Epoxy potting method for insulation box on end portion of electric generator

A technology of insulation box and generator stator, which is applied in the direction of laying solid insulation, etc., can solve the problems of complex shape of connection structure of end wire bars, influence on the production and manufacture of steam turbine generator, and high labor intensity of operators, so as to achieve simple structure and high performance. Reliable and solve the effect of low production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the present invention more comprehensible, a preferred embodiment is described in detail below with accompanying drawings.

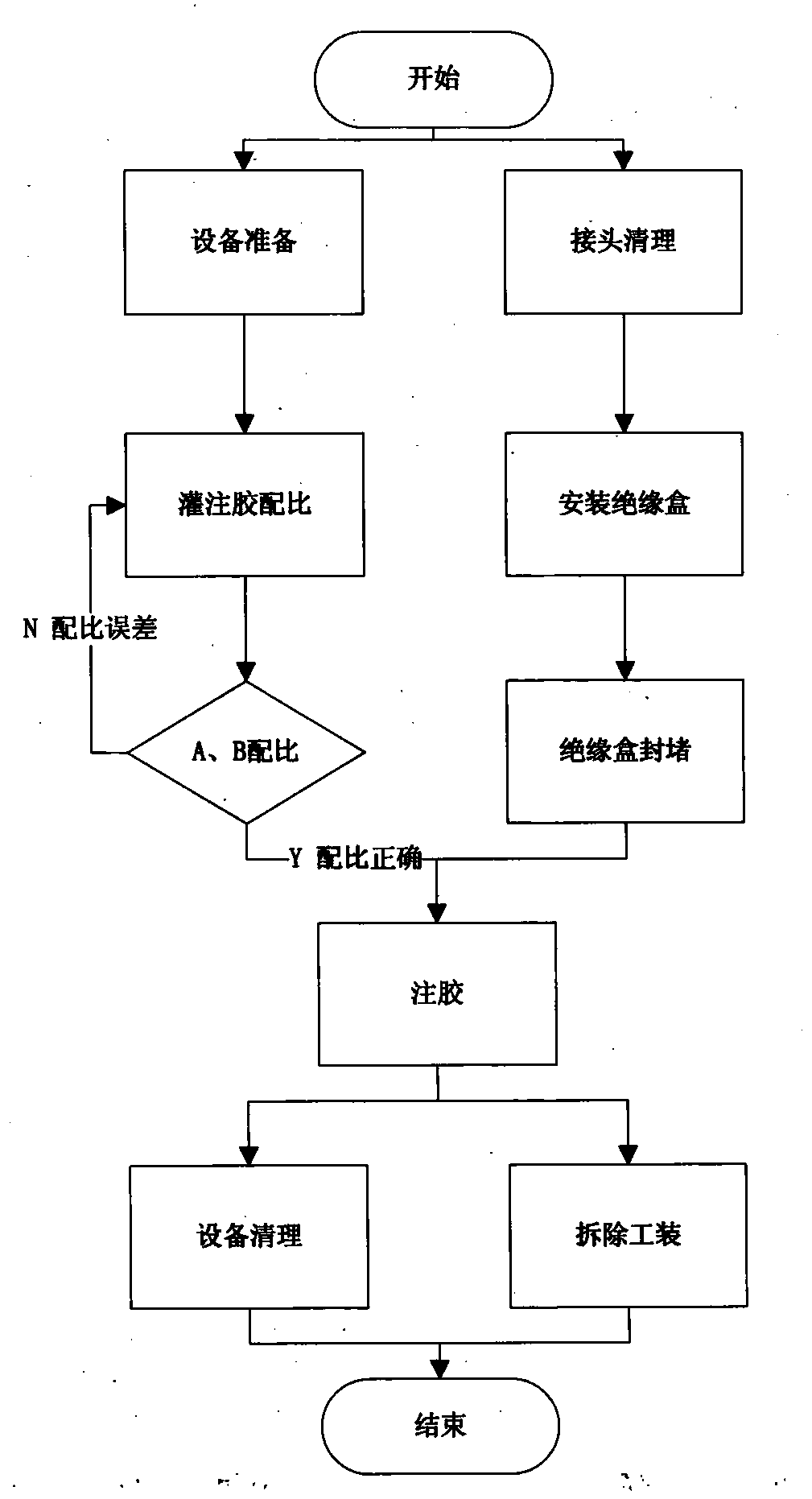

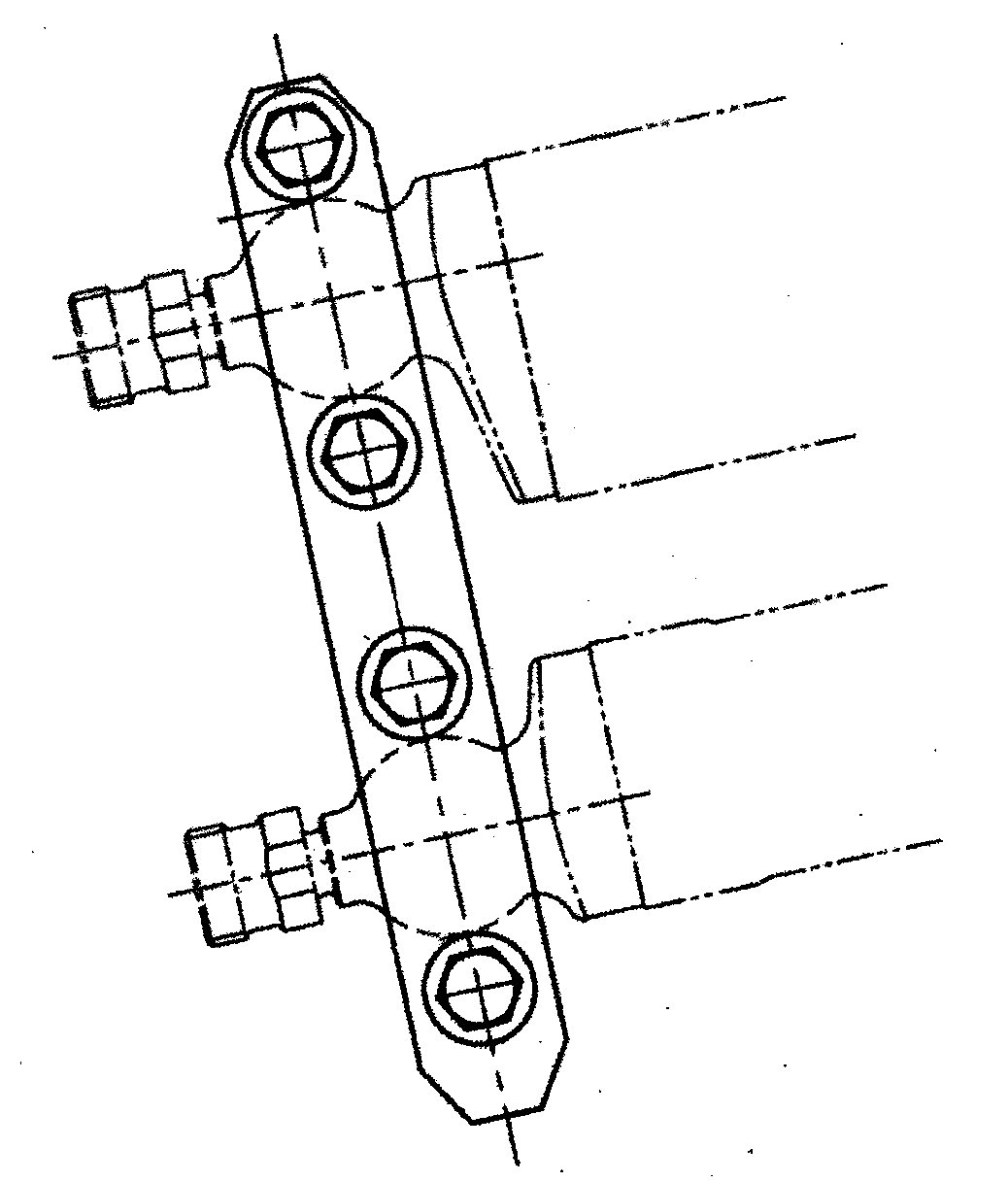

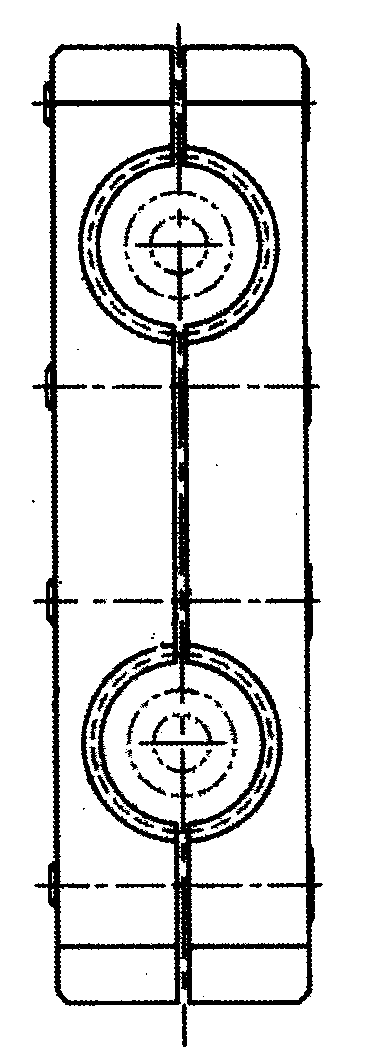

[0024] figure 1 The process flow chart of the method for filling the insulating box at the end of the stator winding of the generator provided by the present invention. The method of filling the insulating box at the end of the stator winding of the generator provided by the present invention is to use a mica insulating box and tooling to seal the joint, and use a ring Oxygen putty seals the joint between the mica insulating box and the tooling. The mica insulating box pre-opens the glue injection hole. Using the potting glue equipment, inject the epoxy potting glue into the glue injection hole, and let the epoxy potting glue cure at room temperature. Remove the tooling Finally, the mica insulation box should be integrated with the epoxy potting glue.

[0025] The mica insulation box is made of multi-layer mica paper and glass cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com