Patents

Literature

122results about How to "Shrinkage control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Compliant blood vessel graft

ActiveUS20070293932A1Smoothening of irregularitiesReduce the differenceStentsSurgeryVenous SegmentVenous graft

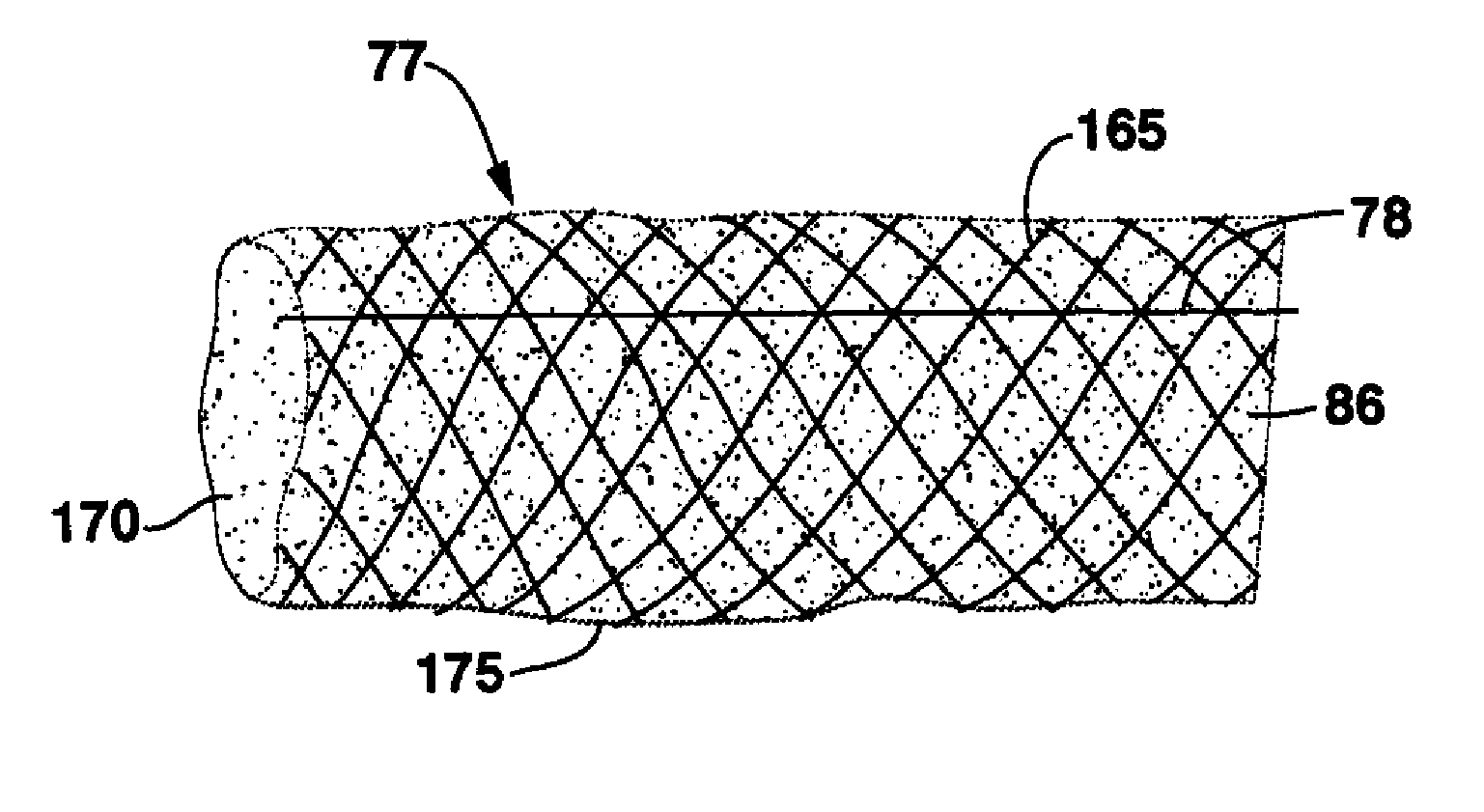

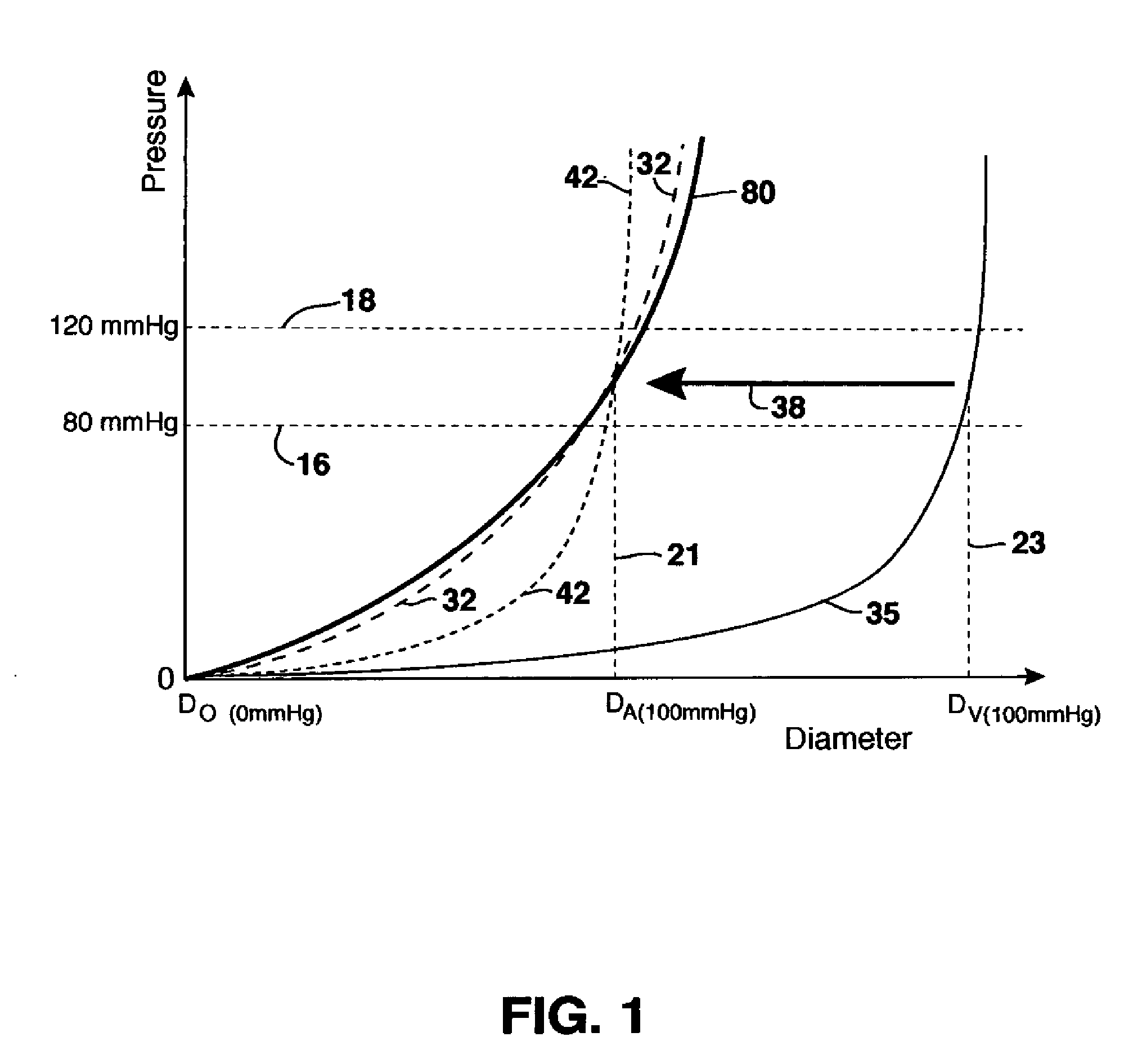

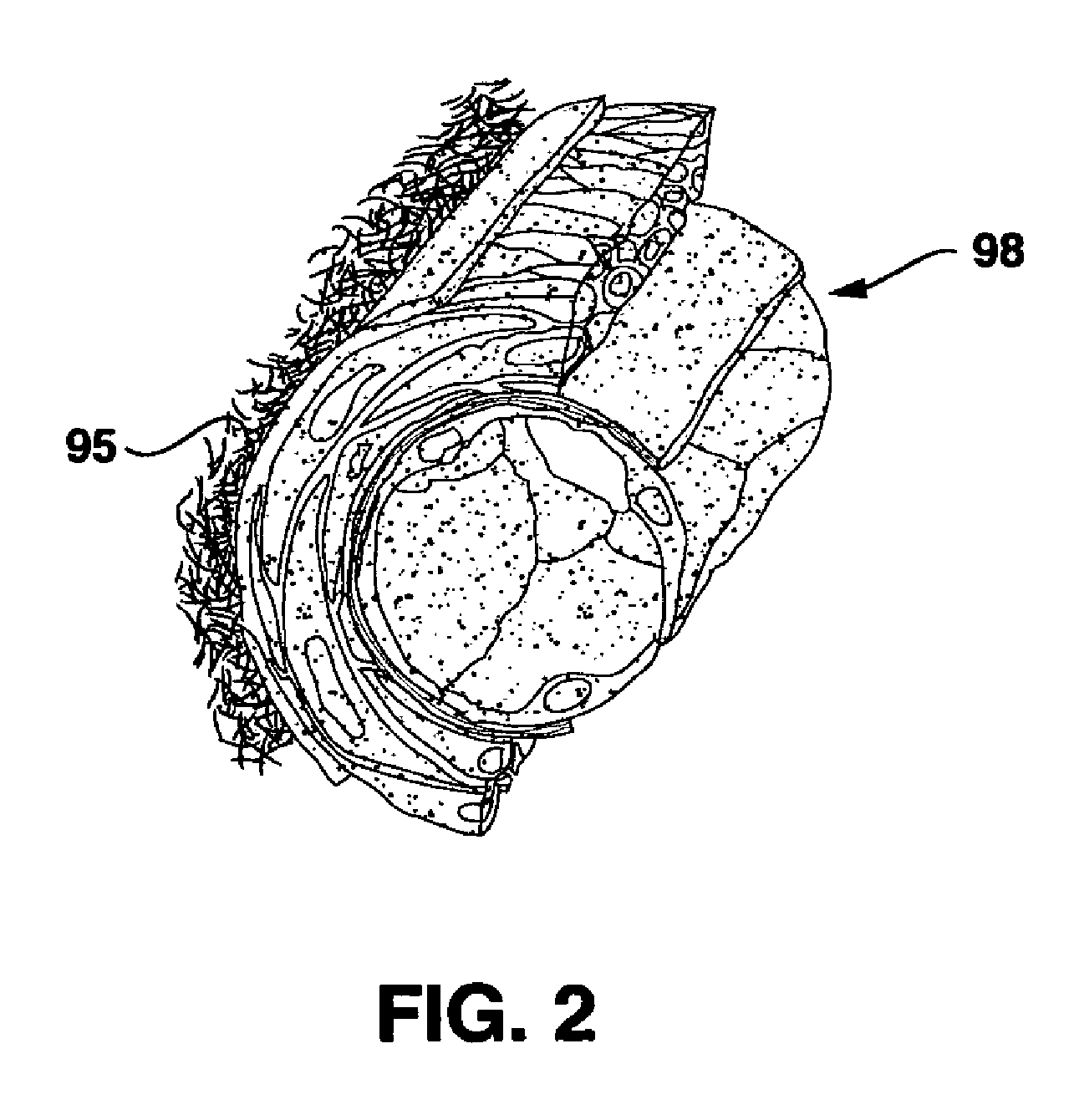

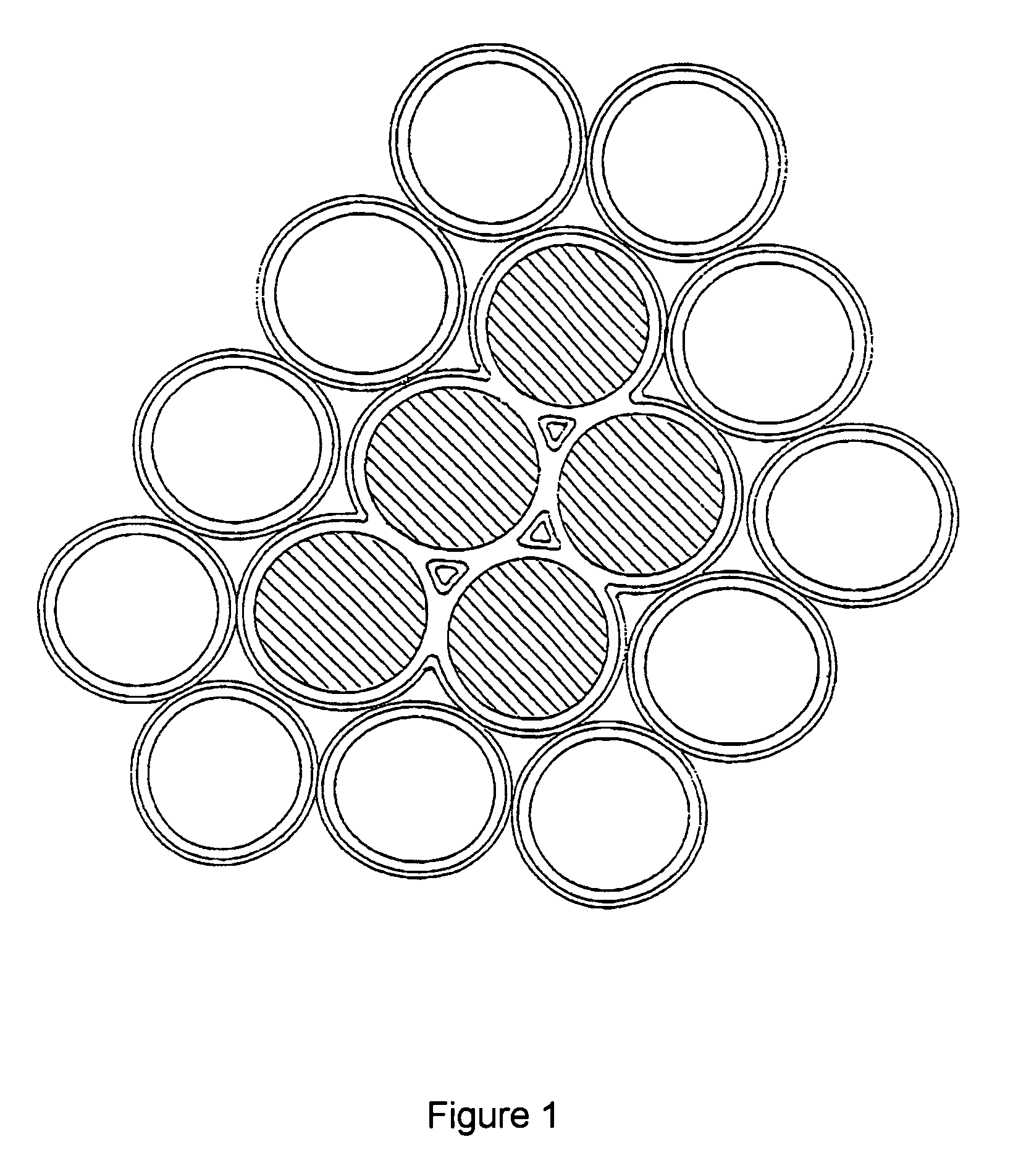

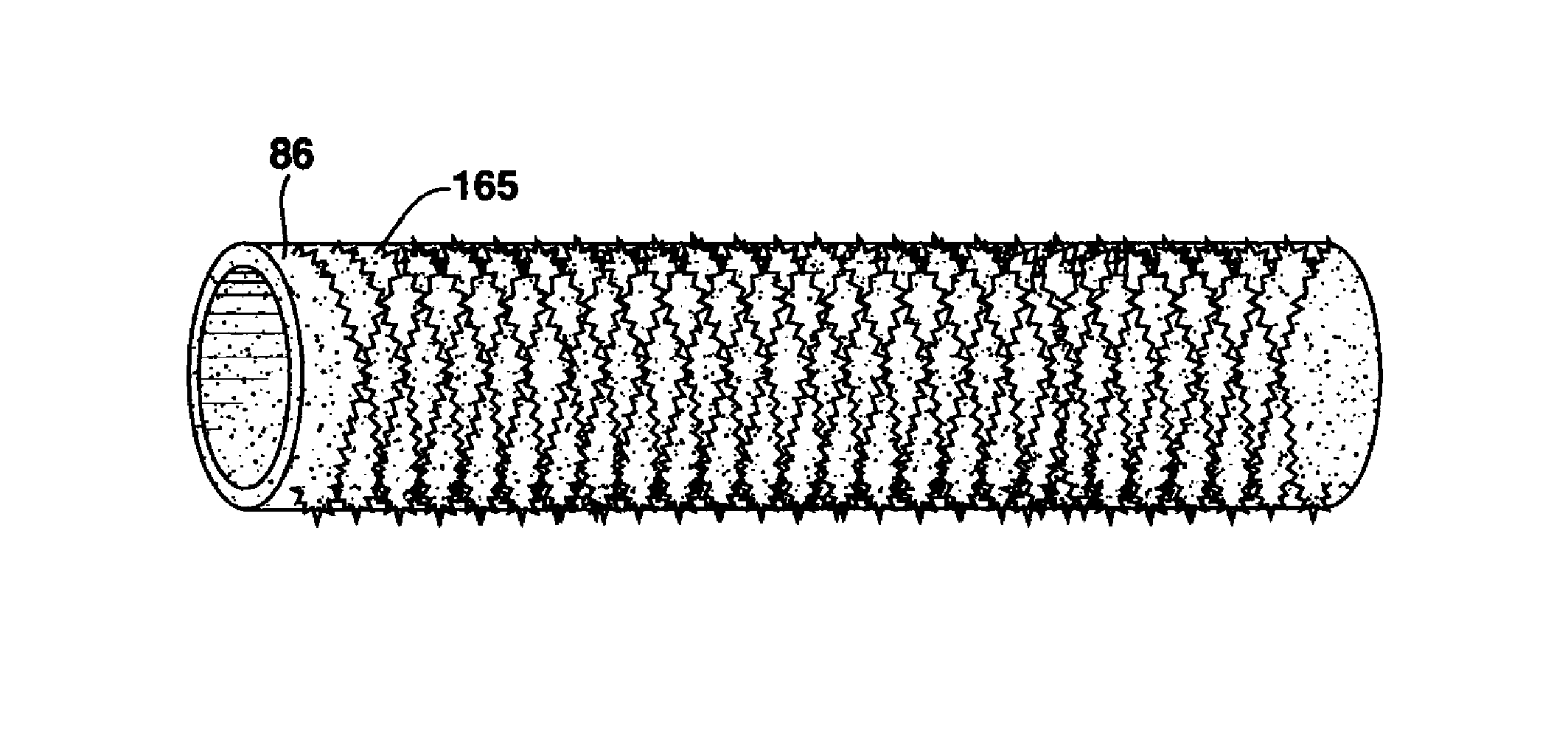

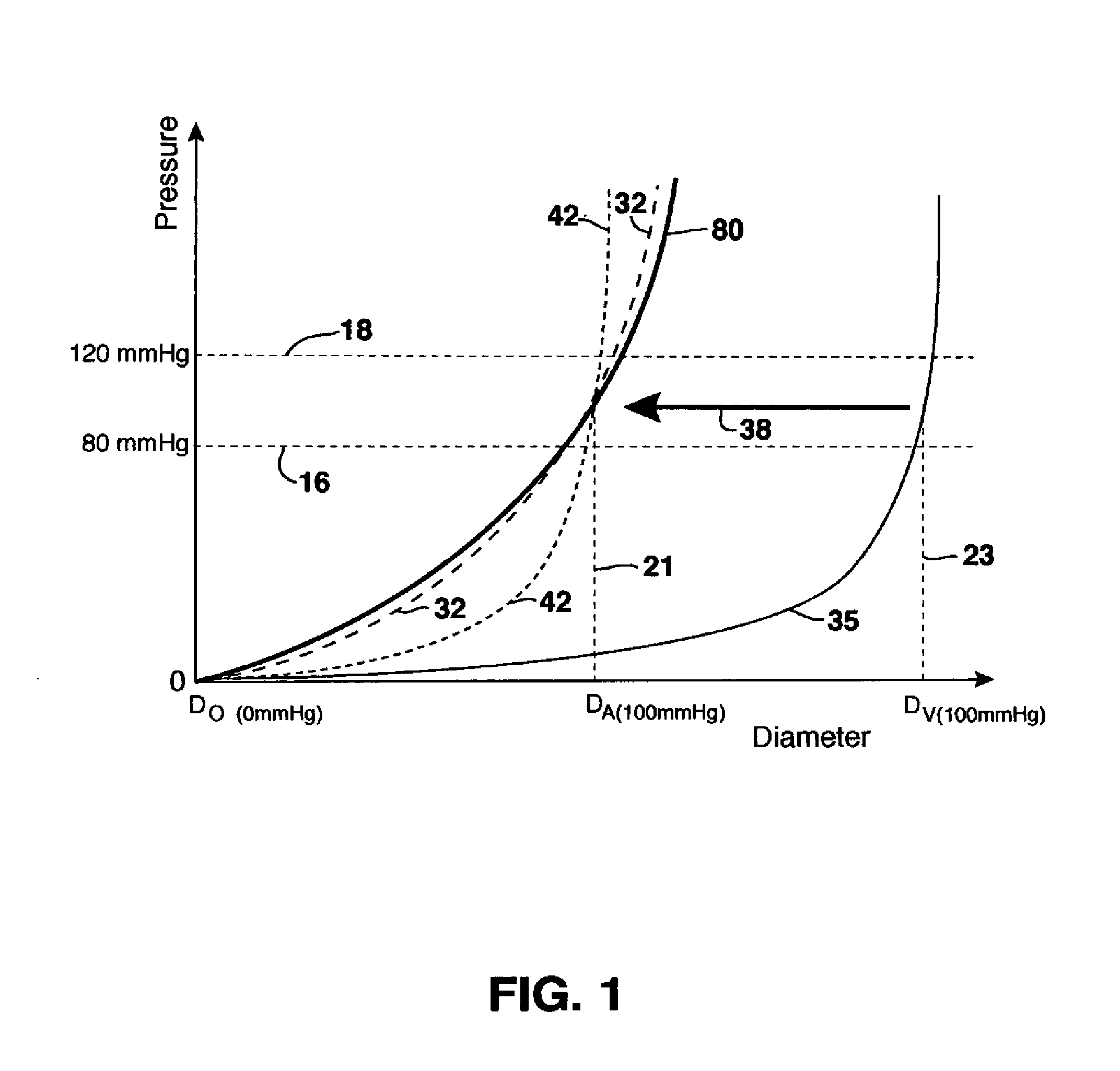

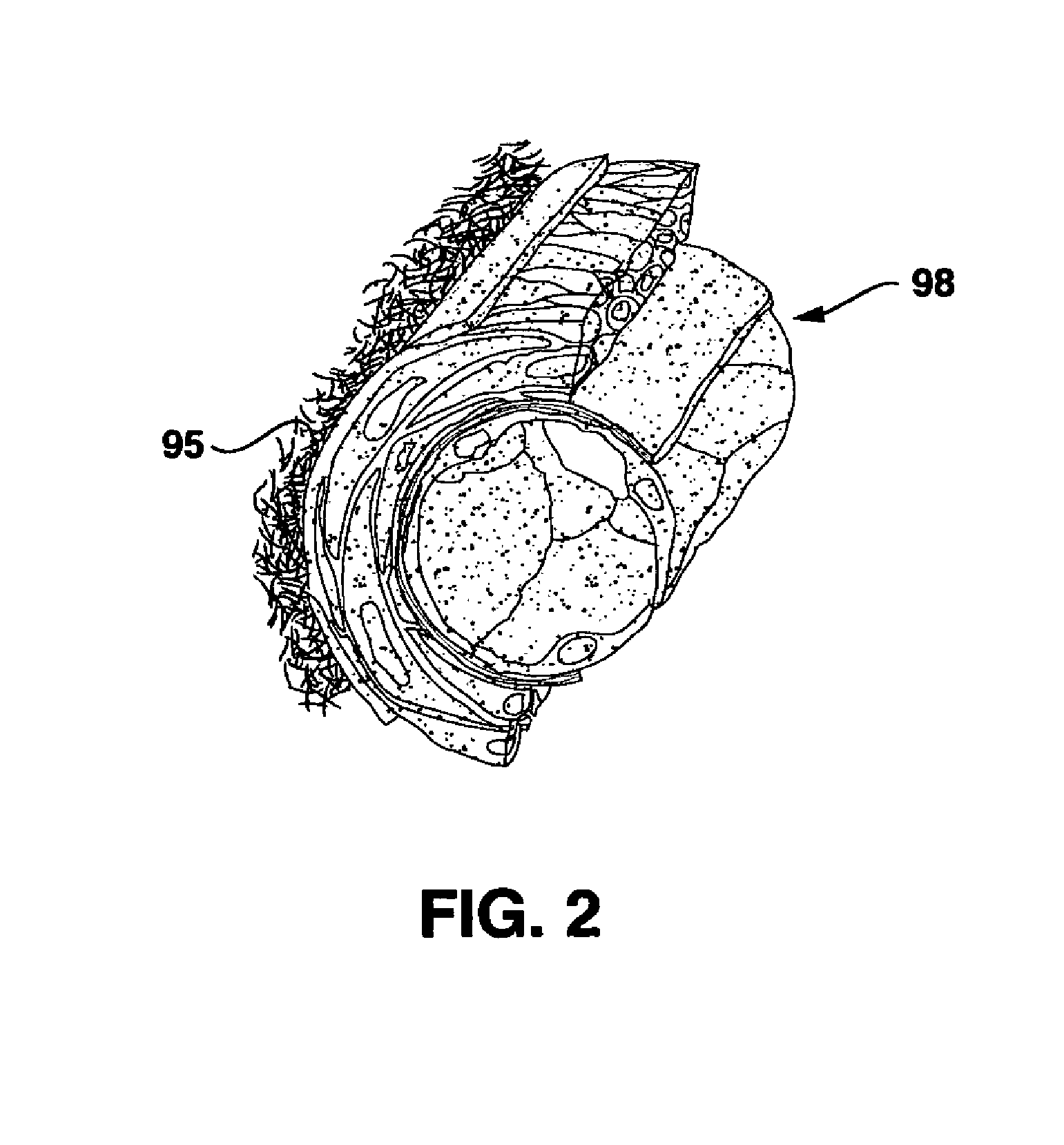

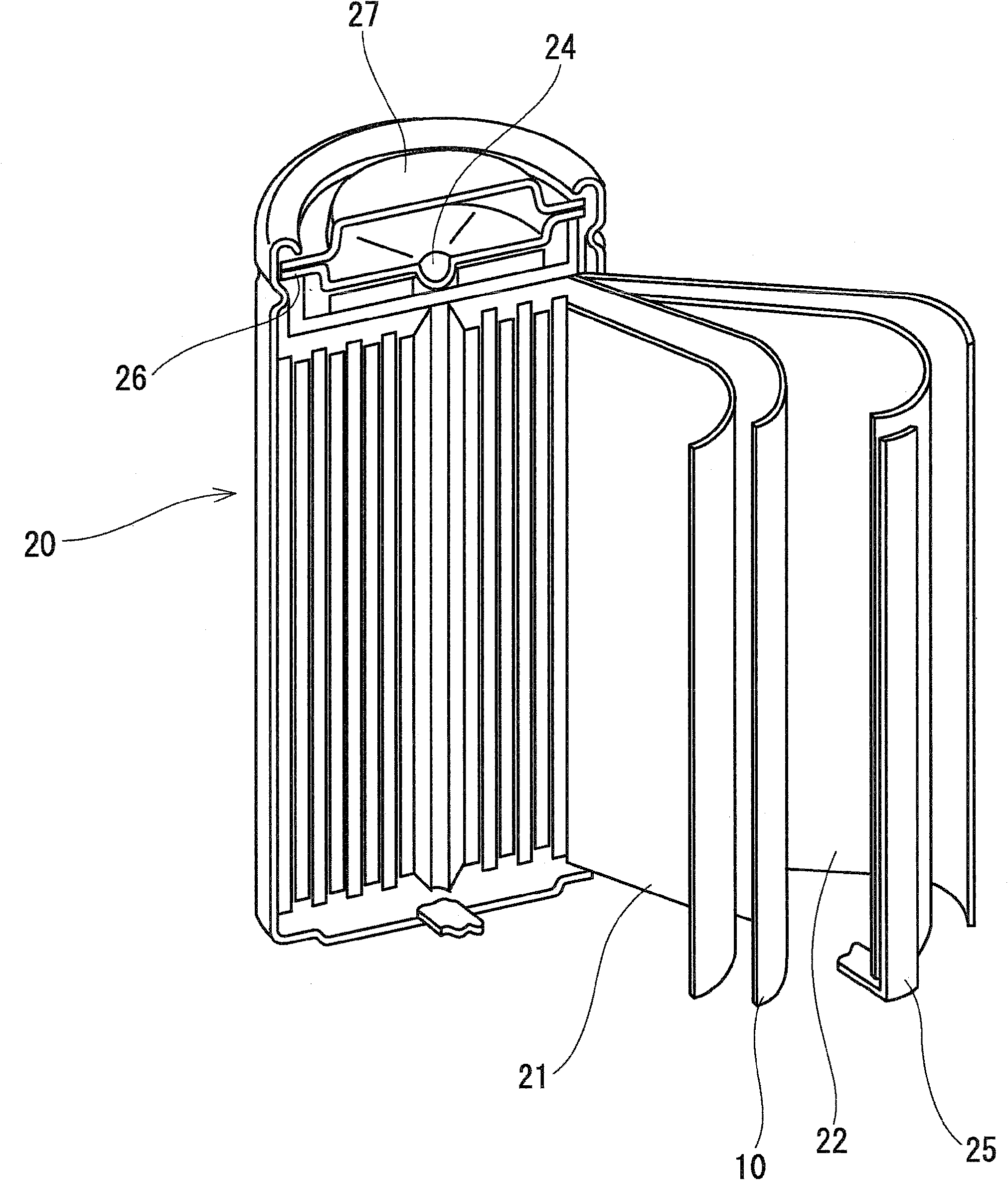

Stents and methods of using stents are provided. Stents of the invention provide external support structure for a blood vessel segment disposed within, wherein the stents are capable of resilient radial expansion in a manner mimicking the compliance properties of an artery. The stent may be formed of a knitted or braided mesh formed so as to provide the needed compliance properties. A venous graft with the stent and a vein segment disposed within is provided, wherein graft is capable of mimicking the compliance properties of an artery. Methods of selecting stents for downsizing and methods of using the stents of the invention in downsizing and smoothening are provided. Methods of replacing a section of an artery with a venous graft including a stent of the invention are provided. Methods of reducing intimal hyperplasia in implanted vein segment in a venous graft using stents of the invention are provided.

Owner:VASCULAR GRAFT SOLUTIONS

Single-component high-performance mortar for repairing and reinforcing concrete

InactiveCN101935201AShrinkage controlImprove bindingSolid waste managementFlexural strengthPollution

The invention provides single-component t high-performance mortar for repairing and reinforcing concrete, which comprises the following components in part by mass: 200g of sand, 55 to 75 parts of ordinary portland cement, 10 to 30 parts of sulphate aluminium cement, 3 to 7 parts of siliceous dust, 8 to 12 parts of flyash, 0.18 to 0.22 part of water reducing agent, 2 to 4 parts of flexibilizer, 0.04 to 0.06 part of water-retaining agent, 1.0 to 2.0 parts of swelling agent and 0.1 to 0.2 part of polymer synthetic fiber. The single-component t high-performance mortar has the advantages of high initial strength, good adhesion, excellent cracking resistance, low ratio of compressive strength to flexural strength, excellent toughness, simple and convenient construction, single component, no toxin or smell, no harm to human bodies, and environmental protection without pollution.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP

Core-shell particles having non-polar outer surface and methods for producing a three-dimensional object from the particles

InactiveUS7431987B2Trend downImprove liquidityLiquid surface applicatorsPhotosensitive materialsRapid prototypingCore shell

The invention relates to particles for producing a three-dimensional object by using layer-building methods (powder-based generative rapid prototyping methods), to methods for producing a three-dimensional object therefrom, and to an object that can be produced by using the particles or the methods. The aim of the invention is to improve the precision of production methods of this type by preventing the tendency of the particles used to agglomerate. To this end, a surfactant layer is applied, whereby the nonpolar groups of the surfactants are oriented toward the particle surface thus forming a hydrophobic surface having a low tendency to agglomerate.

Owner:PFEIFER ROLF +2

Compliant blood vessel graft

ActiveUS7998188B2Smoothening of irregularitiesReduce the differenceStentsSurgeryVenous SegmentVenous graft

Stents and methods of using stents are provided. Stents of the invention provide external support structure for a blood vessel segment disposed within, wherein the stents are capable of resilient radial expansion in a manner mimicking the compliance properties of an artery. The stent may be formed of a knitted or braided mesh formed so as to provide the needed compliance properties. A venous graft with the stent and a vein segment disposed within is provided, wherein graft is capable of mimicking the compliance properties of an artery. Methods of selecting stents for downsizing and methods of using the stents of the invention in downsizing and smoothening are provided. Methods of replacing a section of an artery with a venous graft including a stent of the invention are provided. Methods of reducing intimal hyperplasia in implanted vein segment in a venous graft using stents of the invention are provided.

Owner:VASCULAR GRAFT SOLUTIONS

Polyvinyl butyral granular material for 3-D binder printing, production method and uses therefor

InactiveUS7402330B2Flat surfaceFiner and more detailed structureGranule coatingPretreated surfacesSurface layerMaterials science

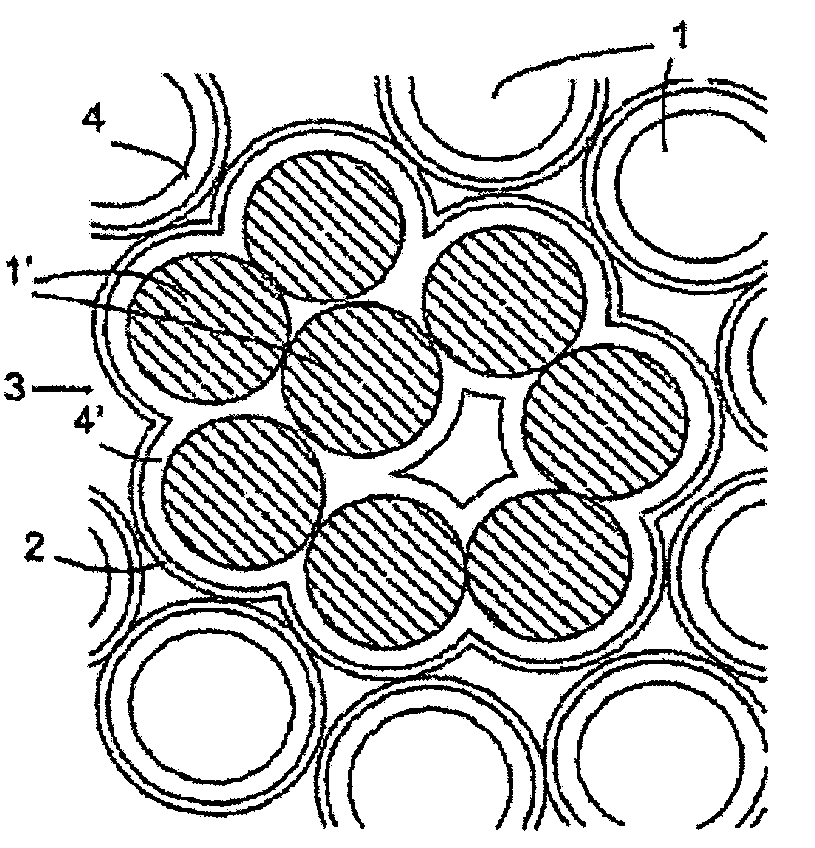

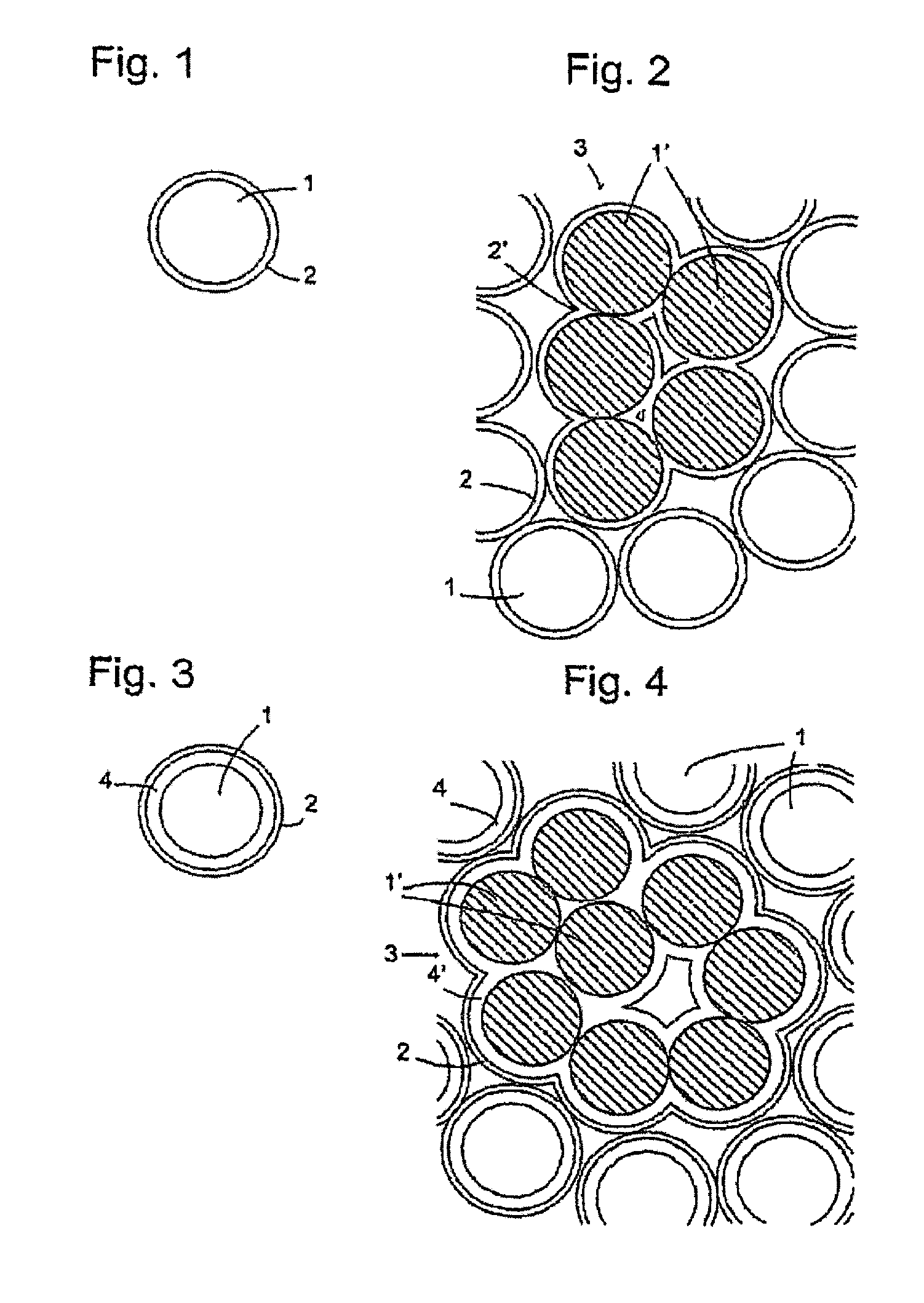

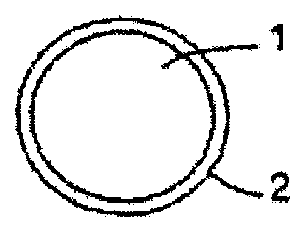

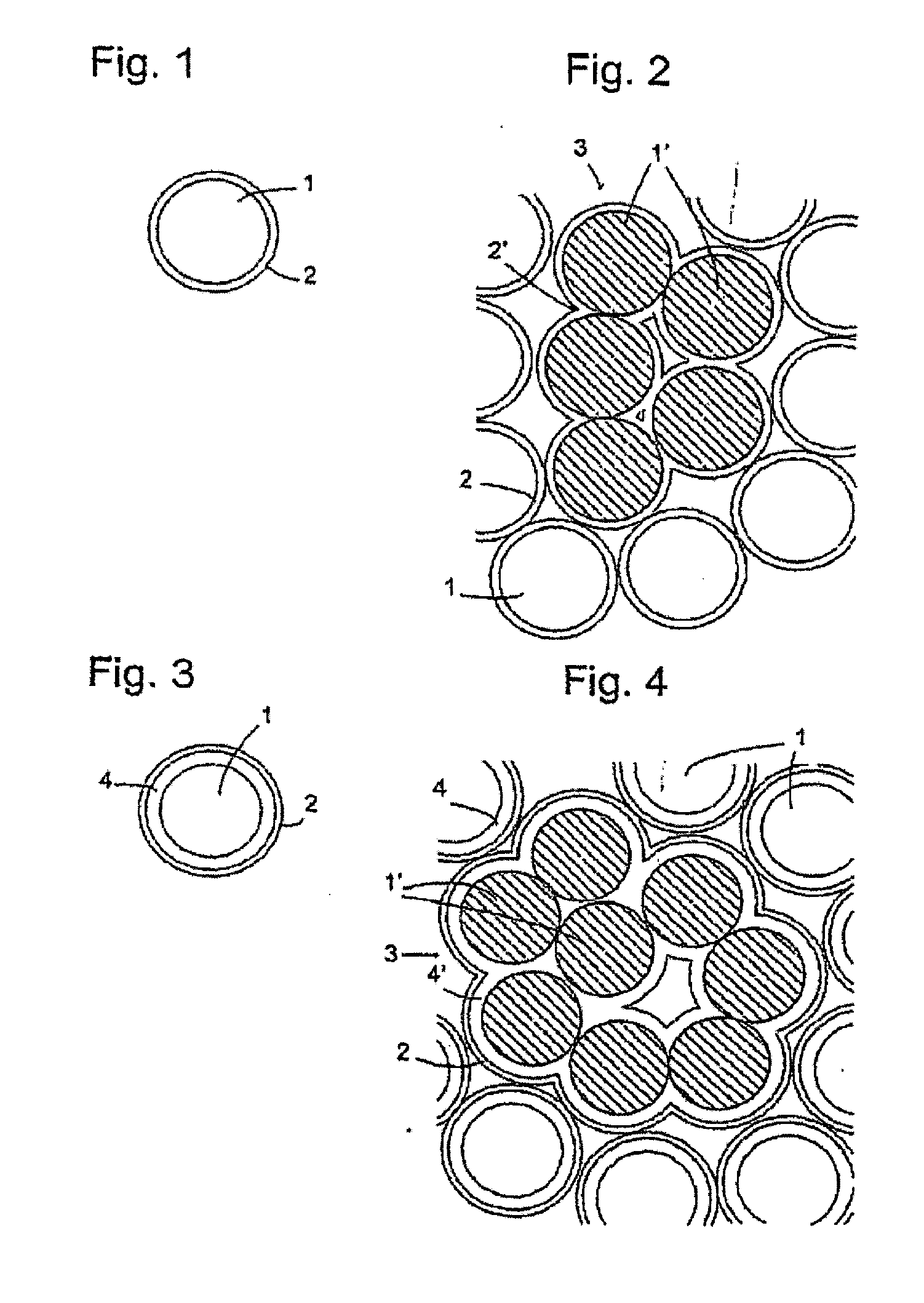

The invention relates to a granular material for 3D binder printing, said granular material consisting of particles provided with an externally non-polar surface layer (2). The invention also relates to a method for producing a granular material for 3D binder printing, whereby a surface layer (2) having a non-polar outer side is applied to initial particles (1), and to a method for producing an object consisting of the inventive granular material, according to which a layer of the inventive granular material is applied to a base, and pre-determined regions (3) of said layer are moistened with a binding fluid, said binding fluid being selected from fluids in which a surface layer of the particles of the granular material is soluble. The invention further realties to objects consisting of interconnected particles of the inventive granular material. The invention enables a very precise printing process.

Owner:VOXELJET AG

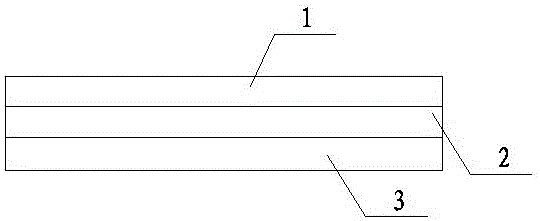

Granular material for 3d binder printing, production method and uses therefor

InactiveUS20050276976A1Extended service lifeFlat surfaceGranule coatingPretreated surfacesSurface layerMaterials science

The invention relates to a granular material for 3D binder printing, said granular material consisting of particles provided with an externally non-polar surface layer (2). The invention also relates to a method for producing a granular material for 3D binder printing, whereby a surface layer (2) having a non-polar outer side is applied to initial particles (1), and to a method for producing an object consisting of the inventive granular material, according to which a layer of the inventive granular material is applied to a base, and pre-determined regions (3) of said layer are moistened with a binding fluid, said binding fluid being selected from fluids in which a surface layer of the particles of the granular material is soluble. The invention further realties to objects consisting of interconnected particles of the inventive granular material. The invention enables a very precise printing process.

Owner:VOXELJET AG

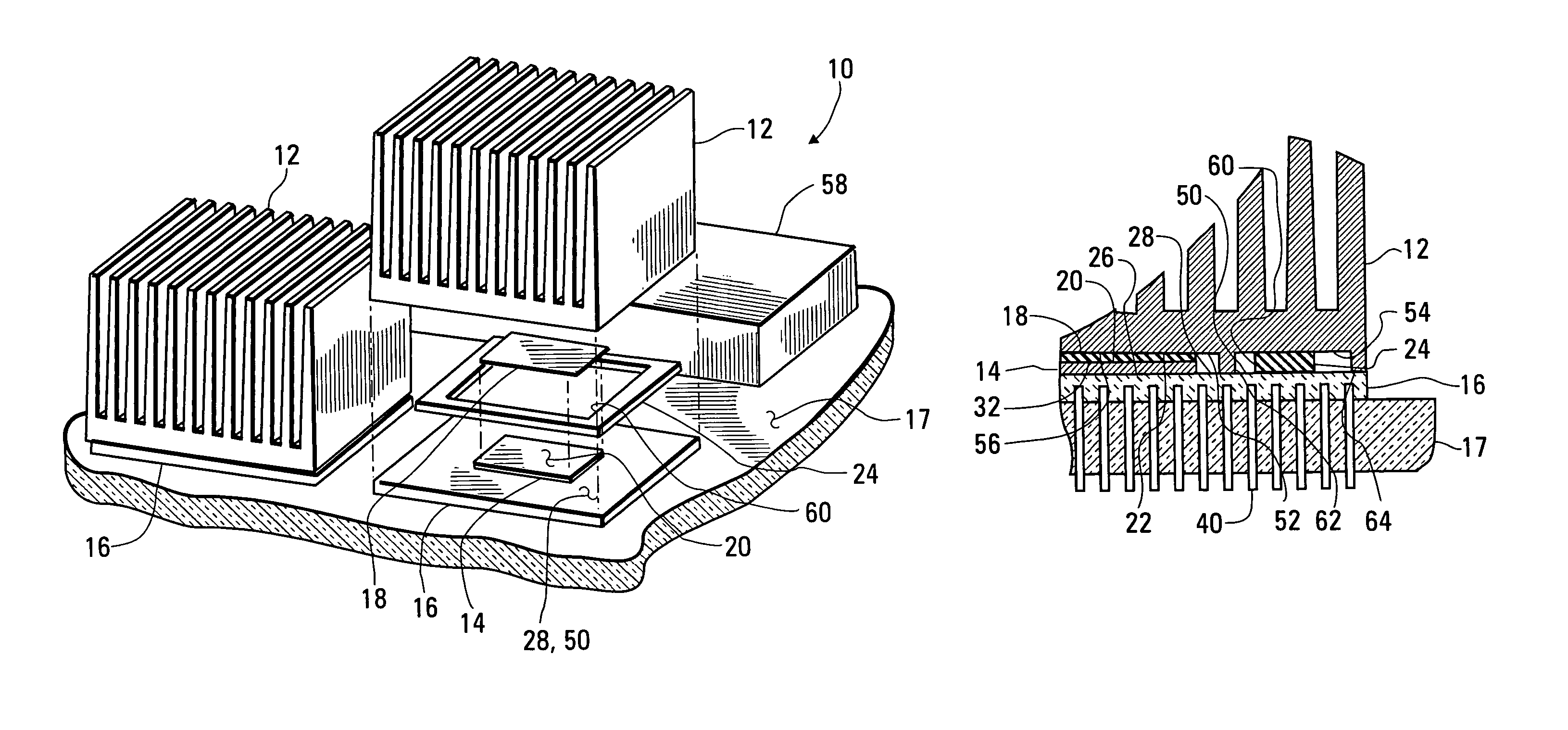

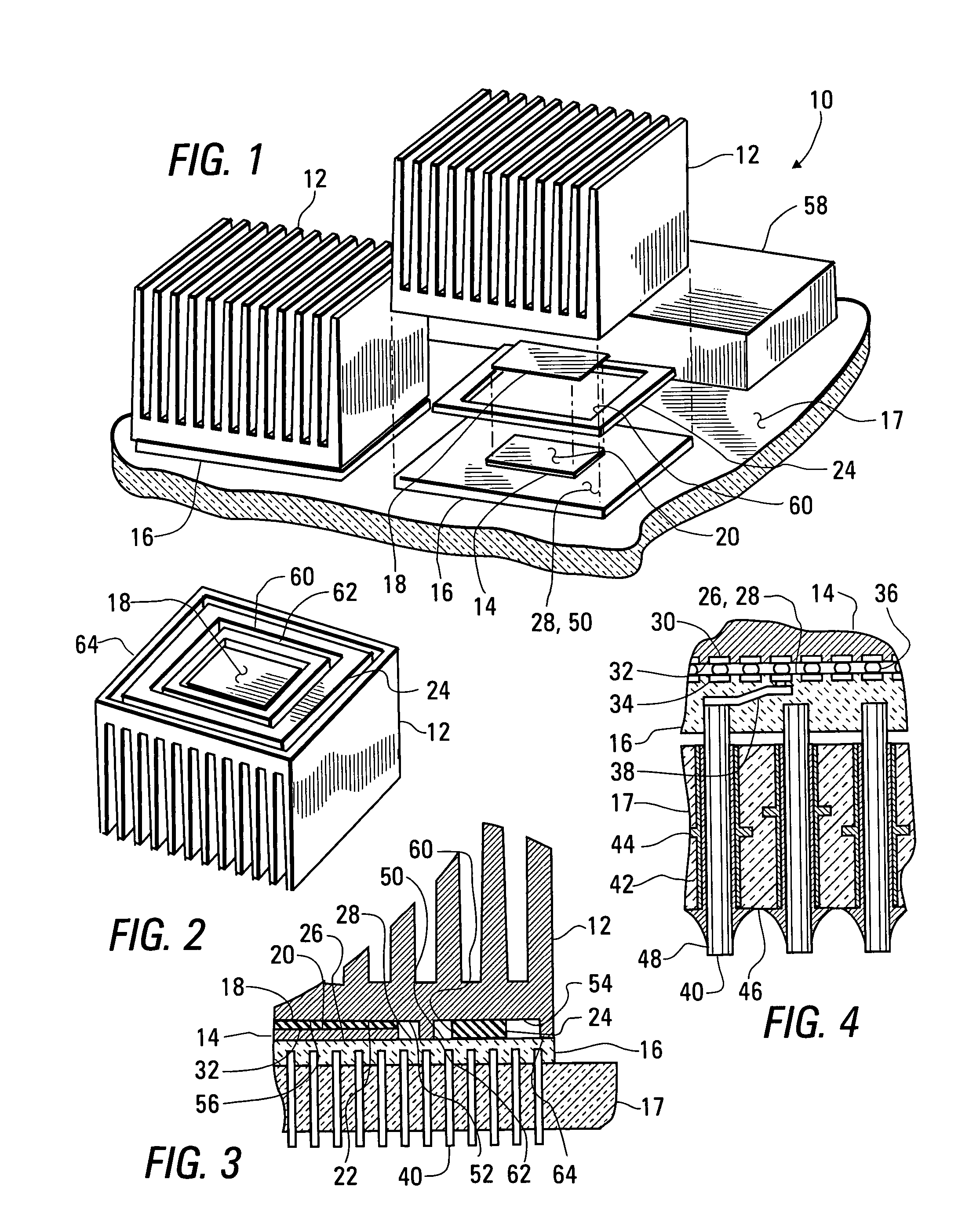

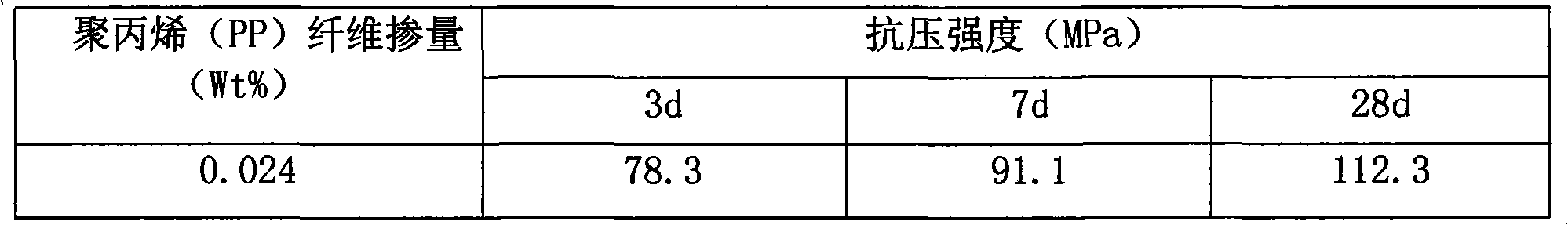

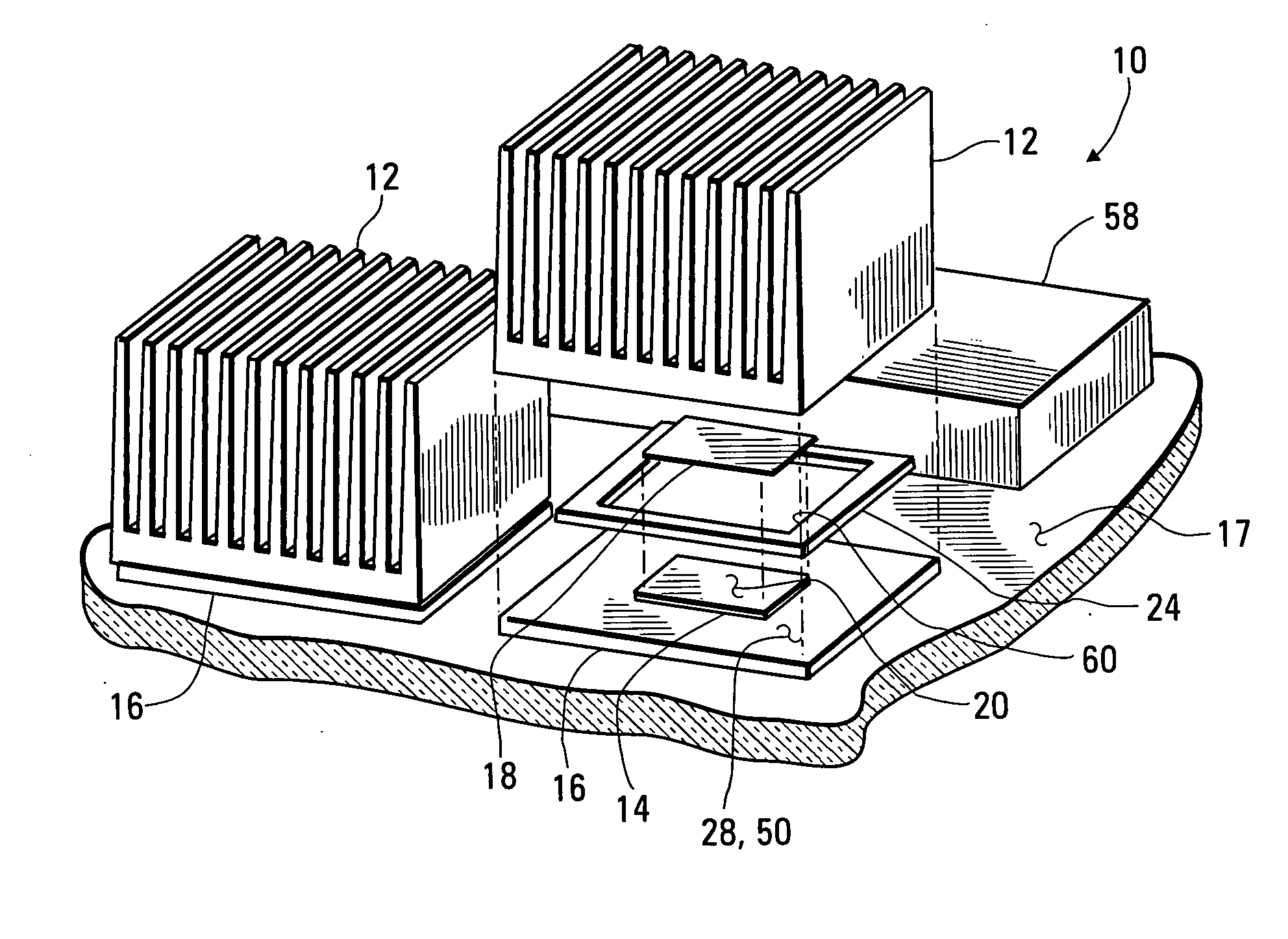

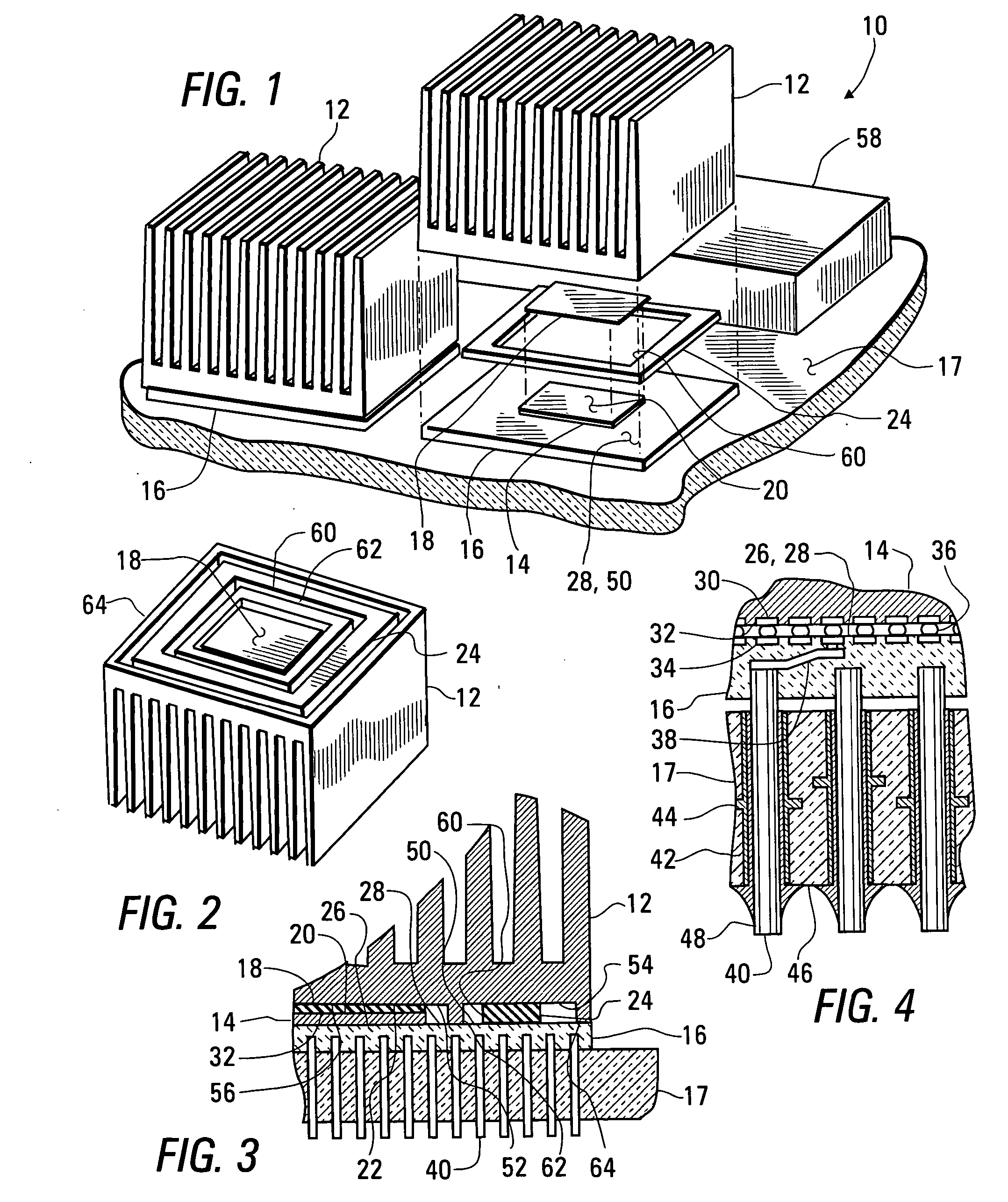

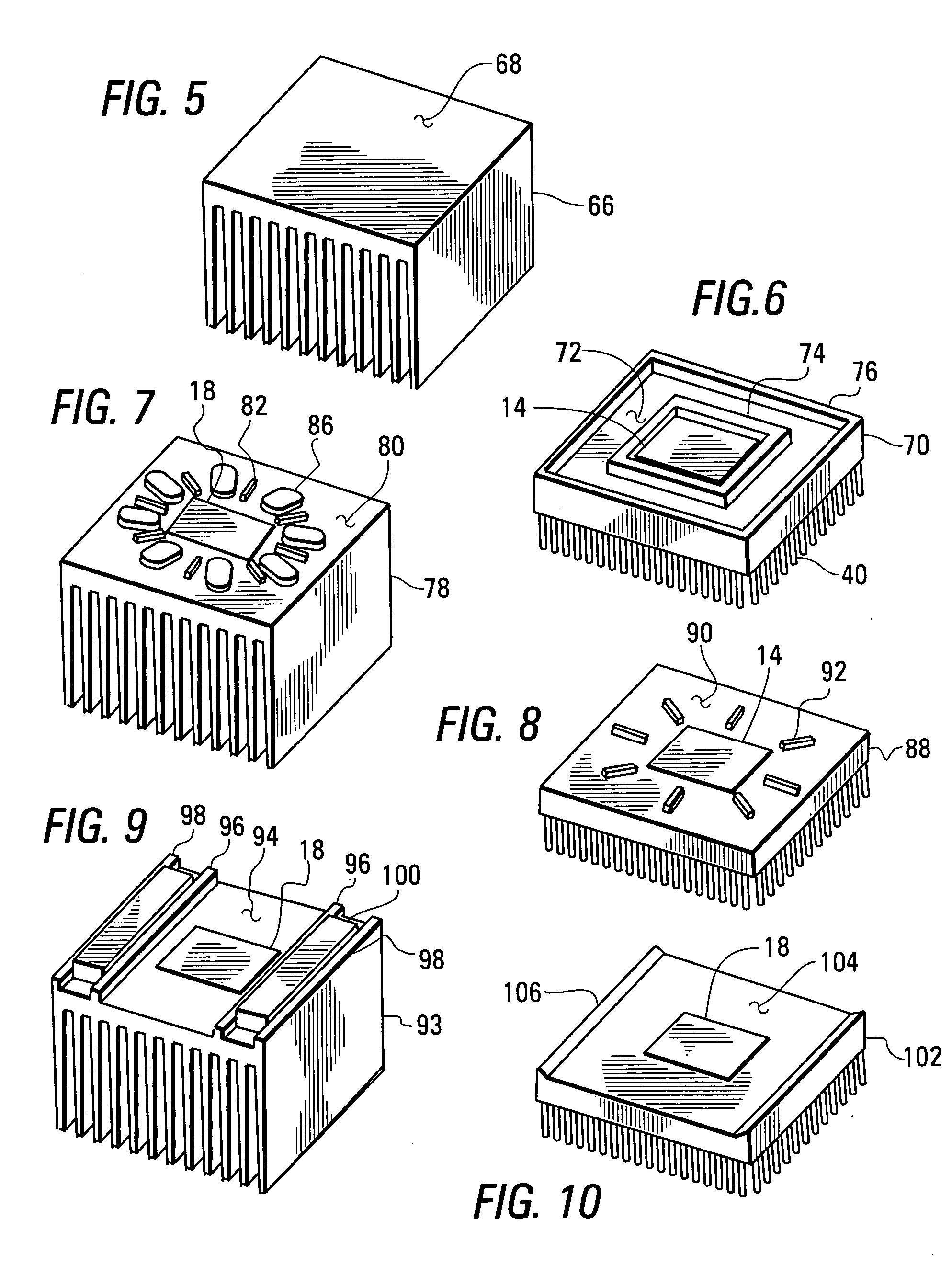

Apparatus and method for attaching a heat sink to an integrated circuit module

ActiveUS7006353B2Limit flexure of the substrateShrinkage controlSemiconductor/solid-state device detailsSolid-state devicesAdhesiveEngineering

A heat sink is fastened to an annular portion of a substrate of an integrated circuit module on a printed circuit card by means of a cured layer of cure shrinkable adhesive. A circuit chip is soldered to a central portion of the substrate, around which the annular portion extends. A layer of thermally conductive material is placed between the circuit chip and a central portion of the heat sink, to be compressed as the layer of cure shrinkable adhesive is cured. A compression limiting structure may additionally extend between the heat sink and the annular portion of the substrate, limiting the shrinkage of the adhesive and thus the compression of the thermally conductive material and the flexure of the substrate.

Owner:INT BUSINESS MASCH CORP

Special thin anti-crack plastering mortar for autoclaved aerated concrete

The invention discloses a special thin anti-crack plastering mortar for autoclaved aerated concrete and belongs to the technical field of building materials. According to the special thin anti-crack plastering mortar disclosed by the invention, a dry material is added with water by a mass ratio that water to dry material ratio is equal to 1:4, and then stirred for 3-5 minutes to prepare mortar, wherein the dry material consists of the following components in mass by percentage: 20%-35% of cement, 10%-30% of 40-70-mesh quartz sand, 30%-50% of 80-100-mesh quartz sand, 2%-7% of 200-mesh coarse whiting powder, 1.5%-4% of redispersible emulsion powder; 0.15%-0.5% of water-retaining agent; 0.2%-0.7% of wood fiber and 0.11%-0.45% of short fiber. Being prepared by adopting quartz sand of 40-70 meshes or 80-100 meshes, the special thin anti-crack plastering mortar for the autoclaved aerated concrete disclosed by the invention has an excellent anti-crack performance, realizes effective control on contraction percentage of the mortar, causes no cracks during large-area construction, achieves good caking property, and realizes organic combination between the mortar and the surface layer of the autoclaved aerated concrete.

Owner:山东高阳建材有限公司

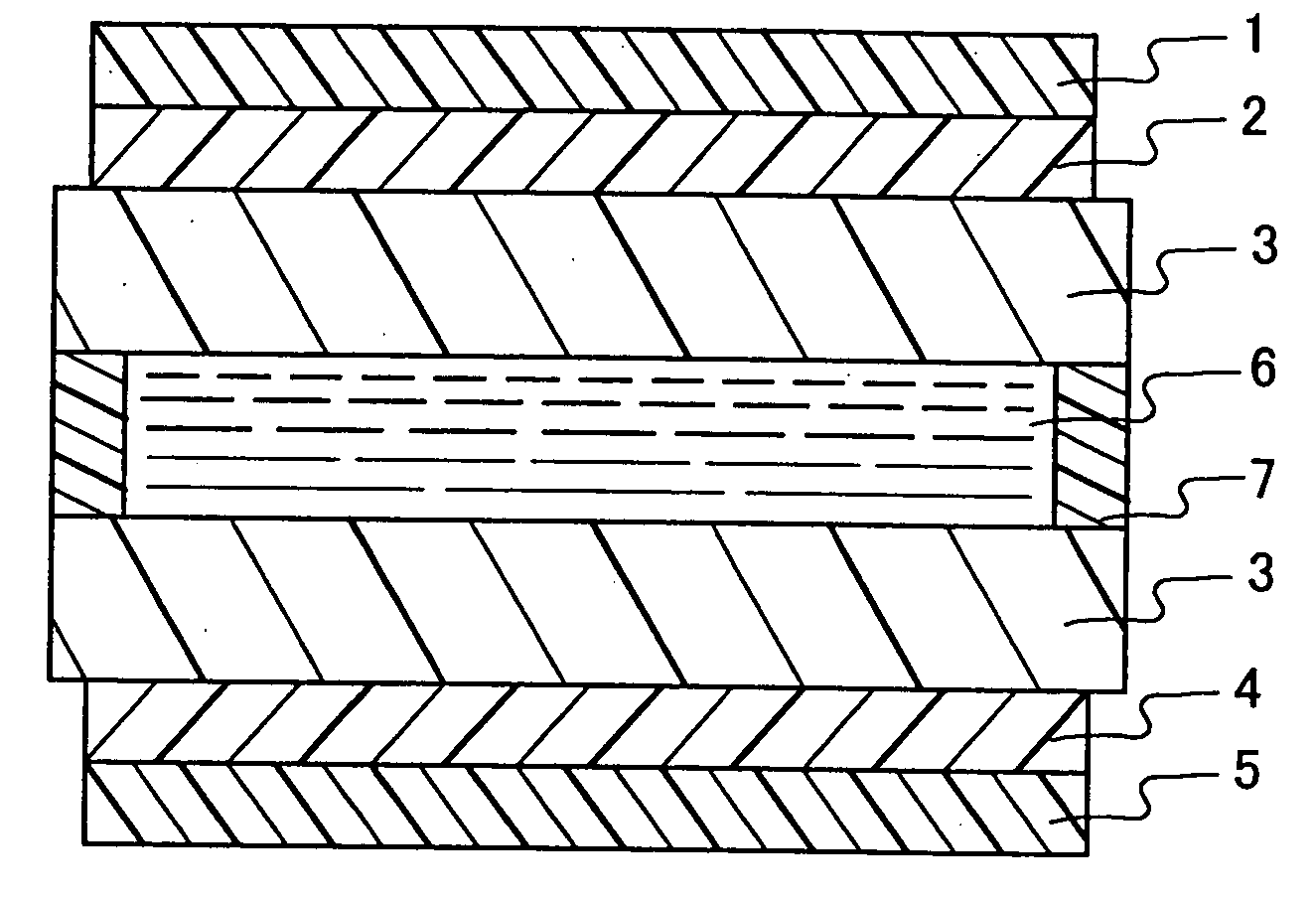

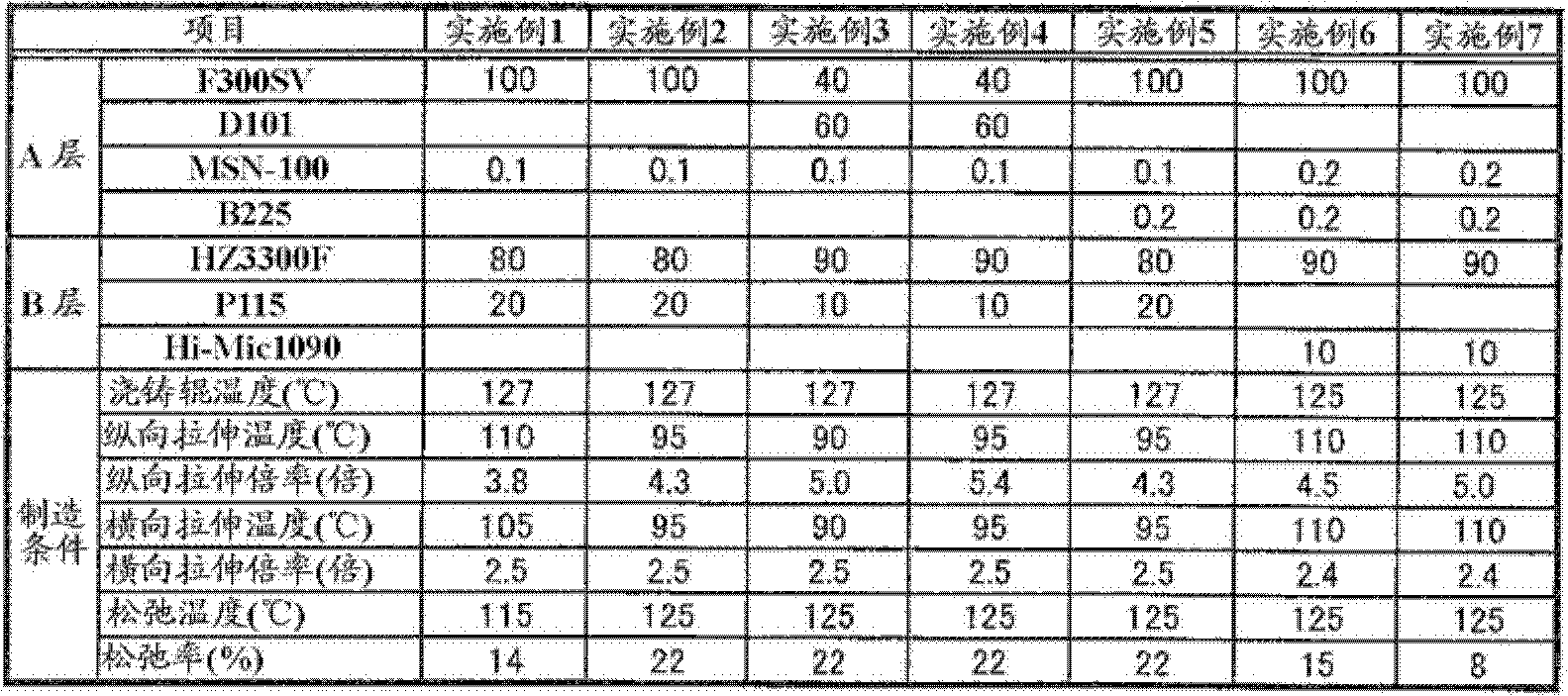

Polarizer, polarizing plate, and liquid crystal display using the same

InactiveUS20050260392A1Small size changeReduce discolorationLayered productsPolarising elementsLiquid-crystal displayPolarizer

The present invention provides a polarizer and a polarizing plate having less dimensional changes to heat stress. The present invention provides also a liquid crystal display that includes the polarizer and the polarizing plate, and is free of color irregularity or decoloration. The polarizer has shrinkage force of not more than 4.0 N / cm in the absorption axis direction after being heated at 80° C. for 30 minutes. A protective film is laminated on at least one surface of the polarizer in order to form a polarizing plate, and the polarizing plate has a following relationship of 0.01≦A / B≦0.16 when A denotes a thickness of the polarizer and B denotes a thickness of the protective film.

Owner:NITTO DENKO CORP

Salt core of engine piston and making method thereof

ActiveCN1994615AHigh strengthFast water solubilityFoundry mouldsMould handling/dressing devicesWater solubleEngineering

The invention relates to a plug salt corn of engine and relative production, wherein it is formed by 70-80% soluble metal salt and 20-30% findings; the salt grainness can reach 60-120 deals; the finding grainness should at least reach 200 deals. And the production comprises that: first breaking metal salt and findings into needed grainness, mixing them, putting some into powder compressing mould to obtain the blank; then putting blank into furnace to be baked; then processing the positioning hole. The inventive salt corn has high strength, while it can be washed by water.

Owner:DONGFENG MOTOR CORP HUBEI

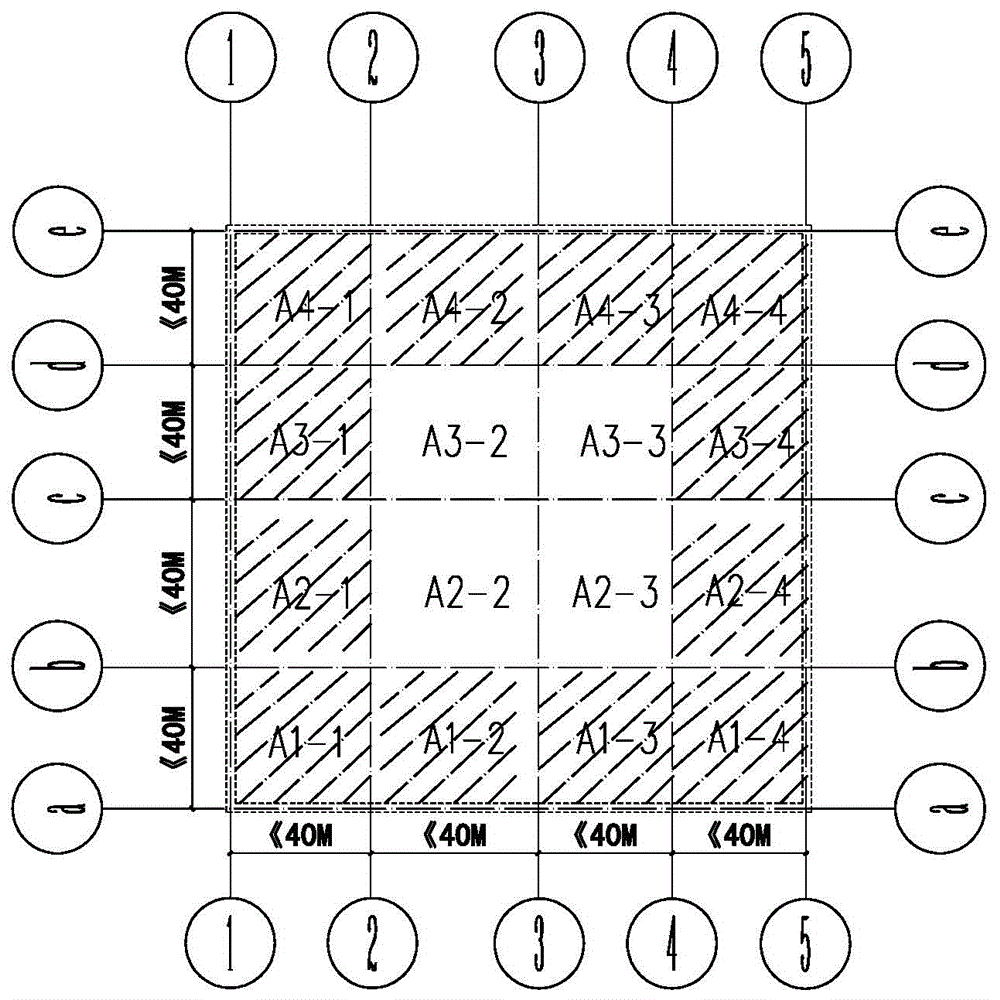

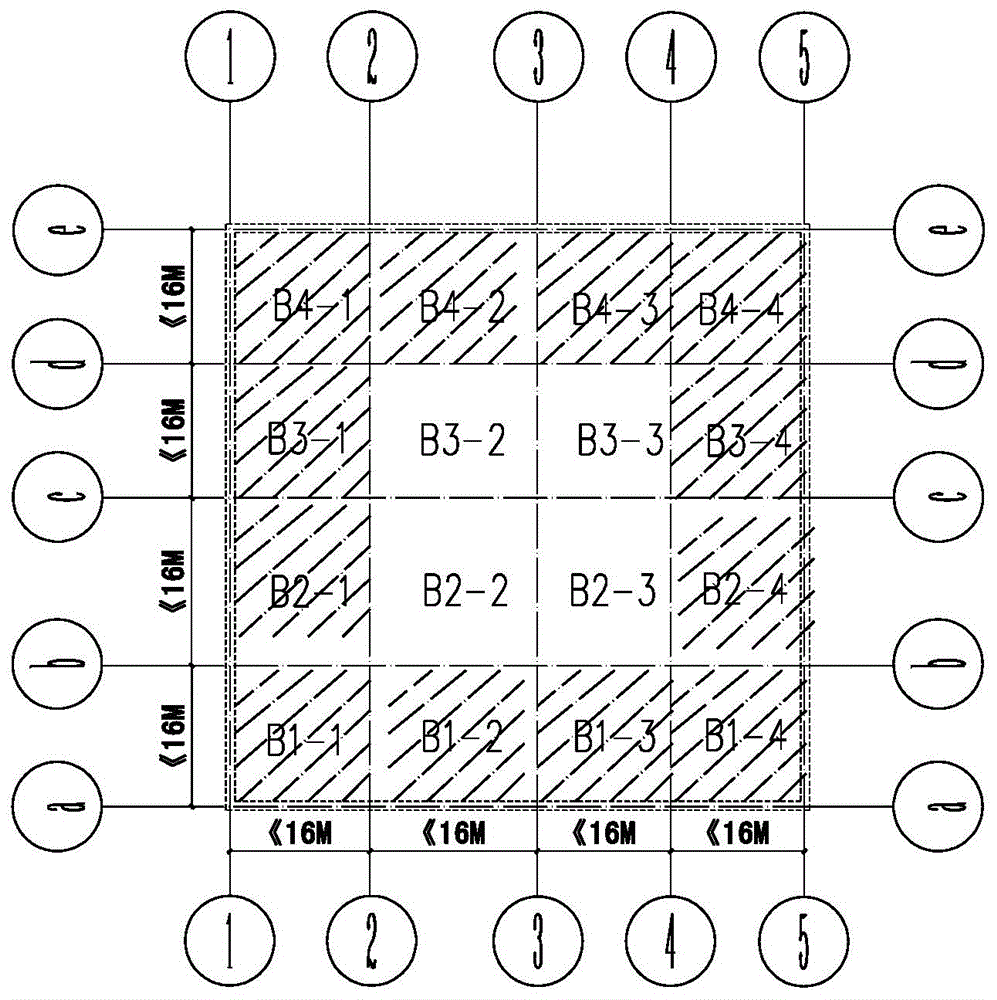

Large-area RC basement structure sequence construction method

InactiveCN104963357AImprove construction efficiencyReduce construction costsArtificial islandsUnderwater structuresBasementRebar

The invention provides a large-area RC basement structure sequence construction method. Firstly, a large-area RC basement is structurally decomposed, and warehouse dividing arrangement, operation conducted according to a rebar binding method, construction joint arrangement, concrete pouring, concrete curing, concrete temperature measurement and briquette retention are sequentially conducted. According to the large-area RC basement structure sequence construction method, a sequence method is adopted for replacing a construction post-cast strip, related work such as RC basement backfill and the like is conducted in advance, engineering construction efficiency is improved, and construction cost is reduced. Construction control is strict, and structural concrete early-stage cracks of the RC basement are effectively controlled. The concrete mixing ratio is optimized, the cement use amount is controlled, and structural concrete shrinkage distortion of the RC basement is effectively controlled. The waterproof quality of concrete of an RC basement structural outer wall and a bottom plate are improved.

Owner:CHINA MCC17 GRP

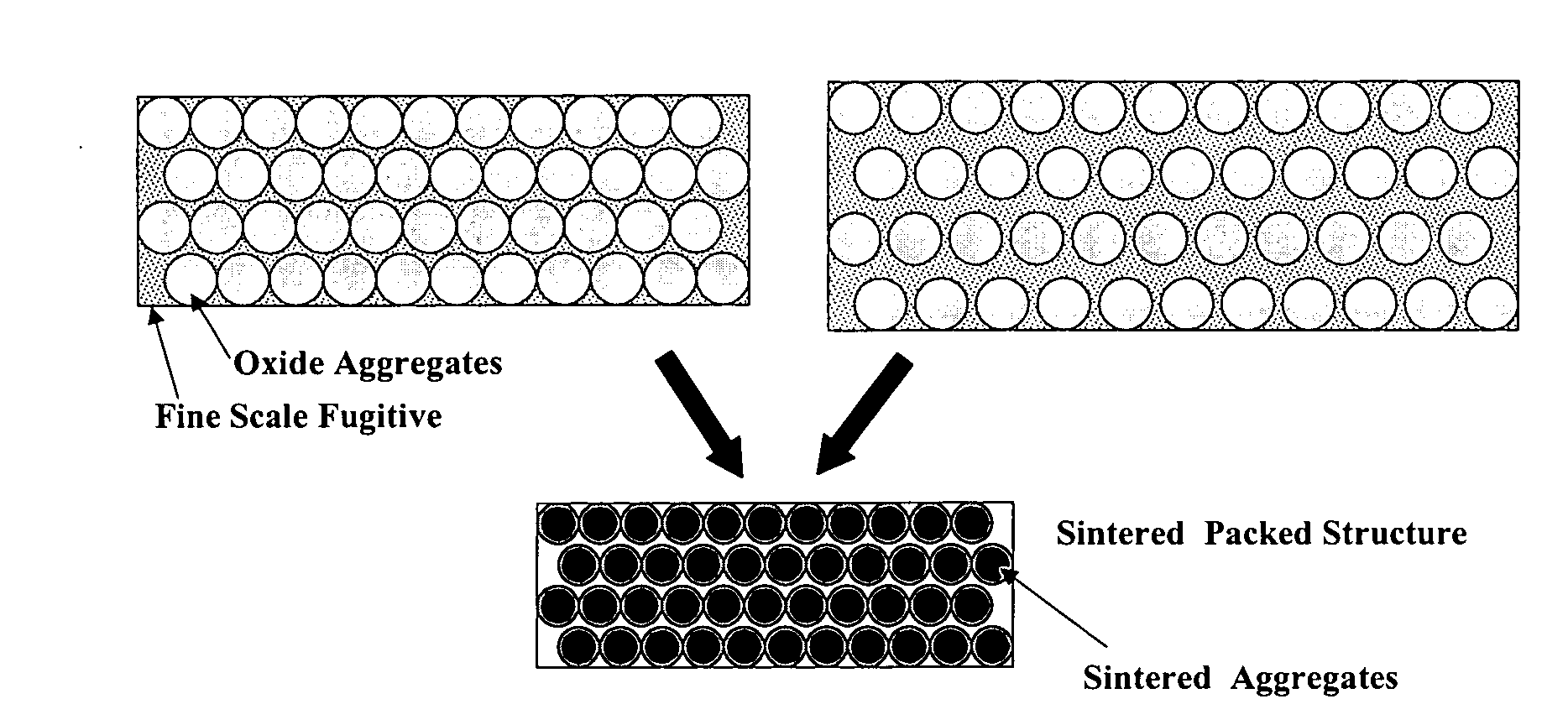

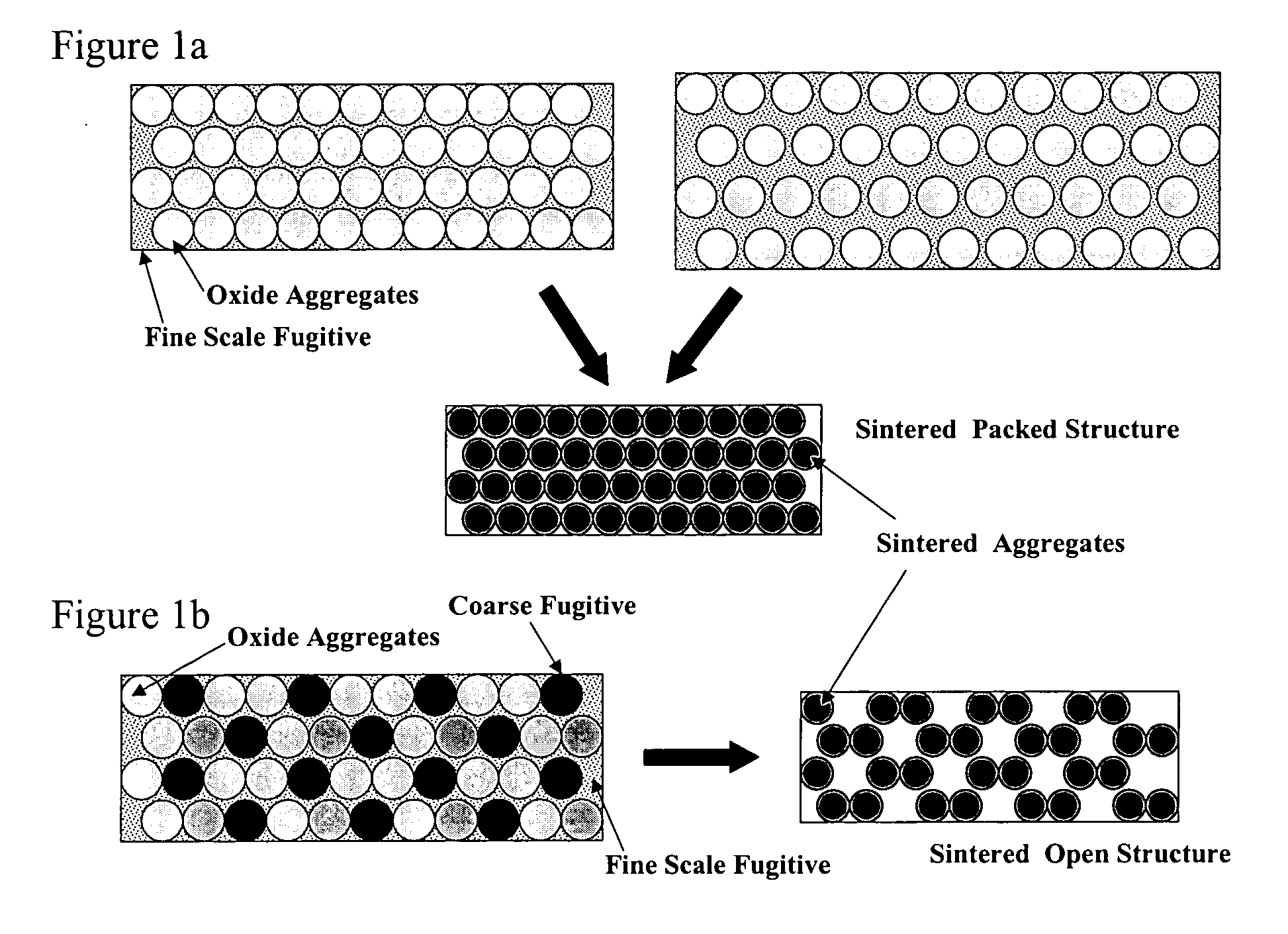

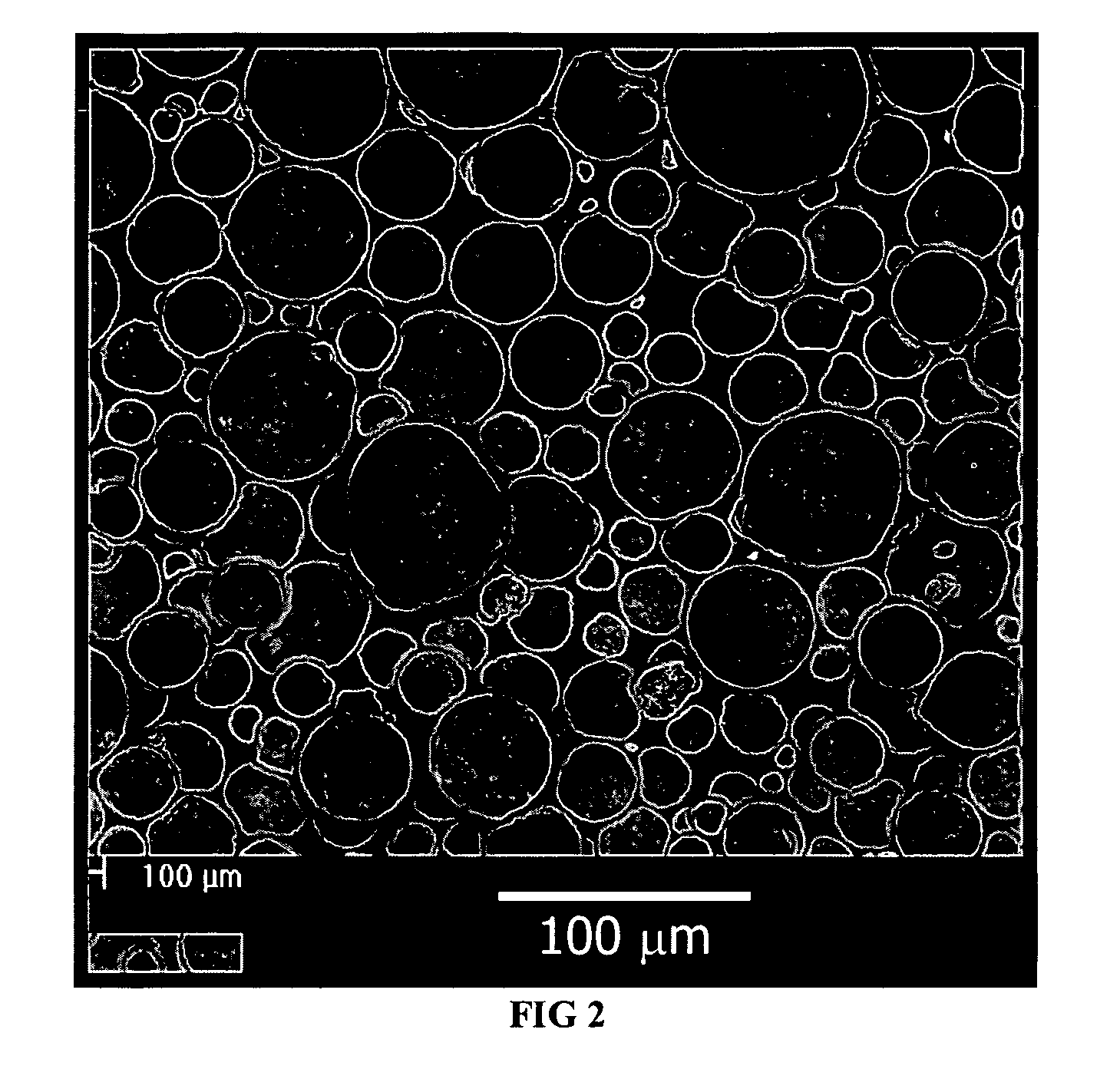

Supported ceramic membranes and electrochemical cells including the same

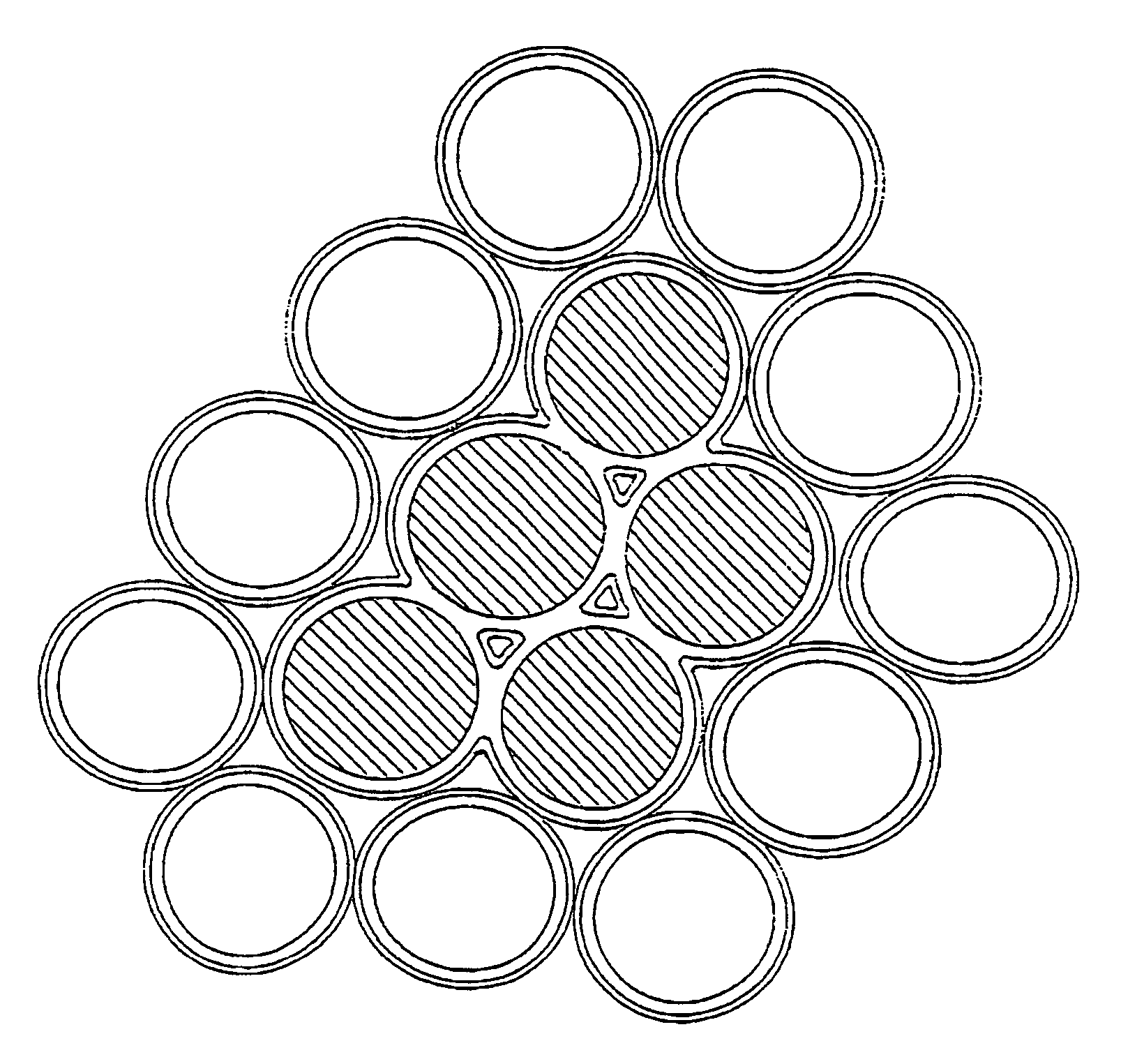

InactiveUS20070042225A1Enhancement of chemicalEnhancement of electrical transportSludge treatmentIsotope separationSlurryOxygen

Supported thin film membranes of ceramic materials and electrochemical cells including supported thin film membranes. The microstructure of the support is particularly well suited for the well suited for subsequent infiltration with electrochemically active species (as solutions, slurries, or salts) to enhance chemical or electrical transport to the membrane and maintains satisfactory gas flow to the membrane after infiltration. This invention may be useful in electrochemical separations or catalytic reactors including, but not limited to, solid oxide fuel cells and oxygen separation membranes.

Owner:NEXTECH MATERIALS

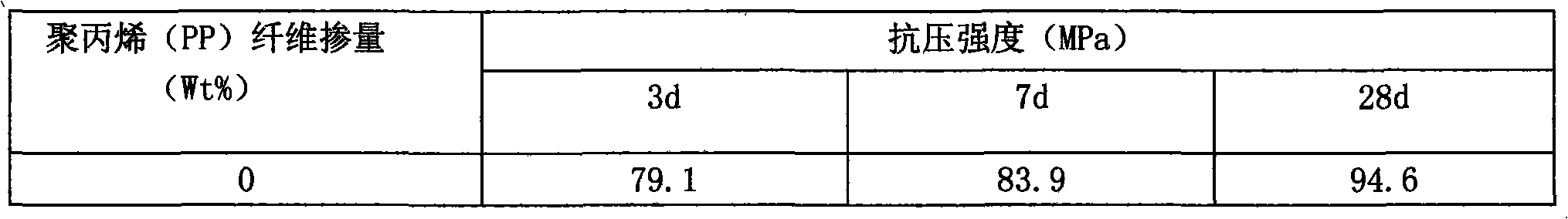

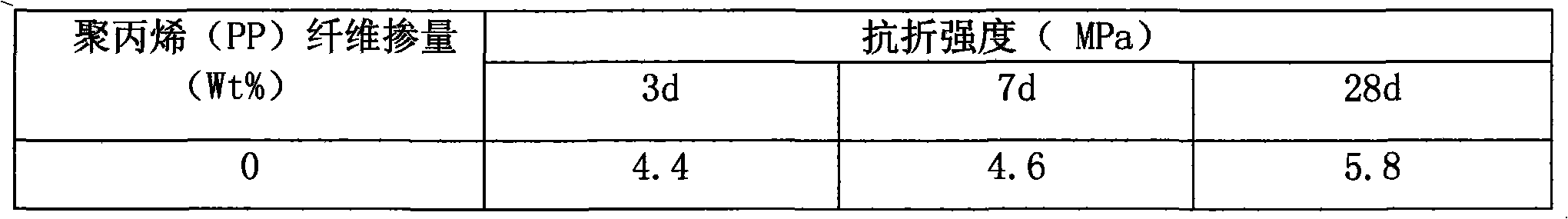

Polypropylene fiber reinforced inorganic polymer composite material and preparation method thereof

InactiveCN101570424AControl plastic shrinkageControl shrinkageSolid waste managementCement productionPolymer scienceSlag

The invention discloses a polypropylene fiber reinforced inorganic polymer composite material and a preparation method thereof. Polypropylene beam-like monofilament fiber and sodium silicate are added in slag, and the mixture is excited by the sodium silicate to prepare the composite material; the adding amount of the polypropylene beam-like monofilament fiber is 0.024 to 0.06 percent of the weight of the slag; and the adding amount of sodium silicate is 11 percent of the weight of the slag. The preparation method comprises the following steps: dispersing the polypropylene beam-like monofilament fiber in the formula ratio in the slag at the room temperature; putting the mixture in a double-rotation double-speed purified paste stirrer for stirring; adding a water solution of sodium silicate in the mixture and evenly stirring the mixture to form an evenly mixed paste, wherein the ratio of water to the slag is 0.31; and forming the paste , putting the paste in a standard curing box for curing, and testing the compressive strength and the flexural strength of the paste. Compared with the slag inorganic polymer, the maximum flexural strength of the composite material at 28d is increased by 5.4 MPa, and the maximum compressive strength of the composite material at 28dis increased by 17.7 MPa. The preparation process has the advantages of easy operation, unnecessary heating and no three-waste emission, so the preparation process is a green preparation process.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Novel approach to improve line end shortening

InactiveUS20050191832A1Improve toleranceEasy to controlRadiation applicationsPhotomechanical apparatusEngineeringProcess window

A process is described for transferring a photoresist pattern into a substrate. In one embodiment a stack comprised of a top photoresist layer, a middle ARC layer, and a bottom hardmask is formed over a gate electrode layer. A line in the photoresist pattern is anisotropically transferred through the ARC and hardmask. Then an isotropic etch to trim the linewidth by 0 to 50 nm per edge is performed simultaneously on the photoresist, ARC and hardmask. This method minimizes the amount of line end shortening to less than three times the dimension trimmed from one line edge. Since a majority of the photoresist layer is retained, the starting photoresist thickness can be reduced by 1000 Angstroms or more to increase process window. The pattern is then etched through the underlying layer to form a gate electrode. The method can also be used to form STI features in a substrate.

Owner:TAIWAN SEMICON MFG CO LTD

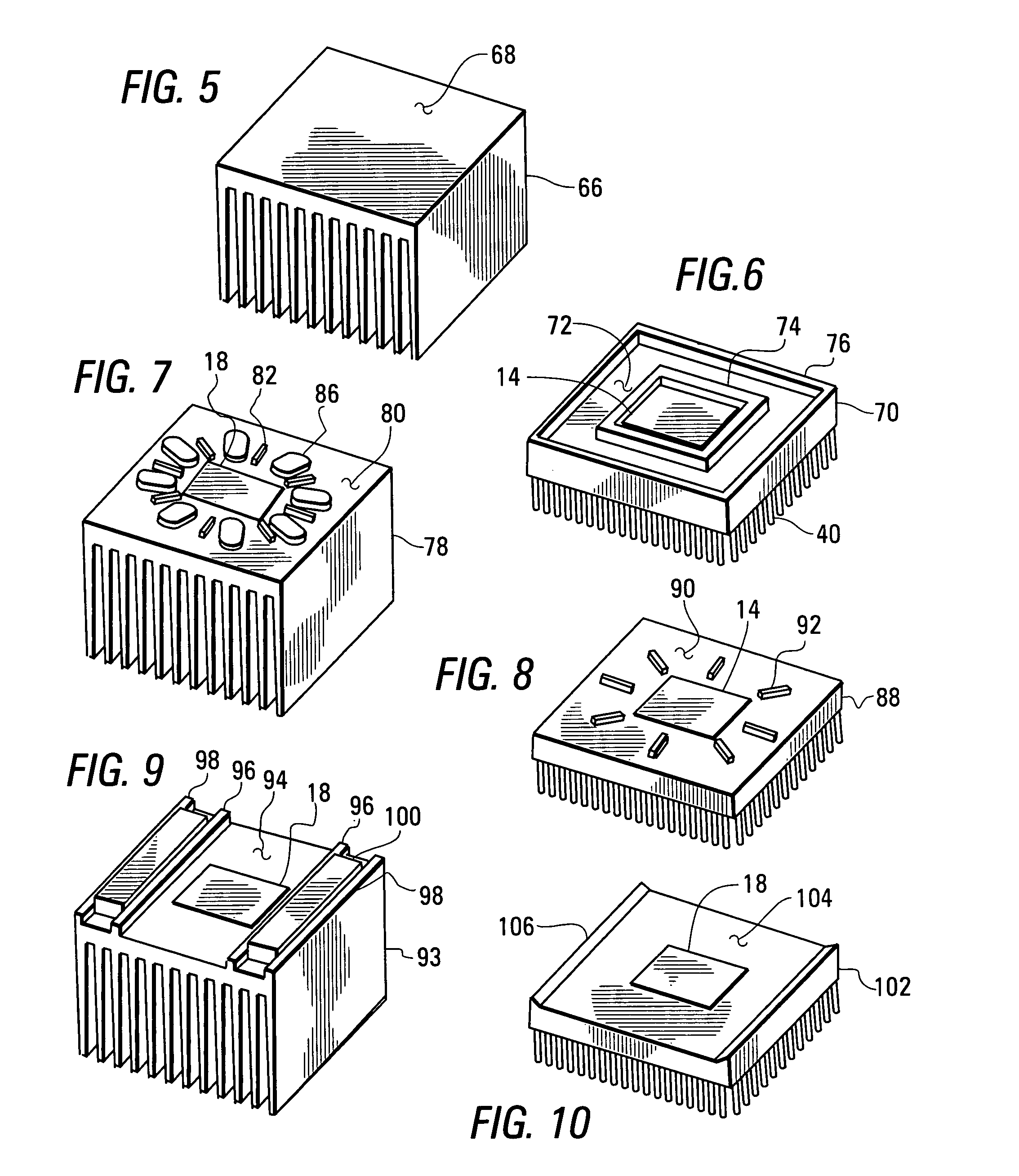

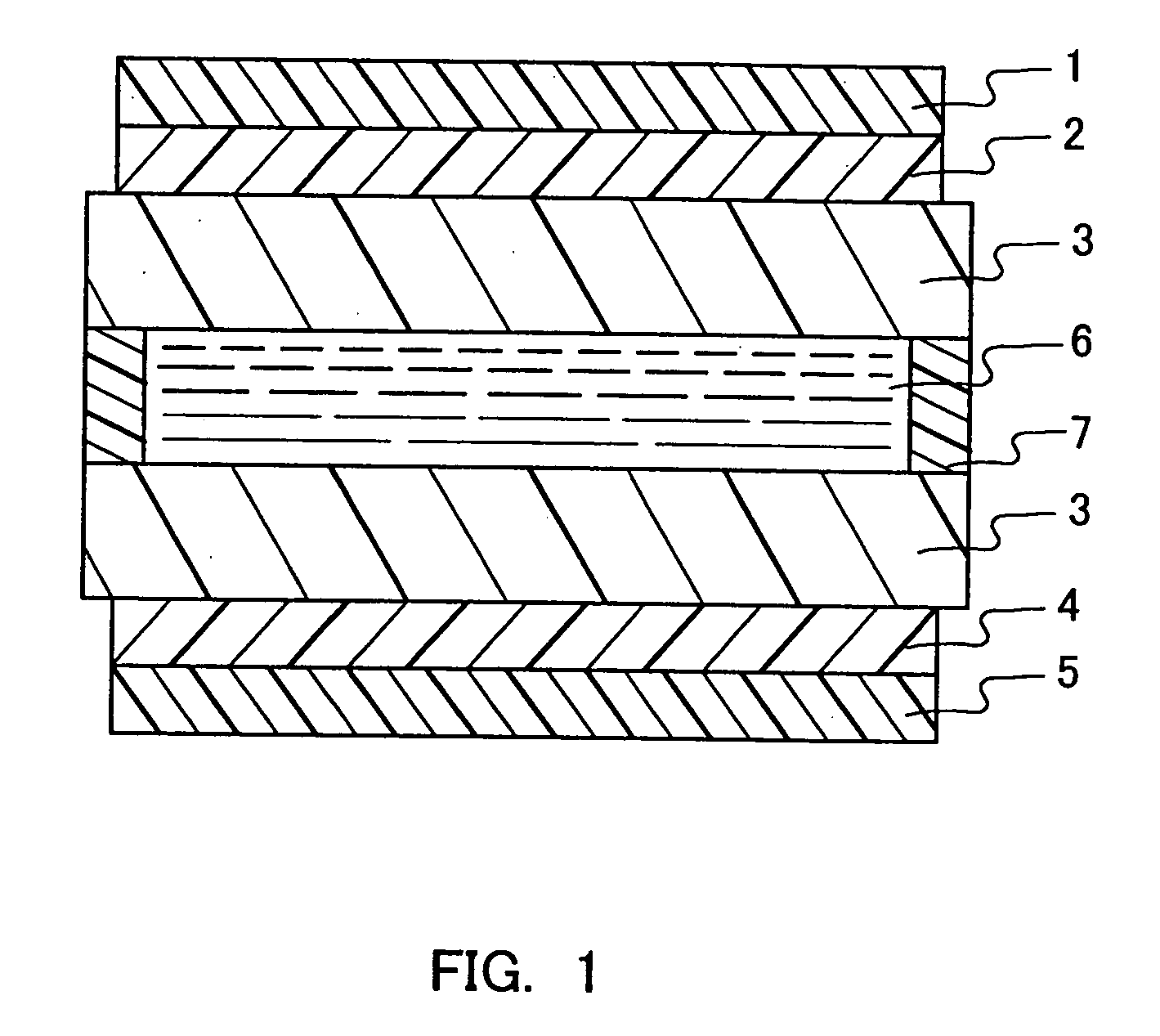

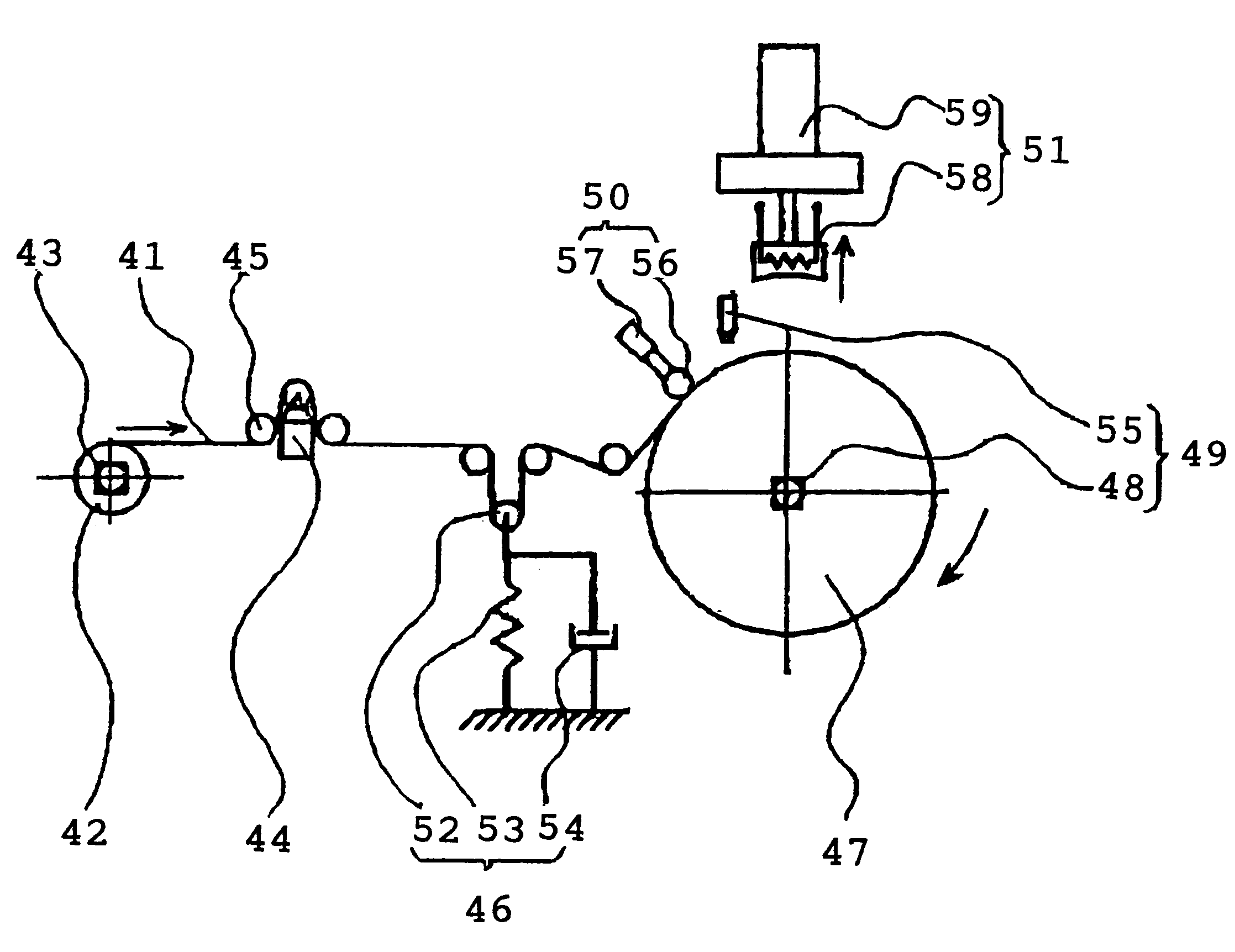

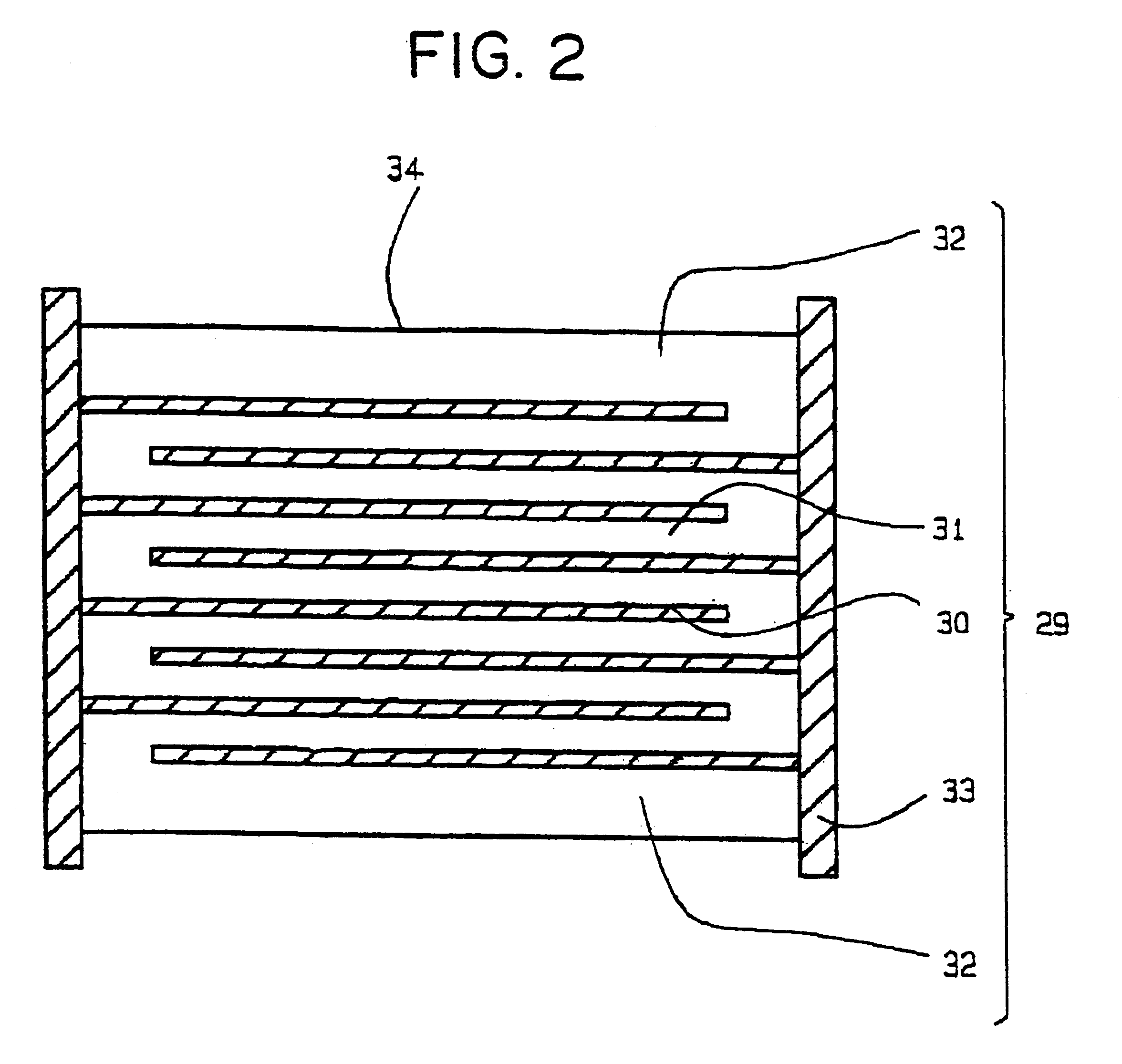

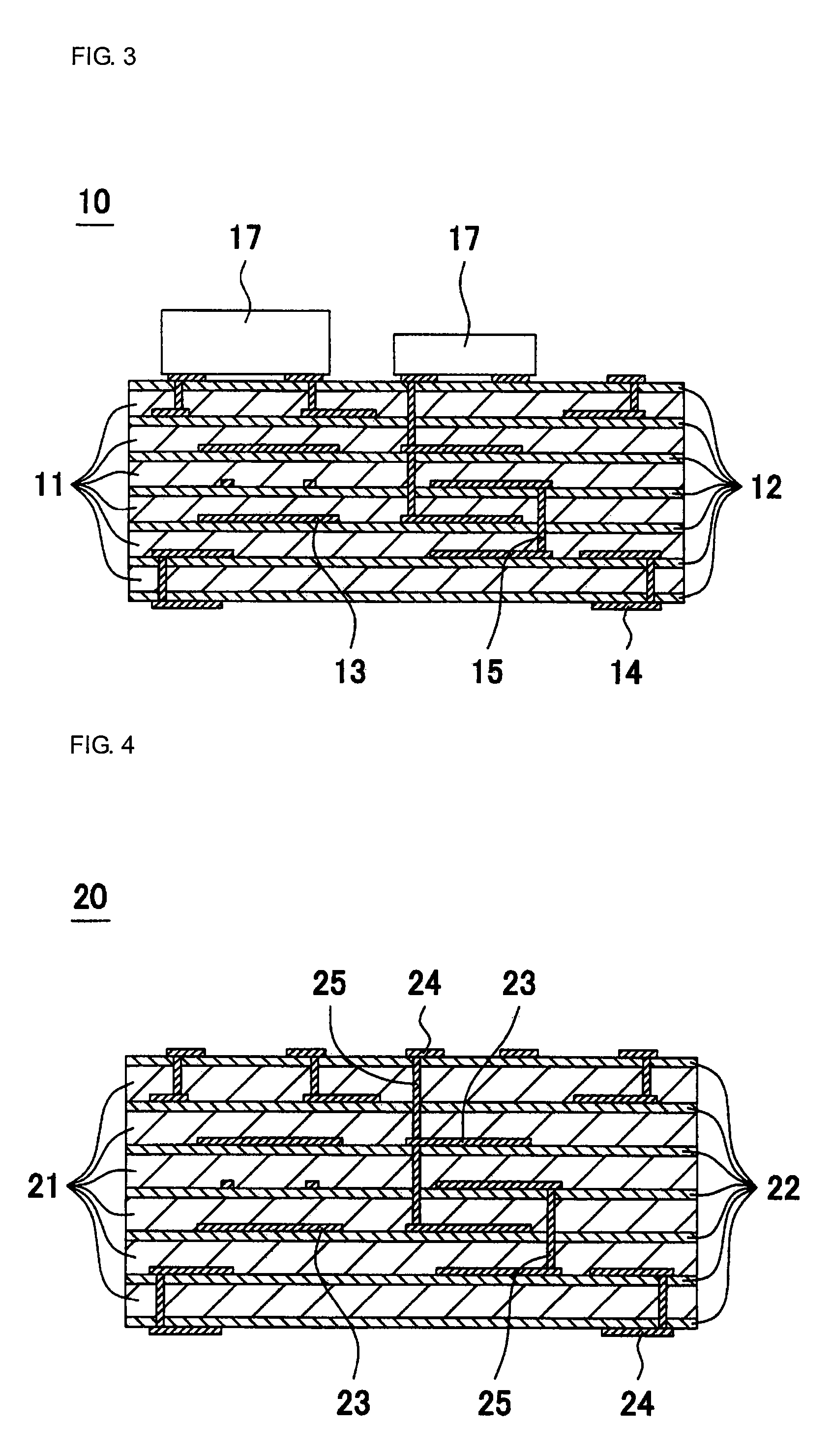

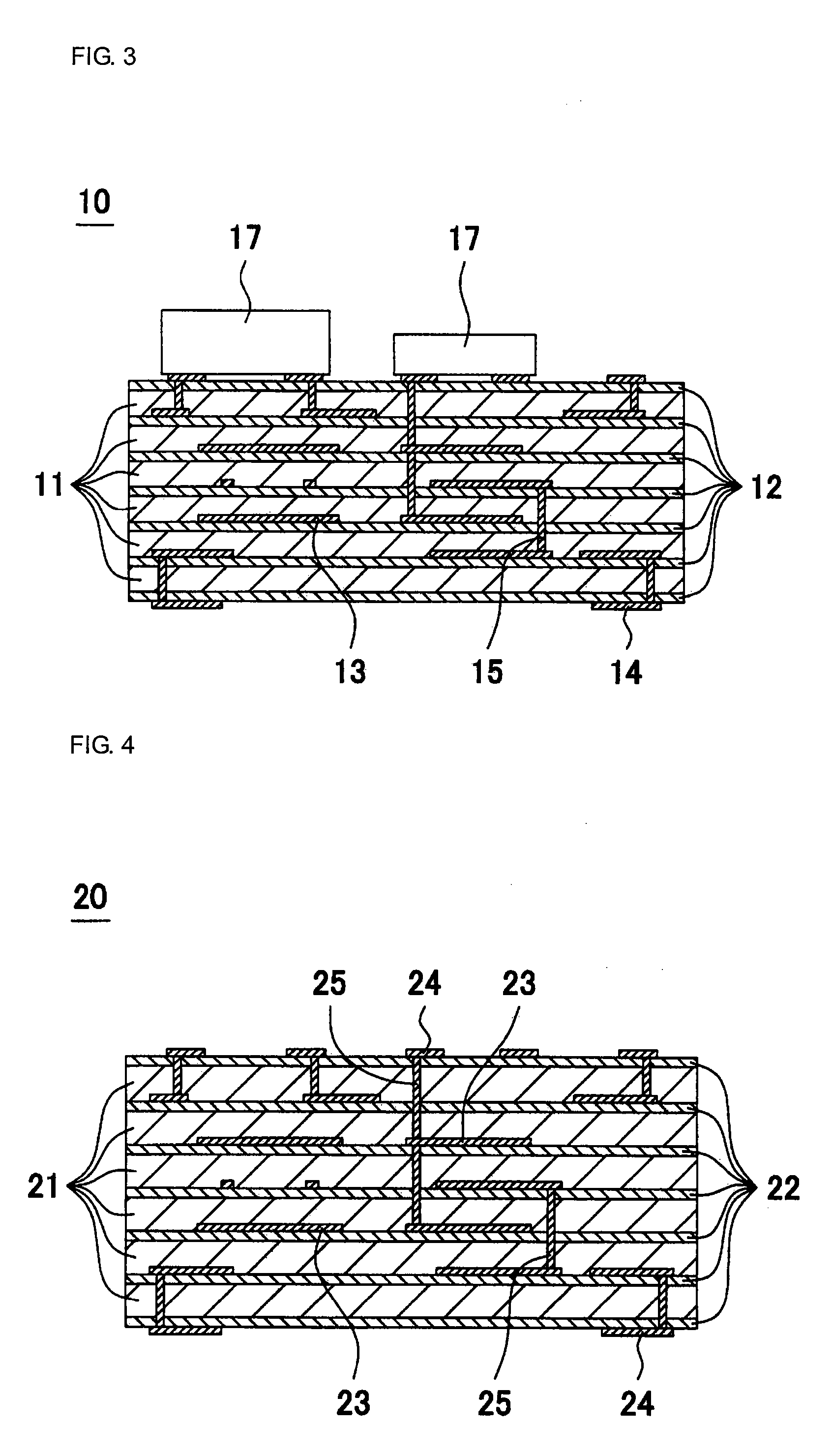

Process and apparatus for producing a laminate for electronic parts

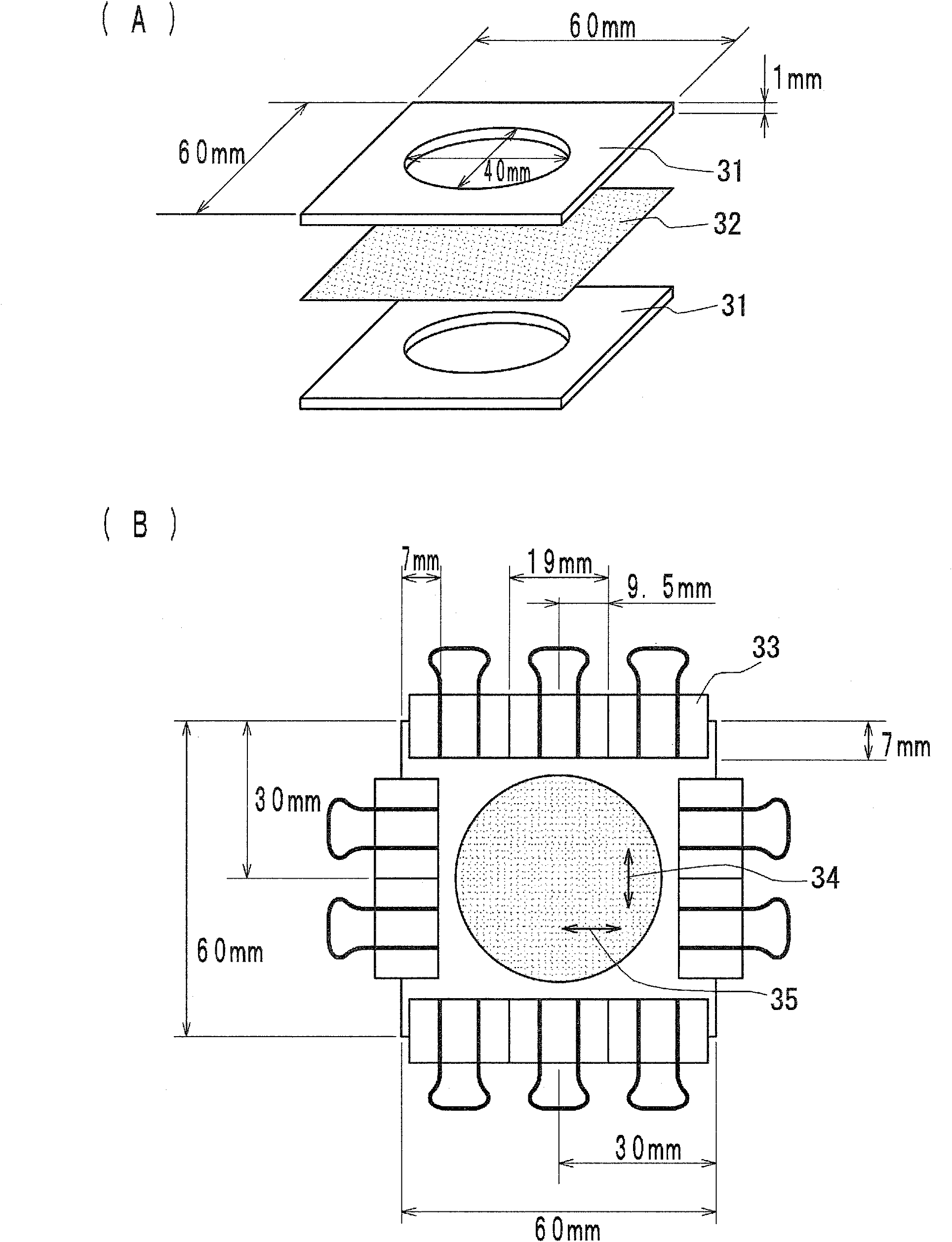

InactiveUS6428644B1Increase productionShrinkage controlMechanical working/deformationLamination ancillary operationsCeramic capacitorComposite material

An apparatus and a process for producing a laminate for electronic parts such as ceramic capacitors. After a predetermined pattern for forming an internal conductive layer is formed on a self-supporting green sheet which contains inorganic powder and an organic binder, the self-supporting green sheet is taken up by a columnar roll and laminated. At this point, the position of the same pattern on the green sheet G2 of the next cycle to be laminated adjacently onto the green sheet G1 of the previous cycle as the above pattern with respect to the predetermined pattern on the green sheet G1 taken up by the columnar roll is determined.

Owner:TEIJIN LTD

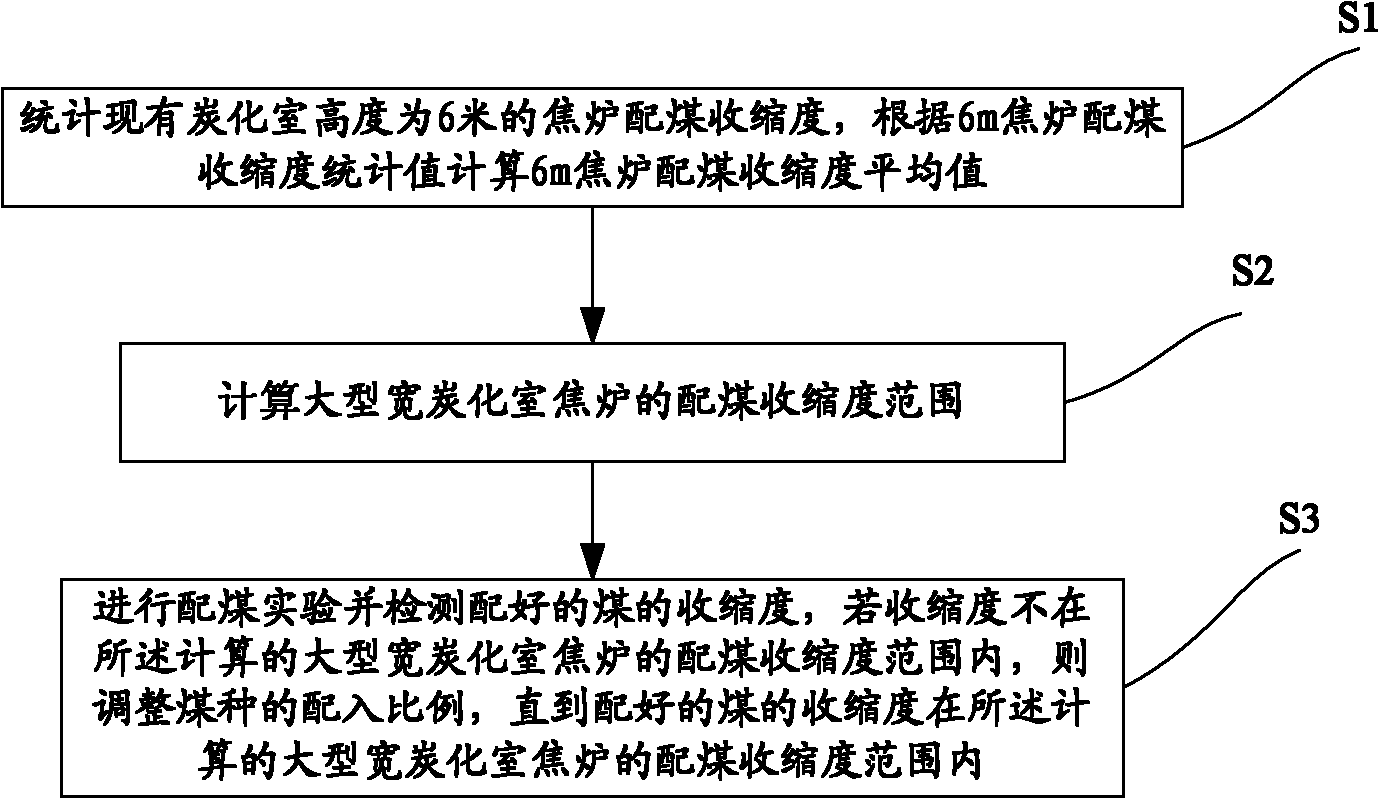

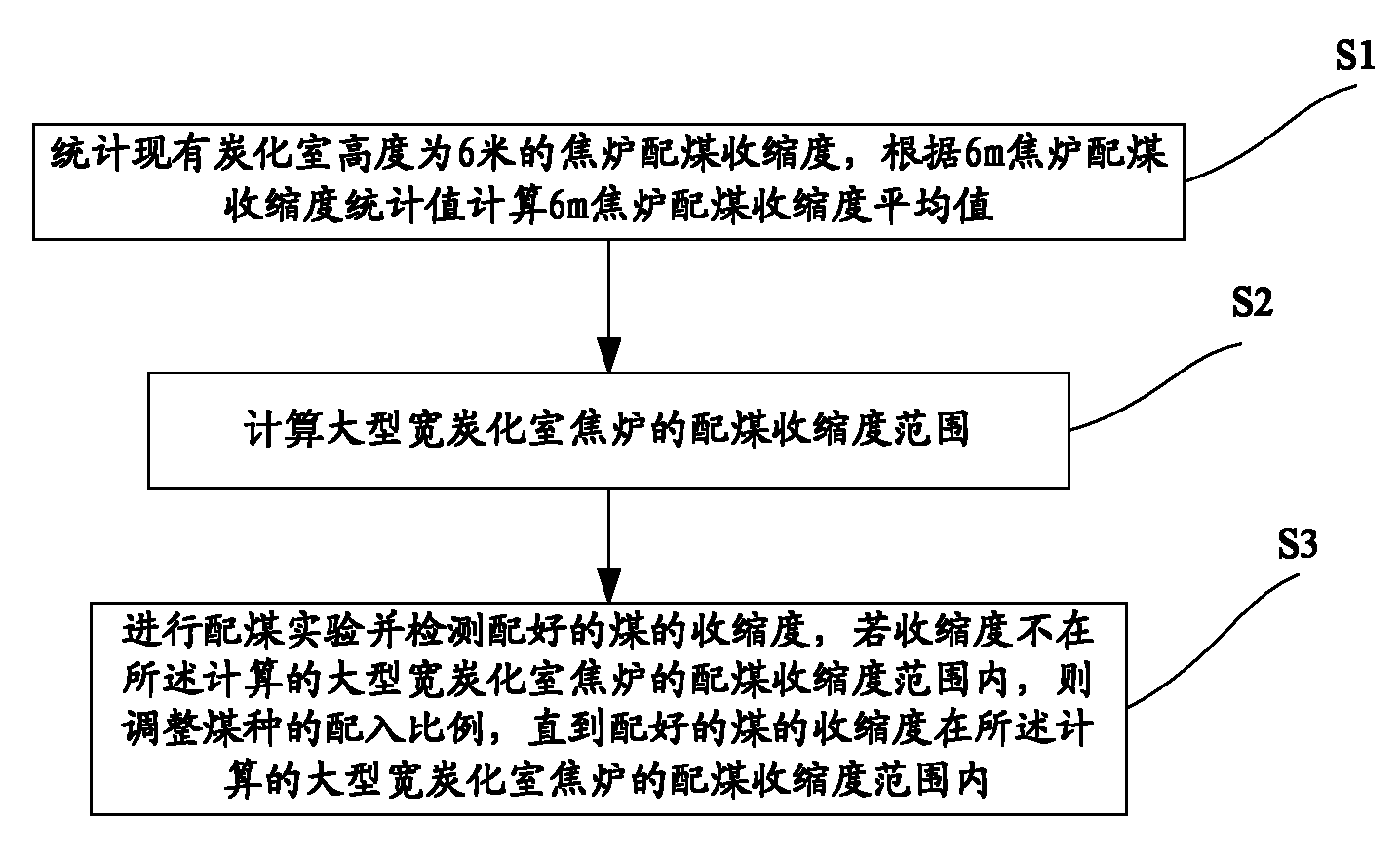

Coal blending method for controlling degree of shrinkage of coal as fired in large coke oven with wide coking chamber

InactiveCN102010735AQuality improvementImprove metallurgical coke rateCoke ovensCoke ovenCoal blending

The invention discloses a coal blending method for controlling degree of shrinkage of coal as fired in a large coke oven with a wide coking chamber, comprising the following steps: making statistics on the degree of shrinkage of the blended coal in the existing coke ovens with 6m-high coking chambers and computing the average value of the degree of shrinkage of the blended coal in the 6m coke ovens according to the statistic of the degree of shrinkage of the blended coal in the 6m coke ovens; computing the range of the degree of shrinkage of the blended coal in the large coke oven with the wide coking chamber; and correspondingly increasing the blending proportion of the coking coal with high degree of shrinkage for blending coal according to the computed range of the degree of shrinkage of the blended coal in the large coke oven with the wide coking chamber, measuring the degree of shrinkage of the obtained blended coal, if the degree of shrinkage is within the control range, determining the coal blending scheme to blend coal for coking, if the degree of shrinkage is not in the control range, correspondingly increasing or decreasing the blending proportion of the coking coal withhigh degree of shrinkage, blending coal and detecting the degree of shrinkage until the measured value of the degree of shrinkage of the blended coal in the obtained coal blending scheme is within the control range, thus obtaining the coal blending scheme for the large coke oven with the wide coking chamber. The method can ensure the blended coal to have reasonable degree of shrinkage in the large wide coking chamber and the coking process, thus improving the quality of the coke.

Owner:武汉钢铁有限公司

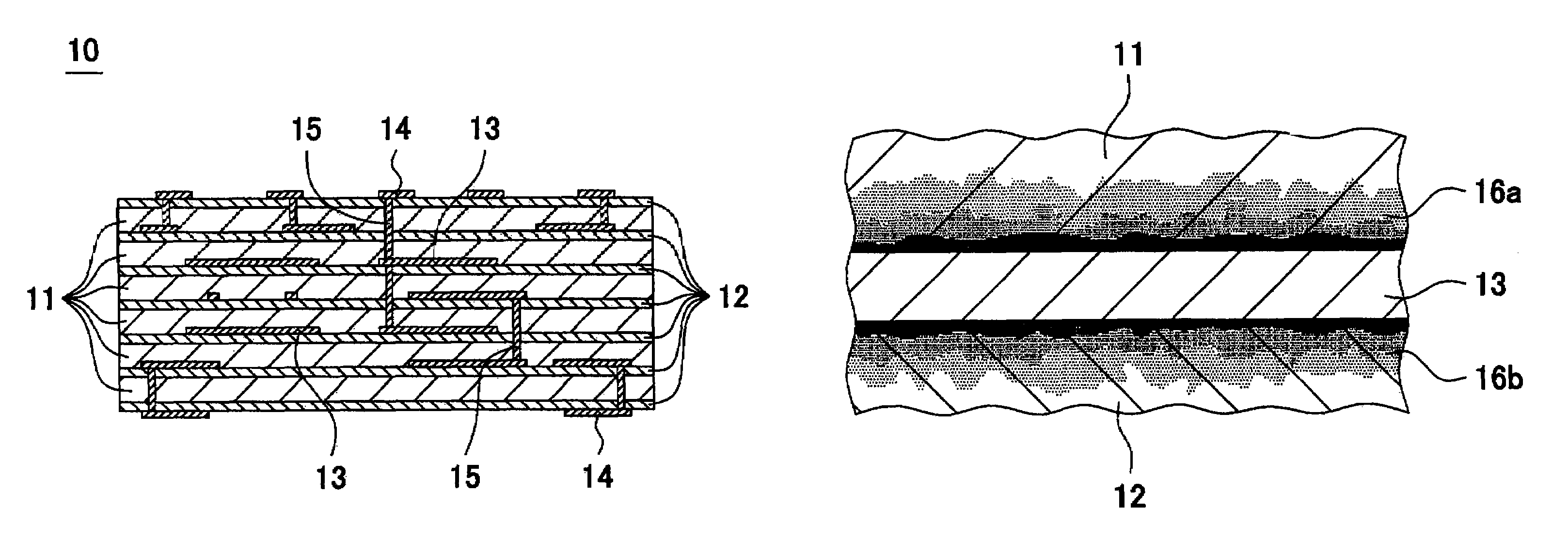

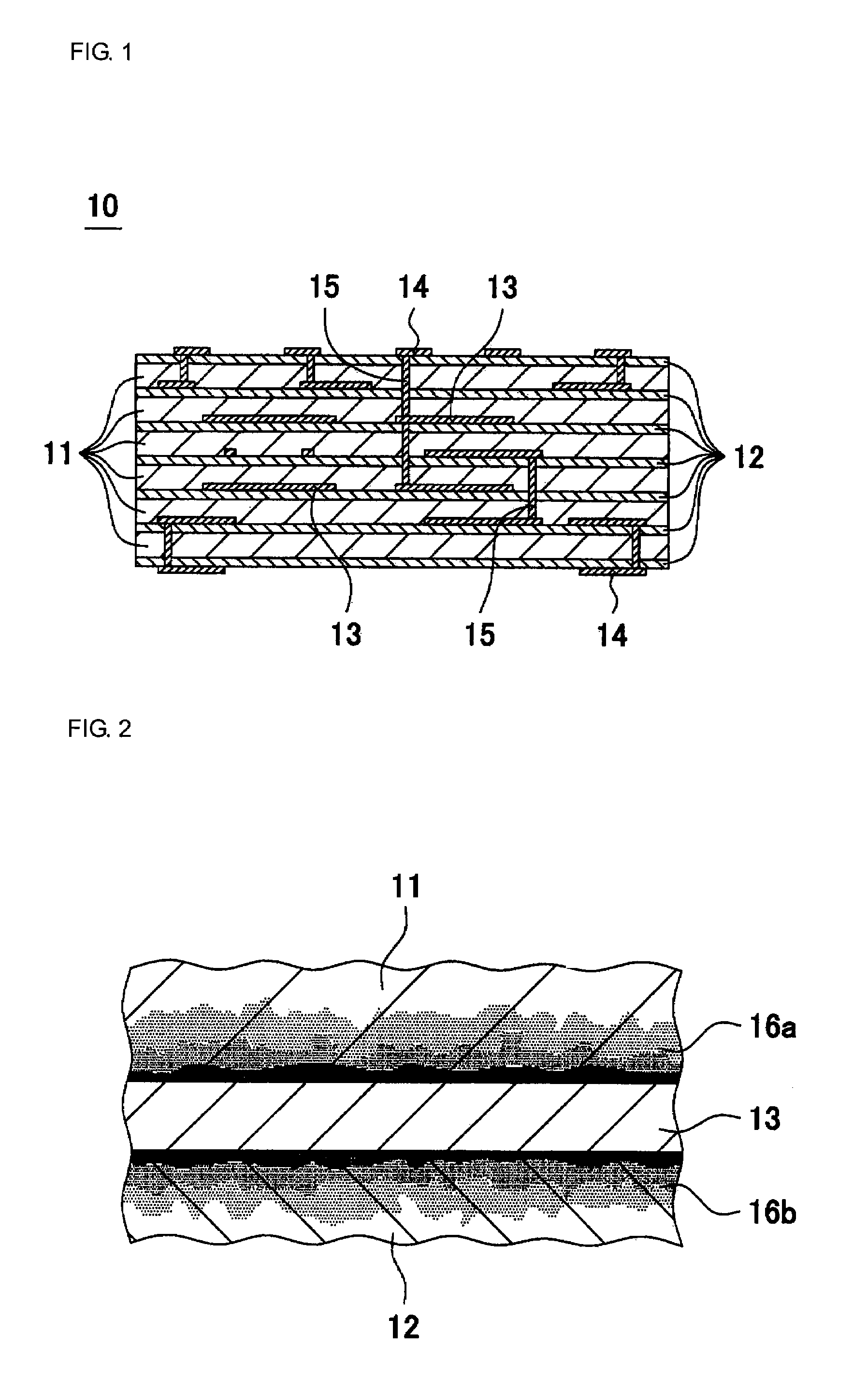

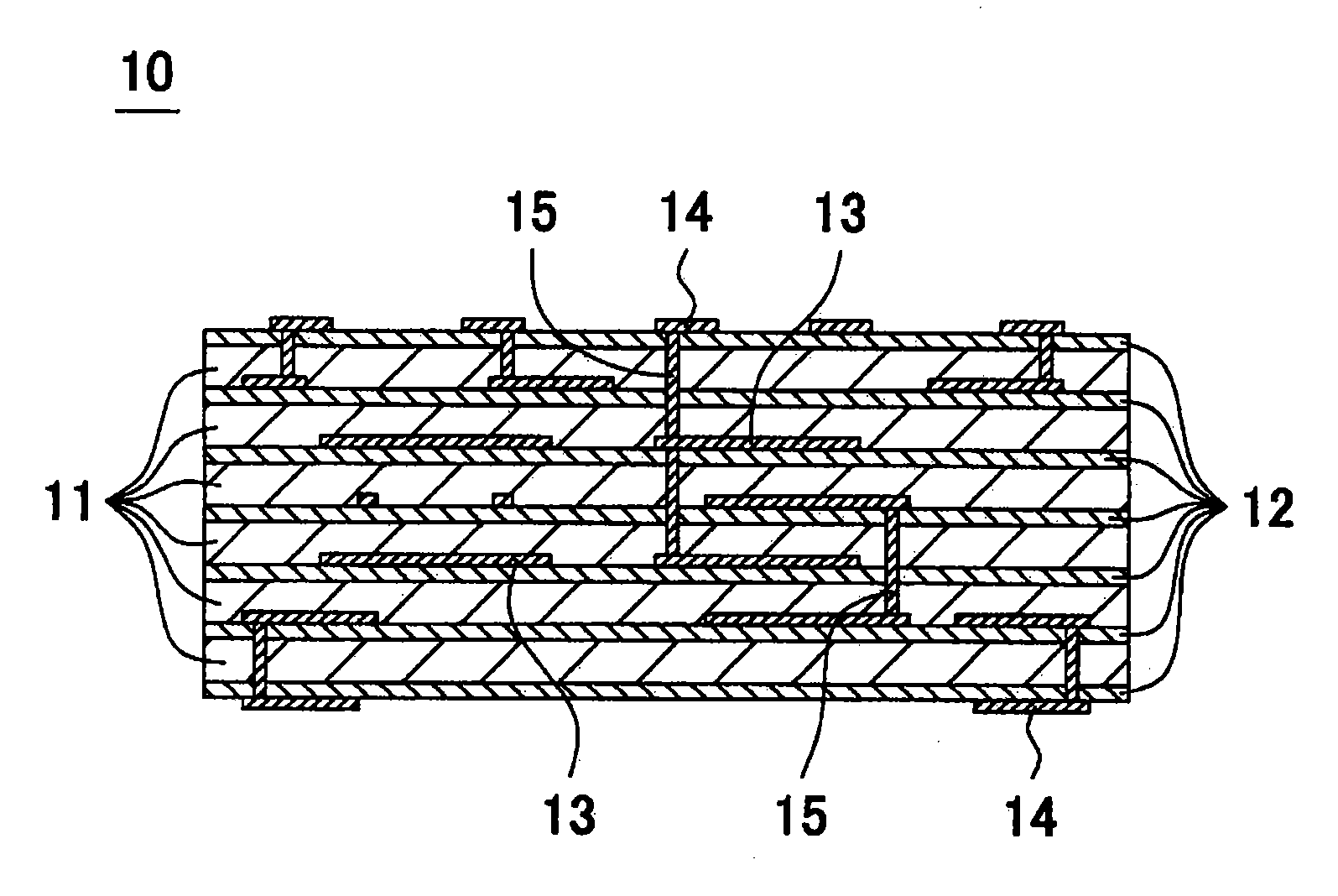

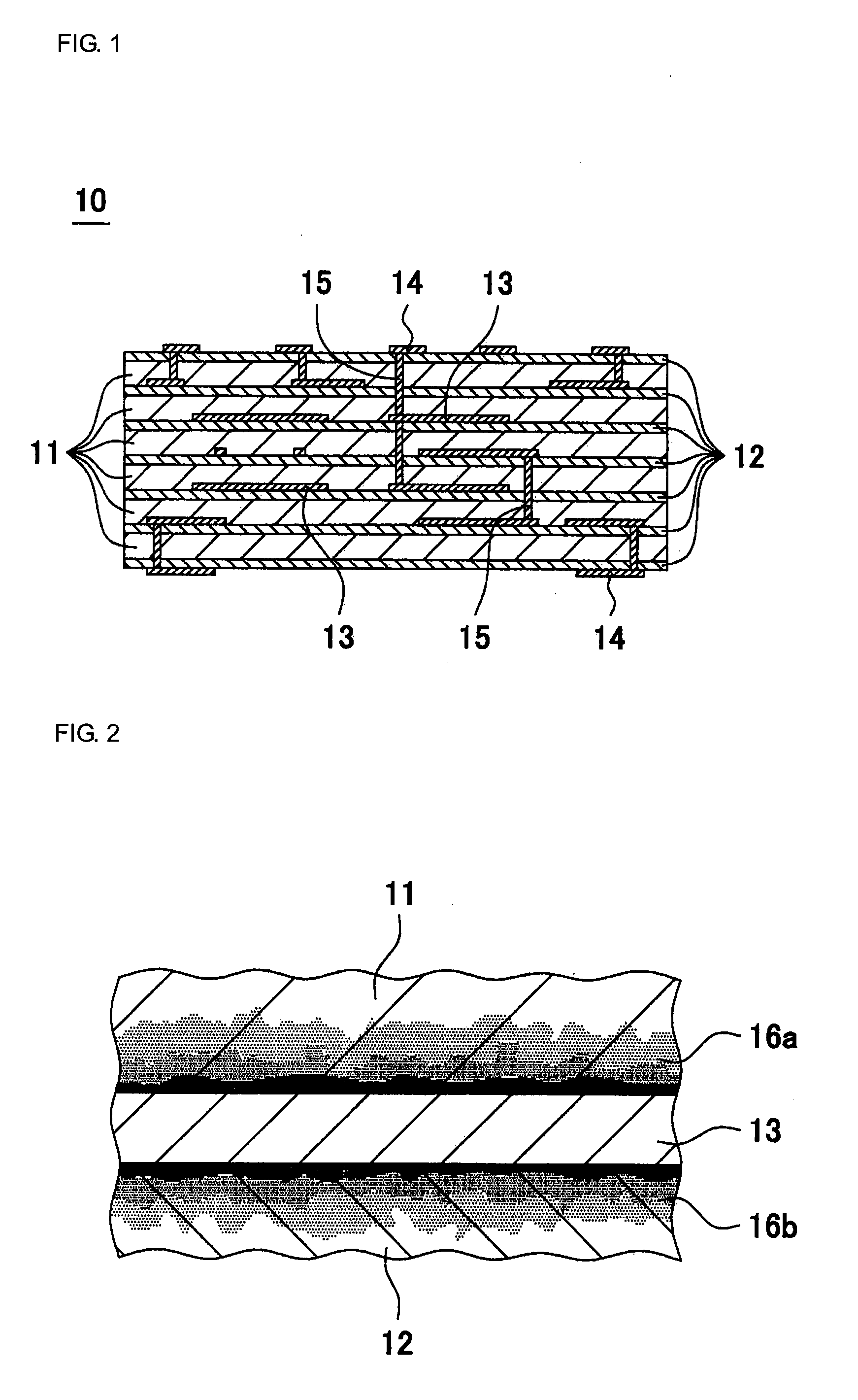

Ceramic multilayer substrate and method for manufacturing the same

ActiveUS7691469B2Reduce flakingShrinkage controlInsulating substrate metal adhesion improvementSemiconductor/solid-state device detailsElectrical conductorConcentration gradient

A ceramic multilayer substrate exhibiting reduced pealing and breakage of an internal conductor disposed between a ceramic layer serving as a base member and a ceramic layer for restricting shrinkage includes a first ceramic layer 11, a second ceramic layer 12 laminated so as to come into contact with a principal surface of the first ceramic layer 11, and an internal conductor 13 disposed between the first ceramic layer 11 and the second ceramic layer 12, a phosphorus component layer 16a is disposed in the first ceramic layer 11 with a concentration gradient in which the concentration decreases in a direction away from the internal conductor 13.

Owner:MURATA MFG CO LTD

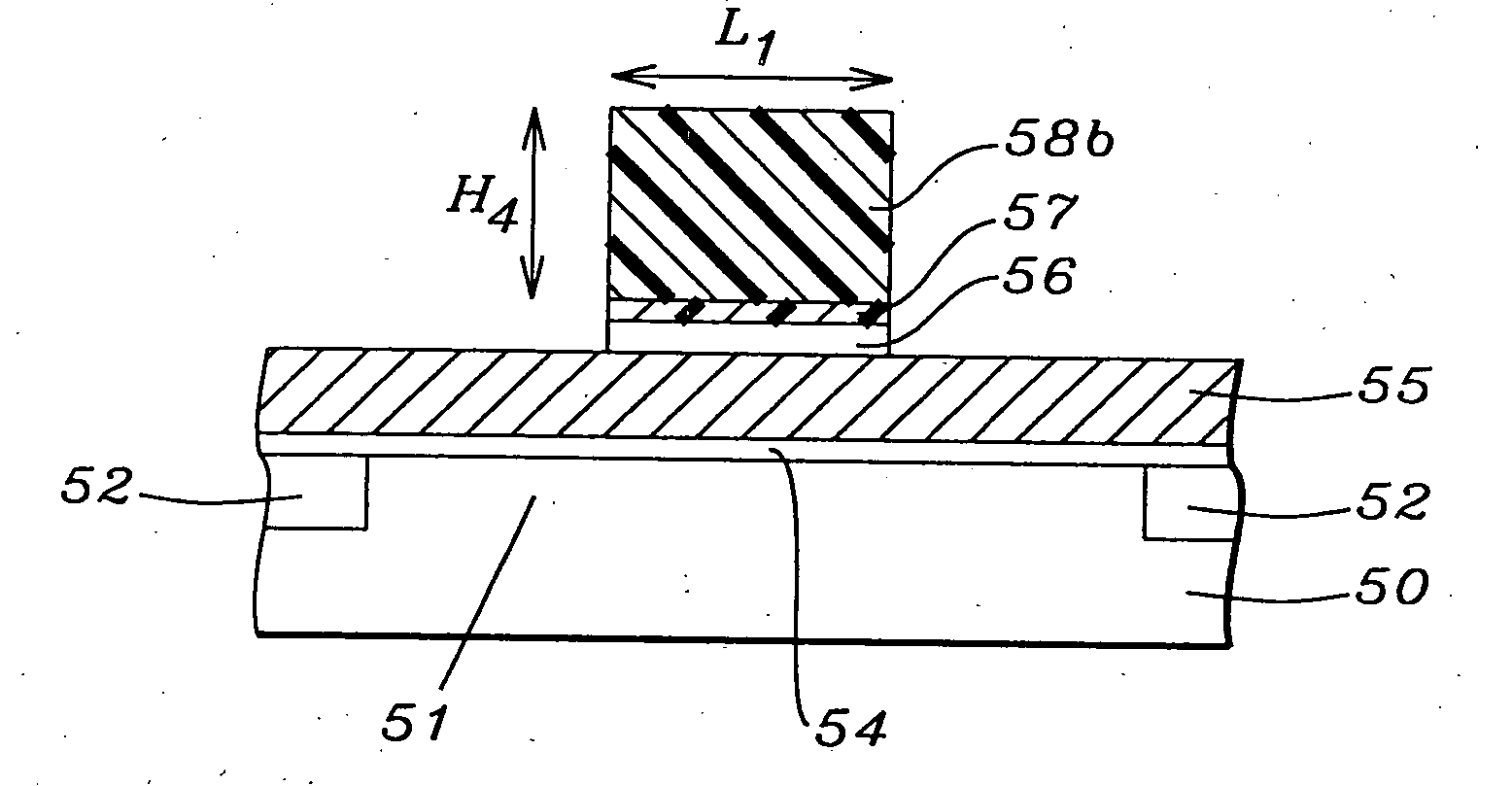

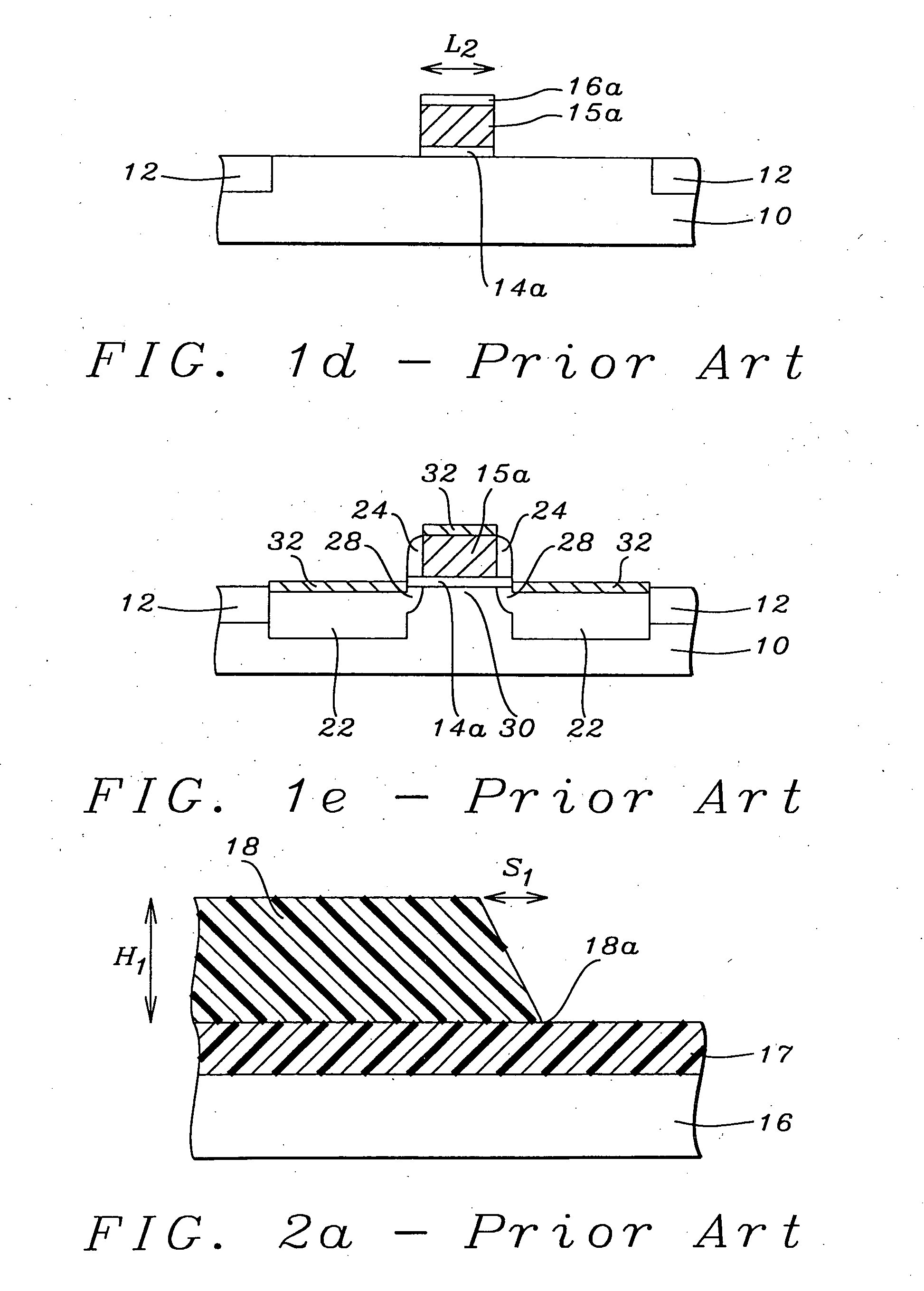

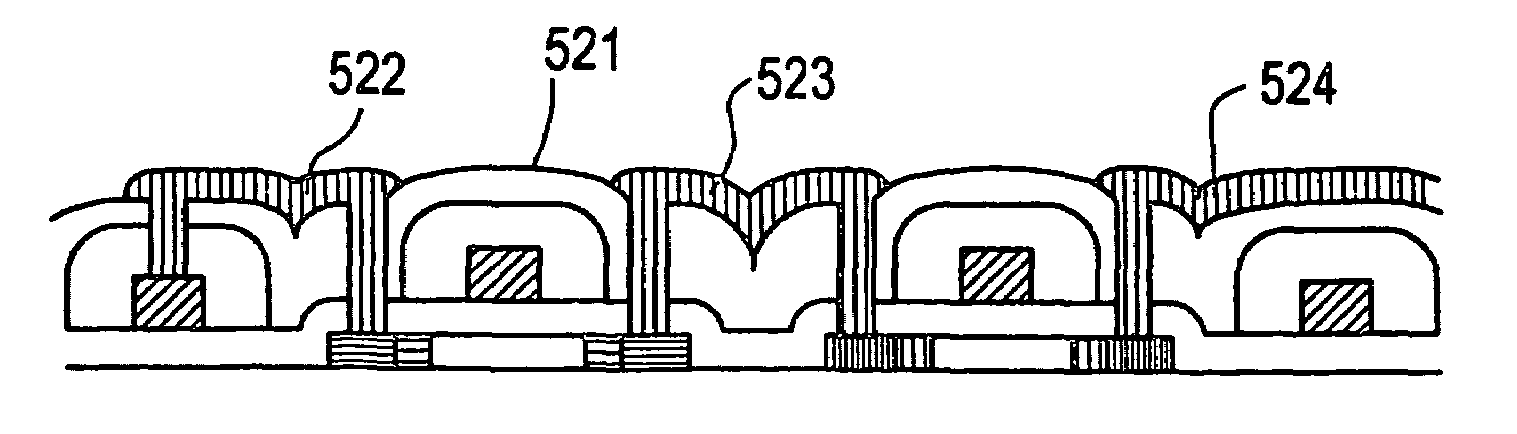

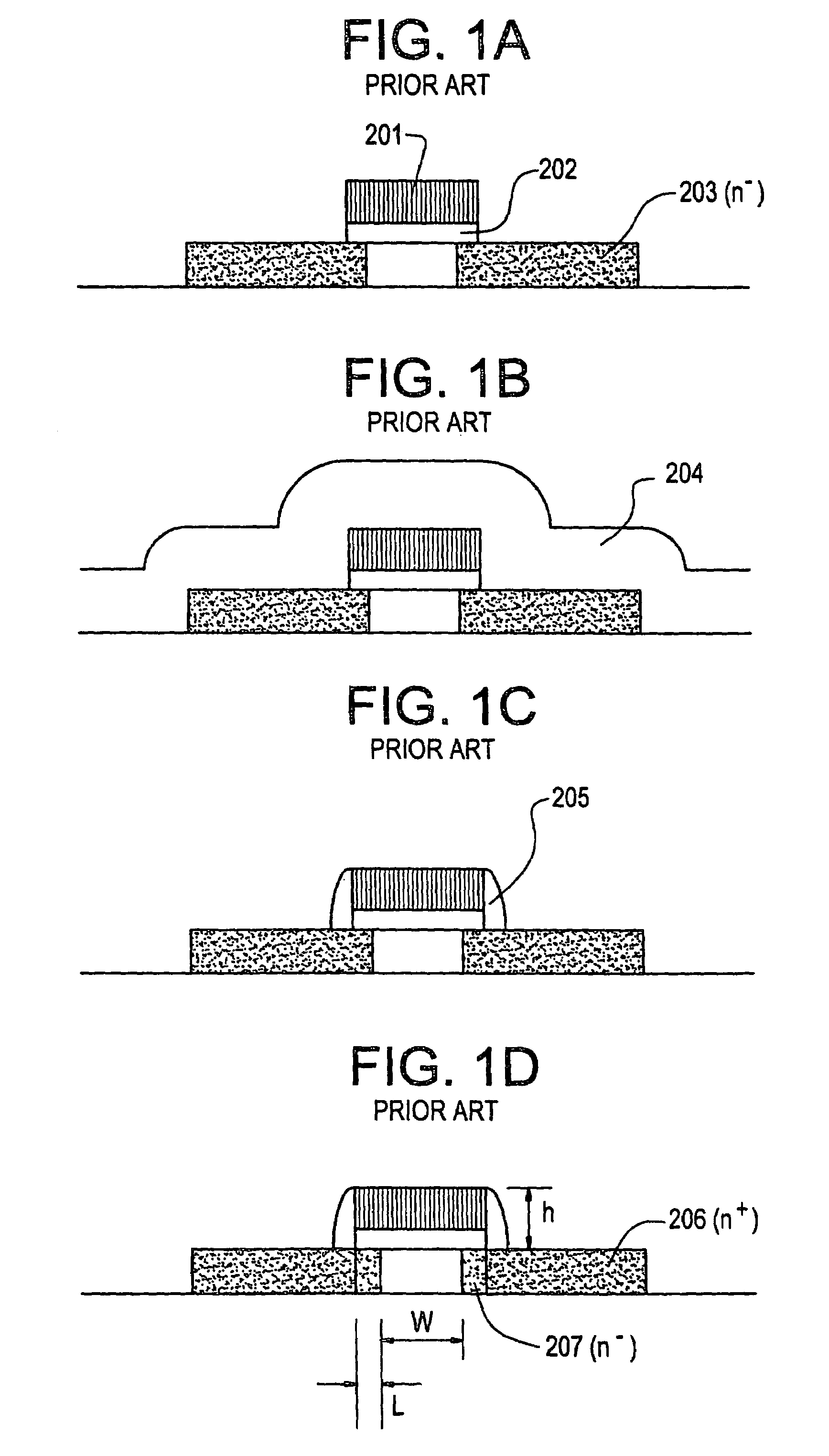

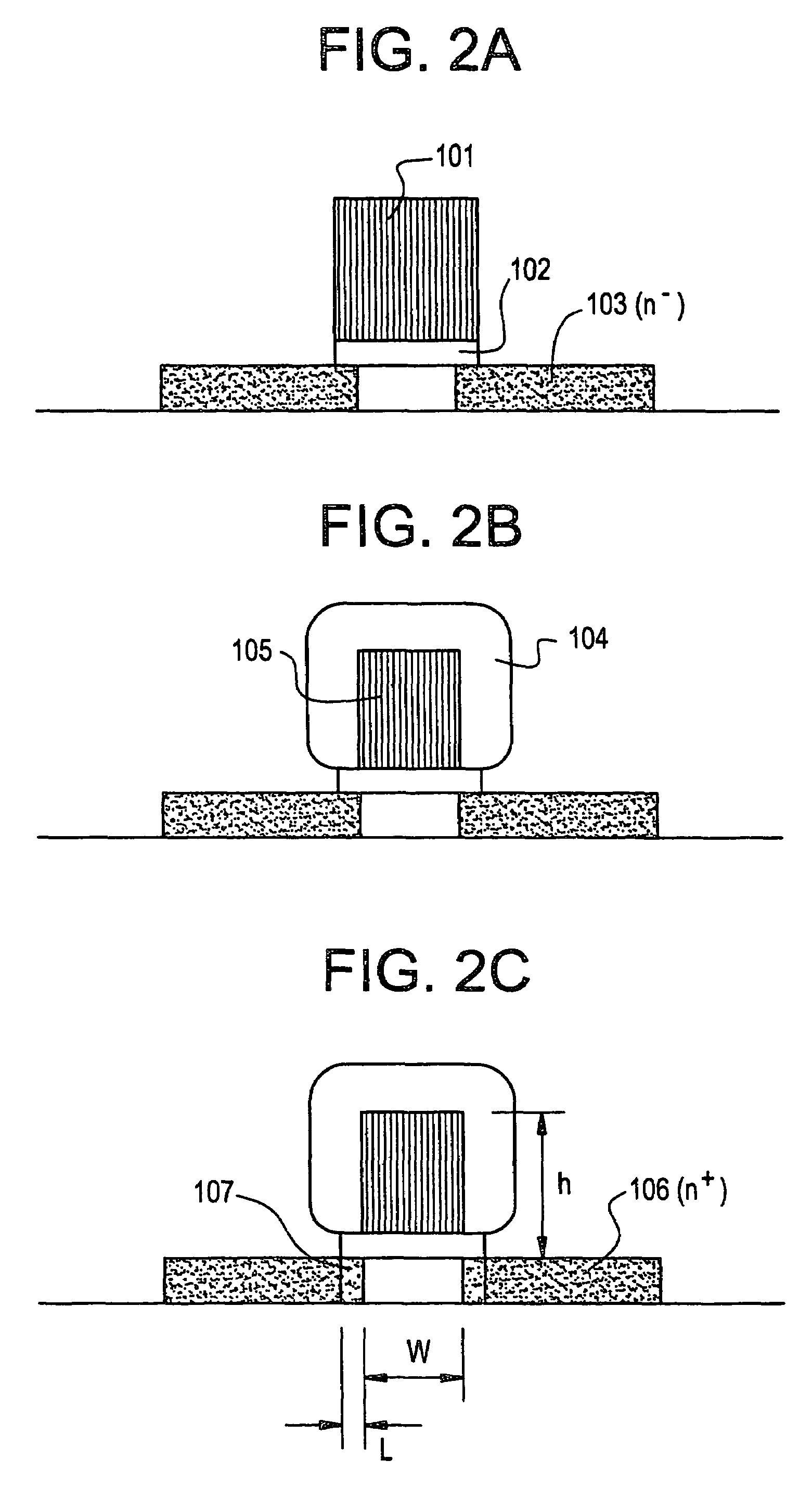

Insulated gate field effect semiconductor devices and method of manufacturing the same

InactiveUS7456427B2Fast switching speedLower on-resistanceTransistorSolid-state devicesField effectSemiconductor

An LDD structure is manufactured to have a desired aspect ratio of the height to the width of a gate electrode. The gate electrode is first deposited on a semiconductor substrate followed by ion implantation with the gate electrode as a mask to form a pair of impurity regions. The gate electrode is then anodic oxidized to form an oxide film enclosing the electrode. With the oxide film as a mask, highly doped regions are formed by ion implantation in order to define lightly doped regions between the highly doped regions and the channel region located therebetween.

Owner:SEMICON ENERGY LAB CO LTD

Laminated porous film, separator for lithium cell, and cell

ActiveCN102209632AKeep BD characteristicsExcellent acupuncture strengthLamination ancillary operationsSynthetic resin layered productsLithiumPolypropylene

Owner:MITSUBISHI CHEM CORP

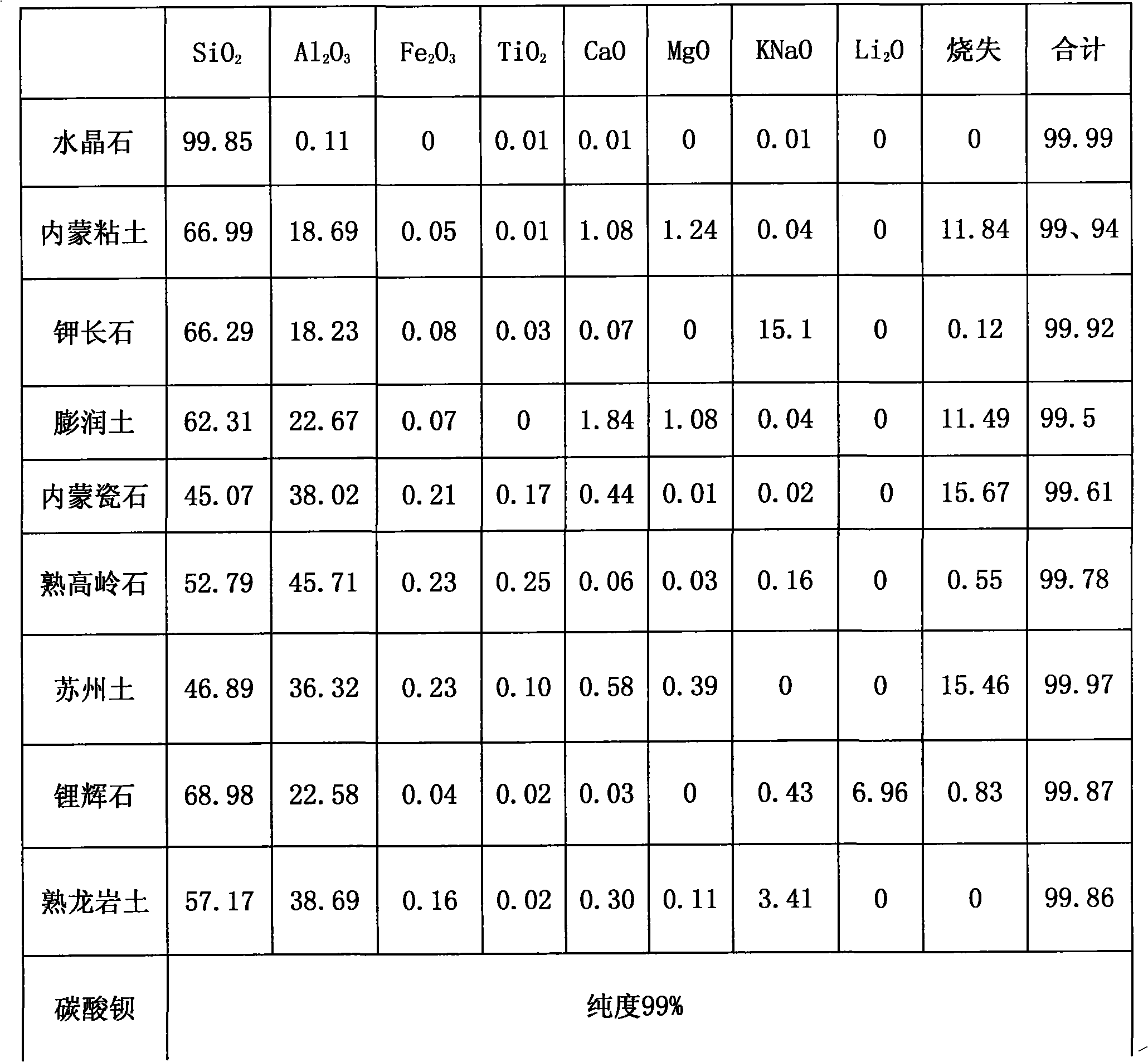

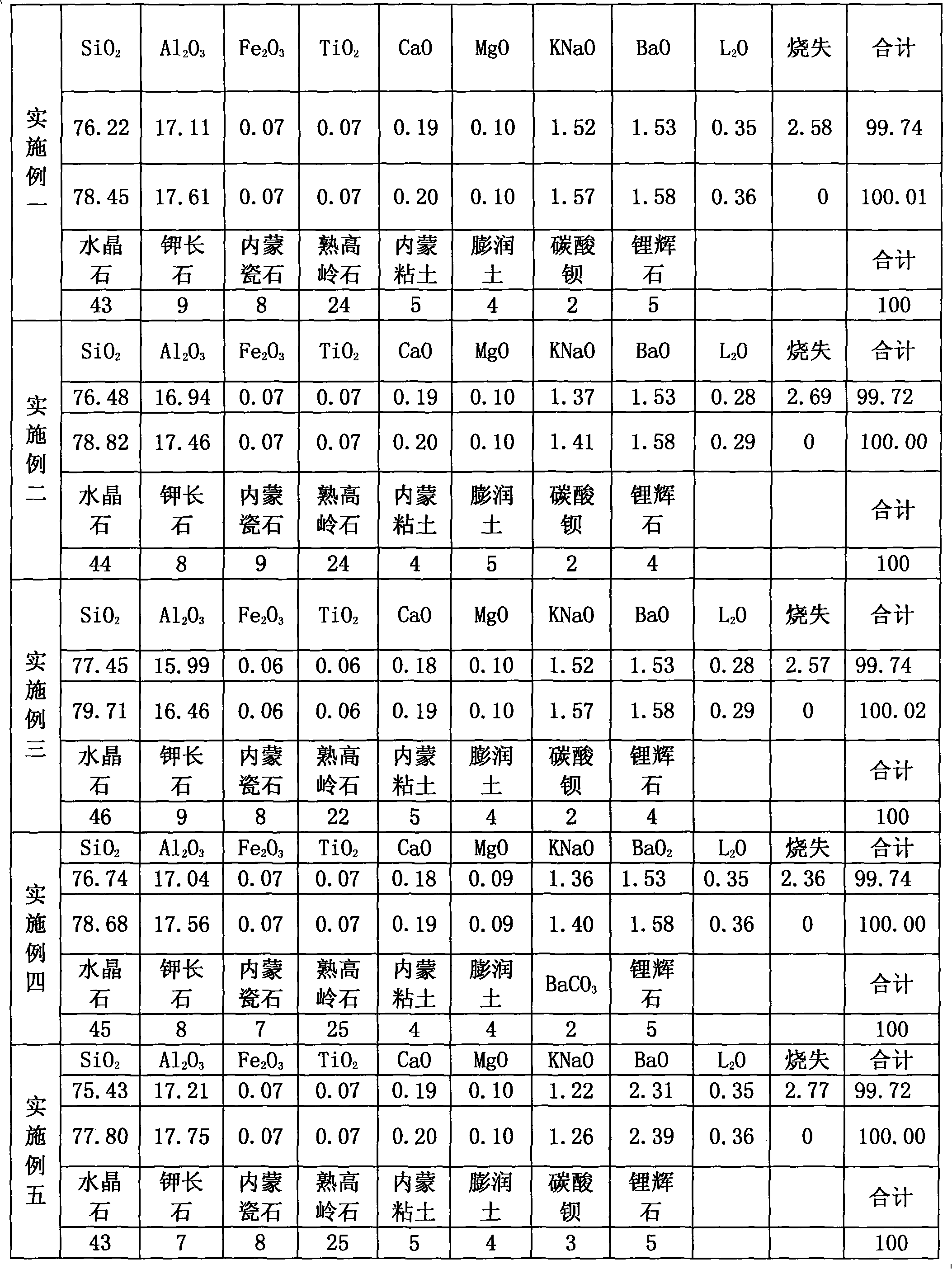

Crystal ceramic and preparation method thereof

The invention relates to a crystal ceramic which is a new product of ceramic products, or a new ceramic type. Glaze is coated on a green body which is prepared from the following components by weightpercent: 75-82 percent of SiO2, 15-21 percent of Al2O3, 0-0.1 percent of Fe2O3, 0-0.1 percent of TiO2, 0-0.5 percent of CaO, 0-0.9 percent of MgO, 0.5-2.6 percent of KNaO, 0.1-0.8 percent of Li2O and0.1-0.5 percent of BaO. The invention has the characteristics of wide range of firing temperature, easy firing control, high whiteness, favorable translucency, high mechanical strength and favorable thermal stability. The invention also provides a preparation method comprising the steps of preparing materials, dosing, molding, biscuiting, enamelling and glaze firing, wherein the crystal needs to be preprocessed, and the preprocessing comprises the steps of calcining at 1250-1300 DEG C, washing with acid, washing with water to neutrality and separately grinding and controlling the grain diameter ranges from 5 to 20 microns. The invention is scientific and reliable, is easy to implement and ensures the quality and qualification rate of products.

Owner:淄博泰山瓷业有限公司

Salt core of engine piston

ActiveCN1994615BHigh strengthFast water solubilityFoundry mouldsMould handling/dressing devicesEngineeringWater soluble

The invention relates to a plug salt corn of engine and relative production, wherein it is formed by 70-80% soluble metal salt and 20-30% findings; the salt grainness can reach 60-120 deals; the finding grainness should at least reach 200 deals. And the production comprises that: first breaking metal salt and findings into needed grainness, mixing them, putting some into powder compressing mould to obtain the blank; then putting blank into furnace to be baked; then processing the positioning hole. The inventive salt corn has high strength, while it can be washed by water.

Owner:DONGFENG MOTOR CORP HUBEI

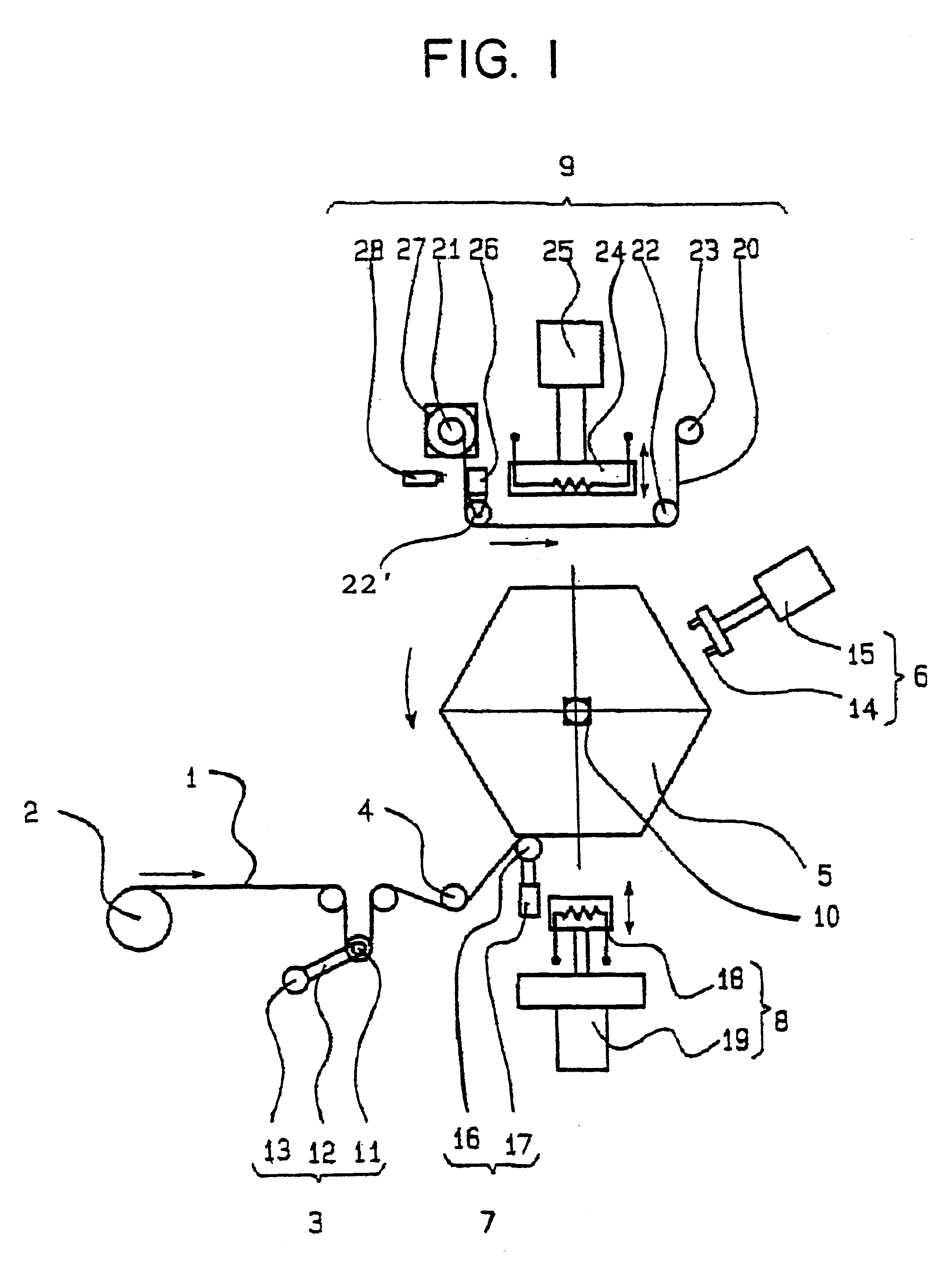

Production process of tubular seersucker shell fabric

InactiveCN103397494AEliminate internal stressShrinkage controlFibre treatmentDry-cleaning apparatus for textilesSizingYarn

The invention discloses a production process of a tubular seersucker shell fabric. The technical process is as follows: yarn spinning, dyeing, warping, slashing, weaving and post-treatment. The post-treatment comprises the steps: singeing, loose type washing, loose type sizing and pre-shrinking. According to the production process, in a loose type drying process, the shell fabric is subjected to resin finishing; one-step loose type finishing is carried out on the shell fabric by a low-temperature resin finishing solution so that the inner stress of the shell fabric is eliminated, the aim of controlling the shrinkage rate is realized, and the textile shape and the size stability are improved.

Owner:张家港市金陵纺织有限公司

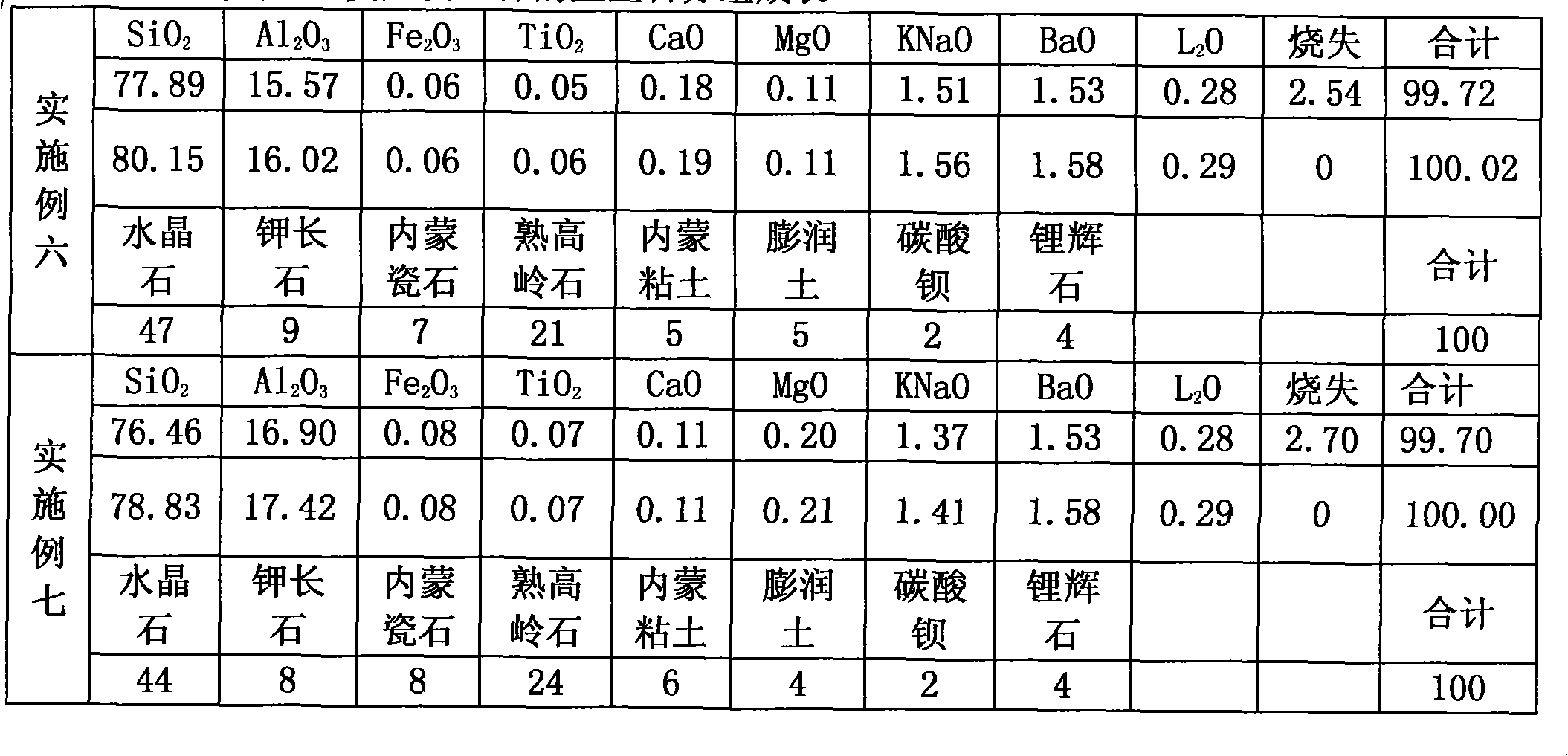

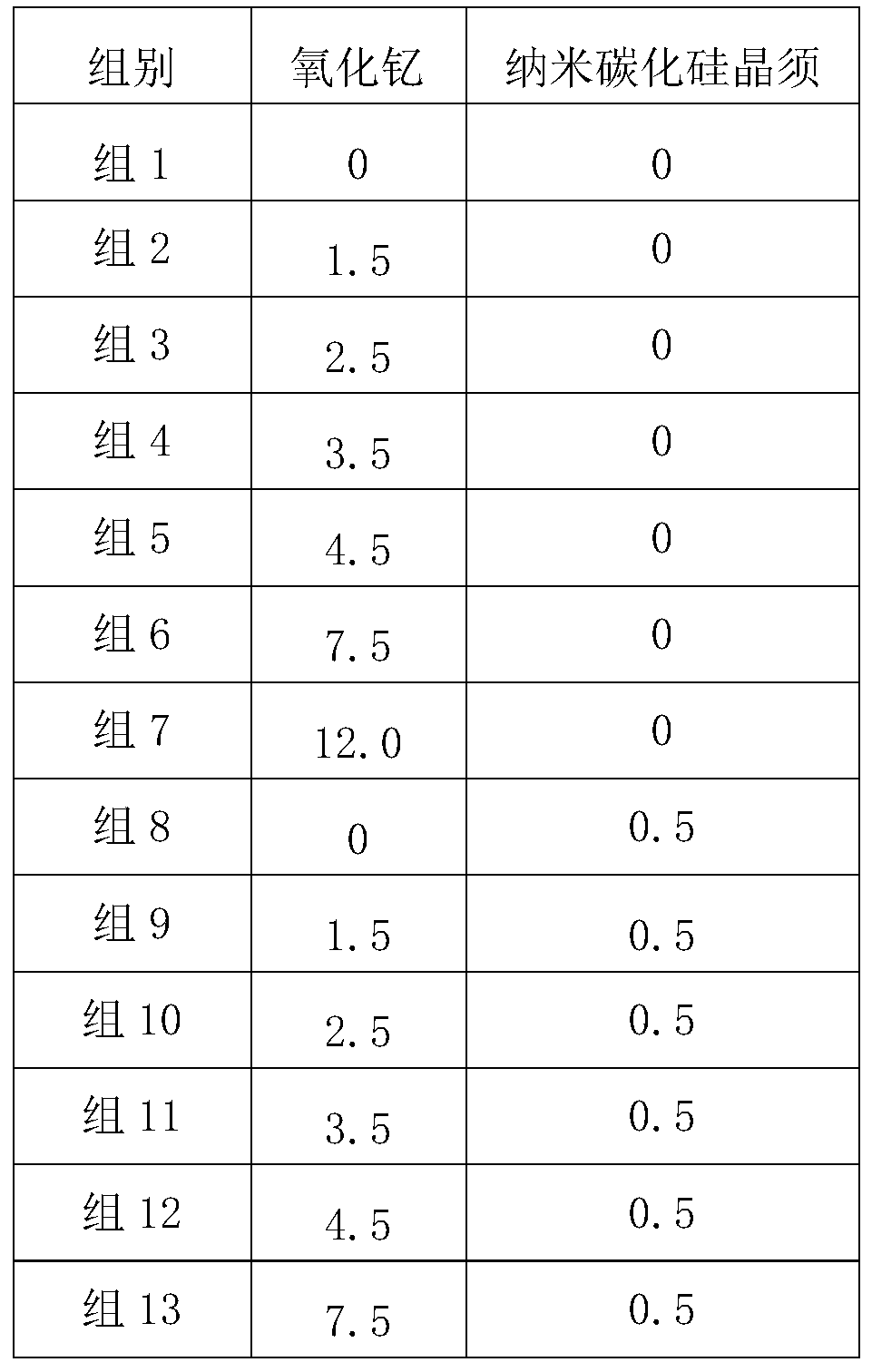

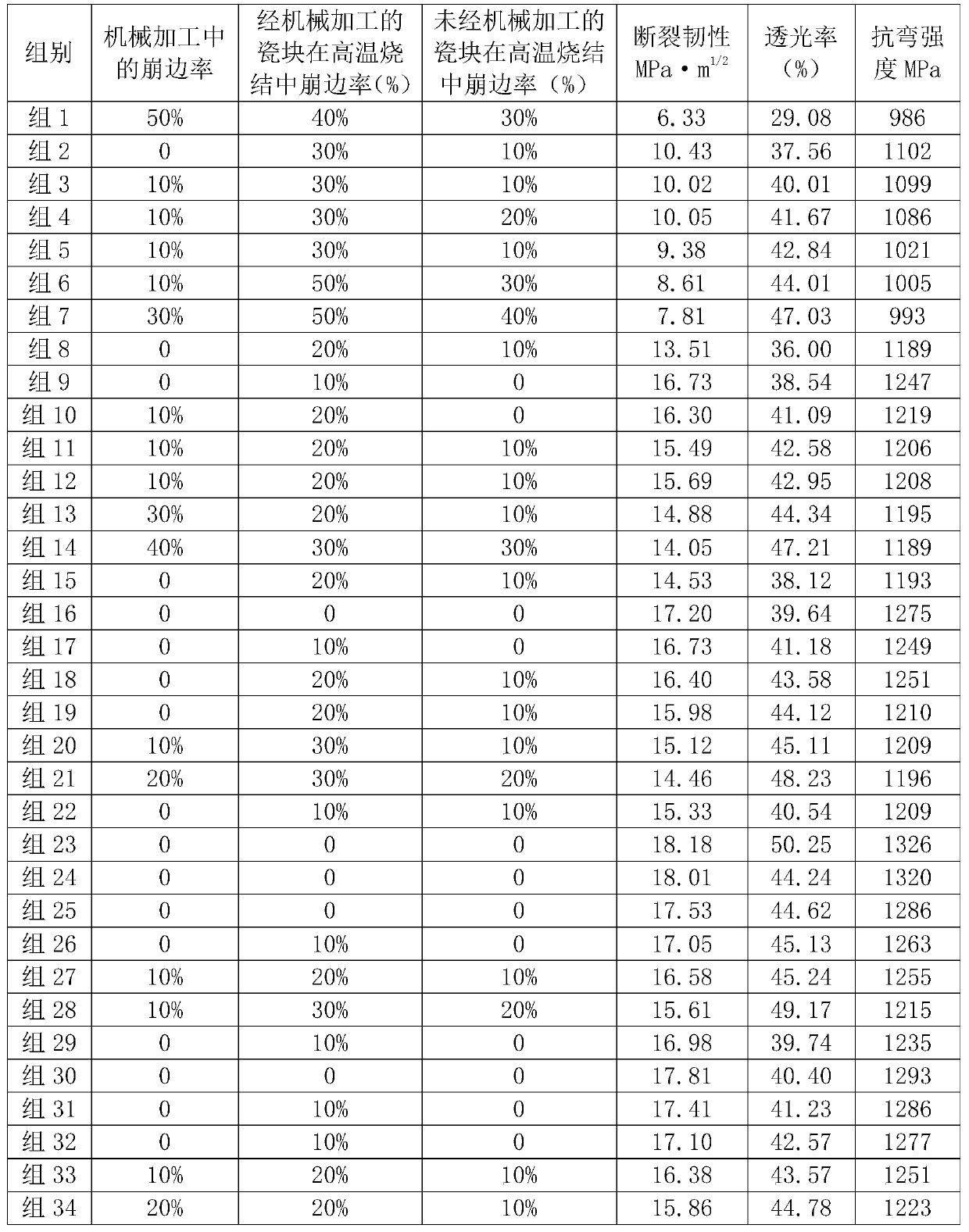

Processing technology capable of rapidly preparing multi-layer zirconia ceramic block with uniform transition

The invention belongs to the field of oral materials, in particular relates to a sintering process for rapidly preparing a zirconia ceramic block with uniform strength and color transition, and in particular relates to a high-toughness zirconia ceramic block, and the powder formula of the zirconia ceramic block comprises 1.5 to 12% of yttrium oxide, 0 to 2.5% of silicon carbide nano whiskers, 0 to1.5% of a coloring matter and the balance of zirconium oxide according to the mass fraction. Based on the ceramic block, the multilayer zirconia ceramic block with uniform transition of comprehensivemechanical properties, color and permeability is provided. At the same time, a process capable of completing the sintering of the zirconia ceramic block with high efficiency and high quality is provided. By using the process, the zirconia ceramic block with excellent comprehensive mechanical properties and uniform color and permeability transition can be obtained in as short a time as possible.

Owner:CHENGDU BESMILE BIOTECH

Apparatus and method for attaching a heat sink to an integrated circuit module

ActiveUS20050201062A1Limit flexure of the substrateShrinkage controlSemiconductor/solid-state device detailsSolid-state devicesAdhesiveEngineering

A heat sink is fastened to an annular portion of a substrate of an integrated circuit module on a printed circuit card by means of a cured layer of cure shrinkable adhesive. A circuit chip is soldered to a central portion of the substrate, around which the annular portion extends. A layer of thermally conductive material is placed between the circuit chip and a central portion of the heat sink, to be compressed as the layer of cure shrinkable adhesive is cured. A compression limiting structure may additionally extend between the heat sink and the annular portion of the substrate, limiting the shrinkage of the adhesive and thus the compression of the thermally conductive material and the flexure of the substrate.

Owner:IBM CORP

Ceramic multilayer substrate and method for manufacturing the same

ActiveUS20080156413A1Reduce flakingShrinkage controlInsulating substrate metal adhesion improvementSemiconductor/solid-state device detailsElectrical conductorConcentration gradient

A ceramic multilayer substrate exhibiting reduced pealing and breakage of an internal conductor disposed between a ceramic layer serving as a base member and a ceramic layer for restricting shrinkage includes a first ceramic layer 11, a second ceramic layer 12 laminated so as to come into contact with a principal surface of the first ceramic layer 11, and an internal conductor 13 disposed between the first ceramic layer 11 and the second ceramic layer 12, a phosphorus component layer 16a is disposed in the first ceramic layer 11 with a concentration gradient in which the concentration decreases in a direction away from the internal conductor 13.

Owner:MURATA MFG CO LTD

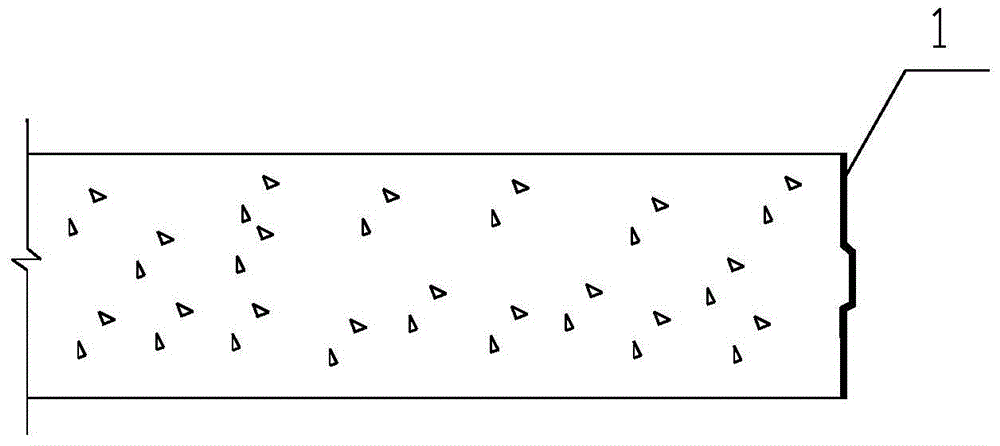

Packaging glue film without flanging and with good bonding

ActiveCN106684186AGood lookingSolve the problem of easy overflow (flange)Photovoltaic energy generationSemiconductor devicesPolymer sciencePolymer substrate

The invention relates to a packaging glue film without flanging and with good bonding. The packaging glue film comprises a first transparent layer, an intermediate non-transparent layer and a second transparent layer which are successively arranged. The first transparent layer, the intermediate non-transparent layer and the second transparent layer are mutually independent EVA, POE or POE and LDPE mixing polymer base materials. The polymer base material of the intermediate non-transparent layer contains inorganic pigment powder. Through using the first transparent layer, the intermediate non-transparent layer and the second transparent layer of specific components, a problem that the packaging glue film is easy to overflow (flange) can be solved; and a purpose of controlling a shrinking percentage can be achieved, a laminated assembly appearance is good and finally generation power is increased.

Owner:CYBRID TECHNOLOGIES INC

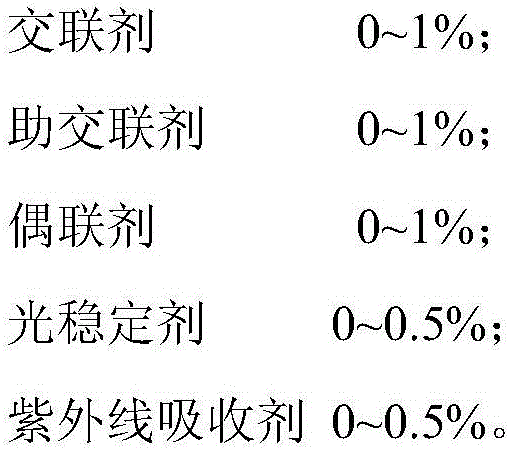

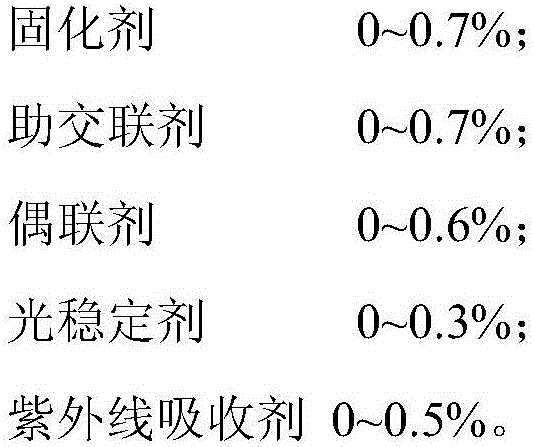

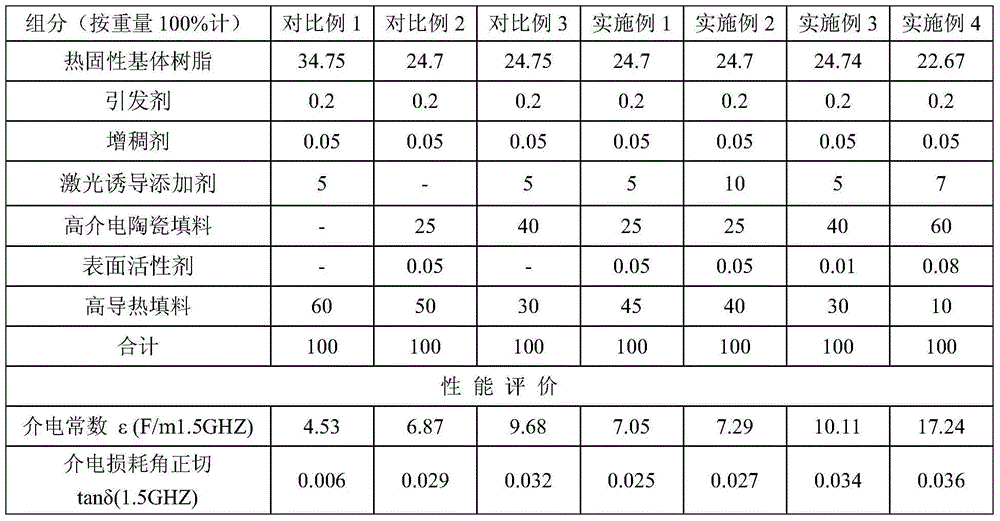

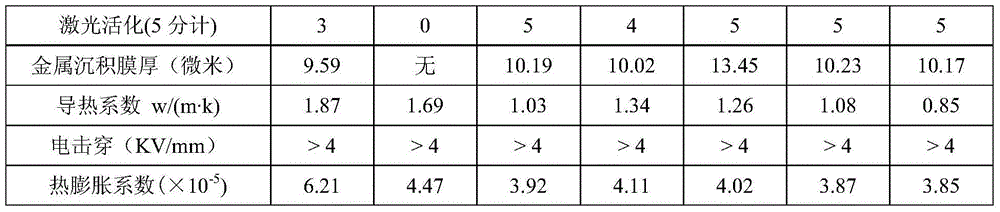

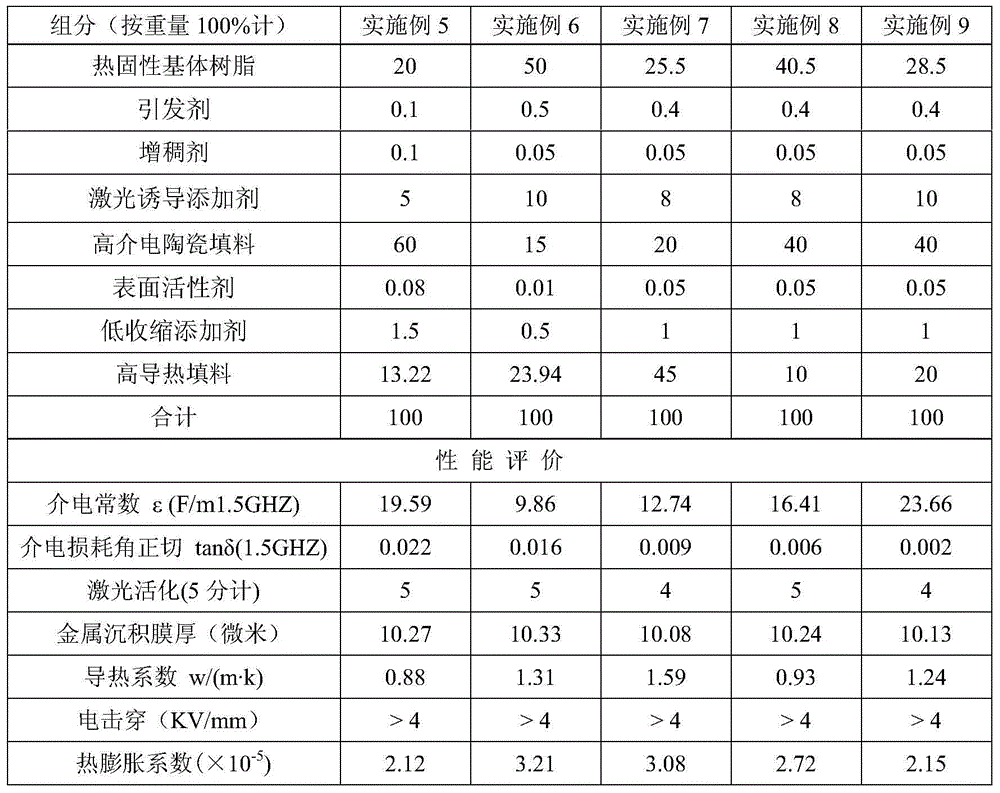

Thermosetting laser-induced metallization thermal-conduction composite material with stable high dielectric constant

ActiveCN104974468AGood high dielectric constant stabilityGood Laser Induced MetallizationShrinkage rateDielectric loss

The invention discloses a thermosetting laser-induced metallization thermal-conduction composite material with a stable high dielectric constant. The material comprises the following components in percentage by weight, 20-50% of thermosetting matrix resin, 0.1-0.5% of an initiator, 0.05-0.1% of a thickener, 5-10% of a laser induction additive, 15-60% of a high dielectric ceramic filler, 0.01-0.08% of a surfactant, 0-1.5% of a low-shrinkage additive, and 10-45% of a high-thermal-conductivity filler. The total of the components is 100%. Under high frequency, the material provided by the invention has good high dielectric constant stability, low dielectric loss angle tangent, and good laser-induced metallization property. The composite material also has a good linear expansion coefficient, an effectively controlled shrinkage rate, and good dimensional stability.

Owner:HEFU NEW MATERIAL TECH WUXI

Warp-knitting dacron short pile fabric and weaving method thereof

InactiveCN107761242AShrinkage ControlNot easy to shrinkPattern makingWarp knittingFiberChemical treatment

The invention discloses a warp-knitting dacron short pile fabric and a weaving method thereof, and belongs to the technical field of warp-kitting fabric weaving. 50-75D of dacron FDY and dacron DTY composite filaments are adopted as pile yarn, 50D / 24F of polyester silk FDY or polyester silk DTY is adopted as bottom yarn, a two-comb or three-comb Tricot warp knitting machine conducts weaving to obtain gray fabric, then the procedures of pre-shaping, fuzzing process implementation, dyeing, drying, hot trimming and burnt-out are carried out, and after dehydration and drying for shaping are conducted, checking and packaging are carried out. By means of a chemical treatment method for dacron fibers, the effect of forming a three-dimensional pattern diversified in color and different in shape onthe fuzzing surface of the fabric is achieved, the gram weight of the fabric is low, and the fabric has better heat preservation performance and higher comfort degree.

Owner:JIANGSU ZHENYANG GROUP

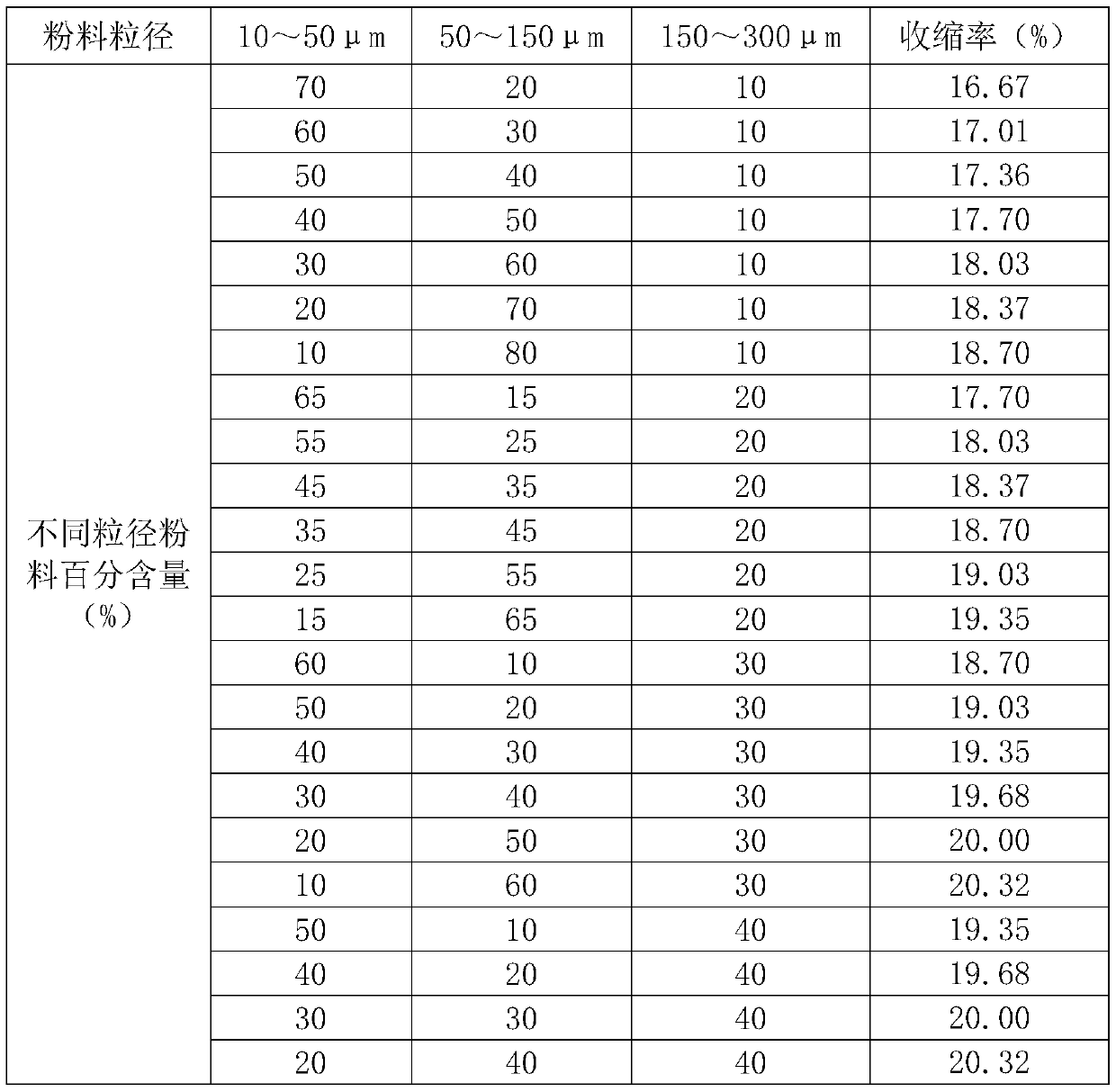

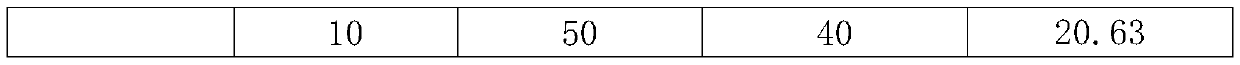

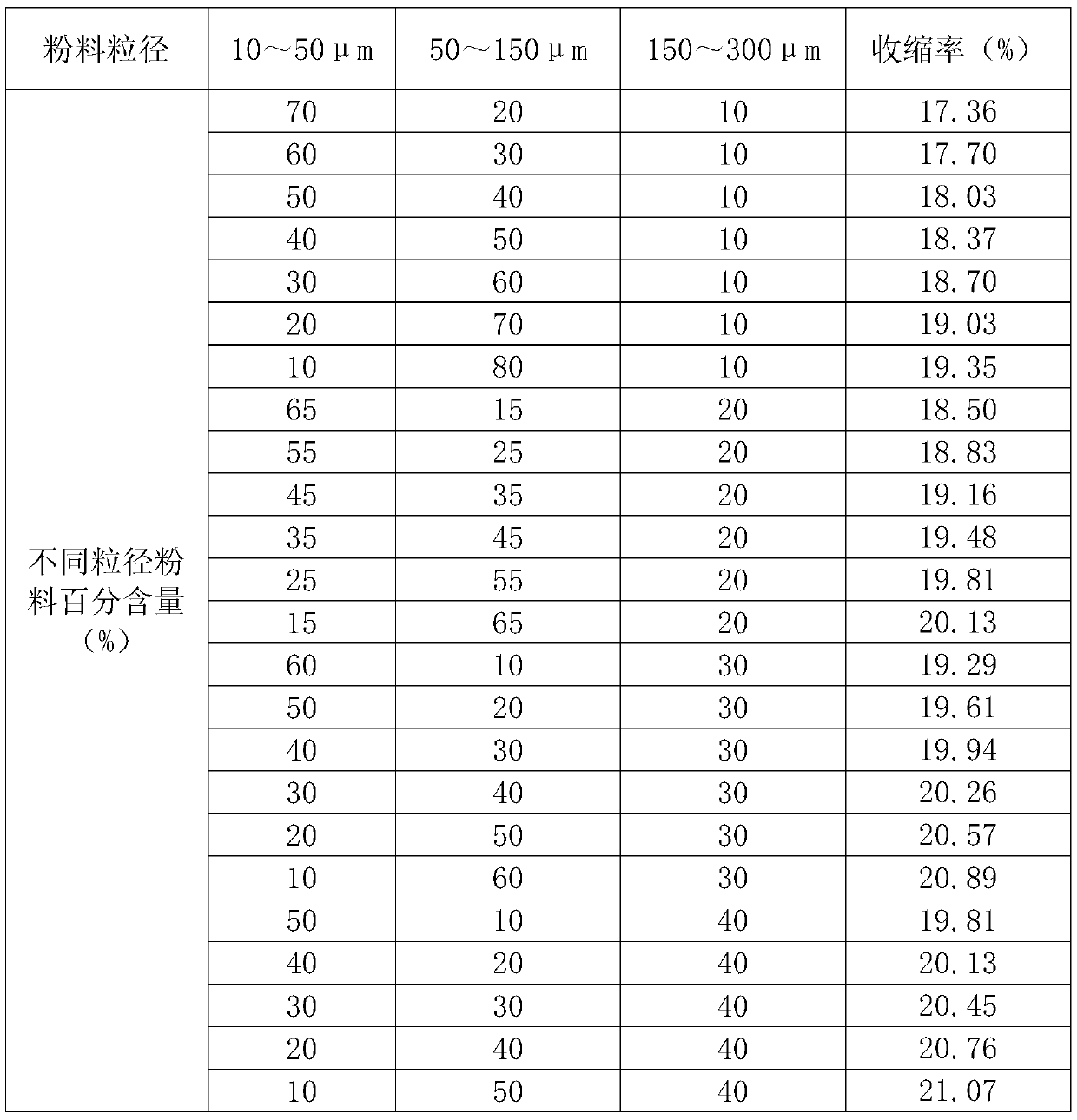

Layered zirconia porcelain block technology with even contraction of all layers

ActiveCN110317059AIncreasing the thicknessGuaranteed color needsImpression capsDentistry preparationsContraction rateTransition layer

The invention belongs to the field of oral cavity materials and particularly relates to a layered zirconia porcelain block technology with even contraction of all layers. By adopting the technical scheme, according to the required colors, the component and content of zirconia powder formulas of all the layers are determined, and zirconia porcelain blocks of all the layers comprise shallowest layers, transition layers and deepest layers; according to the content of yttria in all the formulas, the particle diameter distribution of zirconia and yttria in the shallowest layers and the deepest layers is adjusted, so that it is guaranteed that the contraction rate diversity factor of the shallowest layers and the deepest layers after sintering is smaller than 0.3%; the adjusted shallowest layersand deepest layers are evenly mixed to obtain the transition layers; the shallowest layers, transition layers and deepest layers are placed layer by layer according to the color shade sequence and subjected to isostatic pressing, pre-sintering and high-temperature sintering, and preparation is completed. By adopting the technical scheme, the layered zirconia porcelain block with natural colors, natural penetrability transition and a basically-constant contraction rate can be obtained.

Owner:CHENGDU BESMILE MEDICAL TECH CORP LTD

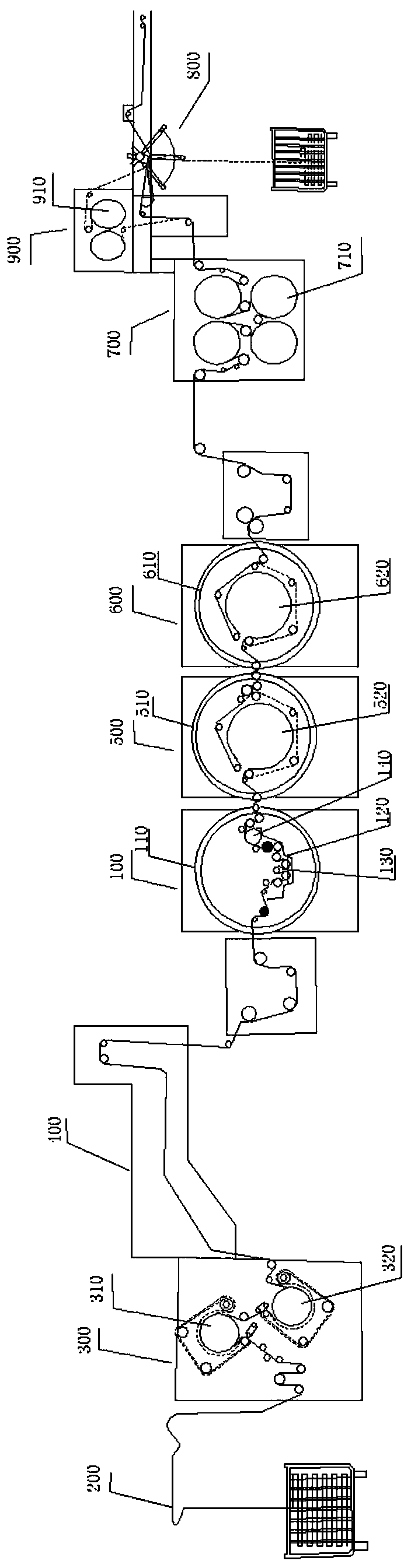

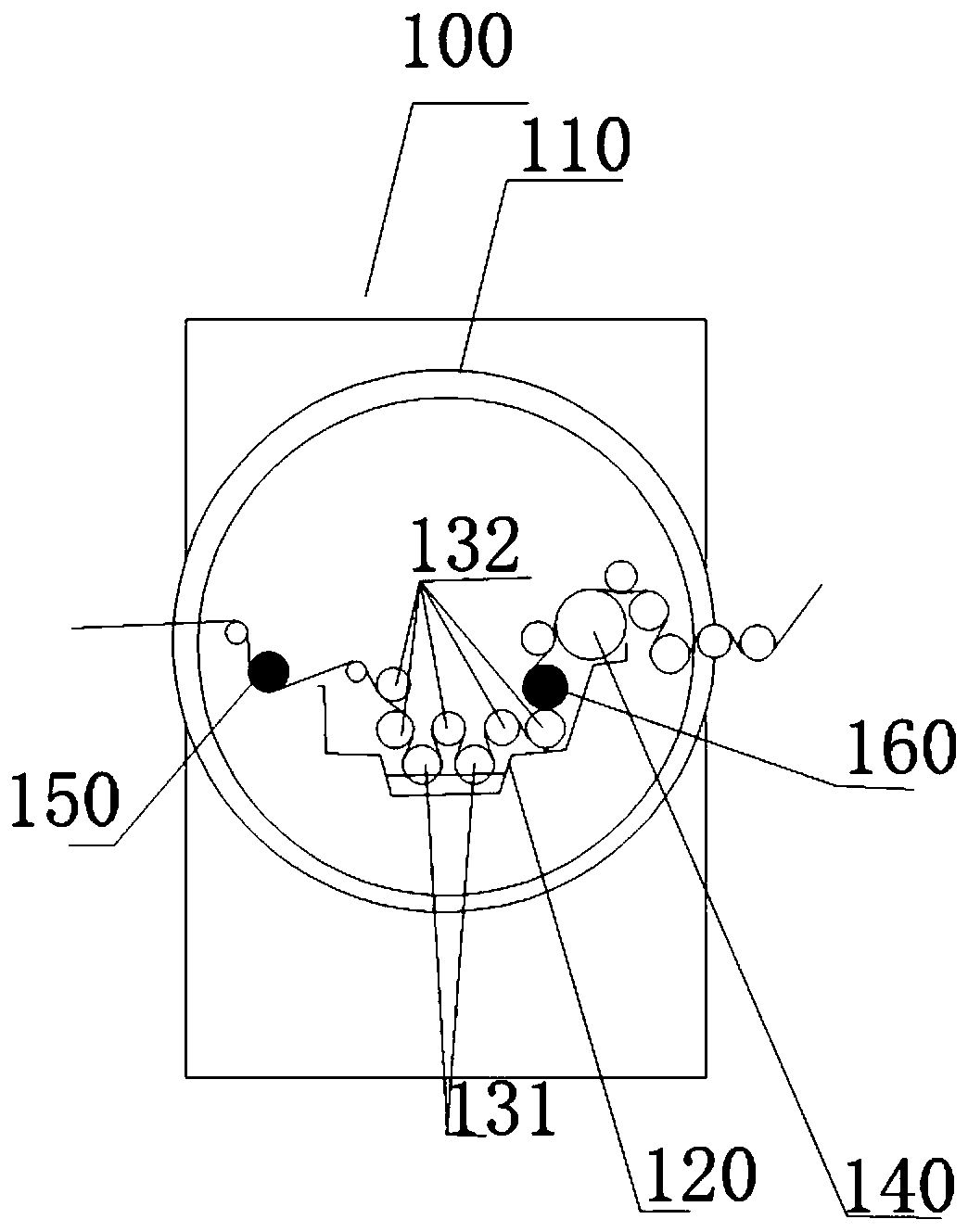

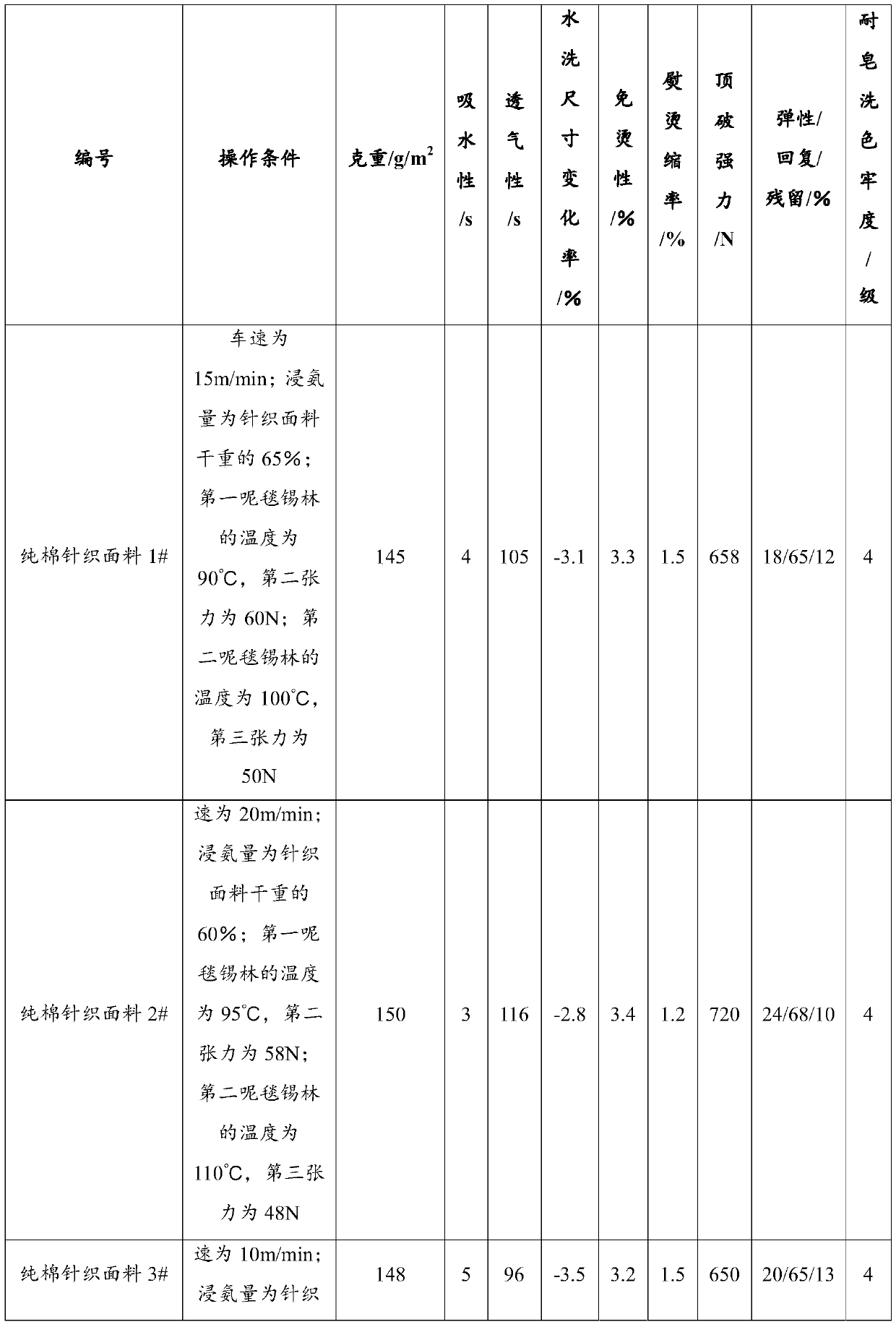

Knitted fabric, making method and use device for knitted fabric and garment made from knitted fabric

ActiveCN110318188AFully soaked in ammoniaDip ammonia evenlyWrinkle resistant fibresHandkerchiefsWrinkle skinYarn

The invention discloses a knitted fabric containing natural fibers, a making method and liquid ammonia device for the knitted fabric and a shirt made from the knitted fabric, and belongs to the fieldof fabrics and clothing. The making method for the knitted fabric containing the natural fibers comprises the steps that a knitting method is adopted for making yarns containing the natural fibers into an original knitted fabric, and the knitted fabric is subjected to functional after-finishing comprising a liquid ammonia finishing process. The liquid ammonia finishing process is that the knittedfabric is subjected to ammonia soaking at least twice under the mechanical restraint condition of a guide roller set, it can be avoided that edge rolling is caused to the knitted fabric due to high-degree shrinking in the ammonia soaking process, the knitted fabric can also be subjected to ammonia soaking sufficiently and evenly, the ammonia soaking effect is ensured, and the shrinking rate of theknitted fabric is controlled; through the subsequent setting finishing processes, the color stability of the knitted fabric is further improved, the rate of shrinkage after washing is reduced, and the wrinkle resistance and resilience of the knitted fabric are improved. The shirt is low in rate of shrinkage after washing, good in stiffness and smoothness draping and resilience, stable in color, high in strength and good in wrinkle resistance.

Owner:LUTAI TEXTILE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com