Laminated optical film, manufacture and use thereof

A liquid crystal display, optical film technology, used in optics, nonlinear optics, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

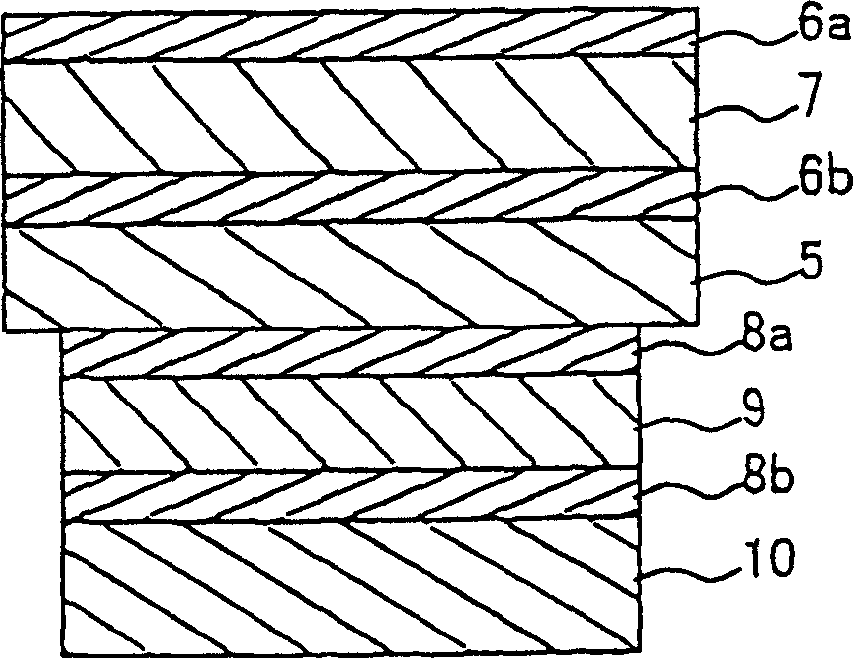

[0071] A retardation film composed of polycarbonate and exhibiting a retardation value of 140 nm was produced. A 25 μm thick acrylic-based adhesive layer was formed on the opposite surface of the retardation film. The dichroic polarizer was attached to the phase retarder by adhesive such that the absorption axis of the dichroic polarizer was at an angle of 45 degrees to the retarded phase axis of the phase retarder. In this way, a polarizer including a retardation film was manufactured.

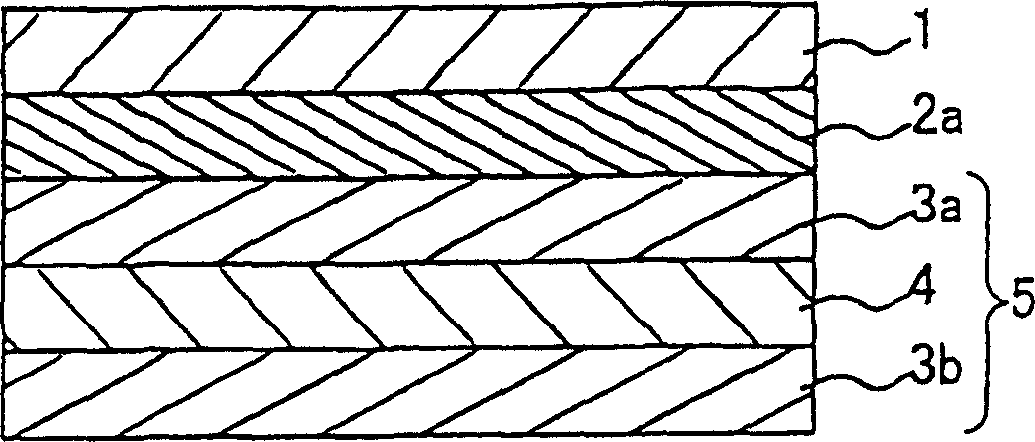

[0072] A 0.1 μm thick PVA alignment film was formed on an 80 μm thick TAC film. After the alignment film was ground, three layers of cholesteric liquid crystal polymers having selective reflection center wavelengths of 400nm, 550nm, and 700nm were formed and sequentially aligned on the alignment film. The thickness of each layer is 3 μm. Then, a λ / 4 sheet of polycarbonate (front-end retardation: 140 nm) was pasted on the cholesteric liquid crystal layer with a 25 µm thick acrylic-based pre...

example 2

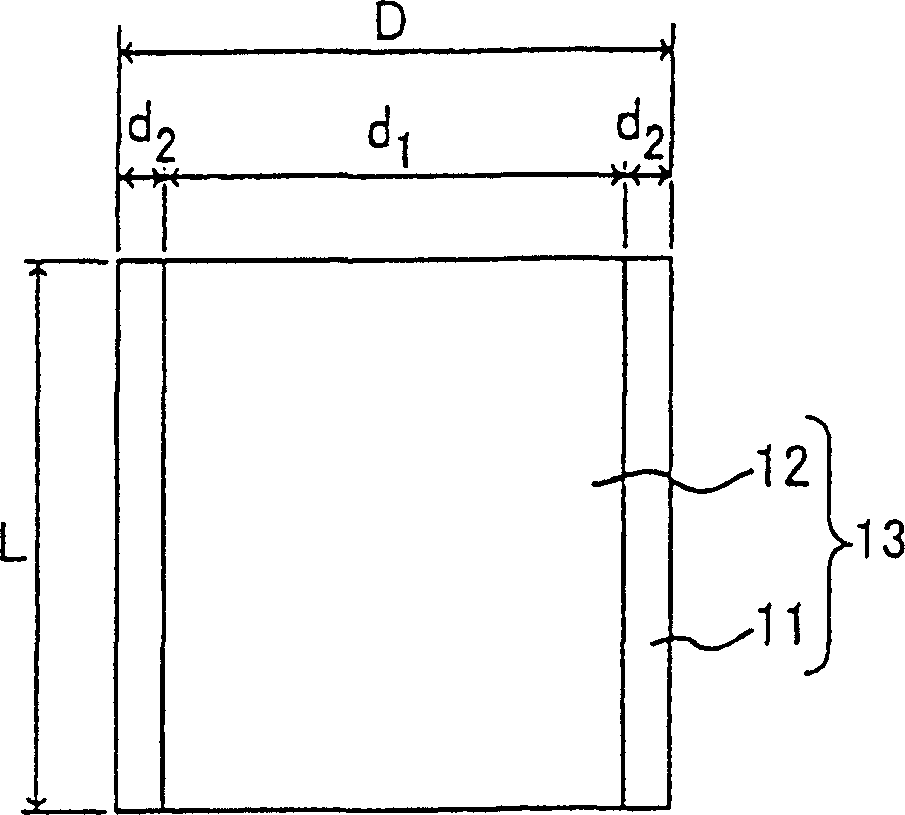

[0078] The laminated optical film manufactured in Example 1 and having protrusions was introduced into a liquid crystal module, and a backlight unit reworkability test and an impact test were performed. The introduction of the laminated optical film into the liquid crystal module was carried out as follows. Such as Figure 7 In the configuration shown, the surface of the phase retarder 22 of the laminated optical film 33 is pasted to the rear of the liquid crystal cell 32 . A double-sided adhesive tape 29 (No. 531MC manufactured by Nitto Denko Co., Ltd.) is attached to one protruding portion of the laminated optical film 33 . The protruding portion of the laminated optical film 33 is adhered to the light guide plate 28 of the backlight unit 34 (according to an example of the present invention) by a double-sided adhesive tape 29 .

[0079] Although this example shows the case where No. 531MC manufactured by Nitto Denko was used as the double-sided tape, the same result can be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com