Laminated porous film, separator for lithium cell, and cell

一种多孔膜、叠层的技术,应用在非水电解质电池用隔板领域,能够解决两极间短路、膜破坏等问题,达到机械强度优异、尺寸稳定性优异、平衡良好有效物性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

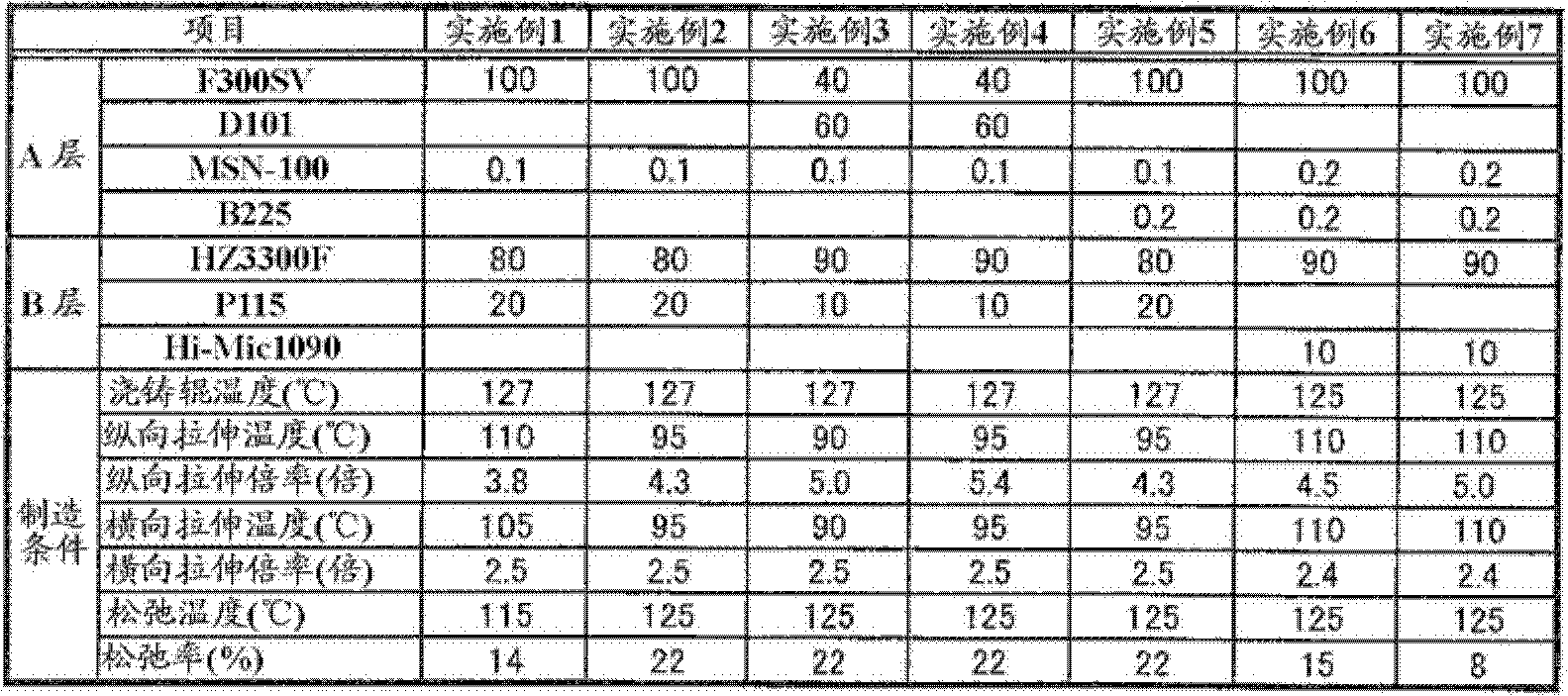

[0238] With respect to 100 parts by mass of polypropylene resin (manufactured by Prime Polymer, Prime Polypro F300SV, MFR: 3g / 10min), 3,9-bis[4-(N-cyclohexylamino) was added as a β crystal nucleating agent Formyl) phenyl]-2,4,8,0.1 mass part of 10-tetraoxaspiro[5.5]undecane, and utilize co-rotating twin-screw extruder (manufacture by Toshiba Machine Co., Ltd., caliber φ 40mm, screw rod effective Length L / D=32) was melt-kneaded at 280° C., and resin composition A1 processed into pellets was obtained.

[0239] In addition, high-density polyethylene (manufactured by Prime Polymer, Hi-Zex3300F, density: 0.950 g / cm 3 , MFR: 1.1g / 10 minutes) 20 mass parts of hydrogenated petroleum resin (manufactured by Arakawa Chemical Industry Co., Ltd., ALCONP115) was added to 80 mass parts, and a co-rotating twin-screw extruder (manufactured by Toshiba Machine Co., Ltd., caliber φ35mm , screw effective length L / D=32) was melt-kneaded at 230° C., and resin composition B1 processed into pellets w...

Embodiment 2

[0243] After laminating the resin compositions A1 and B1 in the same manner as in Example 1, they were cooled and solidified with a casting roll at 125° C. to produce a laminated non-porous film.

[0244] The above-mentioned laminated non-porous film is sequentially biaxially stretched as follows: stretching to 3.8 times along MD at 110°C, then stretching to 2.5 times along TD at 105°C, and then relaxing 14% along TD at 115°C, A laminated porous membrane was obtained.

Embodiment 3

[0246]Add polypropylene-based copolymer resin (D101 manufactured by Sumitomo Chemical Co., Ltd., MFR: 0.5 g / 10 minutes) to 40 parts by mass of polypropylene-based resin (manufactured by Prime Polymer, Prime Polypro F300SV, MFR: 3 g / 10 minutes) ) 60 parts by mass, 3,9-bis[4-(N-cyclohexylcarbamoyl) phenyl]-2,4,8,10-tetraoxaspiro[5.5]undeca as a β crystal nucleating agent 0.1 parts by mass of carbane, and utilize a co-rotating twin-screw extruder (manufactured by Toshiba Machinery Co., Ltd., caliber φ40mm, screw effective length L / D=32) to carry out melt kneading at 280° C. to obtain processed granular Resin Composition A2.

[0247] In addition, high-density polyethylene (manufactured by Prime Polymer, Hi-Zex3300F, density: 0.950 g / cm 3 , MFR: 1.1g / 10 minutes) 10 mass parts of hydrogenated petroleum resin (manufactured by Arakawa Chemical Industry Co., Ltd., ALCONP115) was added to 90 mass parts, and a co-rotating twin-screw extruder (manufactured by Toshiba Machine Co., Ltd., c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile modulus | aaaaa | aaaaa |

| linear shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com