Polyester fiber disperse dye low-temperature coloring accelerant BENTE and technique

A low-temperature dyeing technology of disperse dyes, applied in the field of dyeing technology, can solve the problems of poor dyeing effect and lower color fastness of dyes, and achieve the effects of easy movement, improved dyeing performance, and accelerated diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

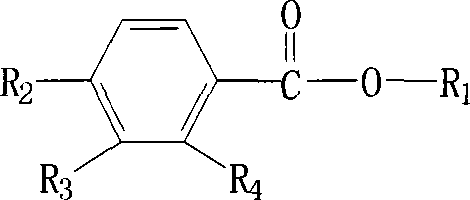

Method used

Image

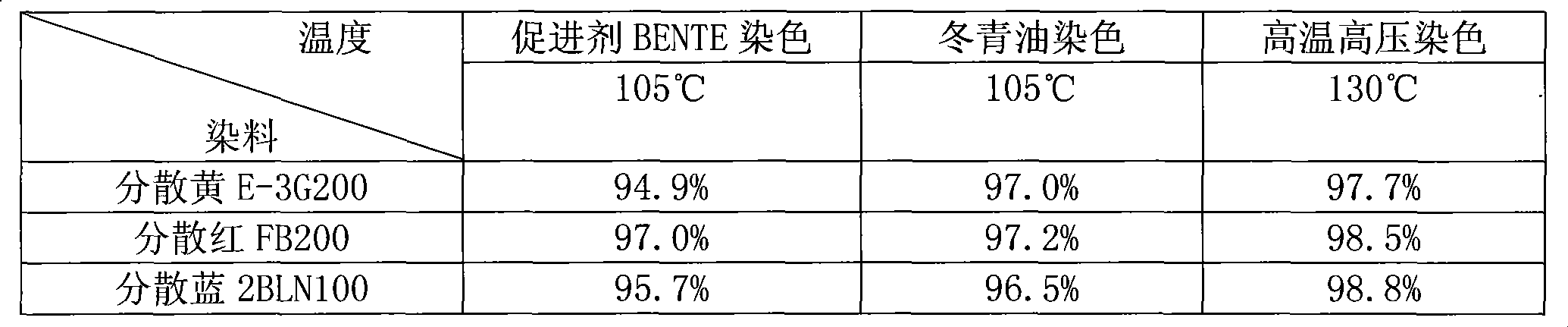

Examples

Embodiment 1

[0031] 1. Compounding of emulsifier

[0032] Alkylphenol polyoxyethylene ether (Op-15) 95g

[0033] Castor oil polyoxyethylene ether (El-40) 4g

[0034] Isopropanol 1g

[0035] 2. Preparation of accelerator BENTE

[0036] Ethyl Benzoate 96g

[0037] Complex emulsifier 4g

[0038] 3. Emulsion Preparation

[0039] Slightly heat 2g of the prepared accelerator BENTE to a liquid state, then vigorously stir in an emulsifier at 10,000rpm for 2min, and slowly add 98ml of warm water at 40-70°C; the added water begins to disperse in the BLB in microdroplets, showing a W / O-type emulsion; continue to add water, the emulsion becomes thinner, and finally the viscosity drops sharply, and the phase inversion becomes O / W type stable emulsion.

[0040] 4. Dyeing process

[0041] The disperse dyes are prepared with warm water at 40-50°C to prepare a dye solution, and in the state of stirring, add buffer solution, accelerator, and dispersed 1% (o.w.f) disperse dyes to the dyeing cup in se...

Embodiment 2

[0043] 1. Compounding of emulsifier

[0044] Alkylphenol polyoxyethylene ether (Op-15) 96g

[0045] Sorbitan Monooleate (Span-20) 2g

[0046] n-Butanol 2g

[0047] 2. Preparation of accelerator BENTE

[0048] Methylparaben 97g

[0049] Complex emulsifier 3g

[0050] 3. Emulsion Preparation

[0051] Slightly heat 2g of the prepared accelerator BENTE to a liquid state, then vigorously stir in an emulsifier at 5000rpm for 10min, and slowly add 98ml of warm water at 40-70℃; O-type emulsion; continue to add water, the emulsion becomes thinner, and finally the viscosity drops sharply, and the phase inversion becomes O / W type stable emulsion.

[0052] 4. Dyeing process

[0053] The disperse dyes are prepared with warm water at 40-50°C to prepare a dye solution, and in the state of stirring, add buffer solution, accelerator, and dispersed 1% (o.w.f) disperse dyes to the dyeing cup in sequence. After feeding, add 2g of fabric, dye at 50°C, heat up to 100°C at a rate of 2°C / min,...

Embodiment 3

[0055] 1. Compounding of emulsifier

[0056] Sorbitan Monooleate Polyoxyethylene Ether (Tween-80) 95g

[0057] Sorbitan Monooleate (Span-80) 4g

[0058] Isopropanol 1g

[0059] 2. Preparation of accelerator BENTE

[0060] Phenyl salicylate 96g

[0061] Complex emulsifier 4g

[0062] 3. Emulsion Preparation

[0063] Slightly heat 3g of the prepared accelerator BENTE to a liquid state, then vigorously stir in an emulsifier at 10,000rpm for 5min, and slowly add 97ml of warm water at 40-70°C; the added water begins to disperse in the BLB in microdroplets, showing a W / O-type emulsion; continue to add water, the emulsion becomes thinner, and finally the viscosity drops sharply, and the phase inversion becomes O / W type stable emulsion.

[0064] 4. Dyeing process

[0065] The disperse dyes are prepared with warm water at 40-50°C to prepare a dye solution, and in the state of stirring, add buffer solution, accelerator, and dispersed 2% (o.w.f) disperse dyes to the dye cup in se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com