Double-drafting centralized control spinning device and spinning method

A drafting and drafting zone technology, which is applied in the field of dual drafting and gathering control spinning devices, can solve the problems of poor flatness requiring ironing, easy wrinkling, and easy felting of wool fabrics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

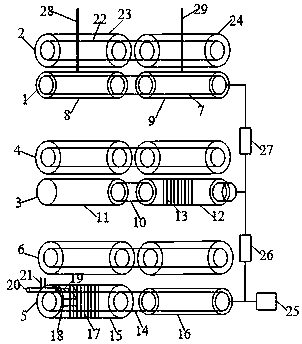

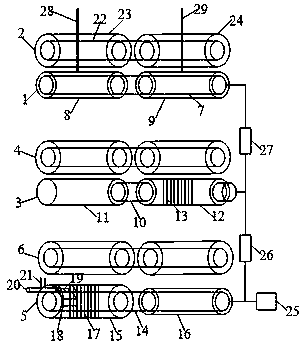

[0009]A spinning device with dual drafting and concentration control, including a drafting system, the drafting system includes a pair of rear drafting rollers, a pair of middle drafting rollers, a pair of front drafting rollers, and the pair of rear rollers includes rear bottom roller 1 and rear gluing Roller 2, middle roller pair includes middle bottom roller 3 and middle top rubber roller 4, front roller pair includes front bottom roller 5 and front top rubber roller 6, rear bottom roller includes rear bottom roller shaft 7, rear bottom roller shaft is solid Cylindrical structure, the left rear roller sleeve 8 and the right rear roller sleeve 9 are arranged on the outer circumference of the rear bottom roller shaft, the left rear roller sleeve and the right rear roller sleeve are both solid structures and integrated with the rear bottom roller shaft Fixed connection, the material of the left rear roller sleeve and the right rear roller sleeve and the rear bottom roller shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com