in 4:1 H 2 SO 4 :H 2 o 2 The solution was cleaned for 10 minutes at a solution temperature of 90 ° C; the deionized water was cleaned for 5 minutes, including 6 cycles; the silicon wafer was immersed in 5:1:1 H 2 O:H 2 o 2 : Wash in HCl solution for 10 minutes at a solution temperature of 70°C; wash in deionized water for 5 minutes including 6 cycles; soak the wafer in a 50:1 HF solution for 15 to 30 seconds; wash in deionized water for 5 minutes including 6 cycles The second cycle: spin-drying treatment under the protection of nitrogen atmosphere, that is, washing with deionized water for 80 seconds, and spin-drying for 120 seconds. After cleaning, a clean silicon surface with a surface saturated by H-bonds is obtained. The cleaned s...

Embodiment 3

[0096] The present invention selects the quartz plate whose substrate is Φ10mm as the substrate.

[0097] In the first step, the substrate is cleaned and placed in the process chamber.

[0098] Wash the quartz sheet with acetone tidal sound for 20 minutes; wash with deionized water for 5 minutes including 6 cycles; spin dry treatment under the protection of nitrogen atmosphere, that is, wash with deionized water for 80 seconds, and spin dry for 120 seconds. The cleaned quartz wafer is placed on the sample stage 232 in the process chamber 23 .

[0099] The second step is to evacuate the process chamber.

[0100] Turn on the oil-free vacuum pump, molecular pump and related valves in sequence to evacuate the process chamber so that the background vacuum reaches 1.0×10 -5 Pa.

[0101] The third step is to set the process conditions respectively.

[0102] 1. The temperature of the substrate is set to 200°C;

[0103] 2. The total gas flow rate is 150 sccm, and the gas flow rati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com