Anti-corrosion pool for solar cell panel production wastewater and construction method thereof

A technology for solar panels and waste water production, applied in anti-corrosion coatings, general water supply conservation, sewage wells, etc., which can solve problems such as easy deformation, erosion of concrete pools, leakage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

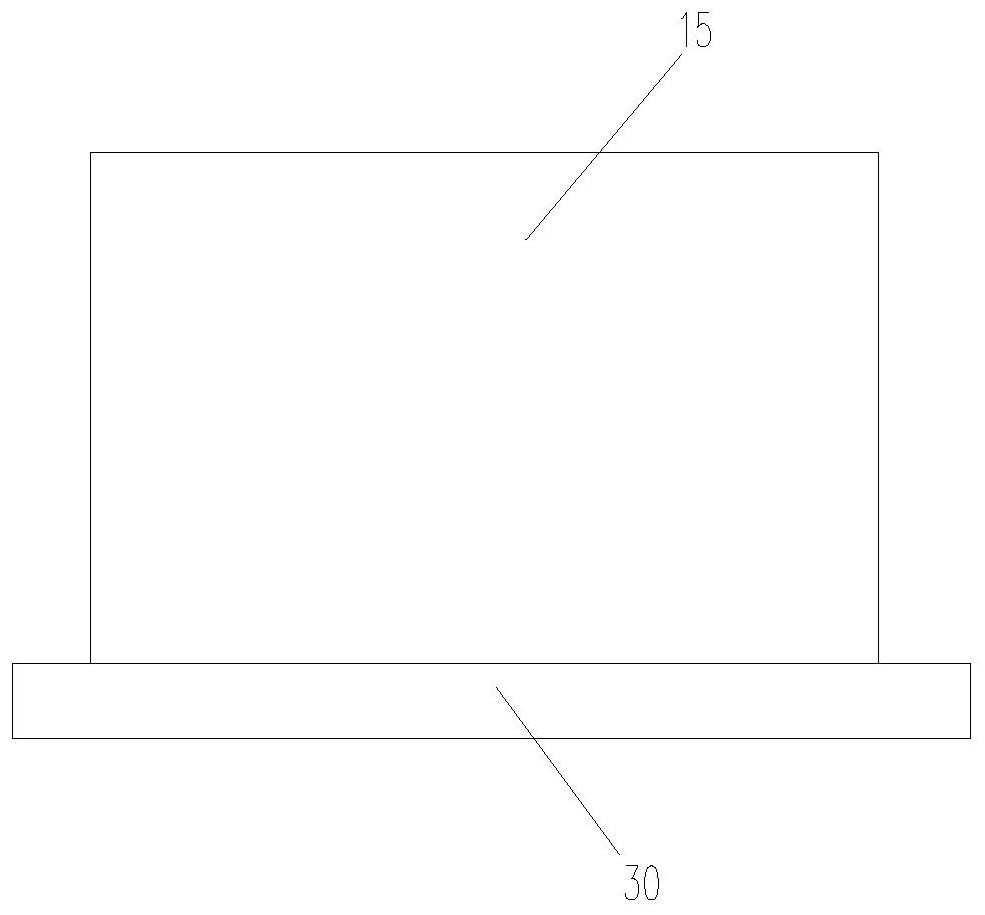

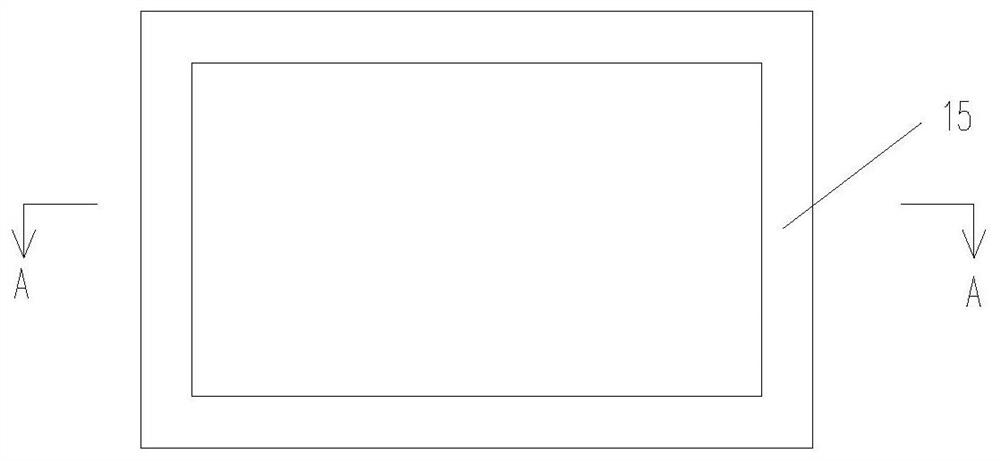

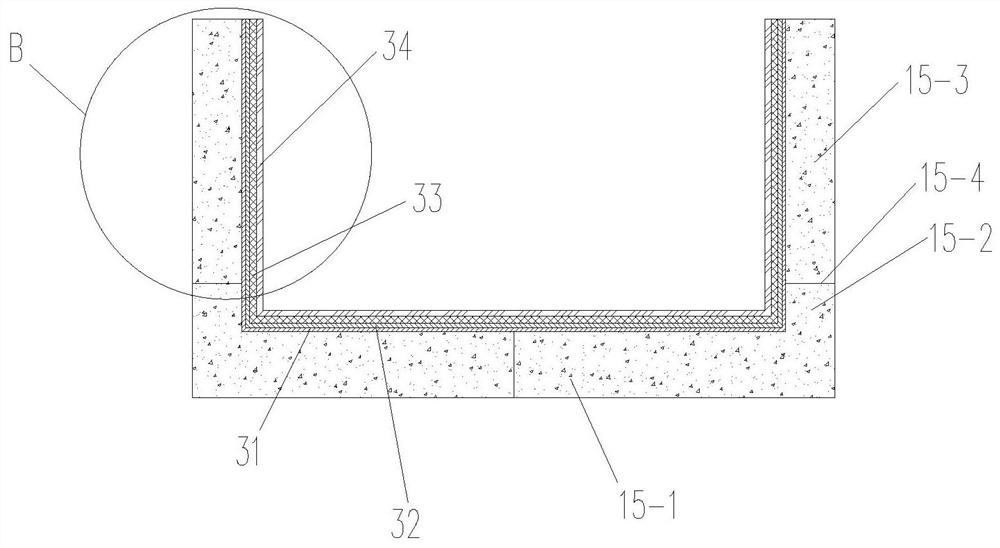

[0097] like Figure 1 to Figure 4As shown, it includes a concrete base 30 and an anti-corrosion pool 15 arranged on the concrete base 30. The anti-corrosion pool 15 includes a pool bottom 15-1 and a pool wall side wall surrounding the pool bottom 15-1. The pool wall The side wall surrounds a rectangular pool, and the concrete base 30 extends out of the side wall of the pool wall. The side wall of the pool wall includes a guide wall 15-2 integrally formed with the pool bottom plate 15-1 and a wall set on the guide wall 15. The pool wall 15-3 on -2, the connection between the guide wall 15-2 and the pool wall 15-3 is recorded as the construction joint 15-4;

[0098] The pool floor 15-1 and the pool side walls are sequentially provided with a primer resin layer 31, a leveling resin layer 32, a glass fiber cloth layer 33 and an epoxy putty layer 34 from inside to outside, and the glass fiber cloth layer 33 includes multiple layers of glass fiber cloth, and the primer resin layer ...

Embodiment 2

[0105] like Figure 5 to Figure 7 As shown, this embodiment includes the following steps:

[0106] Step 1. Pouring construction of the pool body:

[0107] Step 101, setting the rectangular area of the pool body, setting up a formwork in the rectangular area of the pool body, and then pouring concrete to form the concrete base 30;

[0108] Step 102, setting up the bottom formwork of the pool body on the concrete base 30, and then pouring concrete to form the pool bottom plate 15-1 and the guide wall 15-2; wherein, the guide wall 15-2 is surrounded by the pool bottom plate 15-1;

[0109] Step 103: Set up the pool wall formwork on the guide wall 15-2, then pour concrete to form the pool wall 15-3, and complete the pouring of the pool body; wherein, the guide wall 15-2 and the pool wall form the side wall of the pool wall, The concrete base 30 extends out of the side wall of the pool wall, and the connection between the guide wall 15-2 and the pool wall is recorded as a cons...

Embodiment 3

[0186] The difference between this embodiment and embodiment 2 is:

[0187] In step 2, the roughness of the upper surface of the bottom plate 15-1 of the pool and the inner surface of the side wall of the pool wall reaches 45 μm;

[0188] The thickness of the primer resin layer 31 in step 401 is 0.25mm, and the weight ratio of the vinyl ester resin, curing agent and accelerator is 100:3:3;

[0189] In step 402, the primer resin layer 31 is dried and cured for 2.5 hours at a temperature of 18° C.;

[0190] In step 403, the thickness of the leveling resin layer 32 is 0.3 mm, and the weight ratio of the vinyl ester resin, barium sulfate powder, curing agent and accelerator is 100:180:3:3;

[0191] In step 404, the leveling resin layer 32 is dried for 48 hours at a temperature of 18°C;

[0192] In step 405, the thickness of the adhesive layer is 0.4 mm, the lap width of the glass fiber cloth on the side wall of the pool wall is 4 cm, and the lap width of the glass fiber cloth on...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com