Silicon controlled chopping power regulation driving device

A driving device and waveform technology, applied in the direction of output power conversion device, AC power input conversion to DC power output, electrical components, etc., can solve the problems of high cost and low accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

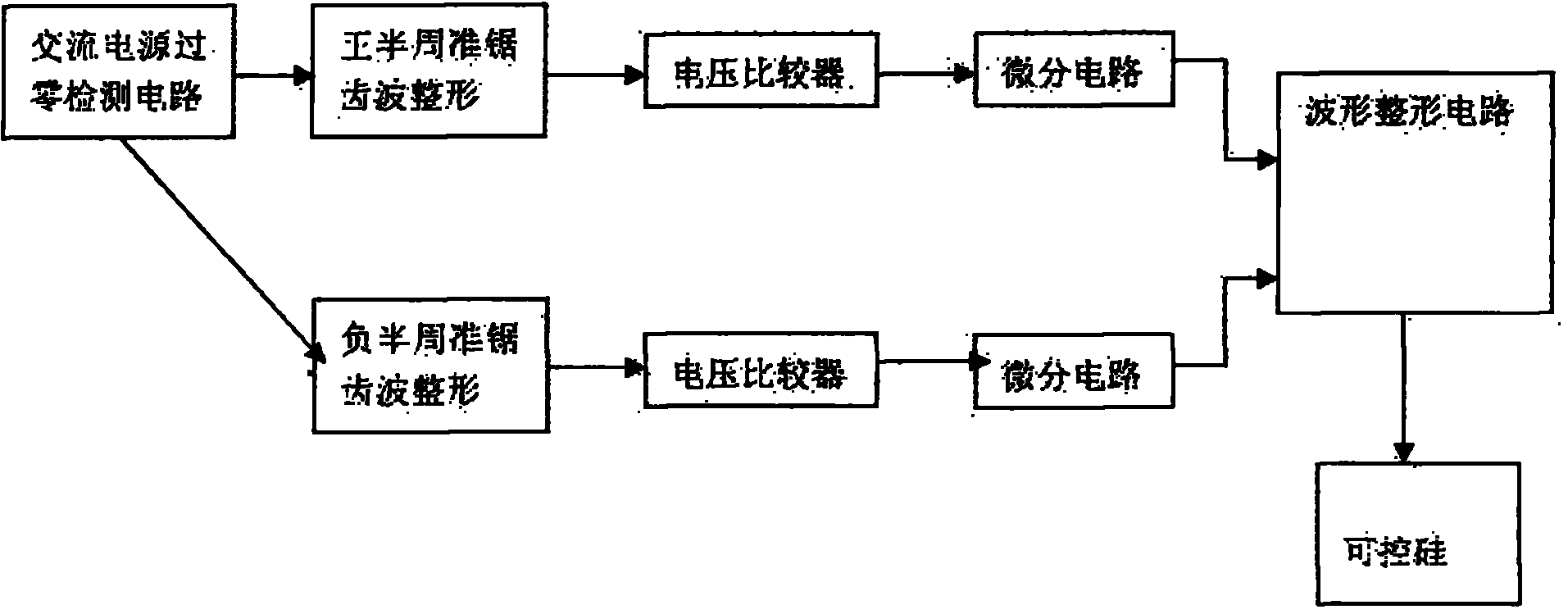

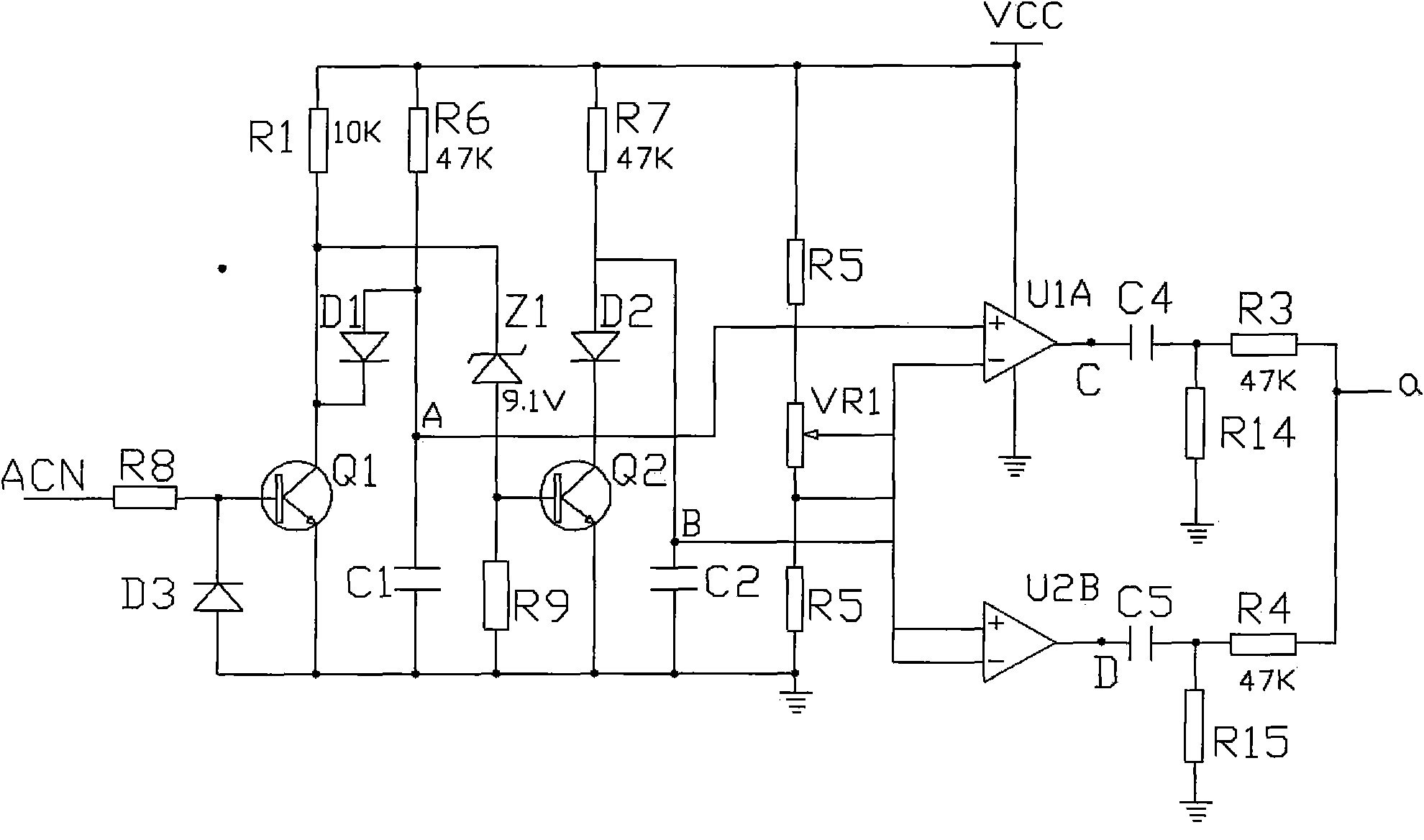

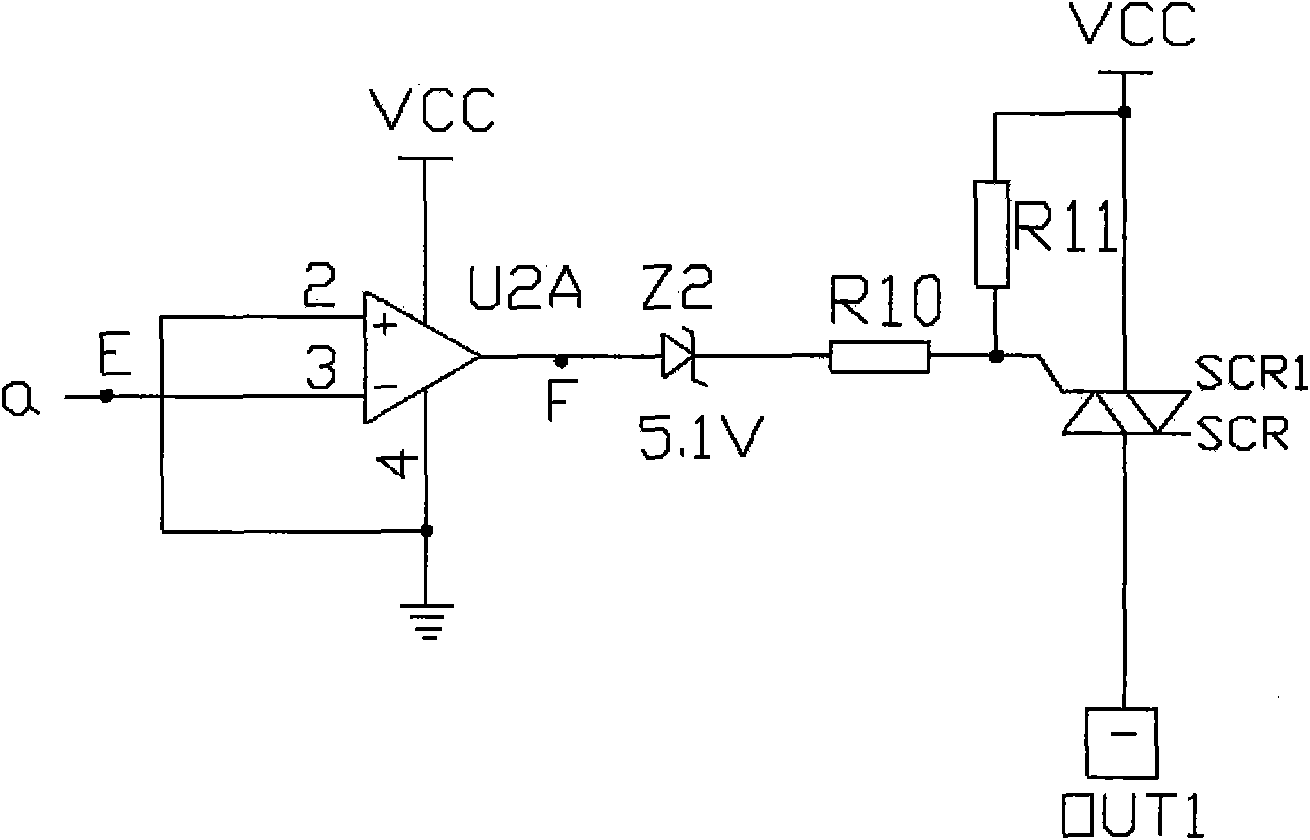

[0020] Example: see Figure 1~4 As shown, a thyristor chopper power regulation drive device includes a thyristor SCR1, which consists of an AC power zero-crossing detection circuit, a quasi-sawtooth wave shaping circuit, a voltage-time converter, a differential circuit, a waveform shaping circuit and a controllable Silicon Scr1 composition;

[0021] The AC power zero-crossing detection circuit consists of the first triode Q1, the second triode Q2 and their peripheral components. The first resistor R1, the eighth resistor R8, the ninth resistor R9, the first diode D1, and the second diode tube D2, the third diode D3, and the first Zener diode Z1;

[0022] The quasi-sawtooth wave shaping circuit is composed of a first capacitor C1, a second capacitor C2, a sixth resistor R6, and a seventh resistor R7;

[0023] The voltage-time converter is composed of a first comparator U1A, a second comparator U2B, a second resistor R2, a fifth resistor R5, and a potentiometer VR1;

[0024] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com