Color master batch capable of improving level dyeing property and preparation method of color master batch

A technology of color masterbatch and super absorbent resin, applied in the field of color masterbatch, can solve the problems of level dyeing limit, poor fuel dyeing fastness, easy migration of dye molecules, etc., to ensure the effect of level dyeing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

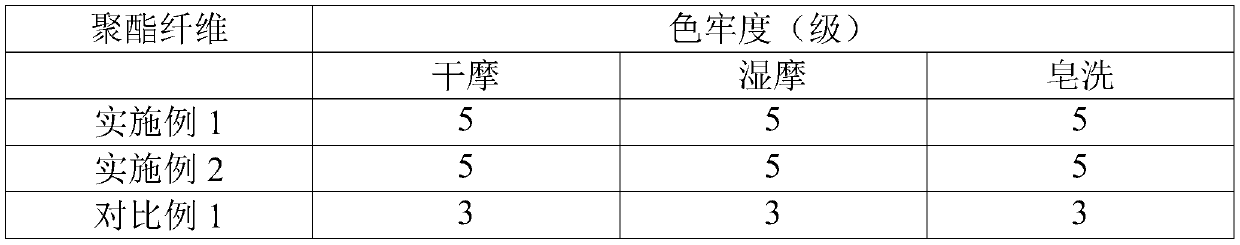

Embodiment 1

[0036] 1. Preparation of super absorbent resin

[0037] The preparation method of a kind of superabsorbent resin of the present embodiment comprises the following steps:

[0038] (a) Add 3% starch and 25-30mL water accounting for the total monomer mass (ie the mass sum of acrylic acid and acrylamide) into the reaction vessel, and heat to 80°C to gelatinize the starch to obtain a gelatinized starch solution;

[0039] (b) When the temperature of the gelatinized starch solution is lowered to 40-50° C., add the ammonium persulfate-sodium sulfite initiation system under the protection of nitrogen, and the ammonium persulfate-sodium sulfite initiation system (both the concentrations of ammonium persulfate and sodium sulfite are 0.05 mol / The molar ratio of L) to the total monomer is 3:1000;

[0040] (c) neutralizing acrylic acid with a sodium hydroxide solution to a molar neutralization degree of 70%, to obtain an acrylic acid neutralizing solution;

[0041] (d) Mix acrylic acid n...

Embodiment 2

[0054] 1. Preparation of superabsorbent resin with porous structure

[0055] The preparation method of a kind of superabsorbent resin of the present embodiment comprises the following steps:

[0056] (a) Add 3% starch and 25-30mL water accounting for the total monomer mass (ie the mass sum of acrylic acid and acrylamide) into the reaction vessel, and heat to 80°C to gelatinize the starch to obtain a gelatinized starch solution;

[0057] (b) When the temperature of the gelatinized starch solution is lowered to 40-50° C., add the ammonium persulfate-sodium sulfite initiation system under the protection of nitrogen, and the ammonium persulfate-sodium sulfite initiation system (both the concentrations of ammonium persulfate and sodium sulfite are 0.05 mol / The molar ratio of L) to the total monomer is 3:1000;

[0058] (c) neutralizing acrylic acid with a sodium hydroxide solution to a molar neutralization degree of 70%, to obtain an acrylic acid neutralizing solution;

[0059] (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com