Method for preparing nano-pearl colored polyester fiber

A nano-pearl and colored polyester technology, which is applied in fiber processing, fiber chemical characteristics, rayon manufacturing, etc., can solve problems not related to polyester fiber in detail, not involved in polyester fiber preparation, etc., to achieve the suppression of melt viscosity changes and compatibility The effect of unevenness, smooth fabric and uniform dryness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Preparation of nano-pearl powder composite Wash and dry 100 parts by weight of pearls with clear water, process them to 300 mesh with high-frequency vibration mill, and then configure them with 1500 parts by weight of deionized water according to the following ratio:

[0026] Table 1: Pearl Powder Recipe

[0027] Numbering Pearl powder Heat stabilizers, Antioxidants Emulsifier

[0028] Prepare a suspension, set the pressure of the high-pressure homogenizer to 120MPa, add the suspension to the feeding tank of the high-pressure homogenizer, automatically feed, and obtain pearl powder with a particle size of 50-100 nanometers after high-pressure crushing The suspension is heated and dried to obtain a pearl powder composite with a particle size of 50-100 nanometers.

Embodiment 2

[0030] Preparation of nano-pearl polyester superfine denier slices After mixing 20 parts by weight of nano-pearl powder composite obtained in Example 1 and 7 parts by weight of polybutylene terephthalate at normal temperature, the above-mentioned mixture was added to 73 parts of polyester chips were granulated by a twin-screw extruder to obtain nano-pearl polyester chips.

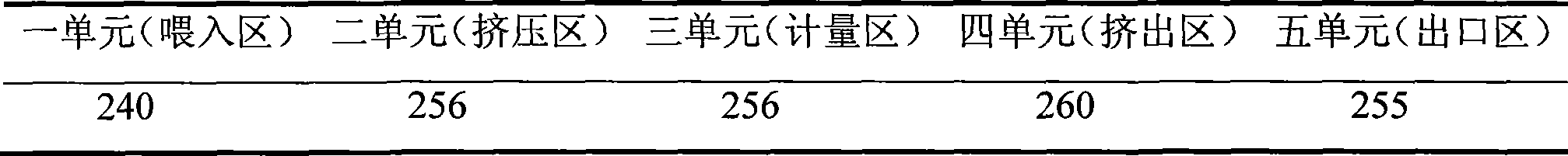

[0031] Slicing and granulation process parameter unit: ℃

[0032]

Embodiment 3

[0034] Preparation of colored pearl polyester fibers with nano-pearls The nano-pearl polyester slices obtained in Example 2 were subjected to high-speed spinning according to the spinning process requirements. The melt temperature for spinning is controlled between 255 and 310°C. Polyester chips are produced by Jinshan Petrochemical.

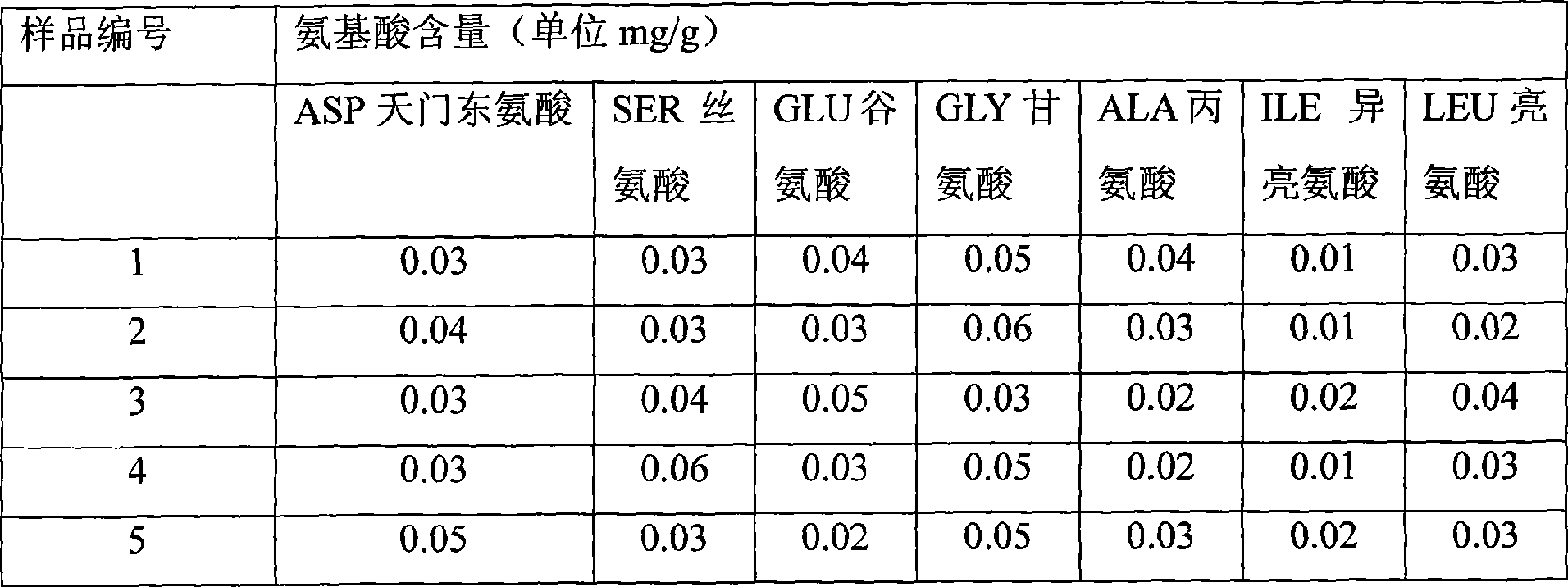

[0035] Table 2: Formulas and performance indicators of various colored pearl luster fibers

[0036]

[0037]

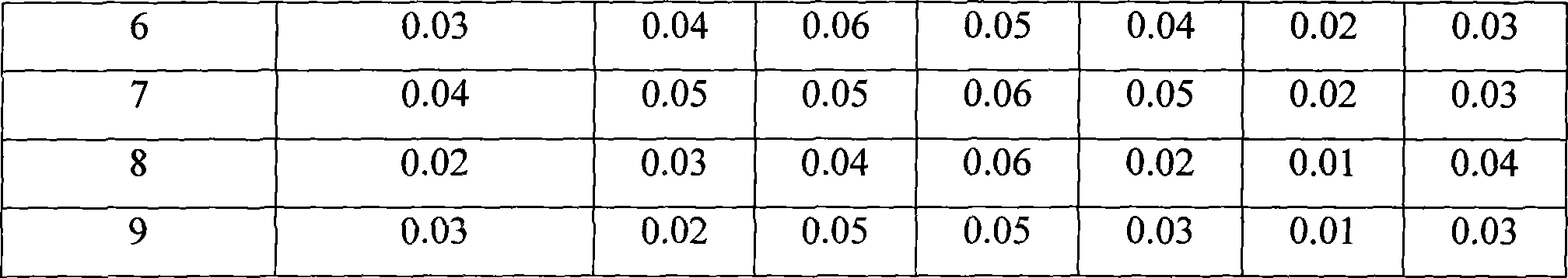

[0038] After spinning according to the ratio in Table 2, see Table 3 for the amino acid content test of nanopearl ultrafine denier fibers of different formulations.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com