High-strength epoxy resin aqueous phase curing agent as well as preparation method and application thereof

A technology of epoxy resin and curing agent, which is applied in the field of epoxy resin adhesives, can solve the problems of low strength of epoxy resin, high brittleness of the cured product, and easy explosion, and achieve excellent water resistance, good dissolution and dispersion, and relative good capacitive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] The preparation of embodiment 1 phenolic amide (formula (1)):

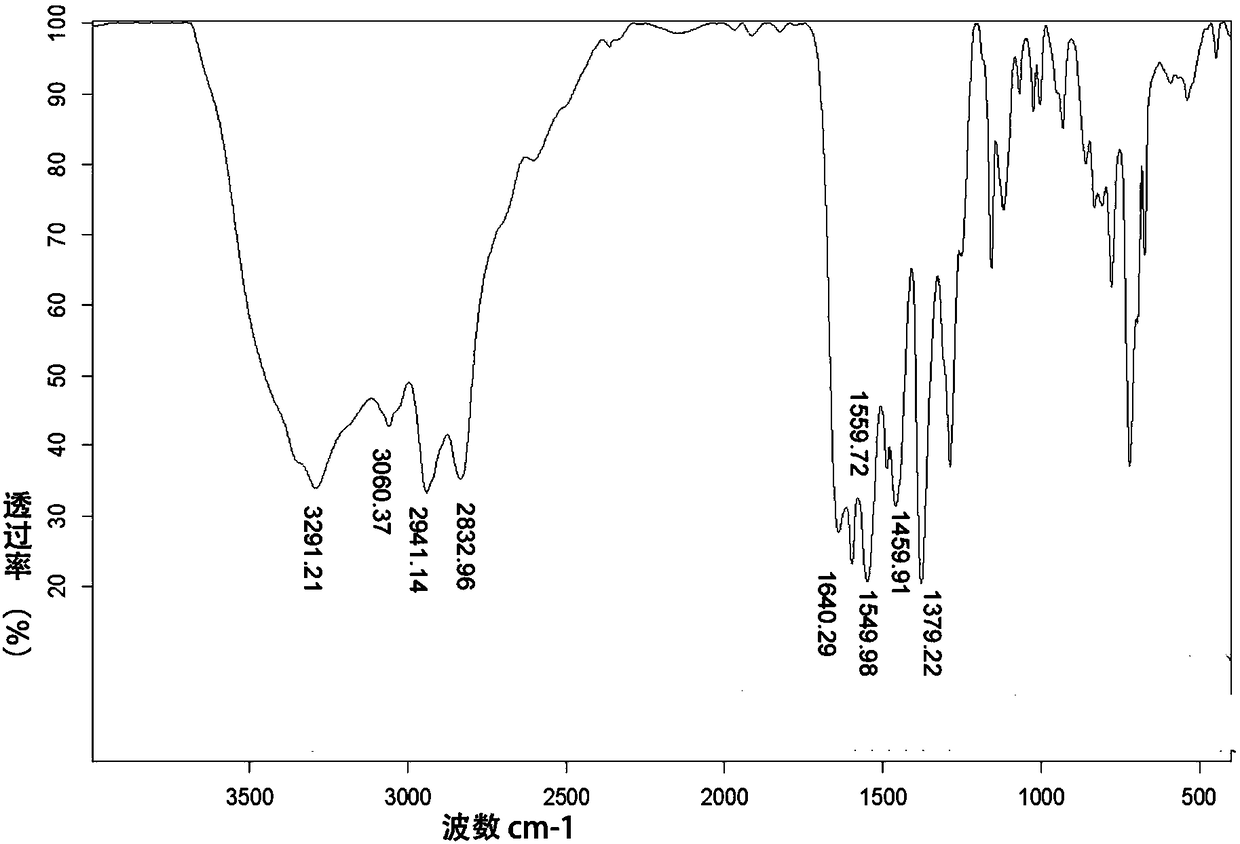

[0046] (1) Add 1 mole of m-cresol, 1 mole of tetraethylenepentamine and 1 mole of paraformaldehyde (calculated as formaldehyde units) in a 1000 ml three-necked flask at 60°C, then raise the temperature to 100°C for 6 hours, Heat up to 160°C to continue the reaction for 1 hour, cool down to obtain 1 mole of Mannich base phenolic polyamine, then add 1 mole of benzoic acid and heat up to 140°C for 2 hours, then heat up to 200°C for further dealcohol amidation reaction for 1 hour, cool down Finally, the phenalkamide FQXA1 as shown in formula (1) is mainly obtained. Sampling, through infrared detection, obtained as attached figure 1 The infrared spectrum shown.

[0047] (2) Add 1 mole of m-cresol, 1 mole of pentaethylenehexamine and 1 mole of formaldehyde solution (calculated based on the actual formaldehyde used) in a 1000 ml three-necked flask at 10°C, then raise the temperature to 70°C for 6 hours, Heat up...

Embodiment 2

[0050] The preparation of embodiment 2 phenolic amide (formula (2)):

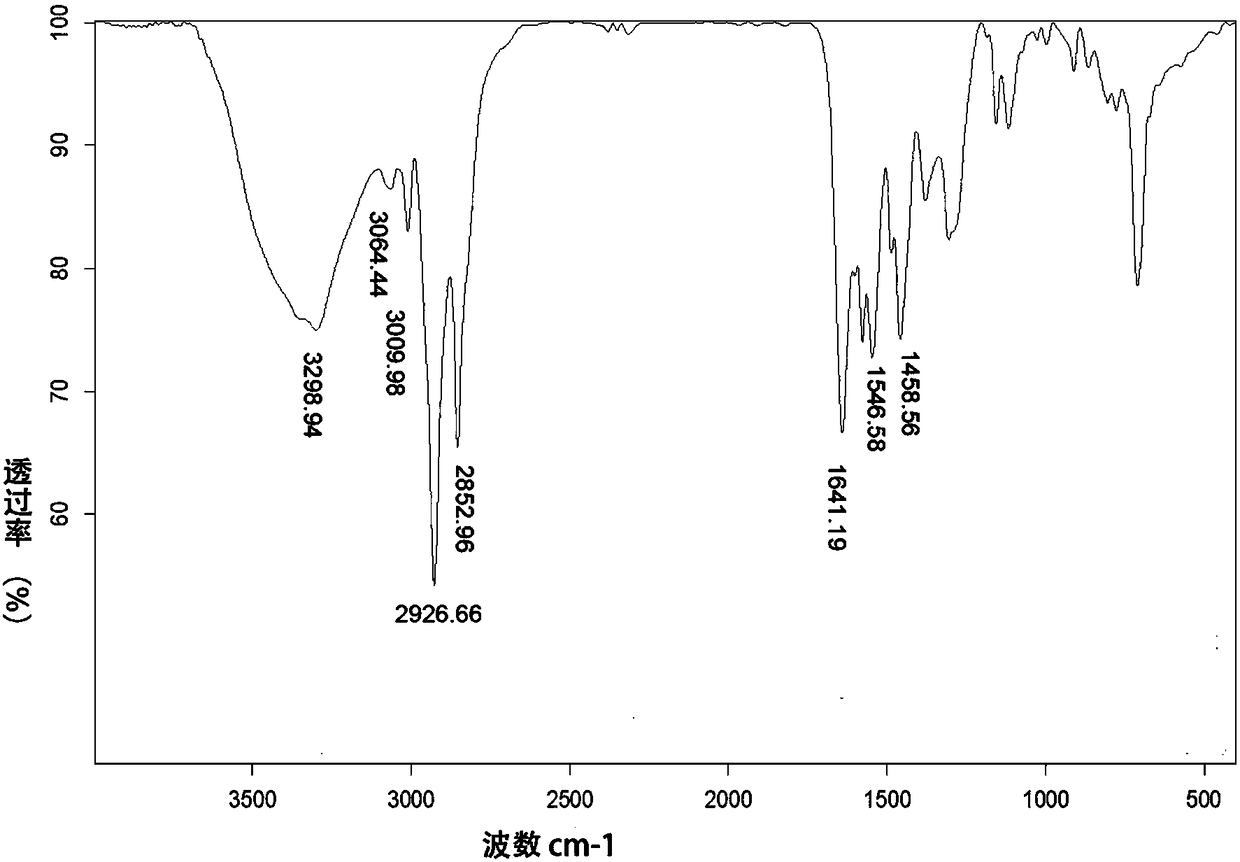

[0051] (5) Add 2 moles of cardanol, 2 moles of triethylenetetramine and 2 moles of paraformaldehyde (calculated as formaldehyde units) in a 2000 ml three-neck flask at 70°C, heat it up to 150°C for dehydration after 3 hours of heat preservation React for 2 hours, cool to obtain 2 moles of Mannich base phenolic polyamine, add 1 mole of methyl acrylate at 10°C and react for 8 hours, then heat up to 70°C for 8 hours, then heat up to 120°C for 7 hours, Remove the small molecule by-product methanol, cool, and mainly obtain the phenalkamide FQXA5 shown in formula (2). Sampling, measured by infrared spectroscopy, obtained as attached image 3 The infrared spectrum shown.

[0052] (6) Add 2 moles of m-cresol, 2 moles of diethylenetriamine and 2 moles of formaldehyde solution (calculated based on the actual formaldehyde used) in a 1000 ml three-necked flask at 10°C, heat up to 60°C and react for 5 hours, Then hea...

Embodiment 3

[0053] Embodiment 3 contains the preparation of six-membered cyclic amidoamine (formula (3)~(6))):

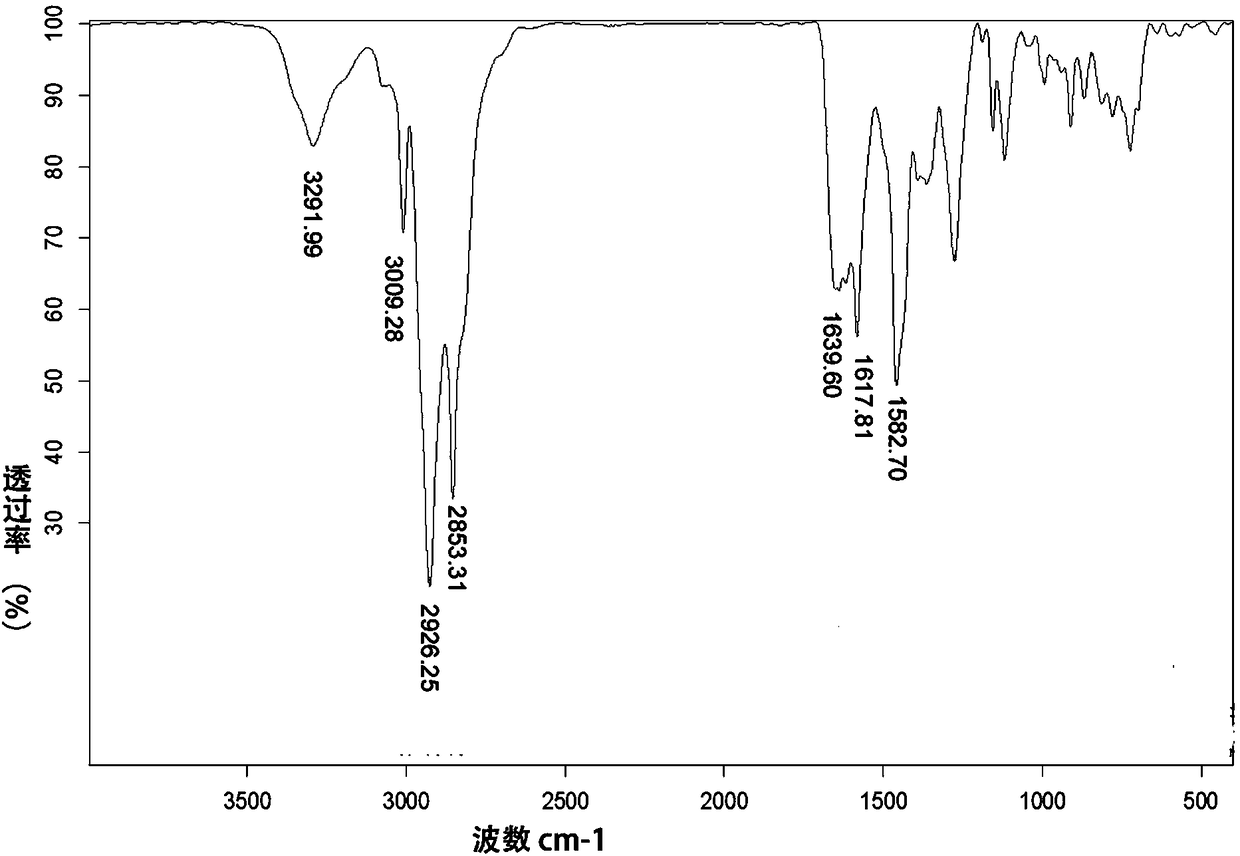

[0054] (1) Add 2 moles of m-xylylenediamine to a 500 ml three-necked flask, and slowly add 1 mole of methyl acrylate dropwise after cooling to 10°C. After 1 hour of dripping, the temperature is raised to 30°C for 20 hours, and then heated to React at 120°C for 2 hours, remove the by-product methanol, and cool to obtain amidoamine XAJA1 mainly represented by formula (3). Sampling, through infrared detection, obtained as attached Figure 4 The infrared spectrum shown.

[0055] (2) Add 2 moles of 1,3-cyclohexanedimethylamine to a 500 ml three-necked flask, cool to 20°C and slowly add 1 mole of acrylic acid dropwise, after half an hour, raise the temperature to 80°C for 2 hours, then raise the temperature React at 140°C for 2 hours, remove by-product water, and cool to obtain amidoamine XAJA2 mainly shown in formula (4).

[0056] (3) Add 2 moles of N-aminoethylpiperazine to a 50...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com