Method for treating nitrate nitrogen-containing wastewater based on Co3O4/Fe3O4/CNTs composite dispersed electrode

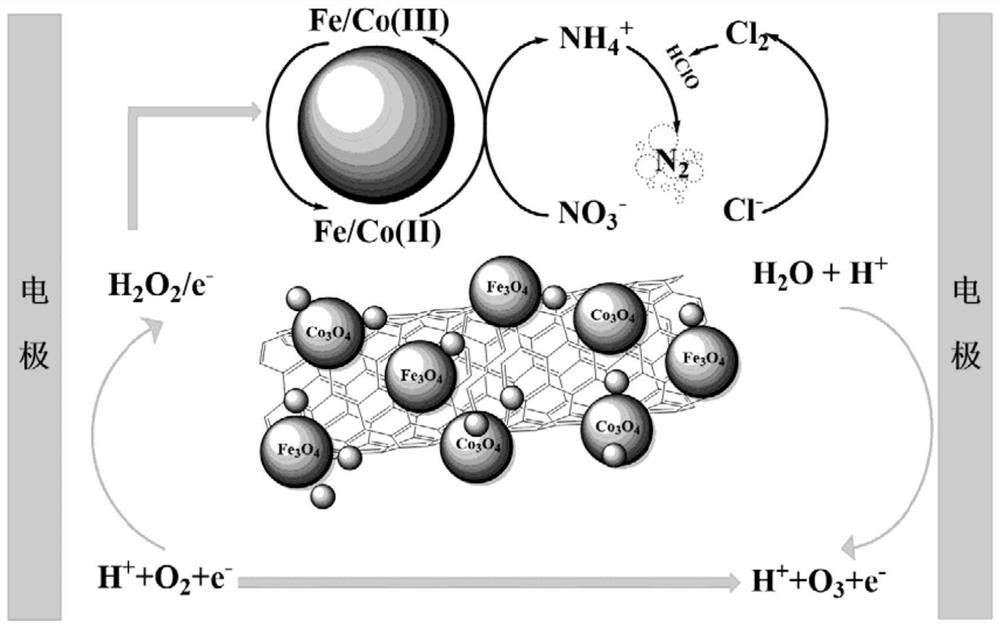

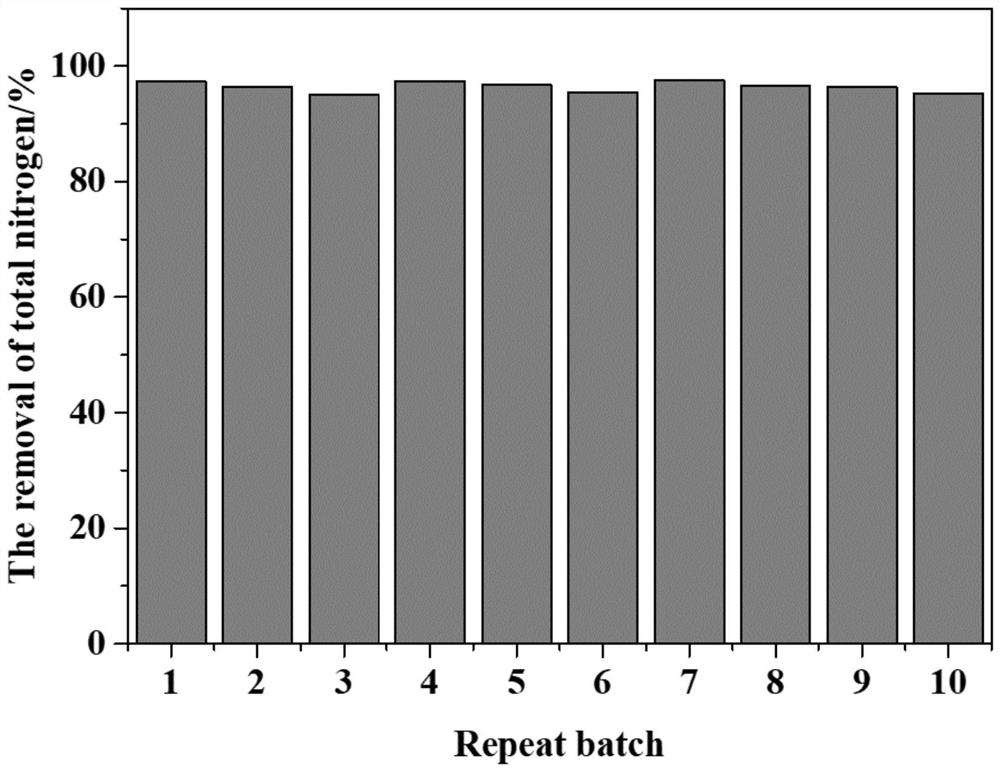

A technology for nitrate nitrogen and wastewater treatment, applied in water/sludge/sewage treatment, sterilization/microdynamics water/sewage treatment, water/sewage treatment, etc., can solve the problem of slow surface reaction kinetics and photoresponse range of catalysts Narrow, serious recombination of photogenerated carriers, etc., to achieve good application prospects, high reuse times, excellent stability and repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] In this example, Co 3 o 4 / Fe 3 o 4 The preparation method of the / CNTs dispersed electrode is as follows:

[0047] S100. Add 120mg of carbon nanotubes into the immersion solution A, the immersion solution A includes 20-40mL ethylene glycol, 10-20mL polyethylene glycol, 1.0-2.0g CoCl 2 ·6H 2 O and 1.0-2.0 g FeCl 3 ·6H 2 O, mixed solution A is obtained; carbon nanotubes are preferably multi-walled carbon nanotubes;

[0048] S200, adding 3.0-4.0 g of sodium acetate into the mixed solution A, and ultrasonically treating it for 1.5-2.0 hours to obtain the mixed solution B;

[0049] S300, sealing the mixed solution B in a stainless steel reaction kettle with Teflon lining, and maintaining it at 200-250°C for 12-20h to obtain an intermediate product;

[0050] S400, washing the intermediate product with ethanol and water, and then drying at 60-90°C to obtain Co 3 o 4 / Fe 3 o 4 / CNTs dispersed electrode; vacuum pump can also be used to filter after washing to shorte...

Embodiment 2

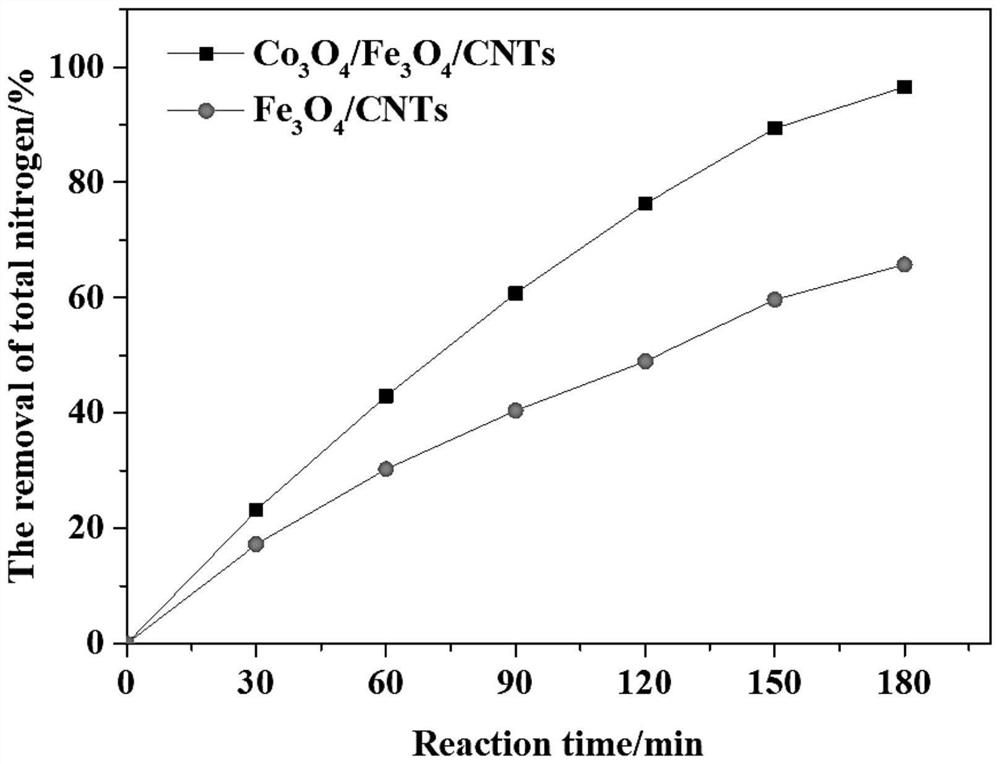

[0054] The basic content of this embodiment is the same as that of embodiment 1, and its difference is: utilize the Co prepared by embodiment 1 3 o 4 / Fe 3 o 4 / CNTs dispersed electrodes are used to treat several groups of nitrate-nitrogen wastewater, among which the concentration of nitrate nitrogen in the nitrate-nitrogen wastewater is 200mg / L. co 3 o 4 / Fe3 o 4 The dosage of / CNTs dispersed electrode is 10g / L, the DC voltage is 8-12V, and the electrolysis time is 3h. Electrolyte was added to the experimental group so that the concentration of sodium chloride in the electrolyte was 1.2 g / L.

[0055] In this embodiment, the pHs in the electrolytes of experimental groups 6-11 were 2, 3, 5, 7, 9, and 11, respectively. Using the above treatment parameters to treat nitrate-nitrogen wastewater, the denitrification rates of experimental groups 6-11 were 85.32%, 87.39%, 95.64%, 90.32%, 89.35%, and 88.27%, respectively.

Embodiment 3

[0057] The basic content of this embodiment is the same as that of embodiment 1, and its difference is: utilize the Co prepared by embodiment 1 3 o 4 / Fe 3 o 4 / CNTs dispersed electrodes treat several groups of nitrate-nitrogen wastewater. The nitrate nitrogen concentration of the nitrate-nitrogen wastewater is 200mg / L, the pH is 5, the DC voltage is 8-12V, and the electrolysis time is 3h. Electrolyte was added to the experimental group so that the concentration of sodium chloride in the electrolyte was 1.2 g / L.

[0058] In this example, the Co in the electrolyte of experimental group 12-16 3 o 4 / Fe 3 o 4 The dosages of / CNTs dispersed electrodes are 1g / L, 2.5g / L, 5g / L, 10g / L, 15g / L respectively. Using the above treatment parameters to treat nitrate-nitrogen wastewater, the denitrification rates of experimental groups 6-11 were 86.32%, 94.31%, 95.12%, 96.01%, and 89.03%, respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| denitrification rate | aaaaa | aaaaa |

| denitrification rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com