Coal blending method for controlling degree of shrinkage of coal as fired in large coke oven with wide coking chamber

A carbonization chamber width and shrinkage technology, applied in coking ovens, petroleum industry, etc., can solve problems such as increased shrinkage and reduced metallurgical coke rate in wide carbonization chambers, so as to improve coke quality and metallurgical coke rate, and avoid absolute shrinkage The effect of volume increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

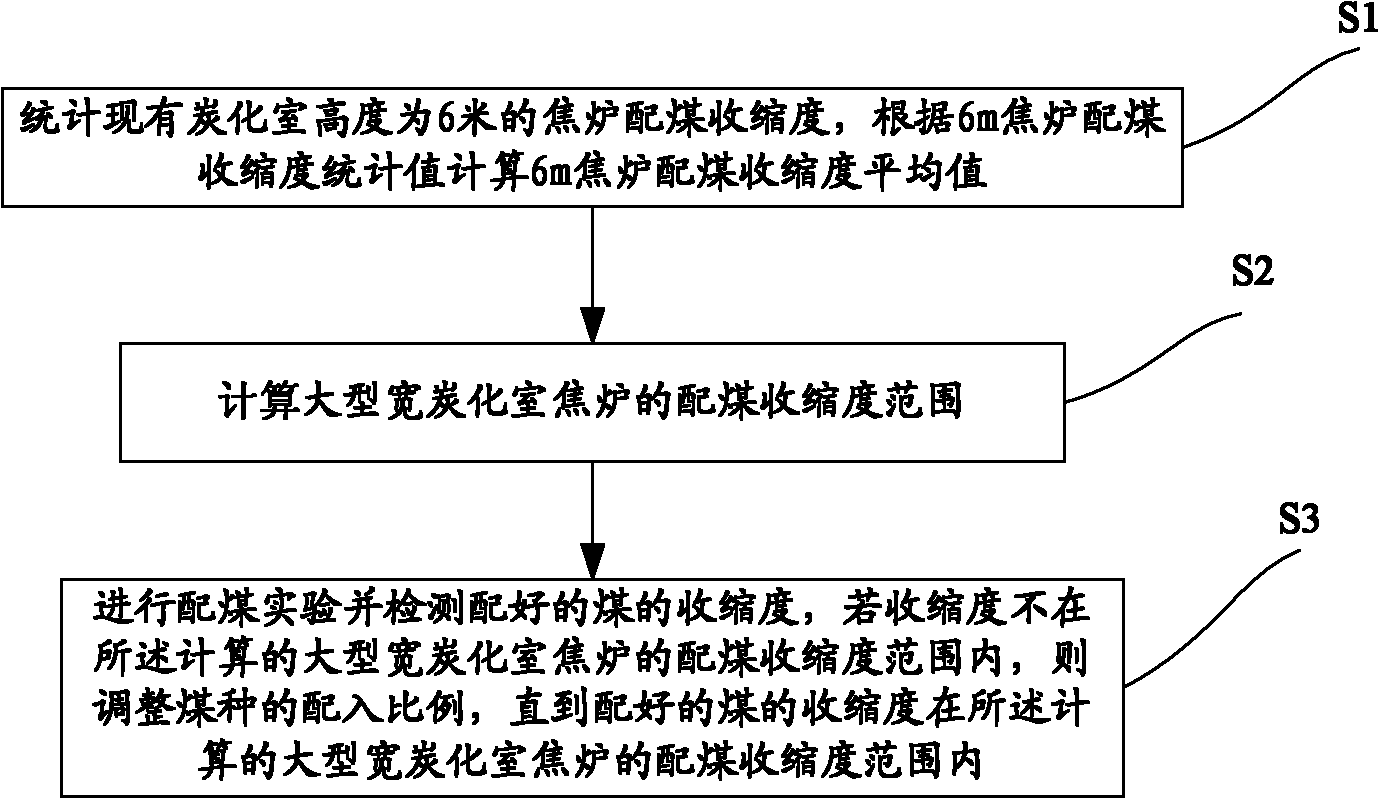

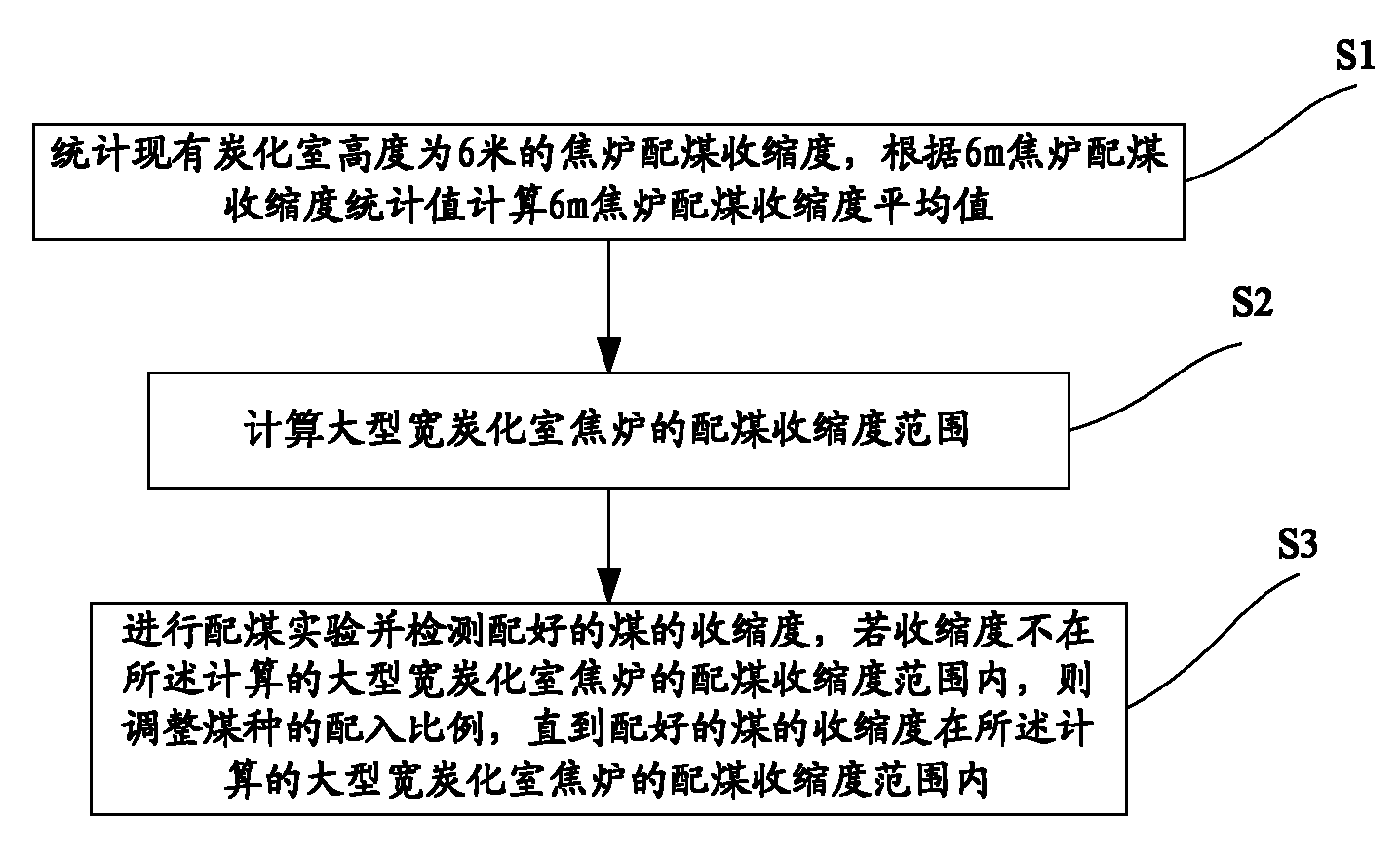

[0013] Embodiments of the present invention will now be described with reference to the drawings, in which like reference numerals represent like elements.

[0014] Such as figure 1 , the coal blending method that the present invention controls the coal shrinkage of coke oven of large-scale wide carbonization chamber, comprises the following steps:

[0015] Step S1, count the coal blending shrinkage of coke ovens with a height of 6 meters in the existing carbonization chamber, and calculate the average shrinkage of coal blending in 6 m coke ovens according to the statistical value of coal blending shrinkage in 6 m coke ovens X 6 ;

[0016] Step S2, calculating the coal blending shrinkage range of the coke oven with large wide carbonization chamber, the calculation formula is:

[0017] x 6 (1+|ΔL| / L 6 )(1-|ΔH| / H 6 )-5≤X L ≤X 6 (1+|ΔL| / L 6 )(1-|ΔH| / H 6 )+5

[0018] in,

[0019] b L is the coal blending shrinkage of coke oven with large wide carbonization chamber;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com