Processing technology capable of rapidly preparing multi-layer zirconia ceramic block with uniform transition

A technology of zirconia and transition layer, which is applied in the direction of dentures, etc., can solve the problems that the natural transition of color cannot be realized, the comprehensive mechanical properties of zirconia porcelain blocks cannot meet the demand, and edge collapse occurs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

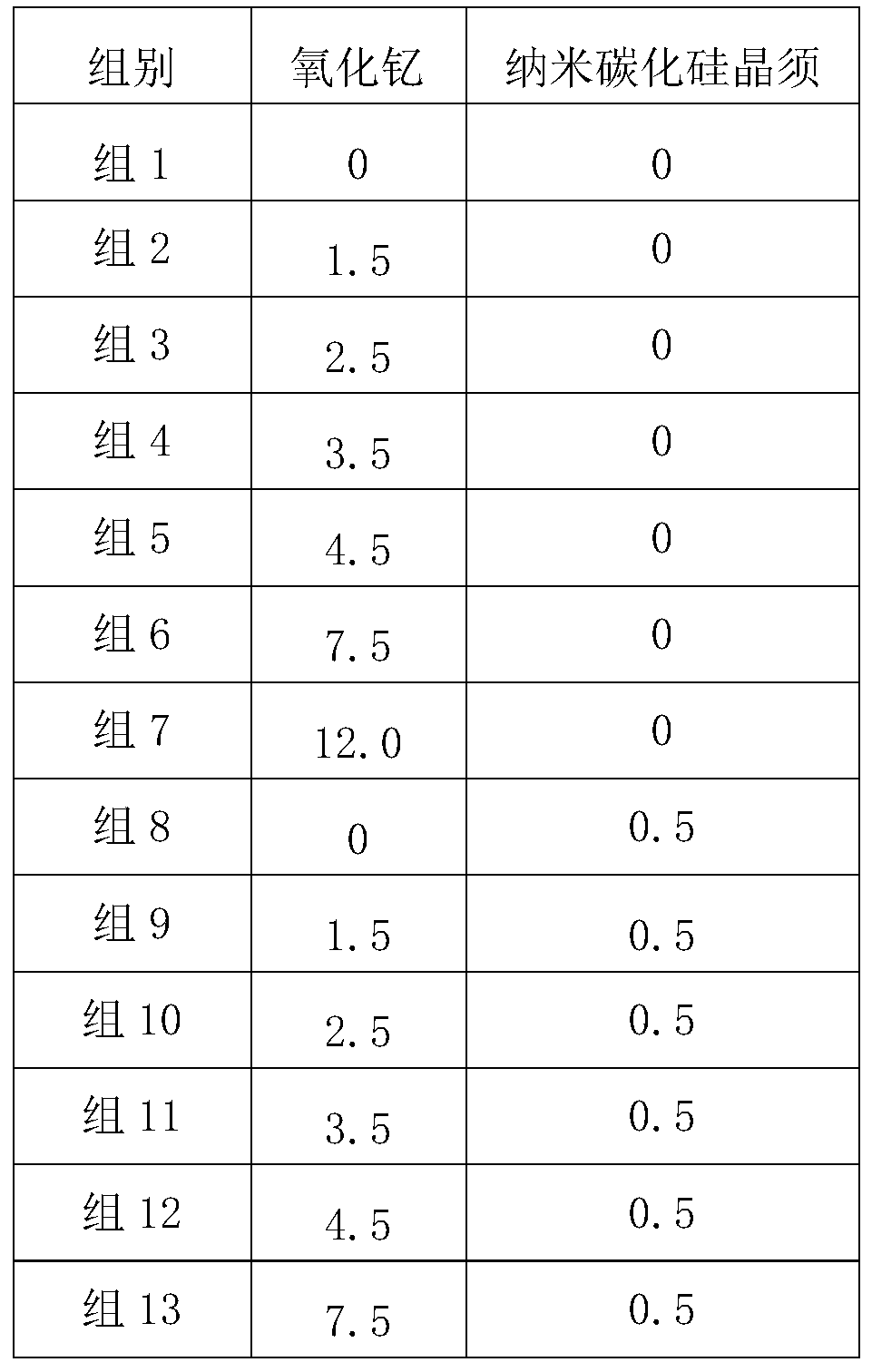

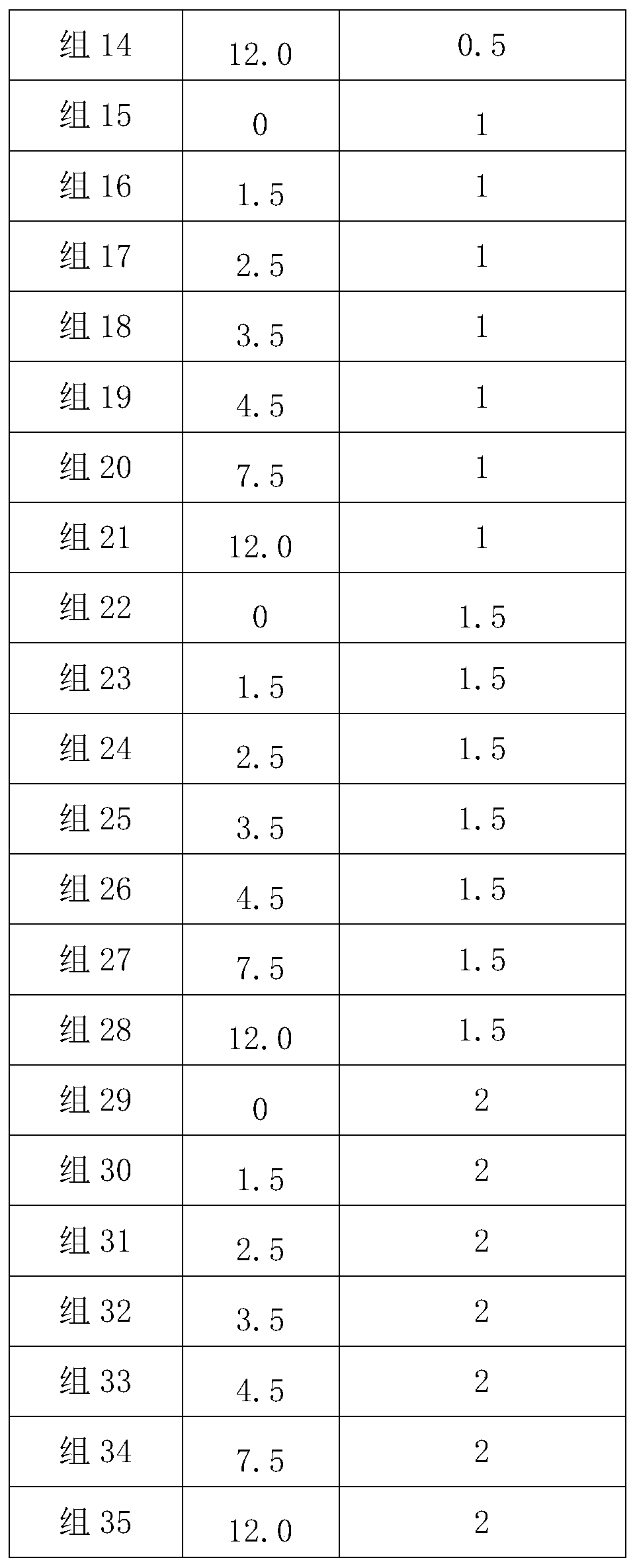

[0095] Example 1: Display of comprehensive mechanical properties and transparency effects of zirconia ceramic blocks

[0096] 1. Prepare 35 groups of monolithic zirconia ceramic blocks according to the above-mentioned general formula, with 20 repetitions for each group. The specific formulations of each group of zirconia ceramic blocks are shown in Table 1. The values in the table are all mass fractions, and the balance is zirconia powder; in each group of zirconia ceramic blocks, the average content of coloring matter is 0.4%. The colorant may be any one or a mixture of erbium chloride, ferric chloride, neodymium nitrate, manganese nitrate, ammonium metavanadate, cerium nitrate, praseodymium nitrate, cobalt nitrate and nickel nitrate. For the convenience of operation, all the embodiments of the present invention use the colored matter obtained by mixing erbium chloride, ferric chloride, and manganese nitrate in a mass ratio of 6:1:2, and the color is tetracycline gray. It ...

Embodiment 2

[0105] Embodiment 2: Determining the shrinkage rate of the lightest layer and the darkest layer of zirconia ceramic block

[0106] 1. According to the actual situation of the patient, or according to the general needs, select the powder formula of each layer of zirconia ceramic block. In this example, according to the general requirements, the formula of Example Group 31 is selected as the occlusal end formula, and the formula of Example Group 23 is selected as the long bridge end formula. And add colorant accordingly, adjust the color of each group formula. Because the occlusal end requires a lighter color, add 0.3% coloring matter to the occlusal end formula, and reduce the zirconia powder content by 0.3% accordingly, as the lightest color layer formula; add 0.5% coloring matter to the long bridge end formula , and correspondingly reduce the zirconia powder content by 0.5%, as the darkest layer formula.

[0107] 2. With the formula determined above, the whole piece of zirc...

Embodiment 3

[0120] Example 3: Demonstration of the effect of high temperature sintering process

[0121] 1. Select Group 1 of Example 2, set 21 components of layered zirconia powder formula, and set 10 repetitions for each group; place each layer of powder in sequence, isostatic pressing molding, and pre-sintering according to the method of Example 2 1. After mechanical processing, high-temperature sintering is carried out according to the method in Table 6 respectively.

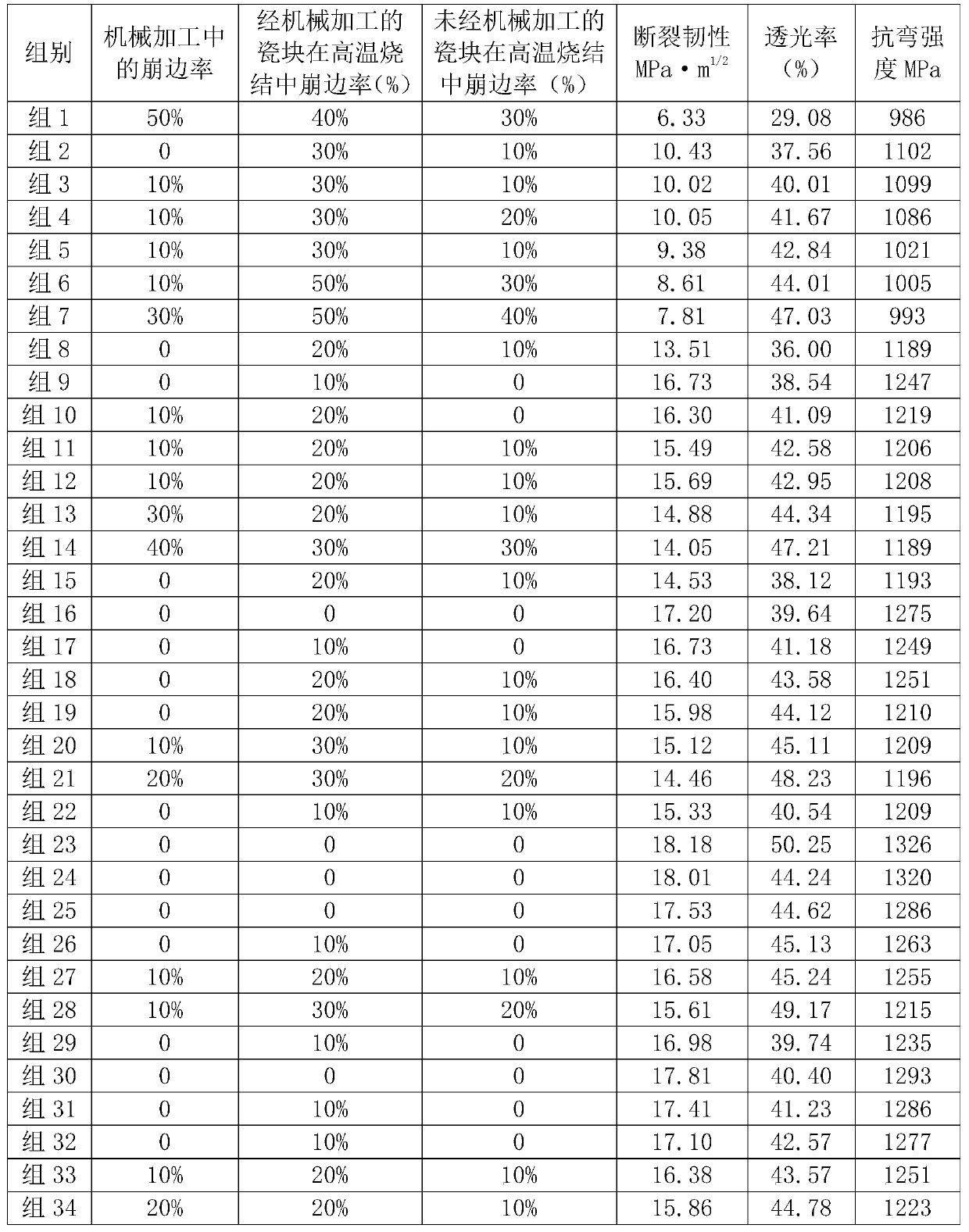

[0122] Table 6 High temperature sintering process parameter list of each group

[0123]

[0124]

[0125] 2. Measure the flexural strength of the zirconia ceramic blocks prepared by each group, observe the chipping rate of each group of zirconia ceramic blocks during high-temperature sintering, and observe the transparency and color transition of each group of zirconia ceramic blocks. The results are as follows: Table 7 shows.

[0126] Table 7 Performance display of each group of zirconia ceramic blocks

[0127...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com