Production process for anti-ultraviolet radiation fabric

A production process and anti-ultraviolet technology, which can be used in fabric surface trimming, textile material processing, liquid/gas/vapor textile processing and other directions, which can solve the problems of unstable protective function and easy failure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

[0014] A production process for an anti-ultraviolet fabric,

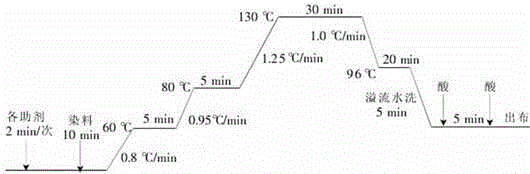

[0015] The production process includes material selection, weaving, pretreatment, dyeing, dehydration and setting;

[0016] Material selection, yarn selection polyester anti-ultraviolet processed yarn (DTY) with a linear density of 11.1tex / 144 (100D / 144f); because polyester has poor water absorption and high static electricity, the polyester yarn can be placed in a constant temperature and humidity environment first. Re-moisturize under the conditioner to improve its weaving; avoid defects such as horizontal stripes and needle marks.

[0017] For weaving, we choose tight double-sided bird's-eye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com