Hydraulic building compound anti-seepage system and system forming method

A hydraulic structure and composite anti-seepage technology, which is applied in construction, hydraulic engineering, sea area engineering, etc., can solve problems such as high water scour force, peeling of anti-seepage materials, threats to the durability and safety factor of hydraulic structures, etc. To achieve the effect of good elasticity and strong binding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

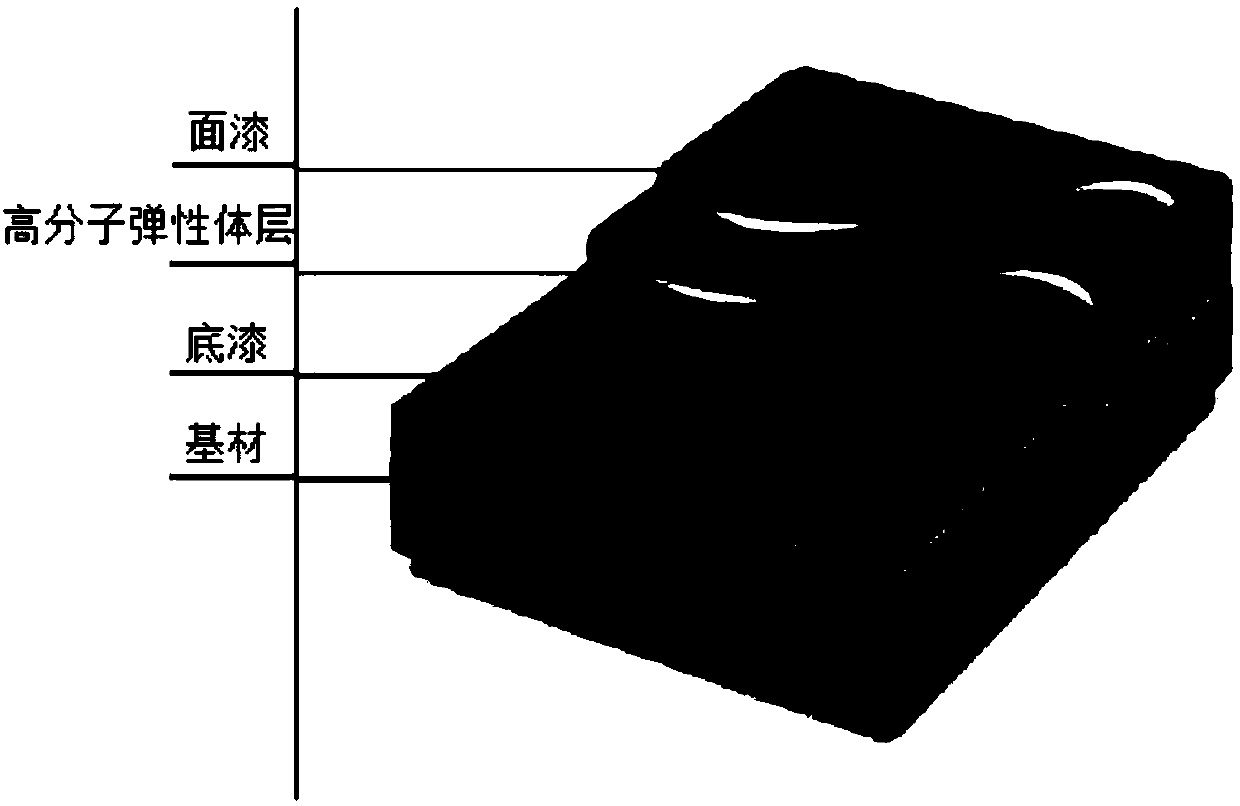

[0093] The preparation method of above-mentioned composite anti-seepage system is:

[0094] 1) Brush the first primer layer and / or epoxy putty layer on the concrete surface of the hydraulic structure, the amount of the first primer layer is 0.35kg / m 2 , if the concrete surface defect is serious, the first primer layer can be replaced by epoxy putty or the concrete defect can be leveled with epoxy putty after the first primer layer is applied, and the interval between painting and the next layer is 7-36 hours Hour;

[0095] 2) Spray or brush the second primer layer, the dosage is 0.1kg / m 2 , the interval between spraying or brushing and applying the next layer is 4 to 24 hours;

[0096] 3) Spray or brush the polymer elastomer material, the dosage is 3~7kg / m 2 , forming a coating film waterproof layer.

[0097] Wherein, and / or, increase step 1a) after step 1) according to 0.8kg / m 2 Spray 20-50 mesh silica sand;

[0098] And / or, step 4) is added after step 3) to coat a laye...

Embodiment 1

[0135] The composite anti-seepage system provided by the present invention is applied to the anti-seepage embodiment of the expansion joints of water delivery tunnels and box culverts. Since the water delivery tunnel does not need to be resistant to impact and wear, and does not need to be exposed to sunlight, it needs to be soaked in water for a long time. During construction, the surface of the base material belongs to the wet base surface. Therefore, the composite anti-seepage system used in this application field is: epoxy primer layer for wet interface + epoxy modified two-component polyurethane primer layer + two-component polyurea-based elastomer coating.

[0136] Among them, the water conveyance tunnel (such as Figure 4A ) and box culverts (such as Figure 4B ) expansion joints coated with the composite anti-seepage system provided in this embodiment.

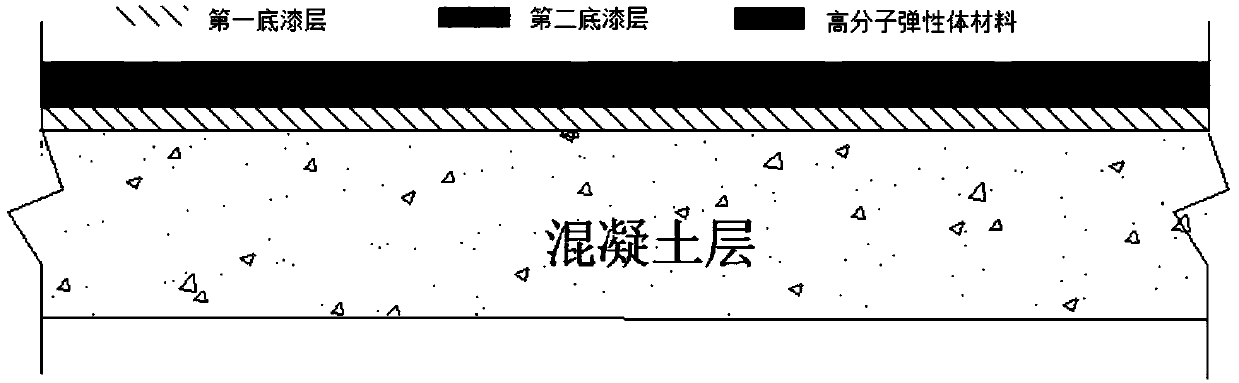

[0137] Figure 4C It is a schematic structural diagram of the composite anti-seepage system in this embodiment. I...

Embodiment 2

[0139] For the anti-seepage embodiment of the composite anti-seepage system provided by the present invention applied to channels and aqueducts, since the channels and aqueducts do not need to be resistant to impact and wear, but need to be exposed to sunlight for a long time and alternate between water and anhydrous repeatedly, in this The application field uses the composite anti-seepage system as follows:

[0140] (1) for channels as indicated by arrows (such as Figure 5A ) expansion joints, the composite anti-seepage system used is: epoxy primer layer + one-component polyurethane primer layer + polyurethane elastomer coating + topcoat layer used on the dry interface;

[0141] (2) Used for aqueducts as shown by arrows (such as Figure 5B ) expansion joints, the composite anti-seepage system used is: epoxy primer layer + one-component polyurethane primer layer + acrylic elastomer coating + topcoat layer used on the dry interface.

[0142] Figure 5C It is a schematic str...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| bond strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com