Water-based terrace phase-change epoxy putty coating and preparation method thereof

A technology of epoxy putty and water-based epoxy resin, which is applied in the direction of epoxy resin coating, coating, etc., can solve the problem of thick coating cracking of putty coating, and achieve the effect of preventing bulging or cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

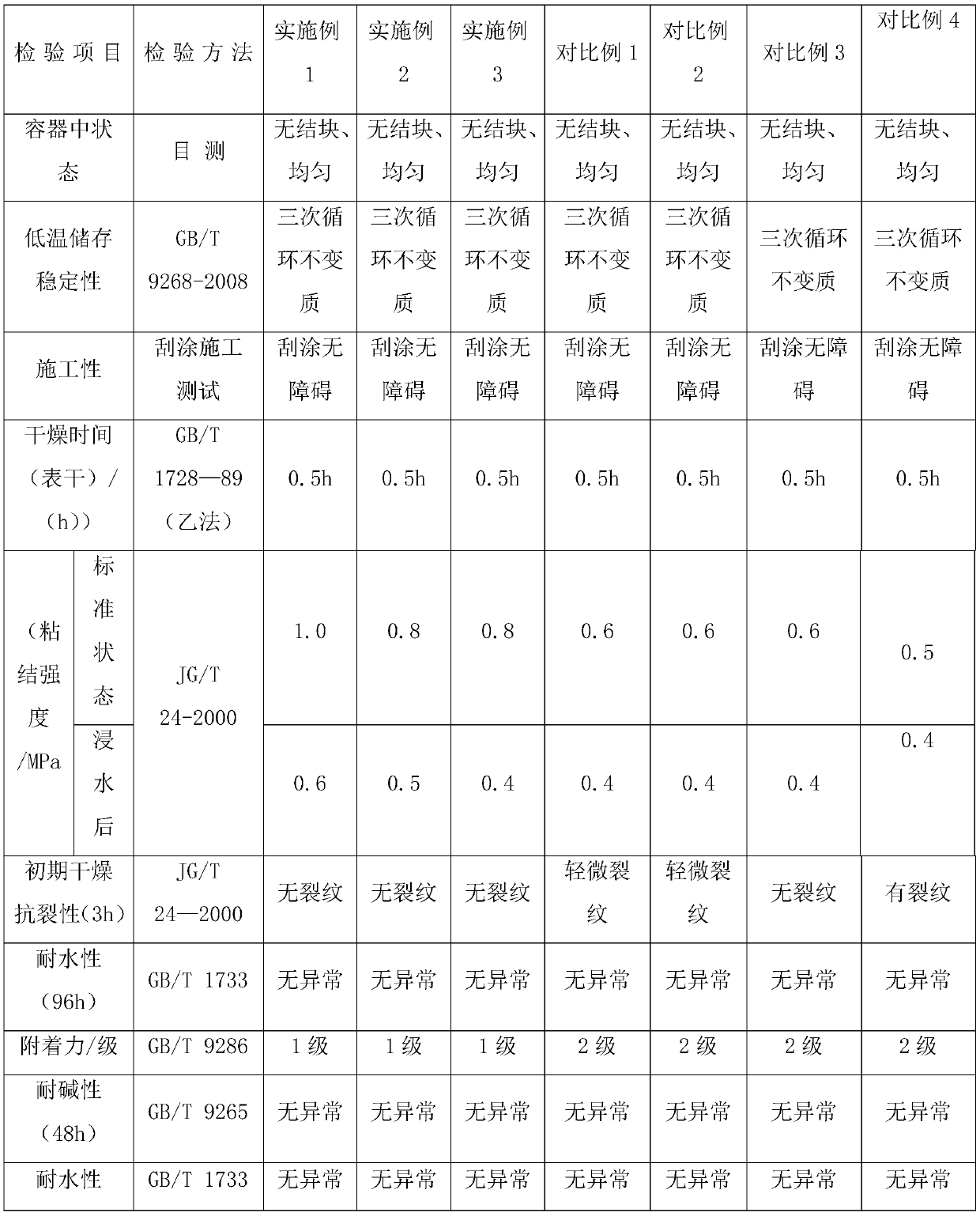

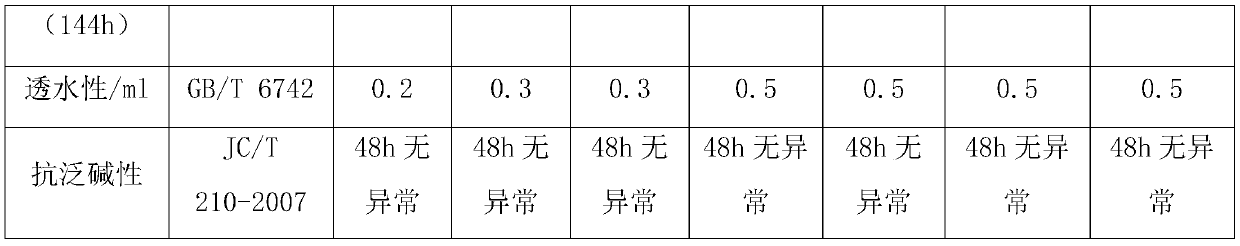

Examples

preparation example Construction

[0054] A preparation method of water-based floor phase-change epoxy putty coating, is characterized in that, comprises the steps:

[0055] (1) Dissolve the defoamer, dispersant and substrate wetting agent in deionized water according to the mass ratio, and stir at a stirring speed of 1500-1600r / min for 15-20min; Stir at a speed of 600r / min for 5-8min to obtain slurry A;

[0056] (2) Add water-based epoxy curing agent and leveling agent to slurry A, stir at 1000-1200r / min for 20-25min, and mix evenly to obtain component A;

[0057] (3) Dilute the water-based epoxy resin with deionized water in a clean container, add aliphatic glycidyl ether, stir at a speed of 1500-1800r / min for 5-8min, and mix evenly to obtain component B;

[0058] (4) Stir 200-mesh quartz powder at 1500-1800r / min for 15-18min, add composite fiber; after mixing evenly, it becomes component C;

[0059] (5) Mix components A, B and C, and stir at 500-800r / min for 25-30min to obtain the finished product.

Embodiment 1

[0063] The water-based floor phase-change epoxy putty paint of the present embodiment is compounded by A component, B component and C component; in parts by weight, each component includes the following raw materials:

[0064] A component: 42 parts of water-based epoxy curing agent;

[0065] 40 parts of deionized water;

[0066] 0.2 parts of defoamer;

[0067] 0.3 parts of dispersant;

[0068] 0.5 parts of substrate wetting agent;

[0069] Leveling agent 0.9 part;

[0070] 15 parts of polyurea microcapsule phase change material; the polyurea microcapsule phase change material is a double shell microcapsule phase change material prepared by using polyurea and polyurethane as double wall materials and phase change paraffin as core material. The preparation method can be referred to (Experimental Research on Preparation of Microcapsule Box Transformer Materials by Interfacial Polymerization (J), Shang Jianli, Wang Zhengjun, Chao Qianggang, Materials Herald, 2010, 24, 92-94), ...

Embodiment 2

[0080] The difference between this embodiment and embodiment 1 is only that the composition ratio is different. The components of this embodiment are as follows:

[0081] A component: 50 parts of water-based epoxy curing agent;

[0082] 40 parts of deionized water;

[0083] 0.3 part of defoamer;

[0084] 0.4 parts of dispersant;

[0085] 0.6 parts of substrate wetting agent;

[0086] Leveling agent 0.9 part;

[0087] 15 parts of polyurea microcapsule phase change material; the polyurea microcapsule phase change material is a double shell microcapsule phase change material prepared by using polyurea and polyurethane as double wall materials and phase change paraffin as core material.

[0088] Component B: 90 parts of water-based epoxy resin; 10 parts of aliphatic glycidyl ether; the aliphatic glycidyl ether meets the following requirements: (1) Viscosity: 6mpa.s at 40°C, (2) Epoxy equivalent : 300g / eq;

[0089] Component C: 100 parts of 200-mesh quartz powder; 1.5 parts ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com