Central-tube-type high-strength all-dielectric introductive optical fiber cable

A fiber optic cable and central tube type technology, which is applied in the field of central tube type high-strength all-dielectric introduction of fiber optic cables, can solve the problems of difficult network wiring, lead to indoor equipment, user safety hazards, etc., and achieve light weight and material reduction. The effect of consumption and elimination of safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

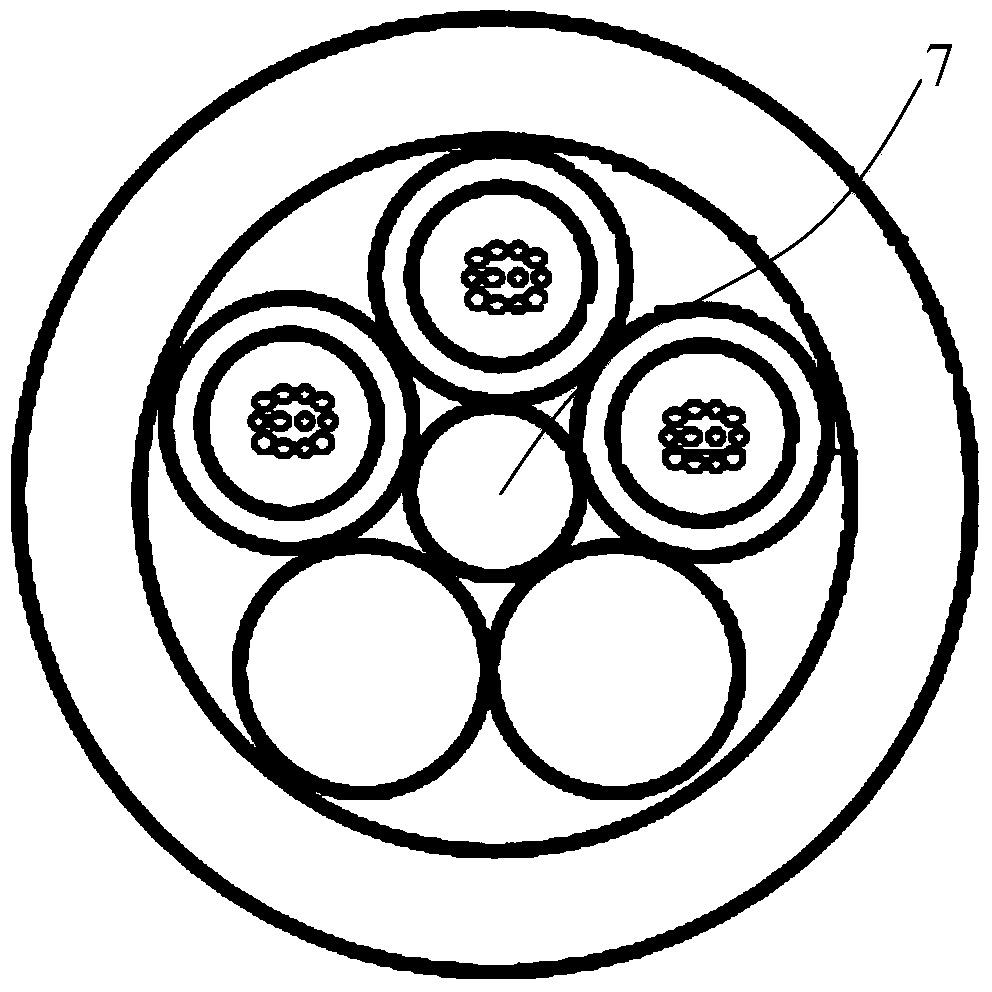

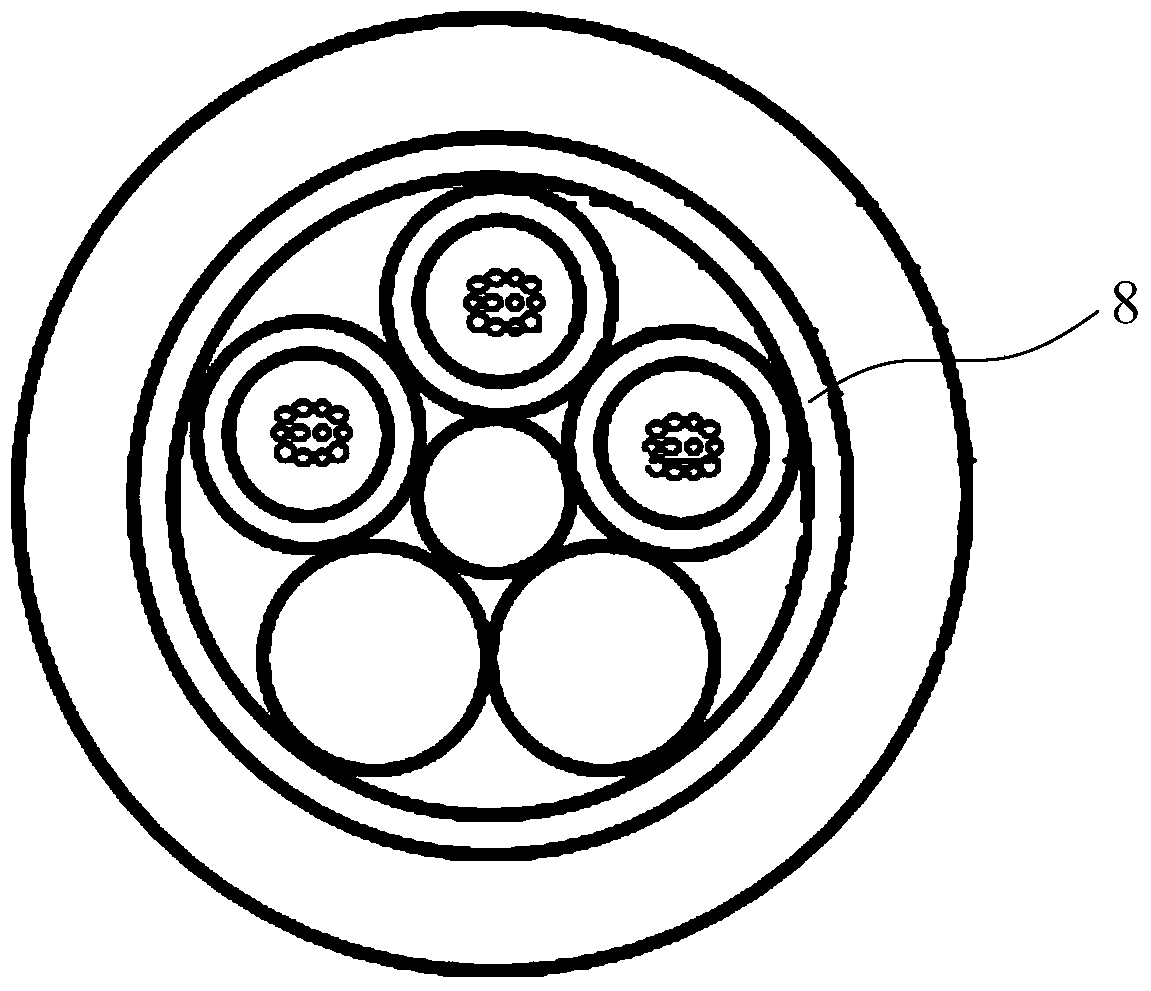

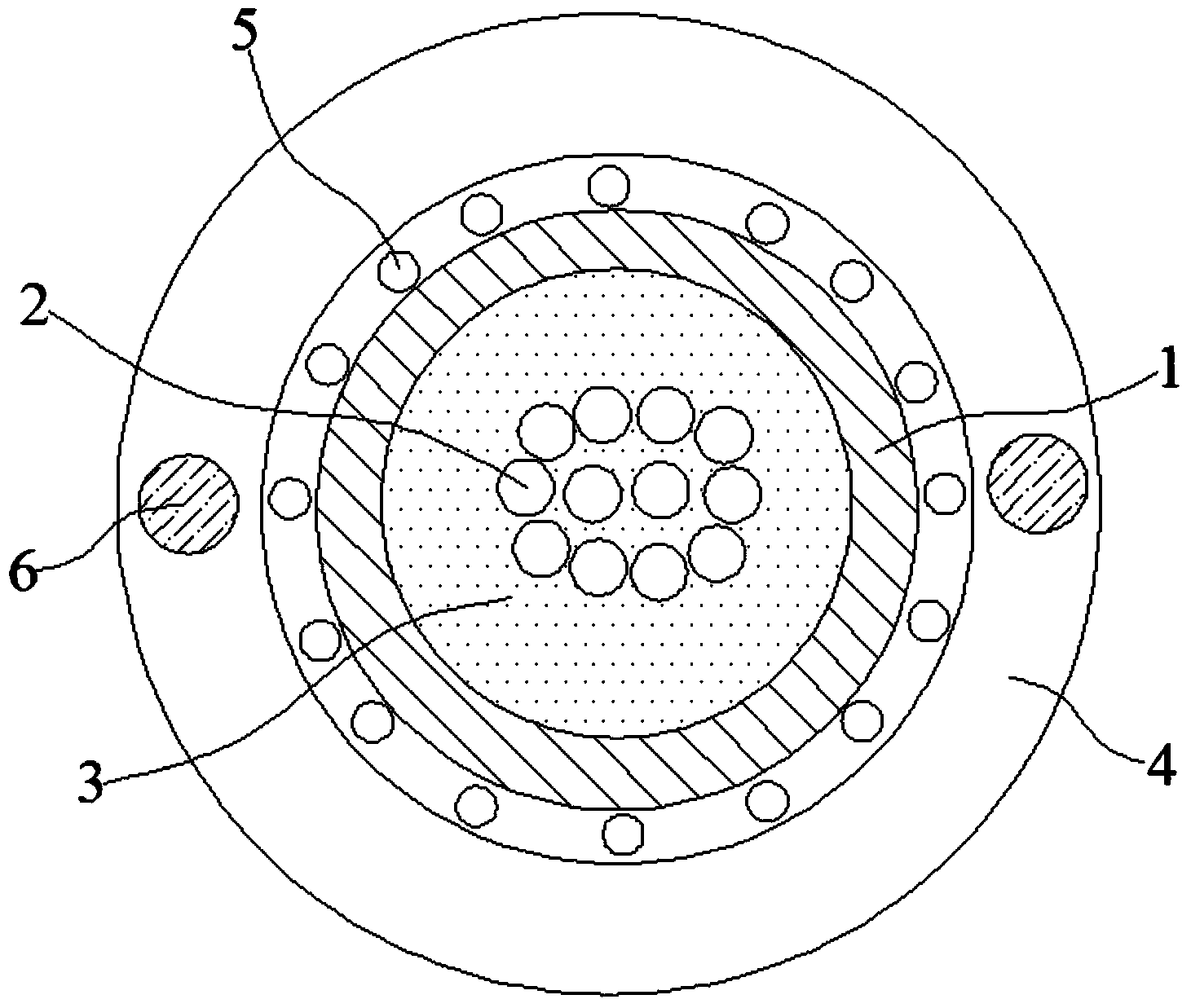

[0018] Embodiment: A central tube-type high-strength all-dielectric lead-in fiber optic cable, including a loose tube 1 located in the center and several glass optical fibers 2 located in the loose tube 1, between the loose tube 1 and the glass optical fibers 2 Filled with thixotropic water-blocking fiber paste 3, a PE sheath layer 4 is coated on the outer surface of the loose tube 1, and there are several wires distributed along the circumferential direction between the loose tube 1 and the PE sheath layer 4. Water-blocking aramid fiber 5, at least two reinforced glass fiber plastic rods 6 are located on both sides of the loose tube 1 and embedded in the PE sheath layer 4. The water-blocking aramid fibers are composed of aramid yarns located in the center and a cured resin layer covering the outer surface of the aramid yarns, and water-blocking particulate matter is adhered.

[0019] The above-mentioned glass optical fiber 2 is a single-mode optical fiber or a multi-mode opti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com